How 5-Axis Machining Unlocks Complex Geometries

TL;DR

5-axis machining is an advanced manufacturing process that moves a cutting tool along five different axes simultaneously—the three linear axes (X, Y, Z) plus two rotational axes. This capability is essential for creating parts with complex geometries, as it allows the tool to approach a workpiece from virtually any angle in a single setup. The primary benefits include significantly reduced production time, higher part accuracy, and superior surface finishes compared to traditional methods.

What is 5-Axis Machining and How Does It Work?

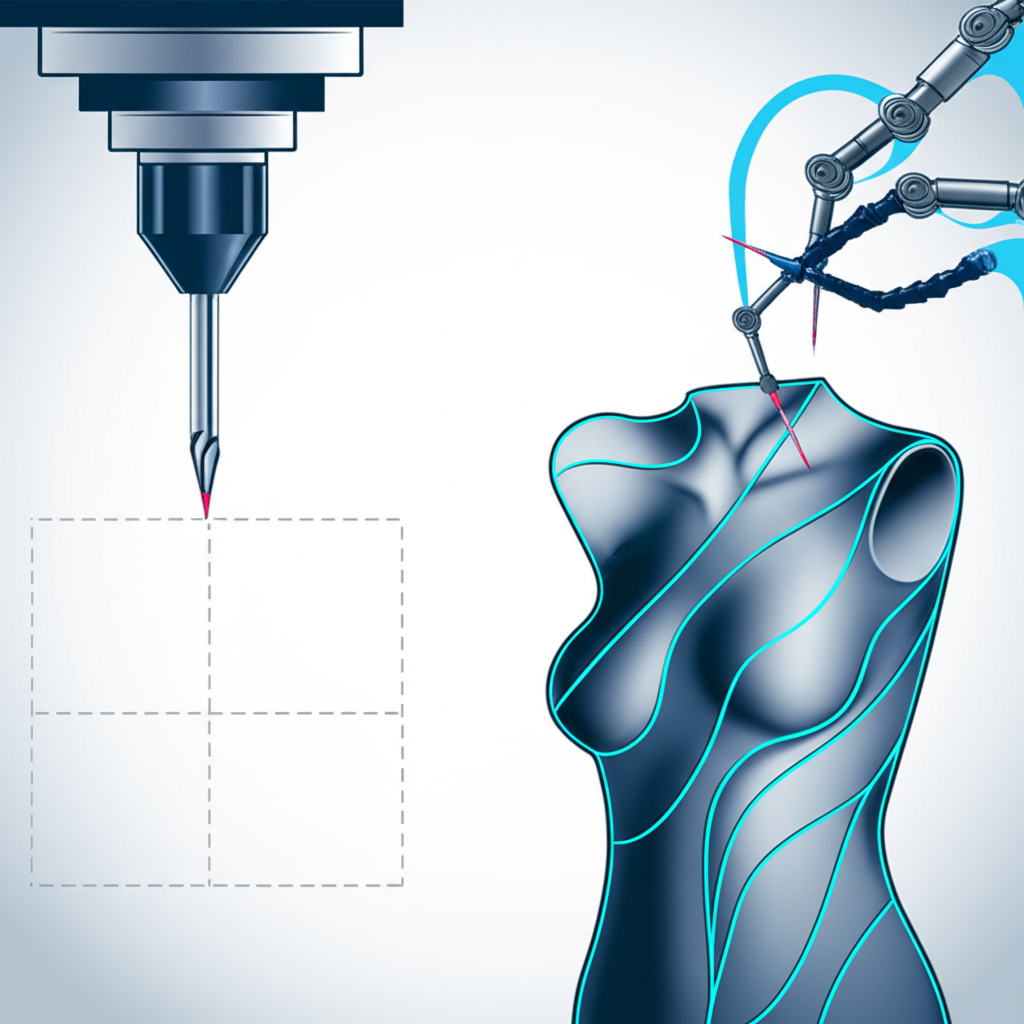

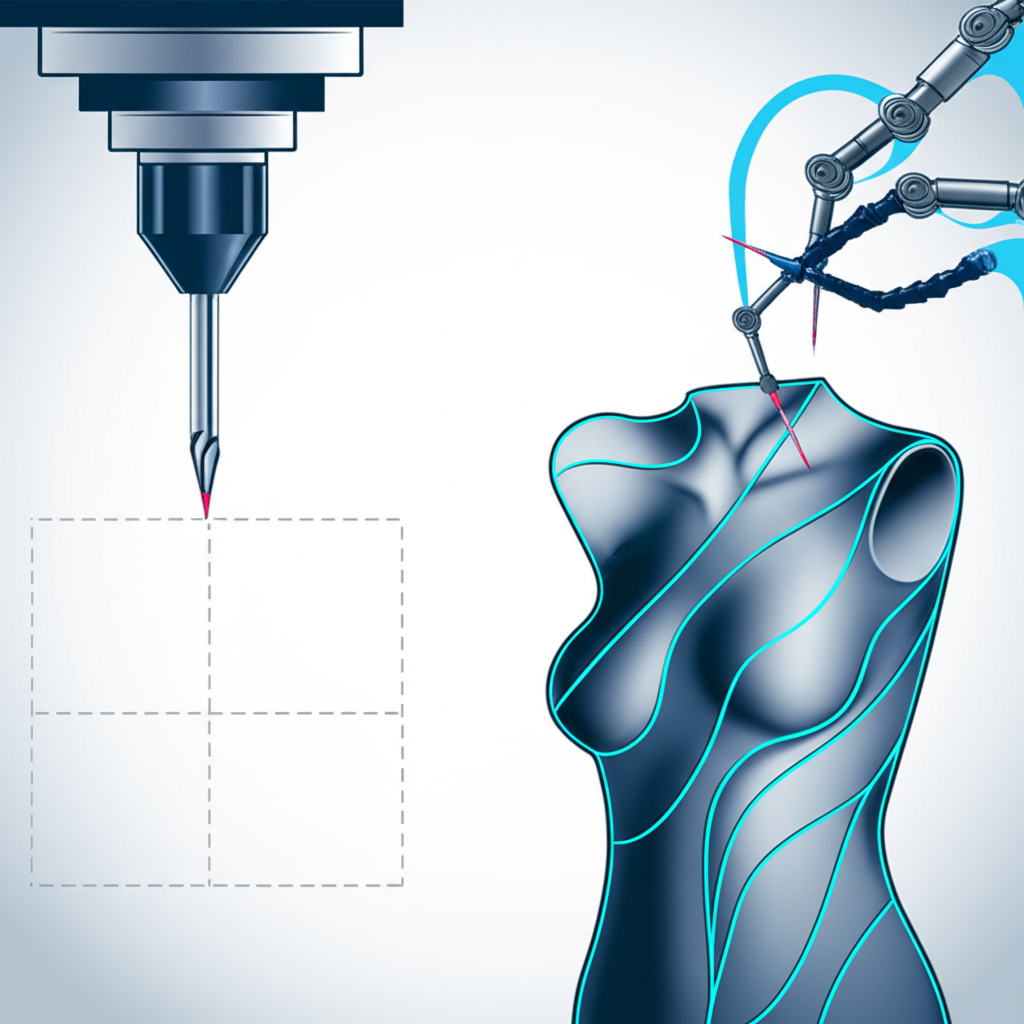

At its core, 5-axis CNC (Computer Numerical Control) machining is a sophisticated subtractive manufacturing process that enhances the capabilities of standard 3-axis machines. While a 3-axis machine operates on three linear axes—X (left-right), Y (front-back), and Z (up-down)—a 5-axis machine introduces two additional rotational axes, commonly referred to as the A-axis and B-axis. This allows either the cutting tool or the workpiece itself to tilt and rotate, enabling continuous access to the part's surface from multiple angles without interruption.

There are two main types of 5-axis machining: 3+2 axis (or positional) and simultaneous 5-axis. In 3+2 axis machining, the machine orients the workpiece using the two rotational axes and then performs cutting operations using the three linear axes. In contrast, true simultaneous 5-axis machining involves the constant, dynamic movement of all five axes at the same time. This continuous adjustment is what makes it possible to produce extremely complex and contoured surfaces, such as those found on turbine blades or medical implants, in a single, fluid operation.

