What Is Titanium? Fast Facts, Real Uses, Costs, And Myths

Titanium Explained

What is titanium in one paragraph?

Titanium is a silver-gray metal element (symbol Ti, atomic number 22) renowned for its exceptional strength-to-weight ratio, natural resistance to corrosion, and lightness. It’s widely used in aerospace, medical implants, jewelry, and high-performance consumer goods because it’s strong yet lightweight, doesn’t rust thanks to a thin protective oxide layer, and is generally nonmagnetic in everyday forms. If you’ve ever wondered, “is titanium a metal or nonmetal,” it’s definitely a metal—one that stands out for its unique balance of durability and low weight.

Key takeaways for consumers, engineers, and manufacturers

-

For consumers:

- Hypoallergenic: Titanium jewelry is ideal for sensitive skin, as it rarely causes allergic reactions.

- Durability: Products like watches, bike frames, and cookware made from titanium are tough and long-lasting, resisting dents and corrosion.

- Color variety: While natural titanium is usually silver-gray, it can be anodized into vibrant colors for personal style.

-

For engineers:

- Strength-to-weight: Titanium offers high mechanical strength at a fraction of the weight of steel, making it a go-to for aerospace and automotive parts.

- Corrosion resistance: Its passive oxide layer shields it from seawater, sweat, and most chemicals, reducing maintenance needs.

- Machining considerations: Despite its versatility, titanium can be tricky to machine due to its low thermal conductivity and tendency to work-harden.

-

For manufacturers:

- Production: Extracting and refining titanium from minerals like rutile and ilmenite requires complex, energy-intensive processes.

- Cost drivers: Multi-step production and contamination control make titanium pricier than steel or aluminum, but recyclability helps offset costs.

- Recyclability: Scrap titanium is valuable and commonly recycled, especially in aerospace and medical industries.

Common misconceptions about titanium

- Is titanium the strongest metal? Not quite—while titanium is among the strongest metals for its weight, there are denser metals like tungsten and some specialty steels that are stronger in absolute terms. Its real advantage is combining strength with lightness.

- Is titanium magnetic? In everyday use and most common alloys, titanium is nonmagnetic, making it suitable for MRI-safe medical implants and electronic housings.

- Does titanium rust? Titanium doesn’t rust like iron. Its natural oxide coating protects it from most corrosion, even in harsh environments like seawater or sweat. However, it can be vulnerable in strongly reducing acids.

- What’s titanium? It’s not a rare, exotic metal—titanium is the ninth most abundant element in Earth’s crust, but pure titanium is never found in nature; it’s always bound to other elements in minerals.

So, when you’re asked, “what’s titanium” or “is titanium a metal,” you’ll know it’s a lightweight, durable, and versatile metal prized for its strength, corrosion resistance, and modern applications in everything from medical implants to aerospace engineering. For more on how natural titanium is processed and why it costs more than common metals, keep reading.

Periodic Table Context and Core Properties of Titanium

Element Ti at a Glance

Ever wondered what makes titanium so special on the periodic table? Let’s break it down—whether you’re a student, engineer, or just curious about materials science, here’s how titanium fits into the big picture.

| Property | Value |

|---|---|

| Symbol | Ti |

| Atomic Number (ti atomic number) | 22 |

| Atomic Mass (atomic mass of ti) | 47.867 |

| Typical Titanium Color | Metallic silver-gray (can appear white when oxidized or anodized) |

| Crystal Structure | Hexagonal close-packed (alpha phase, below 883°C); Body-centered cubic (beta phase, above 883°C) |

| Density (titanium density) | 4.5 g/cm3 |

| Melting Point (titanium melting point) | 1,668°C (3,034°F) |

| Thermal Conductivity | Low (about 21.9 W/m·K at 25°C) |

| Electrical Resistivity | High (about 420 nΩ·m at 20°C) |

| Elastic Modulus | ~116 GPa (varies with alloy and purity) |

Data sourced from Britannica and Wikipedia.

Core Physical Properties Engineers Care About

- Strength-to-weight: Titanium’s density is about 60% higher than aluminum but less than half that of iron, making it uniquely light for its strength. This explains why it’s a favorite in aerospace and high-performance equipment.

- Melting point of titanium: With a melting point of 1,660°C, titanium stands out among metals for its ability to withstand heat—crucial for jet engines and industrial components.

- Electrical and thermal behavior: Titanium is a poor conductor compared to copper or aluminum, which means it doesn’t transfer heat or electricity as efficiently. This can be a benefit in some engineering applications where insulation is desired.

- Crystal structure: Imagine titanium as a shape-shifter: below 883°C, it’s hexagonal (alpha phase), but above that, it switches to a body-centered cubic (beta phase). This transformation influences how titanium alloys behave under heat and stress.

Color and Surface Oxide Basics

Curious about what color is titanium? In its pure form, titanium appears as a shiny, metallic silver-gray. But there’s more to the story: as soon as it’s exposed to air, titanium forms a super-thin layer of titanium dioxide (TiO2). This passive film is only nanometers thick but is incredibly effective at shielding the metal from corrosion—one reason why titanium resists rusting in seawater and even in the human body.

