Key CNC Machine Shop Capabilities for Project Success

TL;DR

A CNC machine shop offers precision manufacturing services using computer-controlled equipment to execute processes like milling, turning, drilling, and boring. Core capabilities involve creating custom parts from a wide range of materials with high accuracy and consistency. When evaluating a shop, it is crucial to assess their specific technical processes, quality certifications (such as ISO 9001), production capacity, and material expertise to ensure your project's success.

Understanding the Modern CNC Machine Shop

A CNC (Computer Numerical Control) machine shop is a manufacturing facility that uses automated, computer-driven machines to produce parts by removing material from a solid workpiece. This process, known as subtractive manufacturing, can be applied to metals, plastics, and other materials to create components with precise specifications. The primary function of these shops is to provide machining services to various industries, from aerospace and medical to automotive and electronics, transforming digital designs into physical objects.

The core advantage of leveraging a modern CNC machine shop lies in its ability to deliver exceptional precision and repeatability. Unlike manual machining, which relies on an operator's skill, CNC machines follow a pre-programmed path, ensuring that every part produced is identical, from the first to the millionth. As noted by industry experts, this automation leads to significant benefits, including the production of highly precise parts, reduced material waste, greater production capabilities, and faster order turnovers. This makes them ideal for both rapid prototyping and large-scale production runs.

Core CNC Machining Capabilities: A Comprehensive List

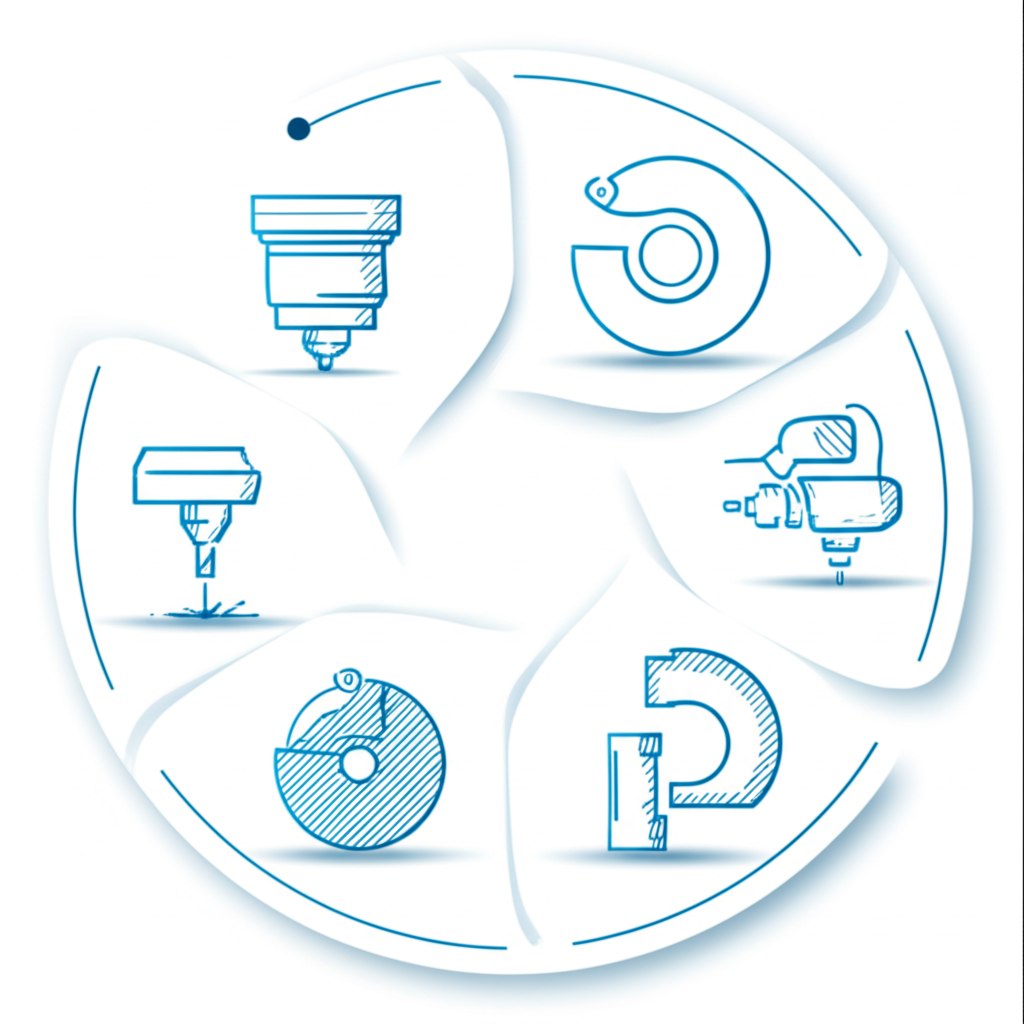

CNC machine shops offer a wide array of processes to shape materials into finished components. Understanding these core capabilities is essential for selecting the right partner for a manufacturing project. While offerings can vary, most full-service shops provide the following fundamental services:

- Milling: This process uses rotating multi-point cutting tools to remove material from a stationary workpiece. CNC milling is versatile and can create a wide variety of features, including flat surfaces, complex contours, pockets, and slots. Advanced shops utilize 3, 4, and 5-axis milling centers for highly intricate geometries.