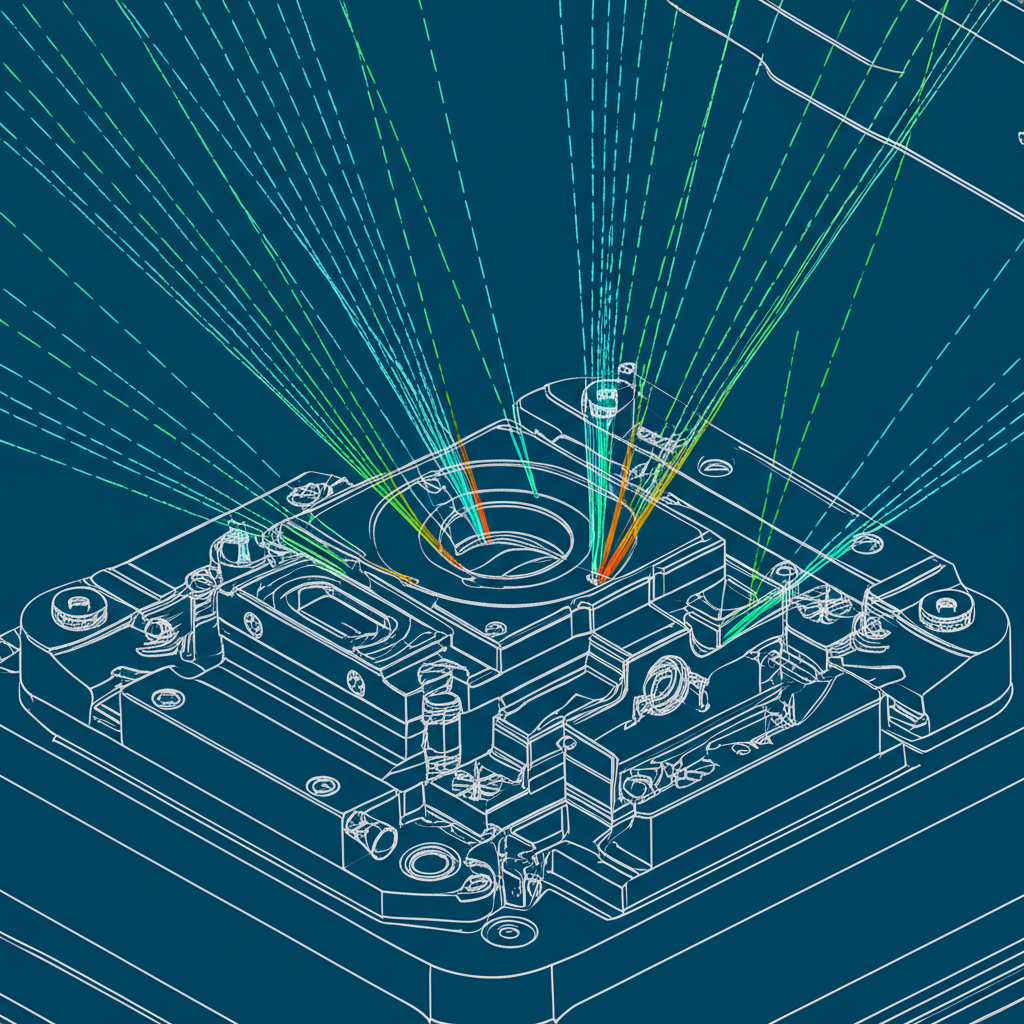

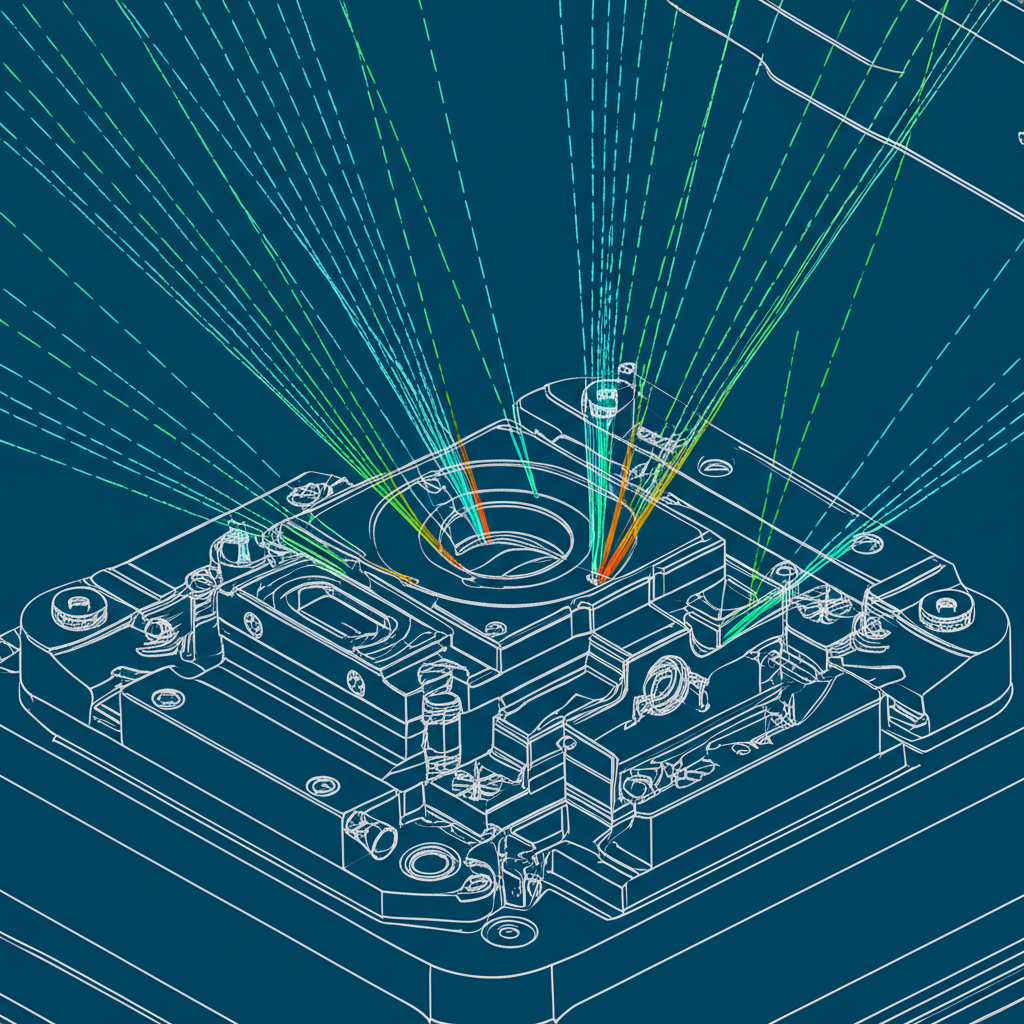

This multi-axis movement is controlled by advanced CAM (Computer-Aided Manufacturing) software, which translates a digital design file into a precise set of instructions for the machine. The software calculates the complex toolpaths required to shape the part while automatically avoiding collisions between the tool, the workpiece, and the machine components. As detailed by Siemens, specialized software can dramatically simplify the programming for features like the internal ports of an engine block or the blades of an impeller, making the process more efficient and reliable.

Key Advantages for Machining Complex Geometries

The ability to manipulate a cutting tool across five axes provides transformative benefits for manufacturing parts with intricate designs. These advantages directly address the limitations of conventional machining, leading to higher quality components and more efficient production workflows. For companies that need to bring intricate designs to life quickly, providers offering advanced 4 and 5-axis CNC machining services can deliver high-precision parts in a variety of materials, meeting demanding specifications for industries like aerospace and medical.

- Single-Setup Machining (Re-fixturing Elimination): Perhaps the most significant advantage is the ability to machine nearly every surface of a complex part in a single setup. On a 3-axis machine, fabricating a complex part requires manually repositioning and re-clamping the workpiece multiple times. As B&G Manufacturing notes, each setup introduces the risk of human error and slight misalignment, which can compromise final accuracy. By completing the part in one clamping, 5-axis machining eliminates this risk, ensuring all features are perfectly aligned to one another.

- Faster Cycle Times and Increased Throughput: By eliminating the need for multiple setups, 5-axis machining drastically reduces the total time required to produce a part. Less time is spent on manual labor for repositioning, and the machine can often use more aggressive, efficient toolpaths. This leads to shorter cycle times and higher throughput, making it a cost-effective solution for low-volume production of complex parts where setup costs would otherwise dominate.

- Improved Part Quality and Accuracy: With a single setup, all features are machined in relation to a single datum, which eliminates the cumulative tolerance errors that can occur with re-fixturing. Furthermore, 5-axis machines can use shorter, more rigid cutting tools because the head or table can be tilted to create clearance. Shorter tools are less prone to vibration and deflection, resulting in a smoother surface finish and the ability to hold tighter tolerances, often in the ±0.01–0.02 mm range.