Want something more colorful? Through a process called anodizing, you can thicken this oxide layer, causing light to reflect in different ways and producing vibrant blues, purples, and even golds—without any dyes or paints.

How Properties Vary by Alloy and Processing

Titanium isn’t a one-size-fits-all material. Commercially pure (CP) grades, like Grade 2, are softer and easier to form, while popular alloys such as Ti-6Al-4V (Grade 5) offer much higher strength and are used in demanding aerospace and medical applications. Processing—like heat treatment or cold working—can further adjust properties like hardness, ductility, and toughness. So, when you’re looking at the titanium periodic table entry, remember: the real-world performance depends on both the alloy and how it’s made.

Key takeaway: Titanium’s unique combination of a high melting point, low density, and corrosion resistance comes from its place on the periodic table and its ability to form a protective TiO2 surface layer. These features make it a go-to material for everything from aircraft to medical implants—and explain why questions like “what color is titanium” or “what’s the melting point of titanium” matter in both science and industry.

Now that you know the basics of titanium’s elemental identity and physical properties, let’s explore how this remarkable metal is transformed from raw mineral to finished product—and why that process is both complex and costly.

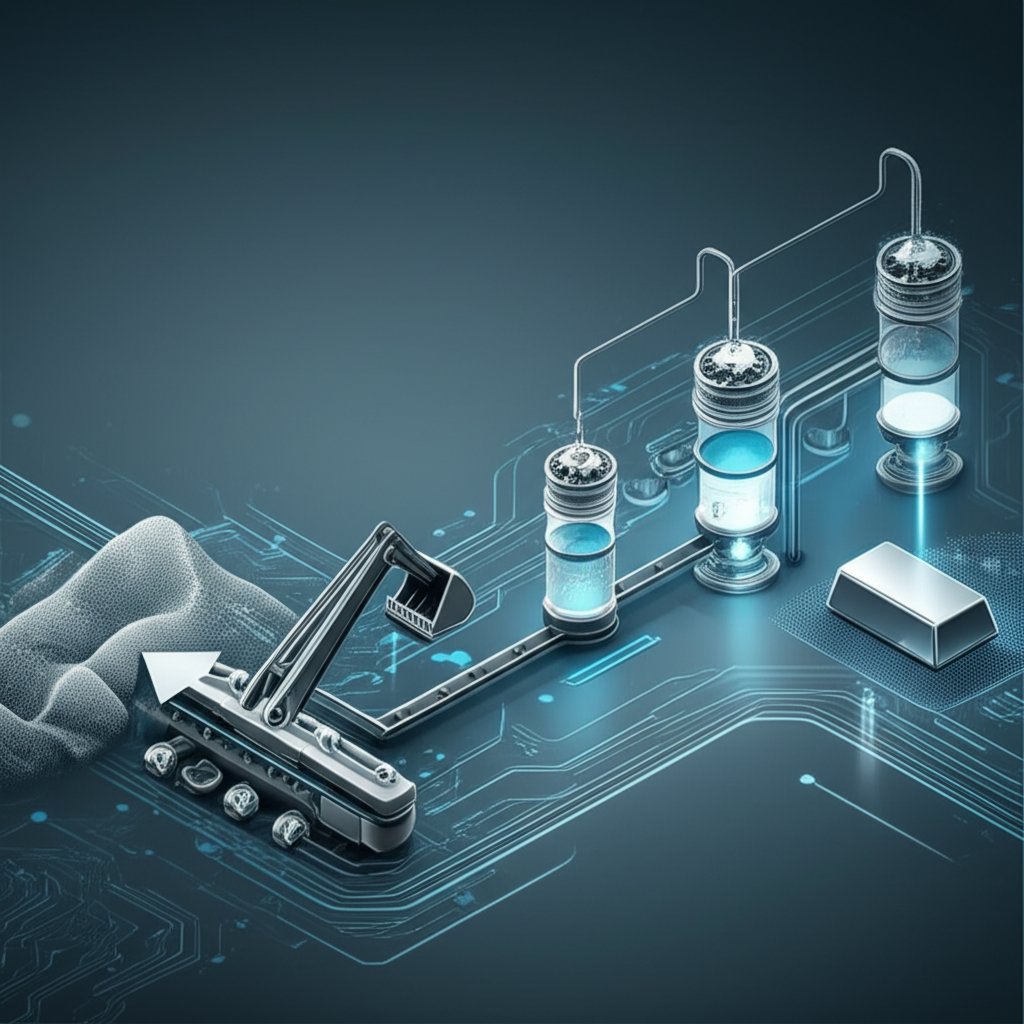

How Titanium Is Produced

From Mineral Sands to Titanium Tetrachloride

Ever wondered how titanium transforms from a dull mineral in the earth into the sleek, high-performance metal in aircraft or medical devices? The journey is anything but simple. It starts with the extraction of titanium ore—primarily rutile (TiO2) and ilmenite (FeTiO3)—from mineral sands using open-pit mining and dredging. But that’s just the beginning of how titanium is formed for industrial use.

