High Precision CNC Turning for Mission-Critical Components

TL;DR

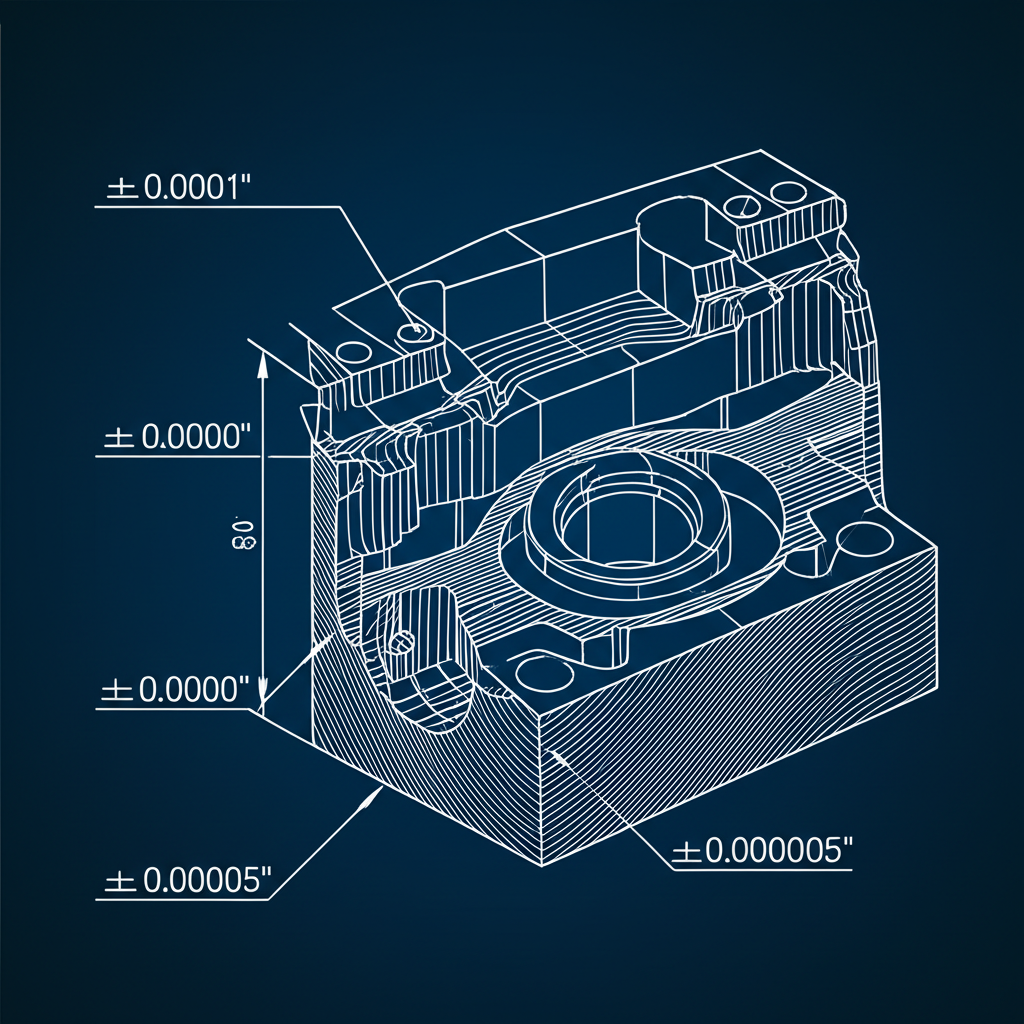

High precision CNC turning is an advanced manufacturing process using computer-controlled lathes to shape materials into complex components with exceptionally tight tolerances, often as accurate as ±0.0001 inches. This method is indispensable for producing high-performance parts where accuracy and repeatability are non-negotiable, particularly in mission-critical industries like aerospace, medical, and defense. It surpasses manual methods by delivering superior quality, consistency, and complex geometries with remarkable efficiency.