- Enhanced Access to Complex Geometries: The additional rotational axes allow the cutting tool to reach areas that would be impossible with a 3-axis machine, such as undercuts and deep, narrow cavities. This capability enables the creation of highly complex shapes and contoured surfaces in a single piece, reducing the need for assembling multiple simpler components and thereby increasing the final part's structural integrity. This is critical for industries like aerospace, where components must be both lightweight and incredibly strong.

Critical Differences: 5-Axis vs. 3-Axis Machining

Understanding the distinction between 3-axis and 5-axis machining is crucial for selecting the right process for a specific application. While both are forms of CNC machining, their capabilities, ideal use cases, and operational complexities differ significantly. The fundamental difference lies in the number of directions the cutting tool and workpiece can move, which directly impacts part complexity and production efficiency.

3-axis machining is simpler and more cost-effective for parts with basic geometries, such as flat surfaces or drilled holes, where the tool only needs to move up-and-down, left-and-right, and forward-and-back. However, its limitations become clear when faced with angled features or contoured surfaces, which require multiple manual setups. In contrast, 5-axis machining adds two rotational axes, allowing the tool to maintain an optimal angle to the workpiece at all times, enabling the creation of complex parts in a single operation.

| Feature | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

| Axes of Movement | Three linear axes (X, Y, Z). The tool's orientation is fixed. | Three linear axes (X, Y, Z) plus two rotational axes (A, B). |

| Workpiece Complexity | Best for simpler, prismatic parts with features on one or a few parallel faces. | Ideal for complex geometries, contoured surfaces, undercuts, and angled features. |

| Setup Time | Requires multiple setups and manual repositioning for complex parts, increasing overall time. | Completes complex parts in a single setup, drastically reducing setup time. |

| Ideal Applications | Drilling, milling flat surfaces, creating simple profiles, and general fabrication. | Aerospace components (turbine blades), medical implants, automotive engine parts, and complex molds. |

| Accuracy | Accuracy can be compromised by cumulative errors from multiple setups. | Higher accuracy and repeatability due to single-setup machining. |

Ultimately, the choice depends on the project's specific requirements. For high-volume production of simple components, 3-axis machining often remains the more economical choice. However, for parts defined by their complex geometries, tight tolerances, and superior surface finish requirements, the capabilities of 5-axis machining are indispensable.

Common Challenges and Programming Considerations

While 5-axis machining offers unparalleled capabilities, it also introduces a higher level of complexity and cost that must be considered. The most significant challenge lies in the programming required to control the machine's movements. Creating a toolpath that coordinates five axes simultaneously is far more intricate than for a 3-axis machine and requires specialized CAM software and highly skilled programmers to avoid collisions and optimize cutting strategies. This programming complexity can increase initial setup times and requires a deeper level of expertise.

Another primary consideration is the initial investment. 5-axis CNC machines are significantly more expensive than their 3-axis counterparts due to their advanced mechanical construction, sophisticated control systems, and precision components. The rigidity and precision required to manage simultaneous multi-axis movements demand a more robust machine design. This higher upfront cost means that the technology is often best justified for applications where its unique benefits—such as producing parts that are impossible to make otherwise—provide a clear return on investment.

Finally, not every part needs the full capabilities of 5-axis machining. A common pitfall is over-engineering, where a part that could be efficiently produced on a 3-axis or 3+2 axis machine is assigned to a more complex simultaneous 5-axis process. This can lead to unnecessarily high costs and longer lead times. A careful design-for-manufacturability (DFM) analysis is crucial to determine if the part's geometry truly warrants the complexity and cost associated with advanced multi-axis machining.

Frequently Asked Questions

1. What are the disadvantages of a 5-axis CNC machine?

The primary disadvantages of a 5-axis CNC machine are its higher initial cost, the increased complexity of its programming, and the need for highly skilled operators. Programming for five simultaneous axes requires sophisticated CAM software and expertise to create efficient and collision-free toolpaths. This can lead to longer setup times and higher operational costs compared to simpler 3-axis machines, especially for parts that do not require such complex machining.

2. What is 5-axis machining used for?

5-axis machining is used to manufacture parts with highly complex shapes and geometries that require exceptional precision. It is essential in industries like aerospace for creating components such as turbine blades and impellers, in the medical field for orthopedic implants and custom surgical tools, and in the automotive sector for engine parts and complex molds. Its ability to machine intricate features in a single setup makes it ideal for applications where accuracy and surface finish are critical.