-

Mining of Rutile and Ilmenite: Heavy mineral sands are collected from deposits using mechanical dredges or excavators. These sands typically contain 3–12% useful minerals, with the rest being waste material.

Purpose: To obtain the raw titanium source material. -

Ore Concentration: The sands are processed in wet spiral concentrators and further separated by gravity, magnetic, and electrostatic methods to isolate rutile and ilmenite.

Purpose: To increase the concentration of titanium minerals and remove impurities. -

Chlorination to TiCl4: The concentrated ore is treated with chlorine gas at high temperatures, producing titanium tetrachloride (TiCl4), a volatile liquid.

Purpose: TiCl4 acts as an intermediate, allowing for purification and easier reduction to metal. -

Purification of TiCl4: The crude TiCl4 is distilled to remove iron, vanadium, and other impurities.

Purpose: Ensures high-purity titanium in the final product. -

Kroll Reduction to Titanium Sponge: In the Kroll process, purified TiCl4 is reduced by molten magnesium in a sealed reactor at 800–850°C. This yields a porous, brittle form called titanium sponge.

Purpose: This is the critical step in how titanium is made into a usable metal. The sponge’s porosity is key for downstream melting quality. -

Sponge Crushing and Pressing: The titanium sponge is crushed and pressed into briquettes or compacts.

Purpose: Prepares the sponge for melting and helps control composition. -

Melting and Remelting: The sponge, sometimes with alloying elements, is melted in a vacuum arc furnace or by electron beam melting, then cast into ingots or billets. Often, multiple remelts are performed to ensure uniformity and remove inclusions.

Purpose: Produces high-purity, dense titanium metal suitable for rolling, forging, and machining into finished products.

- Mining & Concentration: Extracts and upgrades titanium raw material from ore.

- Chlorination & Purification: Converts ore into a form suitable for reduction and removes contaminants.

- Kroll Reduction: The defining step in how titanium is produced—turns TiCl4 into raw titanium sponge.

- Melting & Remelting: Ensures the final titanium metal is strong, uniform, and free of harmful inclusions.

The Kroll Process and Sponge Production

When people ask, “titanium, how is it made?,” the answer almost always involves the Kroll process. Developed in the 1940s and still used today, this method uses magnesium to reduce TiCl4 to metallic titanium. While the process is reliable, it’s energy-intensive and sensitive to contamination—one reason why titanium remains more expensive than steel or aluminum. The resulting titanium sponge is then carefully processed to avoid impurities that could compromise its famous strength and corrosion resistance. For a detailed look at the chemistry and history, see Wikipedia’s Kroll process entry.

Melting, Remelting, and Alternatives Like FFC Cambridge

After sponge production, melting and remelting are crucial. These steps use vacuum arc remelting (VAR) or electron beam melting (EBM) to produce dense, homogeneous ingots. Each melting cycle further purifies the metal and ensures it meets stringent aerospace or medical standards. But is there a better way? Researchers have developed the FFC Cambridge process, which directly reduces TiO2 electrochemically, bypassing some of the chemical steps and potentially lowering costs and environmental impact. While promising, this alternative is still in development and not yet widespread in industry (for more, see ScienceDirect or RSC sources).

The main cost drivers in titanium production are the multi-stage chlorination and reduction steps, the need for high temperatures and energy, and strict contamination control at every stage. These factors explain why titanium, though abundant in the earth’s crust, is costly to turn from ore into the high-performance metal we use in advanced applications.

Now that you’ve seen how titanium is formed from raw mineral to finished metal, you’ll better appreciate why it’s prized for demanding uses—and why its price reflects the complex journey from titanium ore to product. Next, let’s connect these production details to the real-world performance of titanium in corrosive, magnetic, and high-strength environments.

How Titanium Stands Up in Real-World Use

Corrosion Resistance and Does Titanium Rust?

When you think about metals in harsh environments—like saltwater, chemical plants, or even inside the human body—you might wonder, "does titanium rust?" Unlike iron or steel, titanium forms a tough, invisible oxide layer (titanium dioxide) on its surface the moment it’s exposed to oxygen. This natural barrier is what makes titanium so resistant to corrosion and rust, even in aggressive settings like seawater or acidic industrial processes. In fact, titanium piping is often chosen for power plants and desalination facilities because it can withstand years of exposure without needing extra coatings or frequent replacement.

- Aerospace fasteners: Rely on titanium’s resistance to corrosion and light weight for critical aircraft structures.

- Biomedical implants: Use titanium’s biocompatibility and non-corrosive nature for long-lasting joint replacements and dental work.

- Chemical processing equipment: Benefit from titanium’s ability to resist acids and chlorides, extending service life in harsh chemical environments.

- Sports gear: Take advantage of titanium’s durability and corrosion resistance in golf clubs, bike frames, and fishing reels.

