CNC Milling Aluminum 6061: Essential Strategies for Success

TL;DR

Aluminum 6061 is a top choice for CNC milling due to its fantastic combination of strength, light weight, and corrosion resistance. Its excellent machinability allows for creating precise parts with great surface finishes, making it a versatile and reliable material for industries ranging from aerospace to consumer electronics. This alloy offers a superb balance of properties that make it both high-performing and cost-effective for a wide array of projects.

Understanding the Core Properties of Aluminum 6061

Aluminum 6061 stands out as one of the most popular and versatile alloys for CNC machining, and for good reason. Its reputation is built on a well-balanced set of mechanical and chemical properties that make it an ideal candidate for countless applications. The primary alloying elements in 6061 are magnesium and silicon, which contribute significantly to its strength, formability, and resistance to corrosion. It is often used in the T6 temper condition, meaning it has been solution heat-treated and artificially aged to achieve its optimal strength.

The combination of these characteristics makes 6061 a go-to material for engineers and machinists. According to manufacturing experts at PCBWay, it offers excellent processing performance and high toughness with no deformation after processing. This reliability ensures that the final product matches the design specifications with high fidelity, which is critical in precision manufacturing. Its adaptability allows it to be used in everything from simple brackets to complex structural components.

Here are the core properties that make Aluminum 6061 so well-suited for CNC milling:

- Excellent Machinability: This is arguably its most significant advantage for CNC work. 6061 aluminum allows for clean, precise cuts and produces manageable chips. This results in a smooth surface finish directly off the machine, reducing the need for extensive post-processing. Its machinability also contributes to lower tool wear and faster cycle times, making the manufacturing process more efficient and economical.

- High Strength-to-Weight Ratio: With a density of approximately 2.7 g/cm³, 6061 is lightweight yet surprisingly strong, especially in its T6 temper. This property is invaluable in industries like aerospace and automotive, where reducing weight without compromising structural integrity is a primary goal.

- Superior Corrosion Resistance: Aluminum 6061 naturally forms a protective oxide layer that shields it from corrosion. This makes it suitable for parts used in marine environments or those exposed to moisture and various chemicals. This inherent resistance can be further enhanced through anodizing, a common finishing process for 6061 parts.

- Good Weldability and Formability: Unlike some higher-strength aluminum alloys, 6061 can be readily welded, allowing for the creation of complex assemblies. Its good formability also means it can be shaped and worked without fracturing, adding to its versatility in manufacturing.

- Heat Treatable: The ability to be heat-treated (specifically to the T6 temper) allows for a significant increase in its strength and hardness. This process involves heating the material to a specific temperature and then aging it, a procedure that makes the final component much more durable. As noted by Cox Manufacturing, the yield strength of 6061-T6 is over four times that of its untempered state.

Essential Machining Parameters: Speeds, Feeds, and Tooling

Achieving high-quality results when CNC milling aluminum 6061 depends heavily on using the correct machining parameters. Dialing in the right speeds, feeds, tool selection, and coolant strategy is crucial for producing accurate parts with an excellent surface finish while maximizing tool life. While 6061 is known for being forgiving, optimizing these settings separates professional results from amateur ones.

Cutting Speeds and Feeds

Generally, aluminum should be cut at high speeds. High spindle speeds (RPM) combined with appropriate feed rates prevent the material from becoming gummy and sticking to the cutting tool, a common issue with softer metals. The goal is to create a clean shearing action that produces well-formed chips and evacuates them from the cutting area efficiently. Slower speeds can lead to built-up edge (BUE) on the tool, which degrades the surface finish and can cause the tool to break.

While exact parameters depend on the machine's rigidity, the tool's diameter and material, and the depth of cut, general guidelines provide a solid starting point. The table below offers typical ranges for milling 6061 aluminum with carbide end mills.

| Parameter | Recommended Range |

|---|---|

| Cutting Speed (Surface Feet per Minute - SFM) | 1000 - 4000 SFM (approx. 300 - 1200 m/min) |

| Chip Load (per tooth) | 0.002" - 0.010" (or higher, depending on tool diameter and application) |

| Feed Rate (Inches per Minute - IPM) | Calculated based on RPM and chip load |

Tool Selection

The right cutting tool is critical for success. For aluminum 6061, the following are recommended:

- Tool Material: Uncoated solid carbide end mills are a popular choice. However, tools with a Zirconium Nitride (ZrN) or similar slick coating are even better, as they prevent aluminum from sticking to the tool.

