A Practical Guide to Rapid Prototyping Services Online

TL;DR

Online rapid prototyping services provide on-demand manufacturing to quickly convert digital designs into physical parts. Leveraging technologies like 3D printing and CNC machining, these platforms offer diverse materials and instant quotes, enabling engineers to test, iterate, and accelerate product development cycles efficiently. This approach significantly reduces time to market and lowers the financial risk associated with traditional manufacturing methods.

What Are Online Rapid Prototyping Services?

Online rapid prototyping services are manufacturing platforms that allow engineers, product designers, and innovators to upload a 3D CAD (Computer-Aided Design) file and receive a physical part in a matter of days. These services act as a crucial bridge between digital design and physical reality, enabling fast and cost-effective iteration. The core value proposition, as highlighted by industry leaders like Protolabs, is the unmatched speed of production, which fundamentally accelerates the entire product development lifecycle.

The primary benefit of using these online services is the ability to fail fast and learn faster. By having a tangible prototype in hand, designers can validate form, fit, and function early in the process. This iterative feedback loop helps identify design flaws, test ergonomic features, and confirm mechanical properties long before committing to expensive production tooling. This drastically reduces development risks and costs, a key advantage for both startups and established enterprises.

These services are indispensable for professionals who need to move from concept to market with confidence. Whether it's an aerospace engineer testing a new component or a consumer electronics designer refining a product enclosure, online platforms provide the agility needed to innovate. They offer a streamlined workflow: upload a design, receive automated design for manufacturability (DFM) feedback, select materials and finishes, and get parts delivered, often within a few business days.

