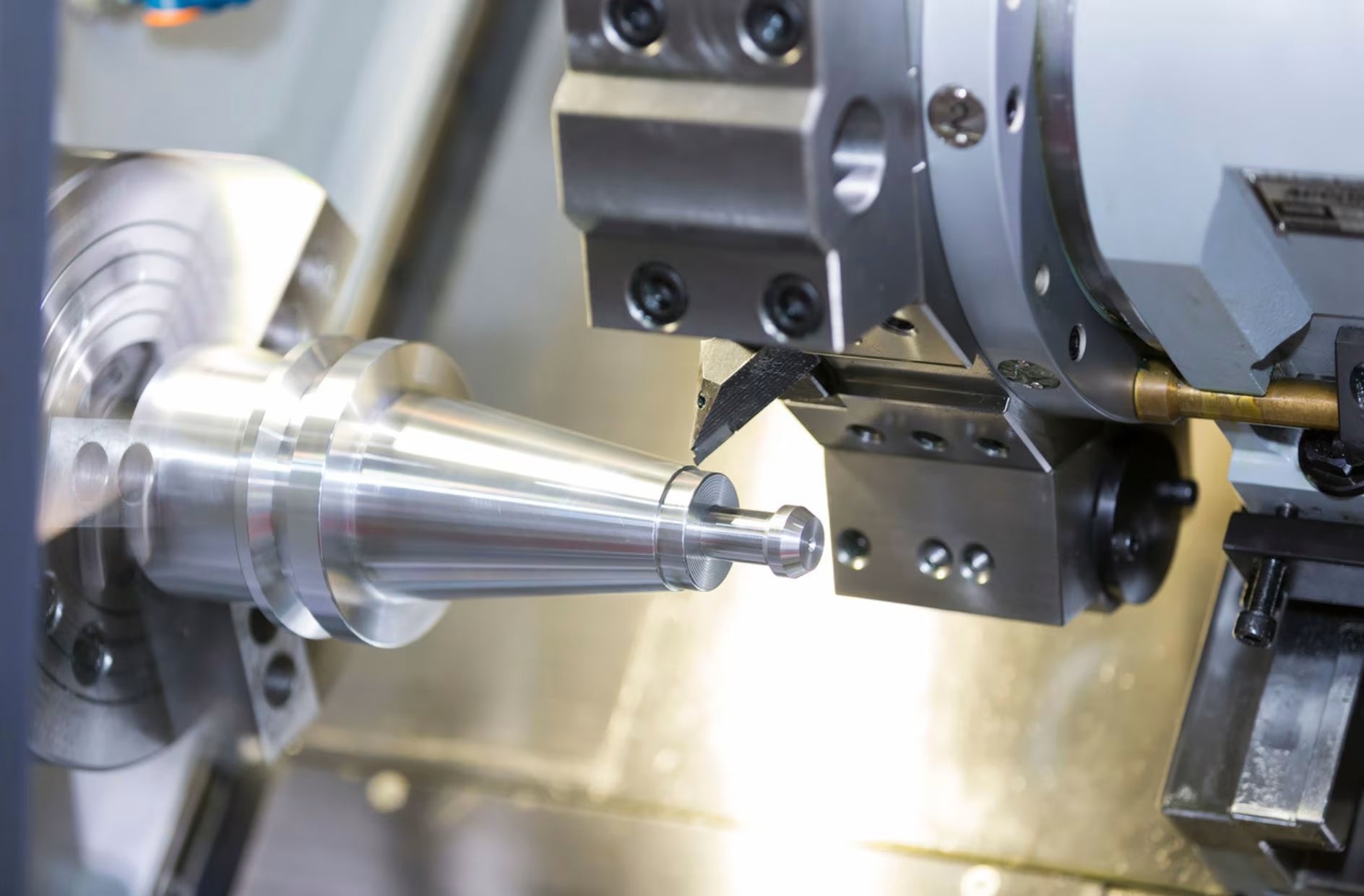

5 Streamlined Manufacturing Processes to Ensure On-Time Delivery of CNC Aluminum Parts

In the world of manufacturing, meeting delivery deadlines without compromising quality is a complex balancing act. Through years of reporting on industrial advancements and manufacturing innovations, I've learned that companies that excel in on-time delivery share one common trait: they've mastered and optimized their production processes from material selection to final inspection.

For CNC aluminum manufacturing, this involves a meticulous approach to five critical areas that together form a seamless, efficient pipeline ensuring parts not only meet exact specifications but arrive exactly when needed.

1. Material Analysis and Selection: The Foundation of Success

The journey to a perfect aluminum part begins long before any metal is cut—it starts with strategic material selection. This decision impacts everything from machining time to final part performance.

The most advanced manufacturers don't just choose materials based on specifications alone; they consider:

-

Material machinability: How efficiently can the material be cut?

-

Part complexity: Does the geometry require specific material properties?

-

Production volume: Is this a prototype or mass production?

-

Total cost factors: Including raw material cost, utilization rate, and processing expenses

A practical example: For robotic components, AL6061 often proves more cost-effective than AL7075 despite the latter's superior strength and hardness, because AL6061 machines faster and costs less, delivering better value without compromising function.

Advanced manufacturers are now utilizing specialized aluminum alloys designed specifically for CNC machining. These new formulations include additives that improve cutting performance while maintaining strength, allowing for faster machining speeds and longer tool life.