- Turning: In contrast to milling, turning involves rotating the workpiece while a single-point cutting tool moves along its surface. This method is ideal for creating cylindrical or conical parts, such as shafts, pins, and rings. CNC lathes can perform operations like facing, contouring, and thread cutting with high precision.

- Drilling: This is the process of creating round holes in a workpiece. CNC drilling machines or machining centers can execute this task with extreme accuracy in positioning and diameter, which is critical for parts that require precise assembly.

- Boring: Boring is used to enlarge an existing hole to achieve a precise diameter and smooth internal finish. It is often performed after drilling to meet tight tolerance requirements for features like engine cylinders or bearing housings.

- Tapping and Threading: These processes create internal (tapping) and external (threading) screw threads on a component. CNC-controlled tapping and threading ensure that threads are cut to exact specifications for pitch and depth, which is vital for fasteners and mating parts.

- Additional Processes: Beyond the basics, many shops offer a suite of related capabilities. According to QMC Technologies, this can include counter-boring (enlarging the end of a hole), countersinking (creating a conical recess for screw heads), profiling (machining a complex outer shape), and reaming (finishing a drilled hole to a precise size).

Key Factors for Evaluating a Shop's Capabilities

Choosing the right CNC machine shop requires a thorough evaluation of its technical capabilities, quality systems, and overall experience. Making a decision based solely on cost can be a mistake; instead, focus on the value and reliability a partner can bring to your project. According to an insightful guide from Vescio Manufacturing, asking the right questions is key to ensuring you receive the best possible service.

Quality Certifications and Processes

A shop's commitment to quality is often demonstrated by its certifications. Credentials like ISO 9001:2015 indicate a proven quality management system, ensuring consistency and reliability. For specific industries, other certifications are critical, such as AS9100 for aerospace or ITAR registration for defense projects. Always verify that a potential vendor holds certifications relevant to your industry to guarantee they can meet stringent standards.

Equipment, Technology, and Material Expertise

The technology a shop utilizes directly impacts the complexity and precision of the parts it can produce. Inquire about their equipment list, paying close attention to the availability of multi-axis machines (4-axis and 5-axis), which are necessary for complex geometries. Additionally, confirm their expertise with the specific materials your project requires, whether they are standard metals like aluminum and stainless steel or more exotic alloys and engineering plastics. A shop with deep material knowledge can often provide valuable input on design for manufacturability.

Production Volume and Scalability

Consider whether the shop is a good fit for your production needs, both now and in the future. Some shops specialize in rapid prototyping and small batches, while others are optimized for high-volume production. An ideal partner can handle your initial prototyping phase and seamlessly scale up to full production runs. For instance, some providers like XTJ offer both rapid prototyping and volume production with advanced 4 and 5-axis CNC centers, handling a wide range of materials to tight tolerances, which provides the flexibility needed for a project to grow.

Advanced Services and Specializations

Beyond core machining, many shops offer value-added services that can streamline your supply chain and simplify your project. These specializations distinguish a standard machine shop from a comprehensive manufacturing partner. Evaluating these advanced capabilities is especially important for complex or industry-specific projects.

One of the most valuable advanced services is product assembly. Shops that offer assembly can take the individual components they machine and put them together into sub-assemblies or even fully finished products. As noted by John Prosock Machine, Inc., this capability provides customers with faster turnarounds, enabling them to bring products to market more effectively. This integrated approach reduces logistical complexity and ensures that all components fit and function together correctly.

Another key specialization is rapid prototyping. Before committing to a full production run, creating exact models of parts allows for design verification and process optimization. Shops with strong prototyping capabilities can help perfect the manufacturing process early on, which reduces production time and overall costs. Additionally, look for shops with specific industry expertise, such as experience in the aerospace, medical, or defense sectors. These shops will be more familiar with the unique standards, materials, and quality requirements of your field.

Frequently Asked Questions

1. What do CNC machine shops do?

A CNC machine shop uses computer-controlled machines to manufacture parts from various materials like metal or plastic. A skilled tradesperson programs the machine to perform specific operations such as cutting, drilling, or milling. The primary role of these shops is to produce highly precise and consistent components for a wide range of industries, handling everything from one-off prototypes to large-scale production runs.