On Demand CNC Machining: How to Select the Right Service

TL;DR

On-demand CNC machining is an online service that allows engineers, designers, and businesses to order custom-machined parts with exceptional speed and efficiency. By uploading a digital design file, you can receive instant quotes for both rapid prototyping and full-scale production runs. The key benefits include rapid turnaround times, access to a vast range of materials, and the ability to produce high-precision parts without owning expensive equipment.

Understanding On-Demand CNC Machining

On-demand CNC (Computer Numerical Control) machining is a manufacturing model that leverages online platforms to connect customers with a network of machine shops. This service transforms a digital CAD (computer-aided design) file into a physical part through subtractive manufacturing, where material is precisely removed from a solid block to achieve the final geometry. This approach provides a streamlined and accessible alternative to traditional manufacturing procurement.

The value of on-demand services lies in their efficiency and flexibility. Unlike traditional machine shops that often involve manual quoting, lengthy negotiations, and longer lead times, on-demand platforms automate much of the process. This digital approach is ideal for everything from a single prototype to low-volume production runs, allowing companies to scale manufacturing up or down based on immediate needs.

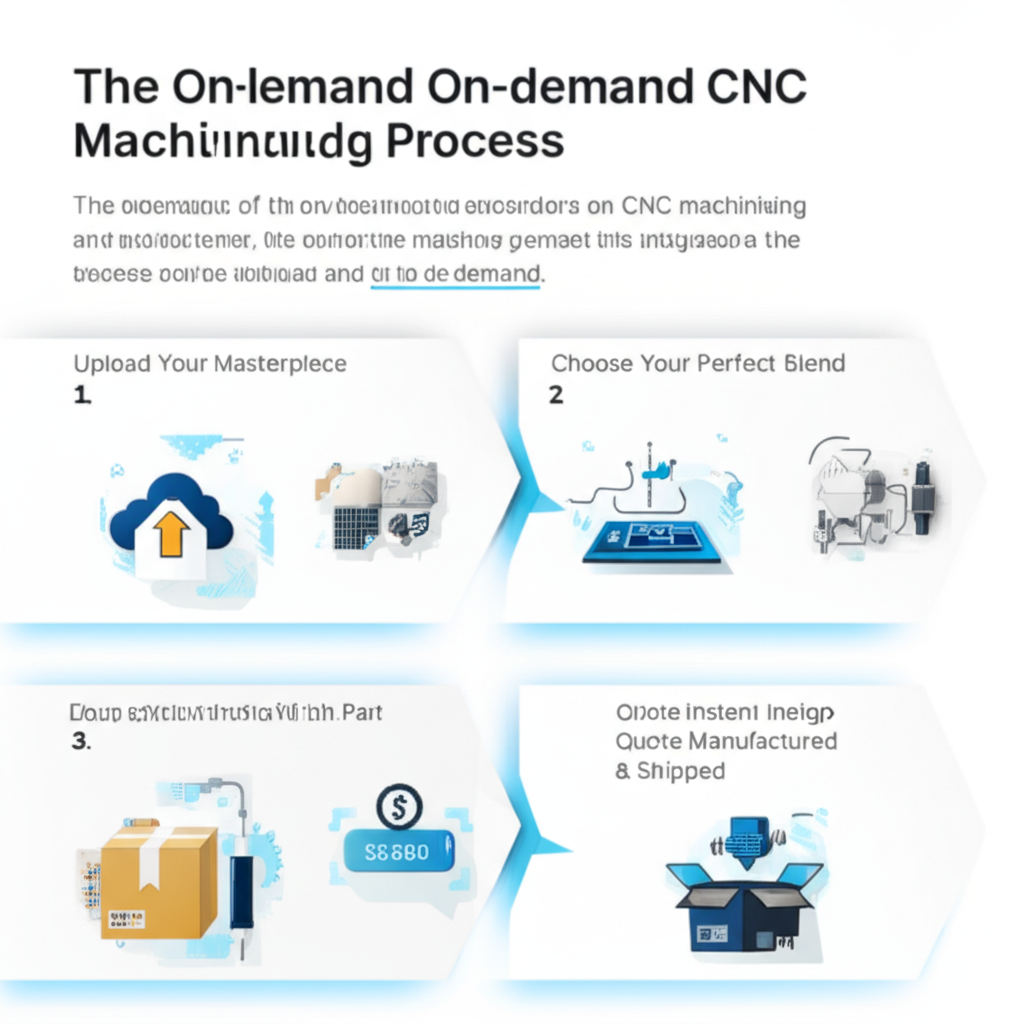

The typical workflow is simple and designed for speed:

- Upload a Design: Customers upload a 3D CAD file (such as STEP, STP, or SLDPRT) to the service provider's online portal.