But is titanium immune to all forms of corrosion? Not entirely. In environments with little to no oxygen (like a vacuum) or in the presence of hot halides and certain strong acids, the protective oxide film can break down, making the metal vulnerable. Still, for most practical applications, titanium is far more rust-resistant than nearly any other commonly used metal.

Magnetism and Is Titanium Magnetic?

Ever tried sticking a magnet to titanium? You’ll notice—nothing happens. Both pure titanium and its common alloys are nonmagnetic, meaning they won’t interact with everyday magnets. This property is crucial for medical devices like MRI machines, where magnetic interference can be dangerous. It’s also why titanium is a popular choice for surgical tools, implants, and even electronic housings (Mako Metal).

- Medical implants: Nonmagnetic, so safe for MRI scans.

- Scientific equipment: Used in sensitive instruments where magnetism must be avoided.

- Security applications: Employed in bomb disposal robots and aerospace where magnetic neutrality is vital.

So, if you’re wondering, "is titanium magnetic?"—the answer is no for both pure titanium and most titanium alloys. This sets it apart from metals like iron or some grades of stainless steel, which are often magnetic.

Strength, Fatigue, and Long-Term Use

How strong is titanium compared to other metals? While it’s not technically the absolute strongest metal (that title often goes to tungsten or certain specialty steels), titanium is celebrated for its outstanding strength-to-weight ratio. In other words, it’s much lighter than steel but can support similar or even greater loads for its weight, which is why it’s so valuable in aerospace and high-performance sports gear. When you hear the question, "is titanium heavy?"—the answer is that it’s about 60% heavier than aluminum but only about half as dense as steel, making it a sweet spot for lightweight strength.

- Implants and airframes: Alpha-beta titanium alloys (like Ti-6Al-4V) are prized for their combination of high strength, toughness, and fatigue resistance.

- Fatigue behavior: Titanium can endure repeated stress cycles without cracking, making it ideal for parts that flex or vibrate over time.

- Hardness: Is titanium harder than steel? Some steels are harder than titanium, especially tool steels, but titanium alloys are still tough enough for demanding uses. The real advantage is in combining hardness, lightness, and corrosion resistance.

Ultimately, "how hard is titanium?" and "is titanium the strongest metal?" depend on the specific alloy and application. For most uses, titanium’s unique blend of properties—strength, weight, corrosion resistance, and nonmagnetism—make it a top performer.

Titanium’s durability comes from its self-healing oxide film, which protects against rust and corrosion even in harsh environments—making it a top choice for applications where long-term performance matters most.

Understanding these real-world titanium characteristics helps explain why it’s so widely used—and why it often outperforms other metals in demanding environments. Next, let’s see how titanium compares directly with stainless steel, aluminum, tungsten, and composites in head-to-head material matchups.

Titanium Compared with Alternative Materials

Titanium versus Stainless Steel

When you’re weighing options for a critical part or product, the decision often comes down to titanium steel (titanium alloys), stainless steel, or aluminum. Each has its own sweet spot—so how do you choose? Let’s break down the key differences, with a special look at stainless steel vs titanium for engineering and manufacturing.

| Property | Titanium | Stainless Steel | Aluminum | Tungsten | Fiber Composites |

|---|---|---|---|---|---|

| Strength-to-Weight | Excellent (highest among metals) | High (but heavier) | Moderate | Very high (but extremely heavy) | Exceptional (if designed correctly) |

| Corrosion Resistance | Outstanding | Good (stainless grades) | Good | Good | Variable (depends on matrix/resin) |

| Thermal Conductivity | Low | Low to moderate | High | Low | Low (anisotropic) |

| Electrical Conductivity | Poor | Moderate | High | Poor | Very low |

| Hardness | Good (varies by alloy) | High (especially tool steels) | Low to moderate | Extremely high | Variable |

| Machinability | Moderate to difficult | Good (especially carbon steels) | Excellent | Poor | Challenging (requires special tools) |

| Weldability | Good (needs shielding) | Good | Good | Poor | Not weldable (mechanical joining only) |

| Cost per Unit Mass | High | Moderate | Low | Very high | High (depends on fiber type) |

| Density (Heaviness) | Low | High | Very low | Extremely high (heaviest metals class) | Very low |

Titanium versus Aluminum

Imagine you need a lightweight solution—aluminum is often the first choice for applications like aircraft frames, bike parts, or heat exchangers. It’s easy to machine, has excellent thermal conductivity, and is cost-effective for large-scale projects. However, aluminum’s strength and fatigue resistance fall short in high-stress or corrosive environments. That’s where titanium shines: it’s stronger for its weight, resists corrosion better, and can handle more demanding loads, though it comes at a higher price point (ANSI).

Titanium versus Tungsten and Composites

The tungsten vs titanium debate comes up in extreme settings. Tungsten is one of the heaviest metals and boasts the highest tensile strength and melting point of all pure metals, making it ideal for ballast, armor, or high-temperature tools. But it’s brittle and nearly ten times heavier than titanium, so it’s not suited for weight-sensitive designs. In contrast, titanium offers an unrivaled strength-to-weight ratio—while not the strongest metal on earth in absolute terms, it’s often the most practical for aerospace, medical, and sports applications.