2. Machining Strategy and Process Analysis: Blueprinting for Efficiency

With the right material selected, attention turns to process planning—the roadmap that guides production. The goal is straightforward: produce parts that meet all technical requirements while maximizing productivity and minimizing cost.

Sophisticated manufacturers employ several key strategies:

-

Design for Manufacturability (DFM) analysis: Identifying potential production challenges before machining begins

-

Technology matching: Pairing each project with the most appropriate CNC equipment (3-axis, 4-axis, or 5-axis) based on complexity and tolerance requirements

-

Bottleneck identification: Streamlining processes to eliminate delays and inefficiencies

The implementation of advanced programming techniques can significantly reduce machining time. One company reported saving 20% in production time through optimized tool paths and strategic operation sequencing.

3. Quality Assurance: Where Technology and Expertise Meet

Precision in CNC machining isn't accidental—it's the result of deliberate practices combining technology, expertise, and continuous monitoring.

While equipment calibration forms the foundation of precision (modern CNC machines can maintain tolerances within ±0.05mm or better), the human element remains irreplaceable. Experienced programmers and operators bring invaluable expertise in:

-

Optimal tool selection for specific operations and materials

-

Strategic operation sequencing to minimize errors

-

Creative problem-solving when unexpected challenges arise

Advanced manufacturers employ real-time monitoring systems equipped with intelligent sensors that automatically adjust cutting speed and feed rate based on material hardness and thickness variations during machining. This technology ensures consistent quality without constant human intervention.

Table: Impact of Precision Machining Technologies

| Technology | Traditional Machining | Precision Machining | Improvement |

|---|---|---|---|

| Dimensional accuracy | ±0.3mm | ±0.2mm | 33% improvement |

| Surface roughness | 3.2-6.3μm | 1.6-3.2μm | 50% smoother |

| Deformation after machining | Up to 20mm | Within 3mm | Up to 85% reduction |

4. Complex Geometry and Internal Feature Machining

Aluminum parts with complex internal features—deep holes, internal cavities, and hard-to-reach geometries—present special challenges that standard CNC machining can't always address.

For these complex applications, manufacturers often turn to specialized processes:

-

Electrical Discharge Machining (EDM): Using electrical sparks to erode material with extreme precision

-

Wire Cutting: Employing charged wire to slice through hard materials

-

Multi-axis machining: Utilizing 5-axis CNC systems to approach parts from virtually any angle

These processes typically require specialized tooling, such as copper electrodes for EDM, and may leave surfaces that require additional finishing. However, they enable the production of geometries that would be impossible with conventional machining methods.

The emergence of multi-channel CNC equipment has revolutionized complex part manufacturing. These advanced systems feature dual spindles that can perform different operations simultaneously—such as milling a part's face while drilling side holes—dramatically reducing cycle times for complex components.

5. Process Optimization: The Continuous Pursuit of Efficiency

The most successful manufacturers recognize that process improvement isn't a one-time initiative but a continuous commitment. They constantly analyze and refine their approaches to reduce costs, decrease production time, and enhance quality.

Effective process optimization includes:

-

Toolpath optimization: Reducing unnecessary movement and air cutting

-

High-speed machining techniques: Utilizing advanced approaches that maintain quality at increased speeds

-

Lean manufacturing principles: Eliminating waste throughout the production process

-

Advanced equipment utilization: Implementing state-of-the-art CNC systems with dual-channel capabilities

The implementation of high-speed machining strategies for aluminum has demonstrated remarkable benefits: cutting forces are reduced by 30%, and 95-98% of heat is carried away with chips, keeping the workpiece relatively cool and minimizing thermal distortion 7.

Automation and robotics represent the next frontier in process optimization. One manufacturer reported a 200% increase in productivity after implementing composite robots for automated loading and unloading of CNC machines. These systems can handle 150 aluminum blocks per hour consistently, compared to a maximum of 50 with manual operation.

Table: Benefits of Automated CNC Production Lines

| Metric | Traditional Production | Automated Production | Improvement |

|---|---|---|---|

| Production efficiency | 50 parts/hour | 150 parts/hour | 200% increase |

| Product defect rate | 8% | <3% | >62% reduction |

| Labor requirements | 2-3 operators per machine | 1 operator monitors multiple machines | Up to 70% reduction |

| Operation pattern | Limited hours | 24/7 continuous operation | 300%+ utilizat |

Conclusion: The Path to Flawless Delivery

Ensuring on-time delivery of precision CNC aluminum parts requires excellence across all five of these interconnected processes. From intelligent material selection through continuous process improvement, each element contributes to a manufacturing pipeline that delivers quality parts when they're needed.

The most successful manufacturers don't view these as separate considerations but as integrated components of a holistic approach to manufacturing excellence. They invest in advanced equipment, train skilled personnel, and implement systems that provide real-time data and adjustments throughout the production process.

As manufacturing technology continues to evolve—with developments in specialized aluminum alloys, more sophisticated CNC systems, and increased automation—the potential for even greater efficiency and precision continues to grow. Companies that embrace these advancements while maintaining focus on the fundamentals of sound manufacturing practice will lead the industry in both quality and delivery performance.

By mastering these five processes, manufacturers can transform the challenge of on-time delivery from a constant pressure point into a competitive advantage—one that assures clients they can count on both exceptional quality and perfect timing.

-

Posted in

Aluminum prototyping, cnc machining