Understanding High-Precision CNC Turning: Core Concepts and Benefits

High-precision Computer Numerical Control (CNC) turning is a subtractive manufacturing process that involves rotating a workpiece (typically metal or plastic bar stock) at high speed while a stationary cutting tool removes material to create a final part. Unlike standard turning, the high-precision variant operates under stringent controls to achieve extremely tight dimensional tolerances and superior surface finishes. The entire operation is automated based on a computer-aided design (CAD) file, which is translated into G-code instructions that dictate every movement of the machine. This level of automation eliminates the inconsistencies and limitations of manual lathe operation.

The distinction between standard and high-precision turning lies in the achievable accuracy and complexity. While both use a lathe, high-precision centers are engineered for greater rigidity, thermal stability, and are equipped with advanced measurement systems. This allows them to produce parts with intricate features and maintain consistency across production runs of thousands of units. The process is the ideal choice when component failure is not an option and when the geometric requirements exceed the capabilities of other manufacturing methods.

Adopting high-precision CNC turning offers several key advantages for demanding applications. These benefits are critical for engineers and designers aiming for optimal performance and reliability in their products.

- Extreme Accuracy and Tight Tolerances: The primary benefit is the ability to achieve tolerances that are impossible with manual processes. This precision ensures that components fit and function perfectly within complex assemblies, which is vital for high-performance machinery.

- Exceptional Repeatability: Once programmed, a CNC turning center can produce thousands of identical parts with minimal deviation. This consistency is crucial for volume production, ensuring that every component meets the required specifications without variation.

- Material Versatility: The process is compatible with a vast range of materials, from standard metals like aluminum and steel to engineered plastics like PEEK and high-strength superalloys used in aerospace. This flexibility allows for part optimization based on specific application needs.

- Superior Surface Finishes: High-precision turning can produce exceptionally smooth surface finishes, often eliminating the need for secondary finishing processes like grinding or polishing. This not only improves the part's aesthetic and functional quality but also reduces production time and costs.

Achieving Superior Results: Tolerances, Materials, and Finishes

The defining characteristic of high-precision CNC turning is its ability to hold exceptionally tight tolerances. A tolerance is the permissible limit of variation in a physical dimension. In industries like aerospace or medical devices, even a microscopic deviation can lead to catastrophic failure. High-precision lathes can consistently achieve tolerances that are measured in ten-thousandths of an inch, ensuring components perform exactly as designed. For instance, service providers like Advanced Industries Inc. cite capabilities of achieving tolerances as close as ±0.0001 inches.

The selection of the right material is equally critical to the success of a project. High-precision turning centers can machine a diverse array of materials, each chosen for its specific properties such as strength, weight, corrosion resistance, or biocompatibility. Common materials include various grades of aluminum, stainless steel, titanium, brass, and copper. Additionally, the process is well-suited for high-performance plastics like PEEK, PTFE, and Nylon, as well as exotic superalloys like Inconel and Hastelloy, which are required for extreme temperature and high-stress environments. For companies needing specialized parts, providers like XTJ offer CNC machining services capable of handling over 30 different materials with tolerances down to +/- 0.002mm.

Beyond dimensional accuracy, the surface finish of a turned part is a critical quality metric. A smooth surface can reduce friction, improve wear resistance, and ensure proper sealing. High-precision turning can produce various finishes, from a standard machine finish to fine or even mirror-like surfaces, often without requiring post-processing. This is achieved through careful control of cutting speeds, feed rates, and the use of specialized tooling. The ability to deliver a finished part directly from the machine streamlines the entire production workflow, saving both time and money.

Applications Across Mission-Critical Industries

The exceptional accuracy and reliability of high-precision CNC turning make it an essential manufacturing process for industries where performance and safety are paramount. The ability to create complex, durable components from advanced materials has solidified its role in numerous high-stakes sectors.

Aerospace and Defense

In aerospace and defense, components must withstand extreme temperatures, pressures, and mechanical stress. There is no margin for error. High-precision turning is used to manufacture a wide range of parts, including turbine engine components, hydraulic fittings, sensor housings, and custom fasteners. Materials like titanium, stainless steel, and nickel alloys are commonly used for their high strength-to-weight ratio and resistance to corrosion. The process ensures that every part meets the stringent quality and safety standards required for both commercial and military aircraft.