Core Technologies Driving Rapid Prototyping

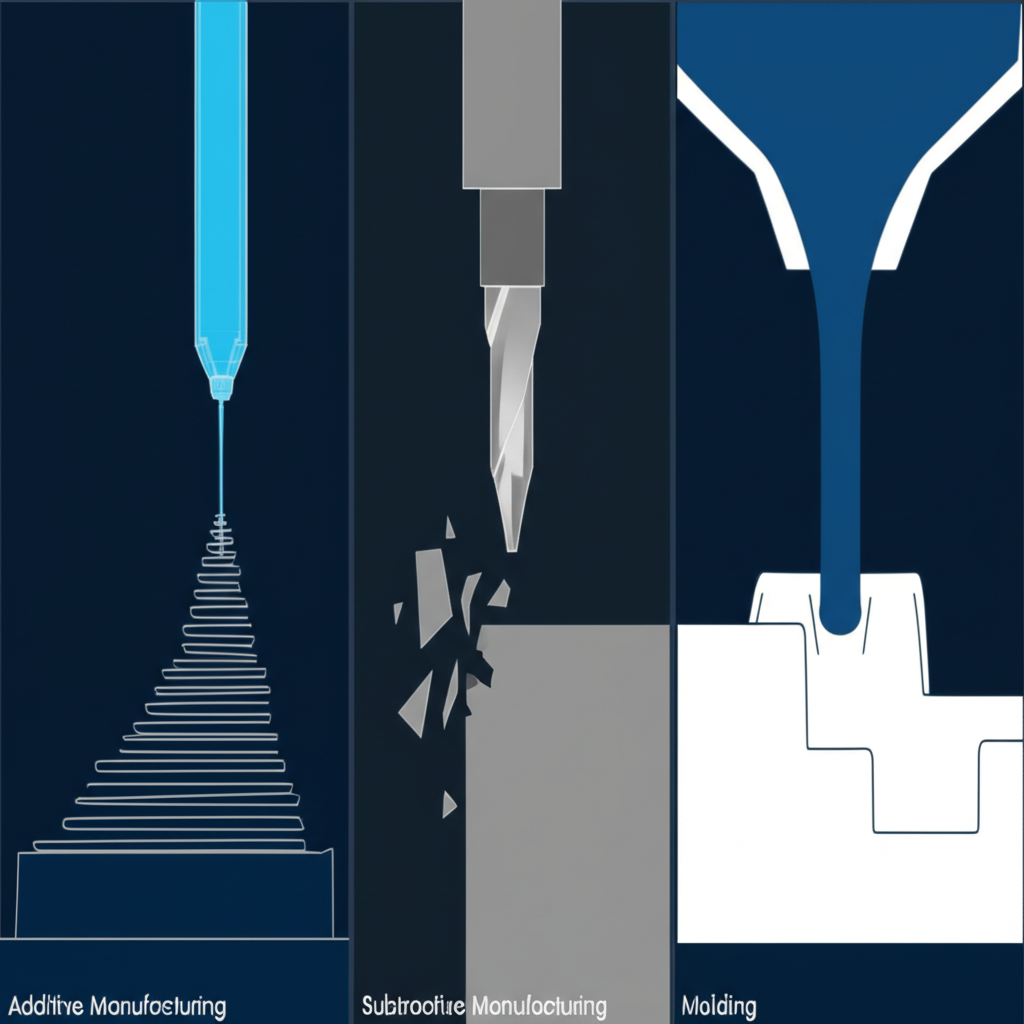

A key strength of online rapid prototyping services is their access to a wide array of advanced manufacturing technologies. This allows users to select the optimal process based on their specific needs for speed, material properties, surface finish, and cost. Leading providers like Xometry offer a comprehensive suite of options to cover nearly any prototyping requirement.

3D Printing (Additive Manufacturing)

3D printing is often the go-to technology for rapid prototyping due to its incredible speed and ability to create complex geometries. It builds parts layer-by-layer directly from a digital file. Several distinct 3D printing processes are available:

- Fused Deposition Modeling (FDM): Best for early-stage concept models and functional prototypes, FDM uses production-grade thermoplastics to create durable parts at a low cost.

- Stereolithography (SLA): Known for producing parts with very fine details and smooth surface finishes, SLA is ideal for visual prototypes that require an injection-molded look and feel.

- Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF): These powder-bed fusion technologies are excellent for functional prototypes with good mechanical properties and complex internal features, without the need for support structures.

CNC Machining

CNC (Computer Numerical Control) machining is a subtractive process that carves parts from a solid block of metal or plastic. It offers high precision and the ability to prototype in true production-grade materials, making it ideal for functional testing where material properties are critical. For projects requiring exceptional precision, services like XTJ specialize in advanced 4 and 5-axis CNC machining, handling over 30 materials with tolerances as tight as +/- 0.005mm, ideal for demanding aerospace or medical applications.

Sheet Metal Fabrication

For prototypes requiring enclosures, brackets, or flat components, sheet metal fabrication is the optimal choice. This process involves cutting, bending, and forming sheets of metal like aluminum or steel into the desired shape. It's a fast and cost-effective way to create durable metal prototypes that accurately represent final production parts.

Injection Molding

While traditionally a high-volume production method, rapid injection molding (or rapid tooling) is used for creating high-fidelity prototypes. By using aluminum molds instead of steel, services can produce a small batch of parts (from 50 to a few thousand) in the exact production material. This is perfect for late-stage functional testing, market validation, or as bridge tooling before scaling to full production.

Choosing Your Material: From Plastics to Metals

Selecting the right material is as crucial as choosing the right technology. Online services offer a vast library of materials to match the functional and aesthetic requirements of any project. As noted by service providers like Stratasys Direct, this range allows for true performance testing with engineering-grade materials.

Plastics

Plastics are the most common materials used in prototyping due to their versatility and cost-effectiveness. Common options include ABS for general-purpose durability, Nylon for strength and flexibility, Polycarbonate (PC) for high impact resistance, and various resins for high-detail applications.

Metals

For prototypes that require high strength, stiffness, and thermal resistance, metals are the ideal choice. Aluminum is popular for its excellent strength-to-weight ratio, while stainless steel and other steel alloys offer superior durability and corrosion resistance. Metal prototyping is typically done via CNC machining or Direct Metal Laser Sintering (DMLS), a 3D printing process.

