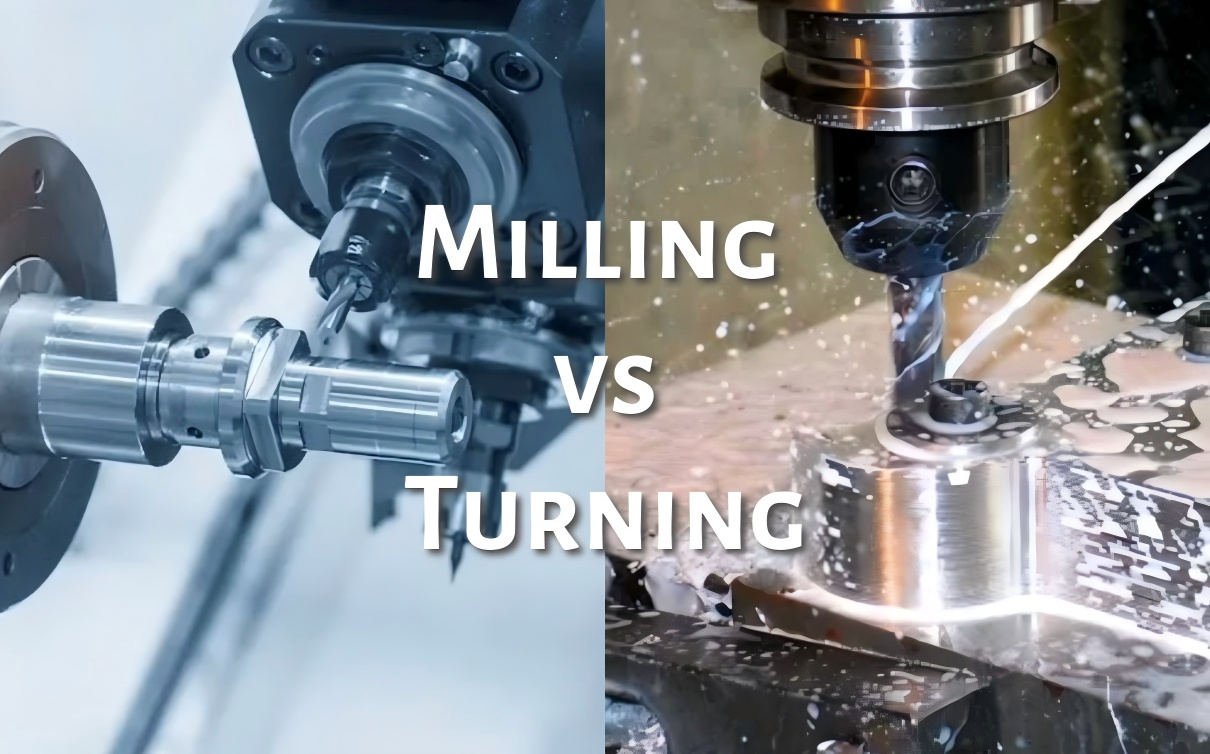

CNC Milling vs. Turning: The Ultimate Precision Manufacturing Key

The Core Divide: How Milling and Turning Work

CNC Turning (The Rotation Master)

-

Why it works: Ideal for parts with rotational symmetry (shafts, bushings, cones). The rotating workpiece meets a fixed cutting tool, enabling high concentricity (±0.005 mm).

-

How it’s done:

-

The workpiece spins on a chuck (up to 5,000 RPM).

-

Tools move linearly to cut diameters, faces, or threads.

-

Live-tooling attachments add drilling/milling capabilities for hybrid operations.

-

-

Results: Mirror finishes (Ra 0.4–1.6 μm) on cylinders with cycle times 30–50% faster than milling for axisymmetric parts.

CNC Milling (The Multiaxis Sculptor)

-

Why it works: Best for complex geometries (pockets, planes, 3D contours). Rotating tools (end mills, face mills) remove material as the workpiece feeds.

-

How it’s done:

-

3–5 axes of tool motion (horizontal/vertical/rotational).

-

Tools like ball-nose end mills machine organic curves.

-

Adaptive toolpaths optimize material removal rates.

-

-

Results: Capable of ±0.025 mm tolerances on intricate molds, aerospace brackets, and non-rotational parts.