Fiber composites (like carbon fiber) can surpass titanium in stiffness-to-weight, but they’re anisotropic (properties vary by direction) and can be sensitive to impact or environmental damage. They’re best for applications where directional strength and minimal weight are crucial, such as racing bikes or aerospace panels.

When Does Each Material Win?

- Aluminum: Best for cost-sensitive, lightweight, and high-thermal-conductivity needs.

- Titanium: Excels in corrosive, weight-sensitive, and high-strength environments—think jet engines, surgical implants, and premium sporting goods.

- Stainless Steel: Chosen for its versatility, ease of fabrication, and lower cost in less weight-critical applications.

- Tungsten: Ideal for maximum density and heat resistance (e.g., radiation shielding, high-temperature tooling), but not for moving parts due to brittleness and weight.

- Composites: Perfect for maximum stiffness-to-weight where anisotropy is acceptable and cost is less of a concern.

Material selection isn’t about finding the “strongest metals” or the “heaviest metals”—it’s about matching the right properties to your application’s needs. For example, what is stronger, black titanium or carbon steel? The answer depends on the specific alloy, processing, and use case. Always consider the full context—strength, weight, corrosion, cost, and manufacturability—before making your choice.

As you compare these advanced materials, keep in mind that the next step in your decision process is understanding how titanium behaves in manufacturing. Up next: practical guidance for machining, welding, and finishing titanium for top performance in your projects.

Manufacturing Guidance for Working Titanium

Machining Strategies and Tool Life

When you first encounter titanium on the shop floor, you might wonder: why does it seem so challenging to machine compared to other metals? The answer lies in its unique combination of low thermal conductivity, high strength, and chemical reactivity. These properties, while making titanium metal alloy ideal for critical parts, also mean that heat builds up quickly at the cutting edge, causing rapid tool wear and potential part distortion. But with the right approach, even demanding jobs become manageable.

- Use sharp, positive-rake carbide or ceramic tooling: These tools cut more efficiently, reducing cutting forces and heat. Coatings like TiAlN or TiCN further improve tool life.

- Apply generous, high-pressure coolant: High-pressure systems are crucial for flushing chips and keeping the cutting zone cool—essential for maintaining titanium hardness and surface finish.

- Lower surface speeds, higher feed per tooth: Run spindle speeds lower than you would for steel or aluminum, but maintain a healthy feed rate to avoid rubbing and work hardening.

- Minimize tool dwell: Avoid lingering in one spot—prolonged contact can cause work hardening and shorten tool life.

- Ensure rigid setups: Secure workholding and minimal tool overhang are critical to prevent chatter, which can quickly degrade both the tool and the part.

- Prioritize chip evacuation: Titanium's stringy chips can wrap around tools; use chip breakers and coolant jets to keep the area clear and prevent heat buildup.

Choosing the correct parameters is key. For most titanium alloys, especially Ti-6Al-4V, keep cutting speeds moderate and adjust feeds to maintain a steady chip load. Remember, titanium mohs hardness is typically around 6, so it’s tough but not brittle—meaning sharp tools and stable conditions matter more than brute force.

Welding Practices and Common Pitfalls

Thinking about joining titanium? A skilled titanium welder knows this metal demands meticulous preparation. Titanium is highly reactive at elevated temperatures, so even trace amounts of oxygen, nitrogen, or hydrogen can embrittle the weld area. Here’s how to ensure quality:

- Full inert gas shielding: Both the root and face of the weld must be protected with high-purity argon (or helium). Trailing shields are often used to extend coverage as the weld cools.

- Spotless cleanliness: All surfaces should be cleaned to remove oils, oxides, and contamination—think cleanroom standards.

- Filler rod selection: Match the filler to the base titanium metal alloy for optimal titanium tensile strength and corrosion resistance.

- Watch for alpha-case and contamination: Improper shielding allows a brittle, oxygen-rich layer (alpha-case) to form, which must be removed post-weld to prevent cracking.

Common pitfalls include insufficient shielding, poor cleaning, or using the wrong filler. These can lead to porosity, embrittlement, or reduced fatigue life—so precision and discipline are non-negotiable for titanium welding success.

Additive Manufacturing and Post Processing

Additive manufacturing (AM) is transforming how complex titanium parts are made. Processes like laser powder bed fusion (LPBF) and electron beam melting (EBM) are especially suited for Ti-6Al-4V, allowing intricate geometries and internal channels not possible with traditional machining. To get the best results:

- Optimize scan strategy and powder handling: Consistent powder quality and careful parameter control reduce porosity and ensure part integrity.

- Use hot isostatic pressing (HIP): This post-processing step densifies the part, closing internal voids and improving mechanical properties, including titanium hardness and fatigue resistance.

- Surface finishing: AM parts often have rough surfaces; machining, grinding, or even shot peening can improve both appearance and performance.

