Precision Perfected: CNC Machining for Robotics Applications

TL;DR

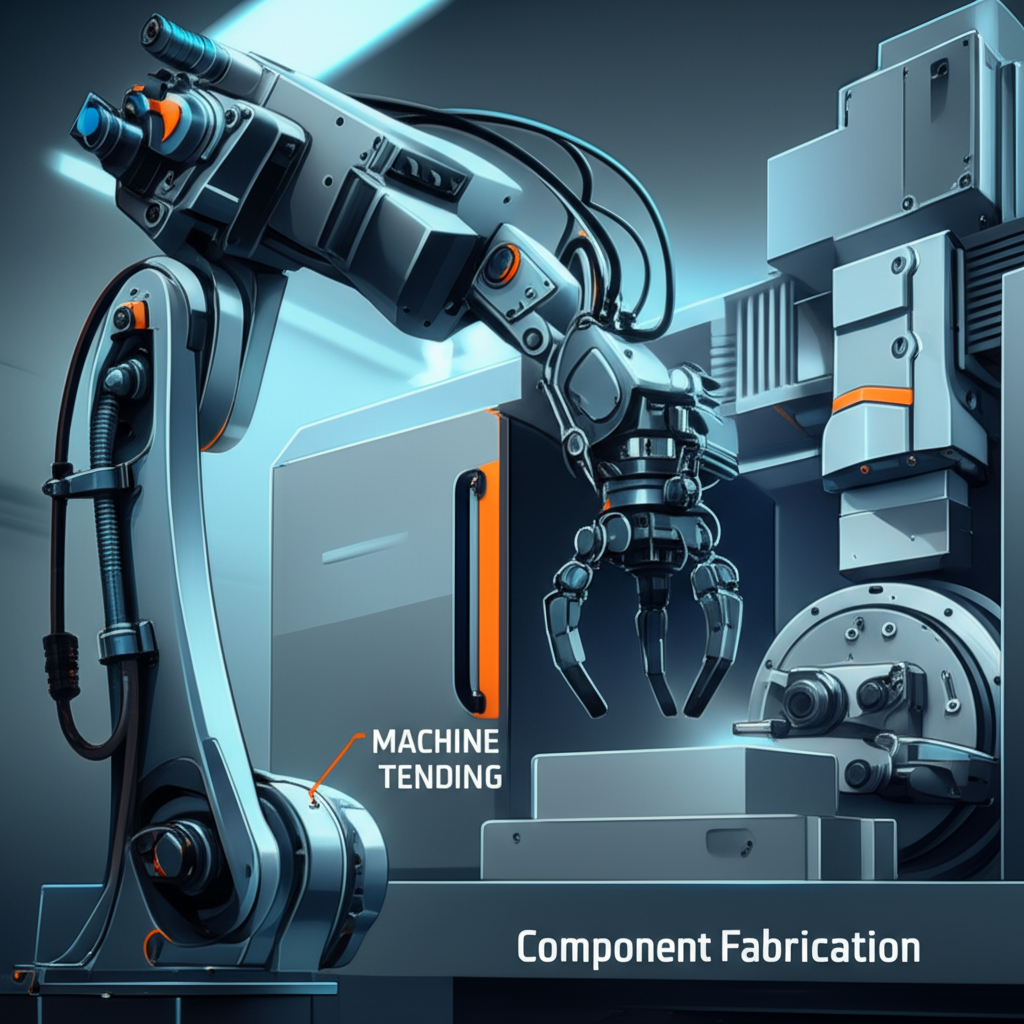

CNC machining for robotics applications describes a powerful, symbiotic relationship in manufacturing. It involves using high-precision Computer Numerical Control (CNC) machines to fabricate complex robot components, and in turn, using industrial robots to automate CNC operations. This integration, often called machine tending, significantly boosts production speed, accuracy, and efficiency.

Defining the Synergy: What is CNC in Robotics?

The term "CNC robotics" encompasses a dual-sided industrial partnership that has become fundamental to modern manufacturing. At its core, it is the integration of CNC machinery with advanced robotics to enhance precision, flexibility, and productivity. This relationship manifests in two primary ways: CNC as a creator of robotic components and robotics as an enhancer of CNC processes. Understanding both aspects is crucial to grasping its full impact on the industry.