3. What type of machining process is best suited for producing complex shapes with high precision and surface finish?

For CNC machining, the 5-axis process is best suited for producing complex shapes with high precision and a superior surface finish. The ability to continuously adjust the angle between the cutting tool and the workpiece allows for the use of shorter, more rigid tools that reduce vibration. This results in smoother surfaces and enables the machine to maintain tighter tolerances throughout the manufacturing of intricate parts.

How 5-Axis Machining Unlocks Complex Geometries

TL;DR

5-axis machining is an advanced manufacturing process that moves a cutting tool along five different axes simultaneously—the three linear axes (X, Y, Z) plus two rotational axes. This capability is essential for creating parts with complex geometries, as it allows the tool to approach a workpiece from virtually any angle in a single setup. The primary benefits include significantly reduced production time, higher part accuracy, and superior surface finishes compared to traditional methods.

What is 5-Axis Machining and How Does It Work?

At its core, 5-axis CNC (Computer Numerical Control) machining is a sophisticated subtractive manufacturing process that enhances the capabilities of standard 3-axis machines. While a 3-axis machine operates on three linear axes—X (left-right), Y (front-back), and Z (up-down)—a 5-axis machine introduces two additional rotational axes, commonly referred to as the A-axis and B-axis. This allows either the cutting tool or the workpiece itself to tilt and rotate, enabling continuous access to the part's surface from multiple angles without interruption.

There are two main types of 5-axis machining: 3+2 axis (or positional) and simultaneous 5-axis. In 3+2 axis machining, the machine orients the workpiece using the two rotational axes and then performs cutting operations using the three linear axes. In contrast, true simultaneous 5-axis machining involves the constant, dynamic movement of all five axes at the same time. This continuous adjustment is what makes it possible to produce extremely complex and contoured surfaces, such as those found on turbine blades or medical implants, in a single, fluid operation.

This multi-axis movement is controlled by advanced CAM (Computer-Aided Manufacturing) software, which translates a digital design file into a precise set of instructions for the machine. The software calculates the complex toolpaths required to shape the part while automatically avoiding collisions between the tool, the workpiece, and the machine components. As detailed by Siemens, specialized software can dramatically simplify the programming for features like the internal ports of an engine block or the blades of an impeller, making the process more efficient and reliable.

Key Advantages for Machining Complex Geometries

The ability to manipulate a cutting tool across five axes provides transformative benefits for manufacturing parts with intricate designs. These advantages directly address the limitations of conventional machining, leading to higher quality components and more efficient production workflows. For companies that need to bring intricate designs to life quickly, providers offering advanced 4 and 5-axis CNC machining services can deliver high-precision parts in a variety of materials, meeting demanding specifications for industries like aerospace and medical.

- Single-Setup Machining (Re-fixturing Elimination): Perhaps the most significant advantage is the ability to machine nearly every surface of a complex part in a single setup. On a 3-axis machine, fabricating a complex part requires manually repositioning and re-clamping the workpiece multiple times. As B&G Manufacturing notes, each setup introduces the risk of human error and slight misalignment, which can compromise final accuracy. By completing the part in one clamping, 5-axis machining eliminates this risk, ensuring all features are perfectly aligned to one another.

- Faster Cycle Times and Increased Throughput: By eliminating the need for multiple setups, 5-axis machining drastically reduces the total time required to produce a part. Less time is spent on manual labor for repositioning, and the machine can often use more aggressive, efficient toolpaths. This leads to shorter cycle times and higher throughput, making it a cost-effective solution for low-volume production of complex parts where setup costs would otherwise dominate.

- Improved Part Quality and Accuracy: With a single setup, all features are machined in relation to a single datum, which eliminates the cumulative tolerance errors that can occur with re-fixturing. Furthermore, 5-axis machines can use shorter, more rigid cutting tools because the head or table can be tilted to create clearance. Shorter tools are less prone to vibration and deflection, resulting in a smoother surface finish and the ability to hold tighter tolerances, often in the ±0.01–0.02 mm range.

- Enhanced Access to Complex Geometries: The additional rotational axes allow the cutting tool to reach areas that would be impossible with a 3-axis machine, such as undercuts and deep, narrow cavities. This capability enables the creation of highly complex shapes and contoured surfaces in a single piece, reducing the need for assembling multiple simpler components and thereby increasing the final part's structural integrity. This is critical for industries like aerospace, where components must be both lightweight and incredibly strong.