- Anodizing and heat treatments: Anodizing not only creates vibrant colors but also enhances the oxide layer for corrosion resistance. Heat treatments can adjust titanium tensile strength and relieve residual stresses.

Whether you’re producing raw titanium metal parts by AM or conventional means, post-processing is vital for achieving the desired surface quality, mechanical performance, and long-term durability.

Fine titanium chips can ignite if not managed—yes, titanium is flammable in chip or dust form. Always collect chips in dedicated containers and keep a Class D fire extinguisher nearby for emergencies. Fire prevention is essential when machining or grinding raw titanium metal.

By following these best practices for machining, welding, and finishing, you can turn titanium’s challenges into advantages. Up next, we’ll bridge the gap between manufacturing excellence and real-world use by exploring titanium grades, standards, and buying tips for everything from jewelry to aerospace parts.

Standards, Grades, and Buying Titanium

Grades and What They Mean in Practice

When you’re shopping for titanium—whether for an engineering project, jewelry, or medical gear—you’ll quickly see terms like Grade 2 or Grade 5. But what do these titanium metal grades actually mean, and how do they affect titanium uses in the real world?

| Grade | Type | Typical Use | Formability | Strength | Weldability |

|---|---|---|---|---|---|

| Grade 1 | Commercially Pure | Chemical processing, marine, medical devices | Excellent | Low | Excellent |

| Grade 2 | Commercially Pure | Aerospace, marine, chemical, desalination | Good | Moderate | Good |

| Grade 3 | Commercially Pure | Industrial, marine, medical | Moderate | High | Good |

| Grade 4 | Commercially Pure | Aerospace, medical, power generation | Moderate | Highest (of CP grades) | Good |

| Grade 5 (Ti-6Al-4V) |

Alpha-Beta Alloy | Aerospace, medical implants, automotive, sports | Moderate | Very High | Good |

| Grade 23 (Ti-6Al-4V ELI) |

Alpha-Beta Alloy (ELI) | Critical medical implants, dental | Moderate | Very High | Good |

In short, Grade 2 is the "workhorse" for general engineering, Grade 5 (Ti-6Al-4V) is the standard for high-performance needs (especially aerospace and implants), and Grade 1 is chosen for its superior formability and corrosion resistance in less demanding structural roles. If you’re wondering how much does titanium cost, alloys like Grade 5 are typically pricier than pure grades due to their enhanced properties and alloying elements.

Standards, Specs, and Certifications to Request

Sounds complex? The good news is, you don’t have to memorize every spec—but you do need to know what to ask for. When sourcing titanium, always check for these identifiers to ensure you’re getting the right material for your application:

- ASTM B348: Bars and billets

- ASTM F67: Commercially pure titanium for implants

- ASTM F136: Ti-6Al-4V ELI alloy for medical implants

- AMS 4928, AMS 4911: Aerospace and industrial bars, sheets

- ISO 5832 series: International standards for surgical implants

Ask suppliers for a mill test report (MTR). This document should list the heat number, chemical composition, mechanical properties (like tensile strength and hardness), and traceability to the original batch. For critical uses—especially in aerospace, medical, or marine—full certification is non-negotiable.

Buying Tips for Jewelry, Gear, and Implants

When you’re browsing titanium rings for men, bike frames, cookware, or medical items, you’ll notice a wide range of options. Here’s how to make an informed choice and avoid common pitfalls:

- Pure titanium vs. alloy: Pure grades (like Grade 2) are hypoallergenic and great for sensitive skin—ideal for jewelry and implants. Alloys (like Grade 5) offer higher strength, making them better for performance gear and medical hardware.

- Finish and color: Titanium can be polished, brushed, or anodized for vibrant colors. Anodizing is a surface treatment that changes the oxide layer, not a paint or coating.

- Coatings: Some products have additional coatings for color or scratch resistance. Always check if the coating is durable and safe for your intended use.

- Customization: Many jewelers offer engraving, inlays, or unique finishes—just confirm the base material is genuine titanium.

Pros and Cons: Coatings vs. Bare Titanium

- Pros (Coated): Enhanced color variety, improved scratch resistance, added style options.

- Cons (Coated): Potential for wear or chipping over time, coatings may not be hypoallergenic, can obscure the natural look of titanium.

- Pros (Bare): Hypoallergenic, authentic metallic sheen, less maintenance, maintains integrity over years.

- Cons (Bare): Fewer color/style options, may show minor scratches (though titanium is highly scratch-resistant).

Quick Buying Checklist

| ✔ | Check the grade and certification (ask for documentation). |

| ✔ | For implants or medical items, confirm biocompatibility and traceability. |

| ✔ | For jewelry, choose pure titanium for sensitive skin; consider finish and color options. |

| ✔ | For gear (bike frames, cookware), verify the alloy (Grade 5 for strength, Grade 2 for corrosion resistance), and ask about warranty or return policy. |

| ✔ | Compare the price of titanium metal and factor in long-term durability—sometimes a higher upfront cost means less maintenance or replacement down the road. |

| ✔ | If you’re wondering where can I buy titanium metal, look for reputable suppliers with clear standards and customer reviews. |

What is titanium metal used for? Beyond aerospace and medical, common uses for titanium include jewelry, high-end sports equipment, marine hardware, and even cookware—anywhere durability, corrosion resistance, and light weight are essential. By understanding grades, certifications, and smart buying practices, you’ll get the most from your investment and avoid surprises.

