Beyond Machining Marks: The Surface Finish Showdown for CNC Parts

The Surface Treatment Spectrum: Processes & Mechanisms

1. As-Machined (No Post-Processing)

-

Why: Lowest cost; ideal for non-critical internal components

-

How: Directly after CNC milling/turning with standard tooling (no secondary steps)

-

Results:

-

Ra 0.8–3.2 μm (visible tool paths)

-

Vulnerable to oxidation; aluminum forms oxide layer in 48 hrs

-

Limited lifespan in dynamic loads

-

2. Bead Blasting

-

Why: Creates uniform matte texture; enhances coating adhesion

-

How: Propelling glass/Al₂O₃ grit (80–220 mesh) at 40–80 PSI

-

Results:

-

Ra 0.3–1.5 μm (depending on grit)

-

Increases surface area for anodizing adhesion by 40%

-

Hides minor machining defects

-

3. Standard Anodizing (Type II)

-

Why: Cost-effective corrosion protection for consumer goods

-

How: Electrochemical bath (15–20V) in sulfuric acid (180g/L, 18–22°C)

-

Results:

-

Thickness: 5–25 μm

-

Salt Spray Resistance: 500–1,000 hrs (vs. 48 hrs for bare Al)

-

Natural colors: Clear, black, gray

-

4. Hard Anodizing (Type III)

-

Why: Extreme wear resistance for aerospace/military applications

-

How: Low-temperature bath (0–5°C) at high voltage (40–100V)

-

Results:

-

Thickness: 50–100 μm

-

Hardness: 500–800 HV (comparable to tool steel)

-

Abrasion Loss: <0.1 mg/1,000 cycles (vs. 2.5 mg for untreated Al)

-

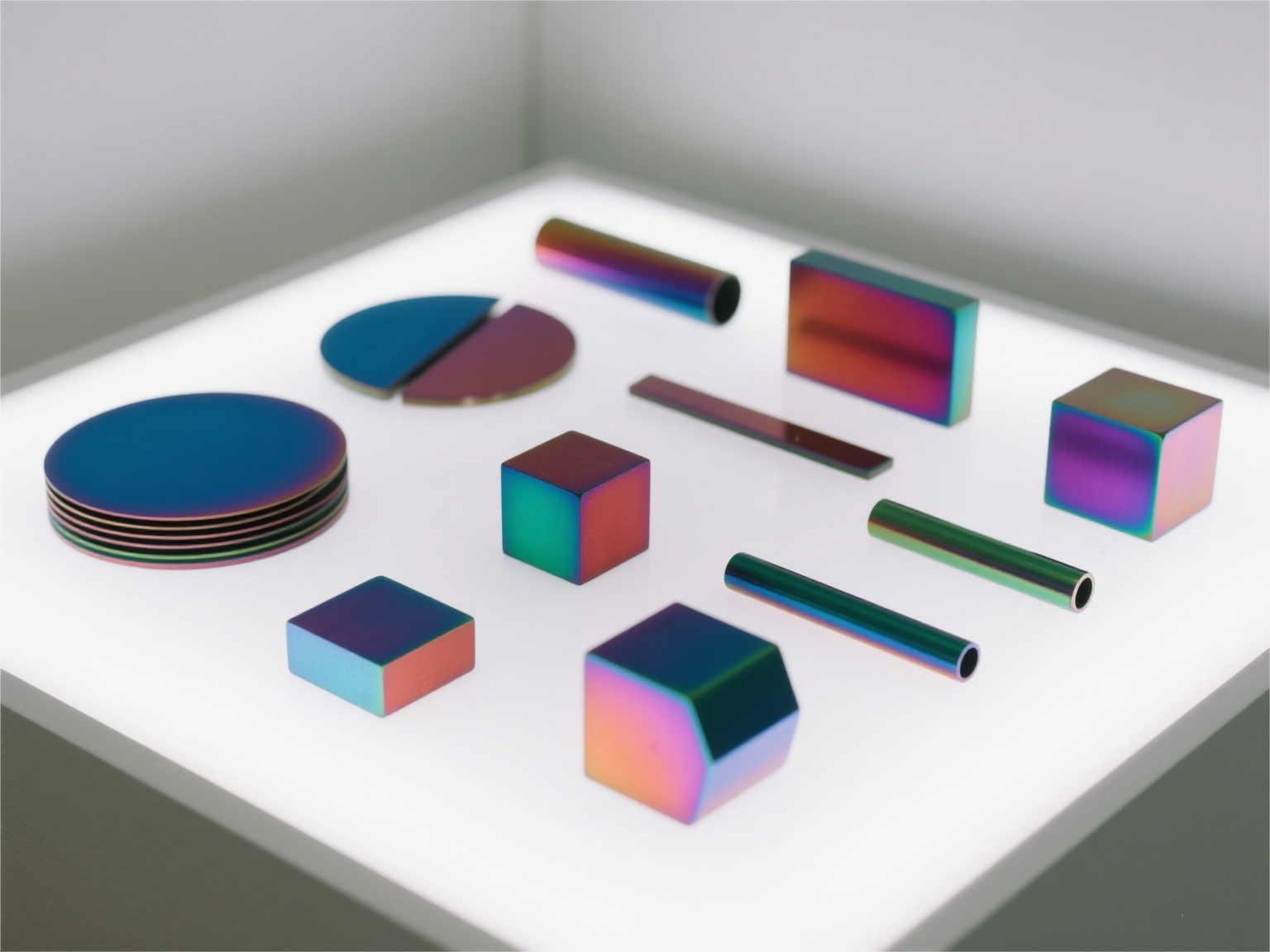

5. Color Anodizing

-

Why: Branding and aesthetic customization

-

How: Dye immersion after Type II anodizing; sealed in boiling water

-

Results:

-

Pantone-matching accuracy: ±5% ΔE

-

UV stability: 500+ hrs (for organic dyes)

-

Limitations: Dark colors fade faster; reds/oranges least stable

-

6. Black Oxide (for Steel)

-

Why: Low-glare corrosion barrier without dimensional change

-

How: Chemical conversion coating (140°C alkaline bath)

-

Results:

-

Thickness: 1–2 μm (adds zero part geometry change)

-

Corrosion Protection: 96 hrs salt spray (with oil sealant)

-

Emissivity: 0.85–0.95 (ideal for thermal components)

-

Performance Comparison: Data-Driven Selection

Table 1: Surface Treatment Performance Metrics (Aluminum 6061 Substrate)

| Treatment | Ra (μm) | Hardness (HV) | Corrosion Resistance (hrs salt spray) | Adhesion (ASTM D3359) |

|---|---|---|---|---|

| As-Machined | 1.6–3.2 | 100 | 48 | N/A |

| Bead Blasting | 0.3–1.5 | 100 | 48 | 5B (excellent) |

| Standard Anodize | 0.4–0.8 | 200–300 | 500–1,000 | 4B (good) |

| Hard Anodize | 0.8–2.0 | 500–800 | 2,000+ | 3B (fair) |

| Black Oxide | 0.5–1.2 | N/A (steel only) | 96* | 4B (good) |

| *With sealant |

Table 2: Cost & Lead Time Analysis (Per Batch)

| Treatment | Cost Factor | Processing Time | Dimensional Impact |

|---|---|---|---|

| As-Machined | 1.0x | 0 min | None |

| Bead Blasting | 1.3x | 10–30 min | ±0.01 mm |

| Standard Anodize | 1.8x | 45–90 min | +0.01–0.03 mm |

| Hard Anodize | 3.0x | 120–180 min | +0.05–0.10 mm |

| Color Anodize | 2.2x | 90–120 min | +0.01–0.03 mm |

| Black Oxide | 1.5x | 30–60 min | None |

The Strategic Selection Guide

When to Choose Which Finish

-

High-Wear Applications (gears, pistons):

-

Hard anodizing increases service life 5–8×

-

Avoid color anodizing (dyes reduce wear resistance)

-

-

Marine/Outdoor Environments:

-

Standard anodizing (clear) + 5% dichromate sealant

-

Bead blasting alone offers zero corrosion protection

-

-

Aesthetic-Critical Parts (consumer electronics):

-

#220 bead blast + color anodizing for uniform matte finish

-

Critical: Specify dye stability (inorganic > organic)

-

-

Precision Components (shafts, bearings):

-

Bead blasting (fine grit) to avoid dimensional shifts from anodizing

-

Black oxide for steel parts needing oil retention

-

Critical Design Considerations

-

Tolerances: Hard anodizing adds 50–100 μm – compensate in CAD

-

Material Limits:

-

Color anodizing: Best on aluminum/titanium (not steel)

-

Black oxide: Only for ferrous metals

-

-

Electrical Conductivity: Anodizing is non-conductive – mask contact points

Maximizing Value: Pro Tips from Industry

-

Sequential Processes: For high-end optics:

-

Machine → Glass bead blast (Ra 0.4 μm) → Hard anodize → PTFE sealant

-

-

Adhesion Boost: On blasted surfaces, anodizing bond strength improves 60%

-

Cost Savers:

-

Use hard anodizing only on wear surfaces (partial masking)

-

Specify Ra 1.6 μm instead of 0.8 μm where possible (cuts blasting time 35%)

-

"Surface finishing isn’t cosmetic – it’s functional engineering. A $5 treatment can save a $5,000 part."

– Aerospace QA Lead, Boeing Supplier Summit 2024

Conclusion: Match the Finish to the Function

CNC part performance hinges on surface science. While raw machining suits prototypes, production demands strategic post-processing:

-

Bead blasting for uniform matte aesthetics

-

Standard anodizing for corrosion-prone environments

-

Hard anodizing where wear determines product life

-

Color anodizing for branded consumer goods

-

Black oxide for dimensionally-sensitive steel components

Test first: Process coupons to validate adhesion, corrosion, and wear metrics before full production. Partner with finishers during design to optimize costs and lead times.

-

Posted in

cnc machining, precision machining, rapid prototyping, surface process