Elastomers

When prototypes require rubber-like properties such as flexibility and shock absorption, elastomeric materials are used. These are available through 3D printing (PolyJet technology) and injection molding (Liquid Silicone Rubber), enabling the creation of seals, gaskets, and overmolded grips.

To simplify selection, the table below outlines key properties of common prototyping materials:

| Material | Key Properties | Common Applications | Manufacturing Process |

|---|---|---|---|

| ABS | Good strength, impact resistance, low cost | Consumer electronics housings, concept models | FDM, CNC Machining, Injection Molding |

| Nylon (PA 12) | High strength, flexibility, chemical resistance | Living hinges, snap fits, durable functional parts | SLS, MJF, FDM, CNC Machining |

| Aluminum (6061) | Excellent strength-to-weight ratio, machinability | Structural components, jigs, fixtures, metal prototypes | CNC Machining, Sheet Metal |

| SLA Resin (Standard) | High detail, smooth surface finish | Visual models, aesthetic prototypes, fit testing | SLA |

| Liquid Silicone Rubber (LSR) | High flexibility, temperature resistance, biocompatible | Gaskets, seals, medical device components | Injection Molding |

How to Select the Best Online Service for Your Project

Choosing the right rapid prototyping partner is critical to project success. With many online services available, evaluating them based on a clear set of criteria ensures you find the best fit for your specific needs. The decision should balance speed, cost, quality, and the unique requirements of your design.

Consider the following factors when making your selection:

- Technology and Material Offerings: Does the service provide the specific manufacturing process (e.g., MJF 3D printing, 5-axis CNC) and material (e.g., PEEK, stainless steel 316L) your project demands? A provider with a wide range of options, like those found on Hubs, offers more flexibility as your project evolves.

- Turnaround Time: Speed is a primary advantage of rapid prototyping. Check the provider's quoted lead times, which can range from one day to a few weeks depending on the technology and complexity. Many platforms provide instant quotes with estimated delivery dates.

- Quoting Platform and DFM Feedback: A user-friendly online quoting engine is essential. Look for platforms that offer instant pricing and automated Design for Manufacturability (DFM) analysis. This feedback can help you identify and correct potential issues before production, saving time and money.

- Quality and Tolerances: Review the provider's stated dimensional tolerances for each manufacturing process. If your part has critical features requiring high precision, ensure the service can meet those specifications. Look for certifications like ISO 9001 or AS9100, which indicate a commitment to quality control.

- Customer Support and Expertise: Access to applications engineers or technical support can be invaluable, especially for complex projects. A good partner can offer guidance on material selection, design optimization, and process choice to help you achieve the best results.

By carefully evaluating these criteria, you can select an online rapid prototyping service that not only delivers high-quality parts quickly but also functions as a strategic partner in your product development process.

Frequently Asked Questions

1. What is the typical turnaround time for rapid prototyping?

Turnaround time varies significantly based on the technology, material, and complexity of the part. 3D printing processes like FDM, SLA, and MJF can often deliver parts in as little as 1-3 business days. CNC machining and sheet metal fabrication typically take 3-7 business days, while rapid injection molding may take 1-3 weeks due to the need to create tooling.

2. How much do rapid prototyping services cost?

Cost is influenced by several factors: the manufacturing process, the material selected, the size and complexity of the part, and the quantity ordered. 3D printing is generally the most affordable for single parts or very small quantities, with prices often starting under $100. CNC machining costs more due to setup and material, while rapid tooling for injection molding has the highest initial cost but a lower per-part cost for small production runs.

3. What file formats are required for an online quote?

Most online rapid prototyping services accept a wide range of 3D CAD file formats. The most common and universally accepted format is STL (.stl), especially for 3D printing. For CNC machining and other processes, solid model formats like STEP (.stp, .step) and IGES (.igs, .iges) are preferred as they contain more complete geometric data. Many platforms also support native files from software like SolidWorks (.sldprt).

-

Posted in

3d printing, cnc machining, manufacturing on demand, product development, rapid prototyping