Critical Differences: 5-Axis vs. 3-Axis Machining

Understanding the distinction between 3-axis and 5-axis machining is crucial for selecting the right process for a specific application. While both are forms of CNC machining, their capabilities, ideal use cases, and operational complexities differ significantly. The fundamental difference lies in the number of directions the cutting tool and workpiece can move, which directly impacts part complexity and production efficiency.

3-axis machining is simpler and more cost-effective for parts with basic geometries, such as flat surfaces or drilled holes, where the tool only needs to move up-and-down, left-and-right, and forward-and-back. However, its limitations become clear when faced with angled features or contoured surfaces, which require multiple manual setups. In contrast, 5-axis machining adds two rotational axes, allowing the tool to maintain an optimal angle to the workpiece at all times, enabling the creation of complex parts in a single operation.

| Feature | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

| Axes of Movement | Three linear axes (X, Y, Z). The tool's orientation is fixed. | Three linear axes (X, Y, Z) plus two rotational axes (A, B). |

| Workpiece Complexity | Best for simpler, prismatic parts with features on one or a few parallel faces. | Ideal for complex geometries, contoured surfaces, undercuts, and angled features. |

| Setup Time | Requires multiple setups and manual repositioning for complex parts, increasing overall time. | Completes complex parts in a single setup, drastically reducing setup time. |

| Ideal Applications | Drilling, milling flat surfaces, creating simple profiles, and general fabrication. | Aerospace components (turbine blades), medical implants, automotive engine parts, and complex molds. |

| Accuracy | Accuracy can be compromised by cumulative errors from multiple setups. | Higher accuracy and repeatability due to single-setup machining. |

Ultimately, the choice depends on the project's specific requirements. For high-volume production of simple components, 3-axis machining often remains the more economical choice. However, for parts defined by their complex geometries, tight tolerances, and superior surface finish requirements, the capabilities of 5-axis machining are indispensable.

Common Challenges and Programming Considerations

While 5-axis machining offers unparalleled capabilities, it also introduces a higher level of complexity and cost that must be considered. The most significant challenge lies in the programming required to control the machine's movements. Creating a toolpath that coordinates five axes simultaneously is far more intricate than for a 3-axis machine and requires specialized CAM software and highly skilled programmers to avoid collisions and optimize cutting strategies. This programming complexity can increase initial setup times and requires a deeper level of expertise.

Another primary consideration is the initial investment. 5-axis CNC machines are significantly more expensive than their 3-axis counterparts due to their advanced mechanical construction, sophisticated control systems, and precision components. The rigidity and precision required to manage simultaneous multi-axis movements demand a more robust machine design. This higher upfront cost means that the technology is often best justified for applications where its unique benefits—such as producing parts that are impossible to make otherwise—provide a clear return on investment.

Finally, not every part needs the full capabilities of 5-axis machining. A common pitfall is over-engineering, where a part that could be efficiently produced on a 3-axis or 3+2 axis machine is assigned to a more complex simultaneous 5-axis process. This can lead to unnecessarily high costs and longer lead times. A careful design-for-manufacturability (DFM) analysis is crucial to determine if the part's geometry truly warrants the complexity and cost associated with advanced multi-axis machining.

Frequently Asked Questions

1. What are the disadvantages of a 5-axis CNC machine?

The primary disadvantages of a 5-axis CNC machine are its higher initial cost, the increased complexity of its programming, and the need for highly skilled operators. Programming for five simultaneous axes requires sophisticated CAM software and expertise to create efficient and collision-free toolpaths. This can lead to longer setup times and higher operational costs compared to simpler 3-axis machines, especially for parts that do not require such complex machining.

2. What is 5-axis machining used for?

5-axis machining is used to manufacture parts with highly complex shapes and geometries that require exceptional precision. It is essential in industries like aerospace for creating components such as turbine blades and impellers, in the medical field for orthopedic implants and custom surgical tools, and in the automotive sector for engine parts and complex molds. Its ability to machine intricate features in a single setup makes it ideal for applications where accuracy and surface finish are critical.

3. What type of machining process is best suited for producing complex shapes with high precision and surface finish?

For CNC machining, the 5-axis process is best suited for producing complex shapes with high precision and a superior surface finish. The ability to continuously adjust the angle between the cutting tool and the workpiece allows for the use of shorter, more rigid tools that reduce vibration. This results in smoother surfaces and enables the machine to maintain tighter tolerances throughout the manufacturing of intricate parts.