- Configure and Quote: You select the desired material, finish, quantity, and required tolerances. An automated system, often powered by AI, analyzes the design's geometry and provides an instant quote and estimated lead time.

- Manufacturing: Once confirmed, the order is routed to a vetted manufacturing partner. Skilled machinists then program the CNC machines—such as mills and lathes—to produce the part according to the exact specifications.

- Delivery: After production and quality inspection, the finished parts are shipped directly to the customer, often in just a few days.

This model stands in stark contrast to traditional methods, which can be slower and less transparent. On-demand platforms eliminate the overhead of sourcing suppliers and managing logistics, providing a single, reliable point of contact for the entire manufacturing process.

Key Factors for Choosing an Online CNC Service

Selecting the right on-demand CNC machining partner is critical to the success of your project. With numerous providers available, evaluating them based on a consistent set of criteria ensures you find a service that aligns with your specific needs for quality, speed, and cost. A thorough evaluation will prevent costly delays and ensure your final parts meet all technical requirements.

Evaluating Cost and Quoting Systems

The first point of interaction with an online CNC service is typically its quoting engine. Leading platforms like Xometry and Protolabs Network (formerly Hubs) provide instant, automated quotes based on your CAD file. This feature is invaluable for rapid budgeting and design iteration. When comparing services, consider the transparency of the pricing. Does the quote clearly break down costs? Are there hidden fees for setup or tooling? A good provider offers a clear, all-inclusive price upfront. Also, assess the platform's ability to provide design-for-manufacturability (DFM) feedback, which can help you optimize your part to reduce machining time and lower costs.

Material Selection and Process Capabilities

The range of available materials is a crucial factor. A provider should offer a comprehensive selection of both metals (like Aluminum 6061, Stainless Steel 316L, and Titanium) and plastics (such as ABS, Polycarbonate, and PEEK). Equally important are the machining capabilities. Look for services that offer multi-axis machining, including 3-axis, 4-axis, and 5-axis milling, as well as CNC turning. These advanced processes allow for the creation of complex geometries with high precision. For projects with demanding specifications, providers like XTJ offer advanced 4 and 5-axis CNC machining in over 30 materials, making them a strong choice for aerospace or medical components. You can learn more about their capabilities at XTJ CNC machining services.

Tolerances and Quality Assurance

Precision is often the primary reason for choosing CNC machining. Verify the standard tolerances a service can achieve. Most providers offer a standard tolerance of around +/- 0.005 inches (0.127 mm), with options for much tighter tolerances upon request. Always check if the provider can meet the specific geometric dimensioning and tolerancing (GD&T) callouts on your technical drawings. Furthermore, inquire about their quality management systems. Reputable services are often certified to standards like ISO 9001, AS9100 (for aerospace), or ISO 13485 (for medical devices), which ensures a commitment to quality and process control.

Turnaround Times and Shipping

Speed is a core benefit of on-demand manufacturing. Lead times can vary from as fast as one day to several weeks, depending on part complexity, quantity, and the provider's capacity. When evaluating services, look for flexible shipping options and clear communication about production timelines. Some platforms differentiate between local and global manufacturing, where local options may offer faster delivery at a slightly higher cost. Consider your project's urgency and choose a partner that can reliably meet your deadlines.

Navigating Prototypes vs. Production Runs

On-demand CNC machining services are uniquely positioned to handle projects at any scale, from a single prototype to a production run of thousands of units. Understanding the differences between these two applications is key to leveraging the service effectively for your specific needs. Both prototyping and production benefit from the precision and material variety of CNC machining, but the logistical and cost considerations differ significantly.

Rapid Prototyping

For engineers and product designers, rapid prototyping is essential for validating form, fit, and function. On-demand CNC services excel here by offering the ability to create high-fidelity prototypes from production-grade materials. This allows for realistic testing that isn't always possible with other methods like 3D printing. Because the setup costs are fixed, producing a single part or a small batch ('one-off' machining) is economically viable. The primary goal of prototyping is speed, enabling quick design iterations and accelerating the product development cycle.

Low- to Mid-Volume Production

When a design is finalized, on-demand platforms can seamlessly scale to low- or mid-volume production. While the per-unit cost for CNC machining is higher than mass-production methods like injection molding, it avoids the steep initial investment in tooling and molds. This makes it a cost-effective solution for quantities ranging from a few dozen to several thousand parts. For production runs, factors like repeatability, quality assurance, and material certification become more critical. Many services offer volume discounts, reducing the cost per unit as the quantity increases.