Next, we’ll explore how titanium’s lifecycle, recyclability, and market dynamics shape its cost and sustainability—key factors for both industry and consumers.

Sustainability, Recycling, and the Market Context of Titanium

Recycling Routes and Separation Challenges

When you think about the full lifecycle of titanium, it’s easy to focus only on its high-performance uses. But what happens when aerospace parts, medical implants, or manufacturing offcuts reach the end of their first life? The answer lies in recycling—a crucial factor for both sustainability and the titanium cost equation.

- In-house revert: Clean titanium scrap generated during machining or forming is collected and directly remelted within the same facility. This closed-loop approach helps preserve high purity and keeps materials traceable.

- Offcuts and clean chips: Larger pieces and chips from manufacturing can be recycled if free from oils, lubricants, or iron contamination. However, titanium’s strong affinity for oxygen means even slight contamination can downgrade the scrap, limiting its reuse in high-spec applications.

- Alloy cross-mixing challenges: Titanium is often alloyed (e.g., with aluminum or vanadium), and mixing different grades during recycling can make it harder to achieve the precise properties needed for aerospace or medical parts. That’s why careful sorting and closed-loop recycling are common in these industries.

- Contamination risks: Exposure to iron, oxygen, or other metals during collection and handling can render scrap suitable only for lower-grade uses, such as ferro-titanium for steelmaking, rather than for new aerospace or medical products.

Innovative recycling methods, such as molten salt electrolysis, are being developed to separate titanium from alloying elements and impurities, enabling high-purity recovery even from complex scrap streams. For example, recent research has demonstrated that high-grade titanium and valuable metals like vanadium can be selectively recovered from Ti-6Al-4V (TC4) alloy scrap using controlled electrolysis, offering a promising path for sustainable titanium recirculation.

Energy and Carbon Intensity: Primary vs. Recycled Titanium

Ever wondered why the price on titanium is so much higher than for steel or aluminum? The answer starts with energy. Primary titanium production (from ore) requires multiple high-temperature processes, including chlorination and the Kroll reduction, both of which are energy-intensive and generate significant carbon emissions (Nature). In fact, producing a single ton of titanium can emit many times its weight in CO2 through current extraction routes.

By contrast, recycling titanium—especially clean, sorted scrap—uses far less energy. Methods like vacuum arc remelting or advanced electrochemical separation allow manufacturers to reclaim valuable metal with a much lower carbon footprint. As more industries focus on sustainability and carbon reduction, recycled titanium is gaining traction as a greener option for high-spec applications.

That said, not all scrap is created equal. The success of recycling depends on the cleanliness and traceability of the feedstock, as well as the ability to manage alloy composition. Closed-loop recycling, where scrap from a specific process or product is returned to the same supply chain, is especially effective at minimizing both waste and environmental impact.

Market Drivers and Price Influences

So, how much is titanium and what drives its price? Several factors come into play:

- Raw material supply: Titanium is the ninth most abundant element in Earth’s crust, but it’s rarely found in pure form. Most industrial titanium comes from minerals like rutile and ilmenite, which are mined in Australia, South Africa, and other regions (ScienceDirect).

- Processing capacity: The global capacity for producing titanium sponge and melting high-purity ingots is limited, leading to bottlenecks and price volatility—especially during periods of rising demand in aerospace or medical sectors.

- Certification requirements: Aerospace and medical applications demand strict traceability and quality control, restricting the use of recycled material unless it meets rigorous standards.

- Geopolitical factors: Trade policies, export controls, and supply chain disruptions can all influence titanium cost and availability.

- Environmental and carbon costs: As more countries adopt carbon taxes or emissions targets, the question "is titanium expensive" will increasingly depend on how much recycled content is used and how energy-efficient the production process is.

Ultimately, while titanium is not rare, the complexity of its extraction and refinement, coupled with the need for ultra-clean processing and certification, keeps costs high compared to more common metals. As recycling technologies improve and demand for sustainable materials grows, expect the balance between primary and recycled titanium to shift—potentially making the market more resilient and eco-friendly.

For practical sustainability, design products for recyclability, minimize material use through smart engineering, and specify recycled content where possible. These steps not only reduce environmental impact but also help manage long-term titanium usage and cost.

Understanding the lifecycle and market context of titanium helps both manufacturers and consumers make informed choices—setting the stage for smarter sourcing and design decisions in the chapters ahead.

Work with Precision CNC Experts on Titanium Parts

When to Partner with a Precision CNC Shop

Designing a part from titanium alloy or pure titanium metal? You may be wondering when it makes sense to work with a specialist CNC machining shop. While titanium material offers outstanding performance, its unique titanium properties—like low thermal conductivity, high strength, and work-hardening tendencies—mean that expert handling can make all the difference.