- Flute Count: Use 2-flute or 3-flute end mills. Fewer flutes provide more space for large, fast-moving chips to be evacuated, which is essential when milling aluminum at high speeds. A 4-flute tool can get clogged with chips, leading to poor cuts and tool failure.

- Helix Angle: A higher helix angle (around 35-45 degrees) helps pull chips up and out of the cut, improving chip evacuation and surface finish.

Coolant and Lubrication

Proper lubrication and cooling are vital to prevent material from welding to the tool and to ensure a smooth finish. Flood coolant is the most effective method, as it continuously flushes chips away and keeps the tool and workpiece at a stable temperature. For machines not equipped for flood coolant, a misting system or even compressed air can be effective for clearing chips. While dry machining is possible for shallow cuts, it is generally not recommended for aggressive milling as it increases the risk of tool failure and poor surface quality.

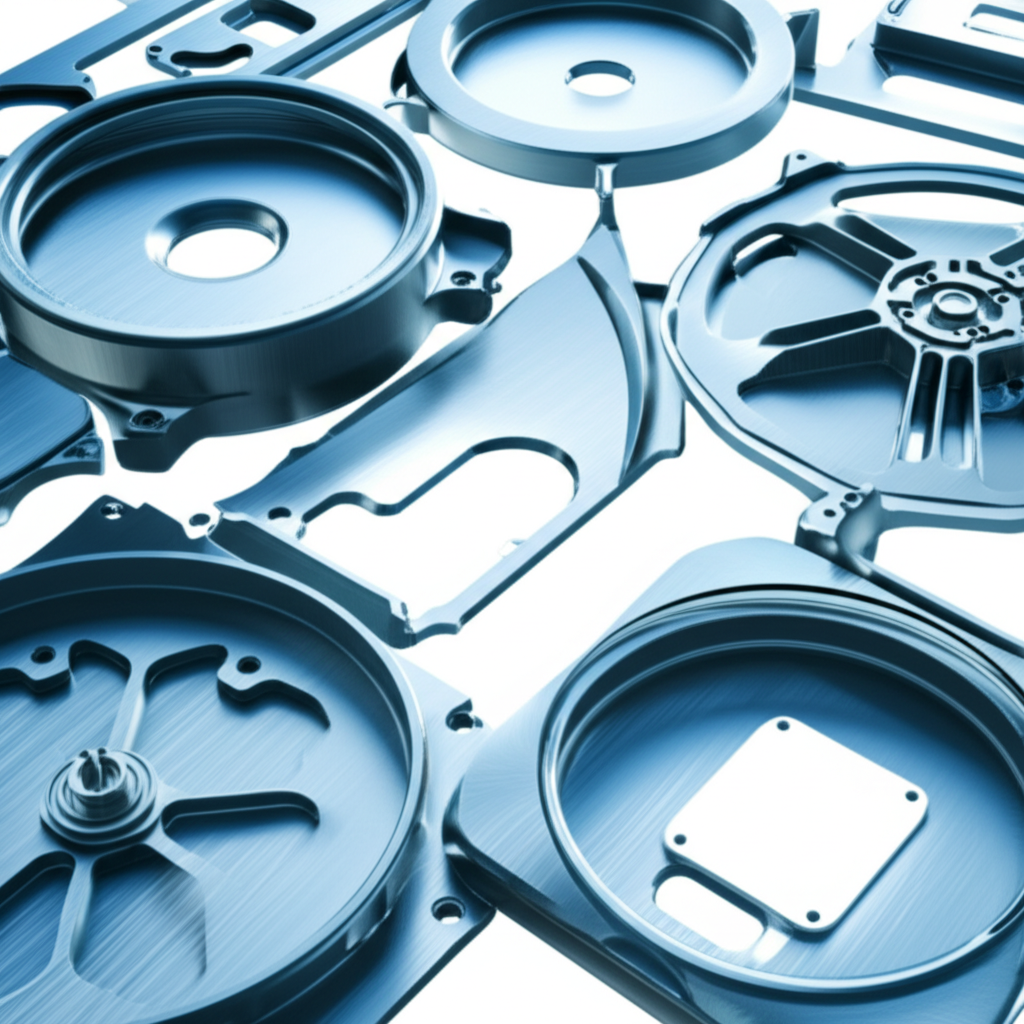

Common Industries and Applications for 6061 Parts

The unique combination of light weight, high strength, and excellent corrosion resistance makes aluminum 6061 a highly versatile material used across a vast spectrum of industries. Its reliability and cost-effectiveness ensure its place in products ranging from everyday consumer goods to critical components in high-tech machinery. The ease with which it can be precisely machined via CNC methods further broadens its appeal, allowing for the creation of intricate and custom parts.