Medical and Healthcare

The medical industry relies on precision-turned parts for surgical instruments, orthopedic implants, and components for diagnostic equipment. Biocompatible materials such as titanium and medical-grade stainless steel are frequently used. The process's ability to produce parts with complex geometries and exceptionally smooth surfaces is critical for items like bone screws, dental implants, and custom surgical tools. As detailed by manufacturers like BTX Precision, these applications demand the highest level of accuracy to ensure patient safety and device efficacy.

Electronics and Semiconductor

As electronic devices become smaller and more powerful, the demand for miniaturized, high-precision components grows. CNC turning is used to create custom connectors, sockets, heatsinks, and alignment pins for the electronics and semiconductor industries. The process can machine conductive materials like copper and aluminum with the precision needed for intricate electronic assemblies, ensuring reliable performance and thermal management in everything from consumer gadgets to advanced telecommunications hardware.

The Technology Behind the Precision: Equipment and Quality Control

Achieving sub-micron accuracy is not accidental; it is the result of sophisticated technology and rigorous process control. The foundation of high-precision turning is the machinery itself. Modern CNC turning centers and lathes are marvels of engineering, designed for maximum rigidity and thermal stability to minimize vibration and dimensional changes during operation. Many of these machines are multi-axis, featuring live tooling and sub-spindles. Live tooling allows the machine to perform secondary milling, drilling, and tapping operations in a single setup, a concept often referred to as "Done-in-One" machining. This integration, highlighted by service providers like M&M Automatic Products, dramatically reduces cycle times and improves part accuracy by eliminating the need to move the workpiece between different machines.

Beyond the machine's capabilities, a robust quality control process is essential to verify that every part meets its specifications. This process begins with initial planning and continues through to final inspection. Machining shops employ a range of metrology tools, including Coordinate Measuring Machines (CMMs), laser micrometers, and profilometers, to measure dimensions and surface characteristics with incredible precision. In-process checks are often performed to catch any deviations early in the production run.

Furthermore, adherence to internationally recognized quality standards provides another layer of assurance. Certifications such as ISO 9001 demonstrate a commitment to a documented quality management system, ensuring consistent processes and continuous improvement. For industries like aerospace, additional certifications like AS9100 are often required. This focus on quality control and certification ensures that customers receive parts that are not only precise but also reliably and verifiably correct, every single time.

Partnering for Precision: Key Considerations

High-precision CNC turning is more than just a manufacturing process; it's a critical solution for creating components that drive innovation in the world's most demanding industries. From the initial design to the final product, every step is defined by an uncompromising commitment to accuracy. Understanding the core principles—the importance of tight tolerances, the versatility of materials, and the technology that makes it all possible—is key to leveraging this capability effectively.

When embarking on a project that requires this level of precision, the focus should be on clear communication of design specifications, careful material selection, and partnership with a manufacturer that demonstrates a strong commitment to quality control. The ultimate success of a high-performance product often rests on the microscopic accuracy of its smallest components. By prioritizing precision from the start, engineers and innovators can ensure their designs achieve their full potential for performance, safety, and reliability.

Frequently Asked Questions About Precision Turning

1. What is ultra-precision turning?

Ultra-precision turning is a specialized subset of high-precision turning that operates at an even higher level of accuracy, often for creating optical-grade surfaces or components with nanoscale features. It is commonly used for machining aspherical lenses, molds for optical components, and parts for medical applications that require free-form surfaces. It represents the pinnacle of turning technology, pushing the boundaries of what is mechanically achievable.

2. How does CNC turning differ from CNC milling?

Though both are subtractive CNC machining processes, they operate differently. In CNC turning, the workpiece rotates at high speed while a stationary cutting tool removes material. This is ideal for creating cylindrical or conical parts. In CNC milling, the cutting tool rotates at high speed against a stationary workpiece, allowing it to create more complex, non-symmetrical shapes and features.

3. What is 'live tooling' on a CNC lathe?

Live tooling refers to powered, rotating cutting tools that can be mounted in the turret of a CNC lathe. This feature allows the machine to perform secondary operations like drilling, tapping, and milling on the workpiece without removing it from the lathe. This 'mill-turn' capability increases efficiency, improves accuracy by reducing setups, and allows for the creation of more complex parts on a single machine.