- Tight tolerances: Complex aerospace or medical parts often require tolerances as tight as ±0.005mm, which demand advanced equipment and process control.

- Thin walls or intricate features: Titanium’s lower modulus means parts can flex or distort during machining. Precision shops use optimized fixturing and strategies to maintain accuracy.

- 5-axis or multi-axis machining: For parts with undercuts, compound angles, or organic shapes, multi-axis CNCs are essential for both efficiency and quality.

- Medical/aerospace documentation: Traceability, certifications, and inspection plans are critical for regulated industries—specialist shops are set up for this level of rigor.

Imagine you need a high-performance bike stem, a surgical implant, or a lightweight aerospace bracket. In these cases, the right partner ensures you get the best from titanium metal without costly trial and error.

Design for Manufacturability Tips for Titanium

Sounds complex? It doesn’t have to be. Designing for titanium characteristics means working with, not against, the material’s strengths—and the challenges that come with them. Here are practical tips to keep your titanium parts efficient and cost-effective:

- Simplify geometry: Avoid deep pockets and sharp internal corners. Use larger radii and uniform wall thickness to reduce tool wear and heat buildup.

- Plan for rigidity: Design features that allow for robust fixturing, minimizing vibration and deflection during machining.

- Specify the right grade: Know whether you need a titanium alloy (like Ti-6Al-4V for strength) or pure titanium metal for corrosion resistance or biocompatibility.

- Surface finish and post-processing: Indicate if you require anodizing, bead blasting, or passivation—these affect both appearance and performance.

Early collaboration with your CNC partner can help you leverage titanium weight savings, optimize production time, and avoid costly rework by addressing potential issues before manufacturing begins.

How to Scope an RFQ for Complex Titanium Parts

Ready to request a quote? A well-prepared RFQ (request for quote) is your ticket to fast, accurate pricing and a smooth project. Here’s a quick checklist to ensure you cover all the essentials for titanium machining:

| ✔ | Grade and specification of titanium material (e.g., Ti-6Al-4V, Grade 2) |

| ✔ | 3D CAD model and 2D drawings with dimensions, tolerances, and GD&T |

| ✔ | Target tolerances (especially for critical features) |

| ✔ | Required surface finish (e.g., anodized, polished, bead-blasted) |

| ✔ | Passivation/anodizing or other post-processing needs |

| ✔ | Inspection plan (first article, sampling, full inspection) |

| ✔ | Quantity and delivery window |

For best results, include a short note explaining which features are function-critical—this helps your machining partner prioritize inspection and process control. If you’re moving from prototype to production, update your RFQ to reflect new learnings and volume requirements.

For projects that demand high complexity, tight tolerances, and expert handling of titanium properties, consider working with a specialist like precision CNC machining services from XTJ. Their experience with titanium alloy and pure titanium metal, combined with advanced 4 and 5-axis capabilities and ISO-certified processes, can help you turn ambitious designs into reality—whether you need a single prototype or a full production run.

Start with a prototype: Validating your machining strategy with a small batch can catch issues early, reduce risk, and save costs before scaling up to full production.

By following these steps, you’ll maximize the benefits of titanium characteristics, streamline your project, and set your team up for long-term success.

Titanium FAQs: Properties, Uses, and Selection

1. Is titanium a metal or steel?

Titanium is a metal, not a type of steel. It is a distinct element (symbol Ti, atomic number 22) with a unique silver-gray color, valued for its high strength-to-weight ratio and corrosion resistance. Unlike steel, which is an alloy primarily made from iron, titanium is used both in pure form and as alloys, especially in aerospace, medical, and premium consumer products.

2. Does titanium rust or corrode over time?

Titanium does not rust like iron because it forms a stable, self-healing oxide layer that protects it from corrosion. This property makes it ideal for harsh environments such as seawater, chemical processing, and even inside the human body. However, in rare conditions with strong acids or no oxygen, its protective layer can be compromised.

3. What are common uses for titanium?

Titanium is widely used in aerospace components, medical implants, jewelry, high-end sports equipment, and marine hardware. Its combination of light weight, strength, and hypoallergenic nature also makes it popular for consumer goods like watches, bike frames, and cookware.

4. How is titanium produced from raw materials?

Titanium is extracted from minerals such as rutile and ilmenite. The process involves mining, ore concentration, conversion to titanium tetrachloride, and reduction using the Kroll process to produce titanium sponge. This sponge is then melted and refined into ingots, which are further processed into usable products. The complexity and energy intensity of this process contribute to titanium's higher cost.

5. Why is titanium more expensive than other metals?

Titanium’s higher price is due to its complex extraction and refining process, which includes multiple high-temperature and contamination-sensitive steps. Limited global production capacity and strict quality requirements, especially for aerospace and medical uses, also drive up costs. However, titanium’s recyclability and durability can offset long-term expenses.