Table 1: Functional Comparison of Milling vs. Turning

| Aspect | CNC Milling | CNC Turning |

|---|---|---|

| Primary Function | Flat/curved surfaces, pockets | Cylindrical shapes, tapers |

| Part Movement | Static or linear feed | Rotational (up to 5,000 RPM) |

| Tool Movement | Multi-axis (X/Y/Z + rotational) | Linear (X/Z-axis) |

| Surface Finish | Ra 0.8–3.2 μm (matte/textured) | Ra 0.4–1.6 μm (smooth/polished) |

| Complexity | High (organic shapes, thin walls) | Medium (facing, grooving, threading) |

Cost Analysis: Breaking Down the Economics

Machine Investment

-

Entry-level turning: Manual lathes start at $15K (vs. $50K+ for 3-axis mills).

-

High-end hybrid: 5-axis mill-turn centers exceed $500K but eliminate secondary ops.

Operational Efficiency

-

Turning wins for cylinders: 30% faster cycle times vs. milling similar geometries.

-

Milling wins for complexity: Single-setup machining reduces handling costs by 40%.

*Table 2: Cost-Per-Part Comparison (Aluminum 6061)*

| Process | Setup Cost | Cycle Time (min) | Tooling Cost | Ideal Batch Size |

|---|---|---|---|---|

| CNC Turning | $120–$300 | 5–15 | Low ($20–$50) | 100–10,000 units |

| CNC Milling | $250–$800 | 20–60 | High ($100–$500) | 1–1,000 units |

| Mill-Turn | $500–$1,500 | 10–30 | Medium ($50–$200) | 50–5,000 units |

Key Insight: For prototypes or complex low-volume parts, milling provides flexibility. For high-volume rotational parts, turning cuts costs by 25–40%.

Industry Applications: Where Each Shines

Turning Dominates in:

-

Automotive: Engine pistons, transmission shafts (1 million+ units/year).

-

Medical: Bone screws, hip stems (Ra < 0.8 μm critical for implants).

-

Energy: Valve bodies, hydraulic fittings (cyclic symmetry required).

Milling Excels in:

-

Aerospace: Turbine blades, wing ribs (5-axis contouring).

-

Consumer Electronics: Phone chassis, heat sinks (thin-wall machining).

-

Tooling: Injection molds, die-casting cavities (hardened steel > 45 HRC).

Emerging Hybrid Solution: Mill-turn centers (e.g., Mazak Integrex) combine both technologies. The market is projected to reach $8.4B by 2030, driven by aerospace/medical demand for "done-in-one" machining.

The Future: AI and Hybridization

Smart Optimization

-

Machine learning algorithms adjust feeds/speeds in real-time:

-

Reduce tool wear by 20% in turning.

-

Predict chatter in milling, boosting surface quality.

-

-

Prime Turning™ (Sandvik): Novel toolpaths increase turning feed rates by 300% and extend tool life 5×.

CAM Software Advancements

Tools like Mastercam and Fusion 360 unify milling/turning programming:

-

Auto-feature recognition slashes programming time by 50%.

-

Simulation prevents collisions in complex mill-turn operations.

Decision Guide: 5 Questions to Choose Right

-

Part geometry: Rotational symmetry? → Turning. Complex 3D contours? → Milling.

-

Volume: >500 units? → Turning or mill-turn. <100? → Milling.

-

Material: Hard metals (Ti, tool steel)? → Milling for tool rigidity. Soft alloys (Al, brass)? → Turning for speed.

-

Tolerances: < ±0.025 mm? → Mill-turn for single-setup accuracy.

-

Budget: Under $100K? → Standalone lathe or 3-axis mill. Over $300K? → Hybrid mill-turn.

"Forcing a square peg into a round hole costs more than buying the right machine. Turning and milling are complementary – not competing – technologies."

– Manufacturing Engineer, Boeing Supplier Summit 2025

The Verdict: Synergy Over Superiority

No process is universally "better." High-volume cylindrical components benefit from turning’s speed and surface finish. Complex, low-volume parts leverage milling’s geometric freedom. For mission-critical applications like aerospace turbines or medical implants, mill-turn centers deliver the best of both worlds:

-

30–50% faster than separate operations

-

20% lower costs via reduced handling

-

True position accuracy under 0.01 mm.

Test both: Run prototyping batches using milling and turning to compare quality, lead time, and cost. Partner with CAM experts to optimize your strategy – the right choice saves thousands per project. For cutting parameters or machine selection datasets, request our benchmark reports.

-

Posted in

cnc machining, Milling, precision machining, rapid prototyping, Turning