First, CNC machining is an essential subtractive manufacturing process for creating the high-precision parts that robots are made of. Robots require components with extremely tight tolerances to function correctly, from the joints and manipulators of robotic arms to the custom end-effectors that interact with materials. As noted by experts at Aztalan Engineering, parts like gears, bearings, shafts, and brackets must fit together perfectly. CNC machines excel at this, carving complex shapes from materials like aluminum and steel to produce durable, lightweight, and dimensionally accurate components that other methods struggle to replicate.

Conversely, robotics plays a vital role in automating and optimizing CNC machine operations. This application is widely known as "machine tending." A CNC machine tending robot is an automated system designed to load raw materials into a CNC machine and unload finished parts. As explained by Automation Within Reach, this eliminates manual, repetitive labor, reduces machine downtime, and allows for continuous, 24/7 production. By handling these tasks, robots ensure a consistent workflow, improve safety, and free human operators to focus on more complex responsibilities like programming and quality control.

Core Applications and Strategic Benefits

The integration of CNC machining and robotics delivers strategic advantages across numerous industries, from aerospace to electronics. The applications are diverse, directly addressing the need for both precision manufacturing and operational efficiency. On one hand, CNC is used to fabricate mission-critical robot components like custom jigs, fixtures, and end-of-arm tooling (EOAT). These parts are essential for a robot's ability to perform specific tasks. On the other hand, robotic machine tending has become a cornerstone of modern production, automating everything from material loading to post-processing tasks like deburring and quality inspection.

For companies that require custom, high-precision parts, advanced CNC machining services are invaluable. For instance, providers like XTJ specialize in rapid prototyping and volume production using 4 and 5-axis CNC machines, handling a wide array of materials to meet demanding specifications. This capability is crucial for developing the sophisticated components needed in today's advanced robotic systems.

The strategic benefits of this synergy are substantial and directly impact a manufacturer's bottom line and competitive edge. These advantages include:

- Increased Precision and Consistency: CNC machining produces parts with exceptional accuracy, often achieving tolerances as tight as 0.0002 inches. When robots handle these parts, the consistency is maintained, reducing human error and ensuring every product meets the same high standard.

- Higher Throughput and Productivity: Robots can operate continuously without breaks or fatigue, maximizing the uptime of CNC machines. This leads to significantly faster production cycles and increased output, allowing manufacturers to meet tight deadlines.

- Reduced Labor Costs: By automating repetitive tasks, robots reduce the need for manual labor, allowing companies to reallocate their workforce to more value-added roles. This addresses labor shortages and lowers operational expenses over the long term.

- Enhanced Worker Safety: Machine tending can involve physically demanding and potentially hazardous tasks. Robots take over these duties, creating a safer work environment and reducing the risk of workplace injuries.

- Greater Operational Flexibility: A single robot can often be programmed to tend multiple CNC machines or handle a variety of parts. This adaptability is especially valuable in high-mix, low-volume production environments where frequent changeovers are necessary.

Key Technologies and Types of Robotic Integration

Successfully integrating robotics with CNC machining relies on a range of specialized technologies and robot types, each suited for different applications. The choice of robot often depends on factors like payload, reach, speed, and the complexity of the task. Control systems and software are equally critical, ensuring seamless communication between the robot and the CNC machine to create a cohesive, automated cell.

Several types of industrial robots are commonly used for CNC machine tending and other related tasks. As detailed by manufacturing experts at 3ERP, these robots offer different movement capabilities and are chosen based on the specific needs of the production line. The most prevalent types include:

- Articulated Robots: These are the most common type, featuring multiple rotary joints (typically six axes) that give them a wide range of motion, similar to a human arm. Their flexibility makes them ideal for complex tasks that require reaching around obstacles or manipulating parts at various angles.

- SCARA Robots: Selective Compliance Assembly Robot Arm (SCARA) robots are designed for speed and precision in a horizontal plane. They excel at high-speed pick-and-place, assembly, and loading/unloading tasks that don't require the full six-axis range of motion.

- Cartesian Robots: Also known as linear or gantry robots, these move along three linear axes (X, Y, Z). Their rigid structure provides high precision and stability over a large work area, making them suitable for tasks like stacking, arranging, and tending multiple machines in a line.