The table below highlights the key differences between using on-demand CNC for prototyping versus production:

| Consideration | Prototyping | Production |

|---|---|---|

| Primary Goal | Speed and design validation | Cost-efficiency and repeatability |

| Quantity | 1 to 50+ parts | 100 to 10,000+ parts |

| Cost Per Unit | Higher | Lower (with volume discounts) |

| Lead Time | As fast as 1-3 days | Typically 1-4 weeks |

| Key Requirement | Fast turnaround | Consistent quality and tolerances |

Common Materials and Finishes in On-Demand CNC

One of the greatest advantages of on-demand CNC machining is the extensive library of materials and finishing options available. This allows for the creation of parts with specific mechanical, thermal, and aesthetic properties suited for nearly any application. Choosing the right combination is crucial for ensuring your part performs as intended.

Popular Machining Materials

Providers typically group materials into two main categories: metals and plastics. Each offers unique properties to meet different engineering requirements.

-

Metals: Metals are chosen for their strength, durability, and thermal conductivity. Common options include:

- Aluminum (e.g., 6061, 7075): Offers an excellent strength-to-weight ratio, is naturally corrosion-resistant, and is easily machined. It is a cost-effective choice for a wide range of applications.

- Stainless Steel (e.g., 304, 316L): Known for high strength, wear resistance, and excellent corrosion resistance. It's often used in medical, marine, and food-grade applications.

- Mild & Alloy Steel (e.g., 1018, 4140): Provides good mechanical properties at a low cost, with options for heat treatment to increase hardness and toughness.

- Titanium: Valued for its exceptional strength-to-weight ratio and corrosion resistance, especially at high temperatures. It is common in aerospace and medical implants.

-

Plastics: Engineering plastics are lightweight and offer properties like chemical resistance and electrical insulation. Popular choices include:

- ABS: A versatile, low-cost plastic with good impact resistance and machinability, ideal for general-purpose prototypes.

- Polycarbonate (PC): Known for its superior toughness, impact strength, and optical clarity.

- POM (Delrin/Acetal): Offers high stiffness, low friction, and excellent dimensional stability, making it suitable for precision parts like gears and bearings.

- PEEK: A high-performance thermoplastic that maintains its mechanical properties at extreme temperatures and has excellent chemical resistance.

Available Surface Finishes

After machining, a part's surface can be treated to improve its appearance, wear resistance, or other properties. Common finishing options include:

- As-Machined: The standard finish with visible tool marks. It's the fastest and most cost-effective option, with a typical surface roughness of Ra 125 μin (3.2 μm).

- Bead Blasting: Creates a uniform matte or satin surface finish, which is great for aesthetic parts.

- Anodizing (Type II & III): Primarily for aluminum, this electrochemical process creates a hard, corrosion-resistant outer layer. It can be dyed in various colors (Type II) or used for a wear-resistant hardcoat (Type III).

- Powder Coating: A durable paint finish that is applied as a dry powder and cured with heat, providing excellent corrosion and wear resistance.

Making the Right Choice for Your Project

On-demand CNC machining has fundamentally changed how custom parts are procured, offering unparalleled speed, flexibility, and accessibility. By understanding the core process and carefully evaluating providers based on factors like quoting systems, material availability, quality standards, and lead times, you can confidently select a partner that aligns with your project's goals. Whether you are developing a single prototype or launching a low-volume production run, these services provide the tools to bring your designs to life with precision and efficiency. The key is to match your specific requirements—be it rapid iteration for prototyping or cost-effective scaling for production—with the strengths of the right on-demand service.

Frequently Asked Questions

1. How much does on-demand CNC machining cost?

The cost of on-demand CNC machining depends on several factors, including part complexity, material choice, quantity, and required lead time. Online platforms use automated algorithms to calculate a price instantly from a CAD file. Generally, simpler geometries, standard materials like Aluminum 6061, and larger quantities will result in a lower cost per part. The best way to determine the exact price is to upload your design to a provider's quoting tool.

2. What is the difference between 3-axis and 5-axis CNC machining?

The primary difference lies in the movement capabilities of the cutting tool and the workpiece. 3-axis machines operate on the X, Y, and Z linear axes, which is suitable for parts with simpler geometries. 5-axis machines add two rotational axes, allowing the cutting tool to approach the workpiece from multiple angles in a single setup. This enables the creation of highly complex parts and can sometimes be more cost-effective for intricate designs by reducing the need for manual repositioning.

3. What are the typical lead times for on-demand CNC parts?

Lead times for on-demand CNC machining are one of its main advantages. For simple prototypes, parts can often be manufactured and shipped in as little as 1 to 3 business days. For more complex parts or larger production quantities, lead times typically range from 5 business days to a few weeks. Many services offer expedited options for urgent projects.

-

Posted in

CNC services, custom parts, on-demand manufacturing, rapid prototyping