As highlighted by Davantech, CNC machining of 6061-T6 is common in the aerospace, automotive, and medical fields. In each of these sectors, the material's properties solve specific engineering challenges. For example, in aerospace, every gram of weight saved translates to fuel efficiency and increased payload capacity, making 6061 an ideal choice for non-critical structural elements.

Here are some of the primary industries and specific applications where CNC-milled 6061 aluminum parts are frequently found:

- Aerospace and Defense: While higher-strength alloys like 7075 are used for critical airframes, 6061 is widely used for fuselage and wing structures, brackets, fittings, and ground support equipment where a balance of strength, weight, and cost is essential.

- Automotive and Transportation: In the automotive world, 6061 is used for chassis components, suspension parts, engine mounts, and housings for transmissions and other systems. It is also a key material in bicycle frames and components, where its light weight and strength are highly valued.

- Consumer Electronics: The sleek, durable feel of many premium laptops, smartphones, and audio equipment enclosures comes from CNC-milled 6061 aluminum. It provides a robust yet lightweight frame and an excellent surface for aesthetic finishes like anodizing.

- Marine Applications: Due to its exceptional resistance to corrosion, especially in saltwater environments, 6061 is used for boat hulls, fittings, hardware, and marine frames.

- Medical Equipment: From surgical instruments to housings for diagnostic equipment and hospital bed components, 6061 provides a strong, easily sterilized, and non-reactive material that meets the demanding standards of the medical industry.

Sourcing Guide: Finding the Right 6061 Aluminum

Once you've decided that aluminum 6061 is the right material for your project, the next step is to source it. Understanding the different forms it comes in and where to purchase it can help ensure you get the right stock for your needs at a competitive price. The choice between sourcing raw material for your own workshop or outsourcing the entire manufacturing process also depends on the complexity of your parts, the required volume, and your equipment capabilities.

Aluminum 6061 is available in several standard stock forms, each suited to different types of CNC projects. The most common forms include:

- Plate/Block: Thick, flat pieces ideal for milling larger parts or enclosures.

- Sheet: Thinner than plate, used for fabricating panels or parts that don't require significant thickness.

- Round/Square/Hex Bar: Long rods of material perfect for turning on a lathe or milling smaller components.

- Extrusions: Pre-formed shapes like angles or channels that can reduce machining time for specific profiles.

When it comes to purchasing, you generally have two main options: online metal suppliers and local distributors. Online suppliers often offer a wider selection and competitive pricing, shipping directly to your door. Local distributors can be a great option for quick turnarounds and avoiding shipping costs, especially for larger orders. For complex parts or volume production, partnering with a specialized service is often more efficient. For instance, services like XTJ's CNC machining services offer rapid prototyping and production using advanced equipment, ensuring tight tolerances and consistent quality without the need for in-house machinery.

Frequently Asked Questions

1. Can you CNC 6061 aluminum?

Yes, absolutely. As noted by experts at Rapid Axis, aluminum 6061 is one of the most widely used and ideal alloys for CNC machining. Its excellent machinability, combined with a great balance of strength, light weight, and corrosion resistance, makes it a preferred choice for machinists and engineers worldwide.

2. What MIG wire for 6061 aluminum?

While this article focuses on CNC milling, welding is often a complementary process. For MIG welding 6061 aluminum, an ER4043 wire is a common and highly effective choice. It contains 5% silicon, which improves puddle fluidity and helps prevent cracking in the final weld, making it suitable for joining 6061 components.

3. Do you want to cut aluminum on a mill faster or slower?

Generally, you want to cut aluminum faster. It benefits from high spindle speeds (RPM) and aggressive feed rates. This approach prevents the aluminum from sticking to the cutting tool (built-up edge) and produces a better surface finish. The key is to balance high speeds with a feed rate that allows for efficient chip evacuation to avoid clogging the tool flutes.

4. What is the cutting speed of 6061 Aluminium?

The ideal cutting speed for 6061 aluminum varies significantly based on the specific cutting tool, machine rigidity, and use of coolant. However, a general range for carbide tools is between 1000 and 4000 surface feet per minute (SFM), which translates to approximately 300 to 1200 meters per minute. It's always best to start with the tool manufacturer's recommendations and adjust based on performance.

-

Posted in

Aluminum 6061, cnc machining, CNC Tooling, manufacturing, Metal Milling