- Collaborative Robots (Cobots): A newer trend in the field, cobots are designed to work safely alongside human employees without extensive safety fencing. They are typically easier to program and are used for lighter-payload tasks, making automation more accessible for small and medium-sized enterprises.

The integration of these robots is managed by sophisticated control systems. Modern systems often allow a single interface to control both the robot and the CNC machine, simplifying programming and operation. Furthermore, advancements like machine vision systems enable robots to identify parts, perform quality inspections, and adjust their actions in real-time, adding another layer of intelligence and reliability to the automated process.

Distinguishing CNC Machines from CNC Robots

While the terms are often used together, it's important to distinguish between a traditional CNC machine and a CNC robot, as they serve different primary functions despite their technological overlap. A traditional CNC machine is a rigid, stationary piece of equipment designed exclusively for high-precision subtractive manufacturing tasks like milling, turning, or grinding. In contrast, a CNC robot is typically an articulated arm that has been equipped with a machining tool, offering greater flexibility but with some trade-offs in rigidity.

The fundamental difference lies in their structure and purpose. As explained by Fictiv, CNC machines are built with a massive, rigid frame to minimize vibration and deflection, which is critical for achieving the highest levels of accuracy. Robots, with their series of joints and links, are inherently less rigid. This makes them more versatile for a range of tasks beyond machining—such as material handling, welding, and assembly—but can limit their precision when performing heavy cutting operations.

Here is a simple comparison to clarify the key distinctions:

| Feature | Traditional CNC Machine | CNC Robot (Robotic Machining) |

|---|---|---|

| Primary Function | High-precision subtractive manufacturing (milling, turning, etc.). | Multi-purpose tasks; can be adapted for machining, handling, assembly. |

| Structure | Extremely rigid frame to absorb cutting forces and minimize vibration. | Articulated arm with multiple joints, offering flexibility over rigidity. |

| Flexibility | Specialized for specific machining tasks with a fixed work envelope. | Highly flexible with a large, spherical work envelope; easily reprogrammed. |

| Best Use Case | High-tolerance, heavy-duty machining of hard materials. | Machining large, complex parts or performing lighter tasks like deburring, polishing, and routing. |

Ultimately, the choice between a traditional CNC machine and a CNC robot depends on the application. For tasks demanding the utmost precision and material removal rates, a dedicated CNC machine is superior. For applications requiring versatility, a large workspace, or the ability to perform multiple different tasks, a robotic system offers compelling advantages.

The Future of Manufacturing: A Unified Approach

The convergence of CNC machining and robotics is more than just a trend; it represents a fundamental shift in manufacturing philosophy. This unified approach moves beyond simple automation to create intelligent, flexible, and highly productive systems. As technologies like Artificial Intelligence (AI), machine learning, and the Internet of Things (IoT) become more integrated, the synergy between creating precision parts and automating production processes will only deepen, paving the way for the smart factories of the future.

Looking ahead, we can expect to see even more sophisticated collaborations. Robots will not only tend machines but also use real-time data to predict maintenance needs, optimize tool paths, and perform in-process quality control, reducing waste and improving outcomes. The continued development of collaborative robots will make this powerful technology more accessible to businesses of all sizes, democratizing high-efficiency manufacturing. This powerful partnership is not just streamlining today's production lines—it's building the foundation for a more agile, resilient, and innovative industrial landscape.

Frequently Asked Questions

1. What is CNC in robotics?

CNC in robotics refers to the combination of Computer Numerical Control (CNC) machines with robotic technology. This has two main aspects: using CNC machines to manufacture highly precise components for robots, and using robots to automate the operation of CNC machines, a process known as machine tending. The goal is to improve manufacturing precision, efficiency, and flexibility. This integration has revolutionized industries by enabling faster production times and higher quality standards, as highlighted by a report on Robotics 24/7.

2. Which motor is used in CNC machines and robotics?

Servo motors are commonly used in both CNC machines and robotics. These motors are chosen for their ability to provide precise control over position, velocity, and acceleration. In CNC machines, they can respond quickly to computer commands to guide cutting tools with extreme accuracy. In robotics, servo motors enable the rapid and precise movements of robotic arms and joints, making them essential for tasks that require high levels of dexterity and repeatability.

-

Posted in

automation, cnc machining, machine tending, manufacturing, robotics