CNC Machining Services Turn Your Ideas into Reality

As we all know, the value of a computer depends on two key components: hardware and software. Machining services also include these two components, though slightly different in computer, their overall focus is similar.

"Hardware": machining equipment, process selection, and supporting testing devices;

"Software": Technical evaluation and machining plan development.

Precision CNC Machining Services for Engineering and Procurement Teams

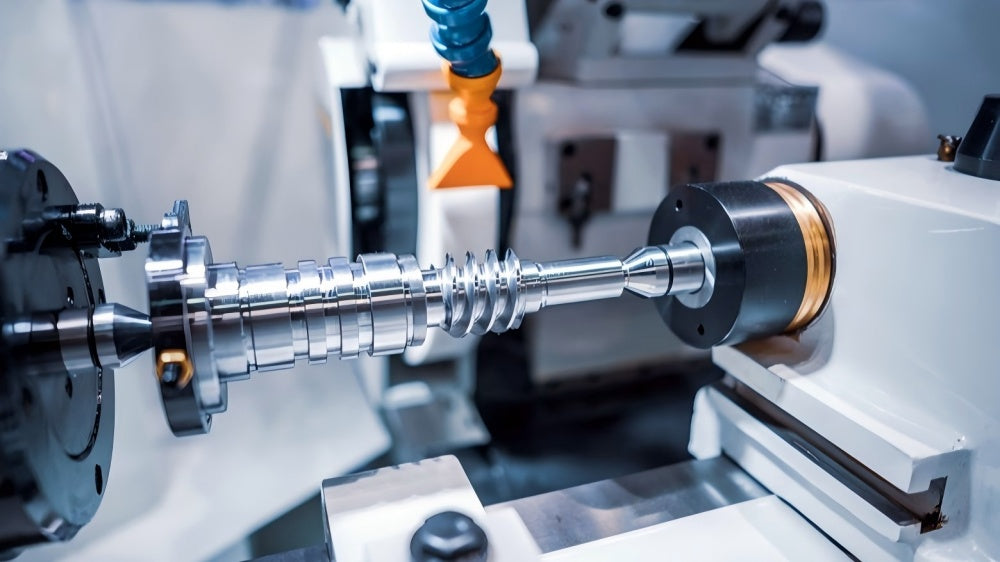

Advanced Multi-Axis Machining Equipment for Complex Components

XTJ is equipped with a comprehensive range of advanced CNC machining centers, including 3-axis, 4-axis, and 5-axis systems such as German-made DMG 5-axis machining centers and Beijing Jingdiao high-speed milling machines. This diverse equipment portfolio enables us to handle highly complex, tight-tolerance custom machining projects with precision and reliability.

Comprehensive Manufacturing Processes for Custom Requirements

- Milling:Our vertical machining centers equipped with automatic tool changers perform multi-axis cutting operations. We machine flat surfaces, grooves, gears, helical profiles, complex contours, and also offer drilling, boring, reaming, and threading in integrated setups.

- Turning:Our lathes process rotating workpieces using cutting tools and support auxiliary operations including drilling, reaming, threading, knurling, and taper turning, delivering precision on cylindrical, conical, and formed surfaces.

- EDM:Utilizing spark erosion to shape materials without physical contact, we process difficult-to-machine metals and conductive materials, especially suitable for intricate geometries and special requirements.

- Wire Cutting:Using a moving wire electrode to perform precision cutting through spark erosion, this process is ideal for intricate and delicate components.

We also provide laser cutting and other advanced processes to meet diverse custom manufacturing needs.

CNC Machining Facility

Precision Metrology and Inspection Equipment Ensuring Quality

Our quality assurance lab includes CMMs, optical projectors, surface roughness testers, hardness testers, feeler gauges, radius gauges, and other instruments. This allows full validation of dimensions, positioning, geometry, surface finish, hardness, deformation, and internal/external radii—ensuring parts meet specified tolerances and performance requirements.

Quality-Assured Machining Services

Professional DFM Support to Optimize Your Design

XTJ’s engineering team provides in-depth design-for-manufacturability (DFM) analysis based on your drawings. We offer recommendations to optimize part functionality, external and internal features, critical dimensions, tolerances, and machining strategies—helping improve manufacturability and reduce cost.

Extensive Experience and Resources for Optimal Machining Solutions

With decades of expertise in precision machining, our team rapidly integrates resources and technology to develop the most efficient and cost-effective production strategies for your projects.

Summary

At XTJ, "hardware" is our foundation—advanced CNC equipment that enables high-precision manufacturing. "Software" is our support—the engineering expertise and process knowledge that help optimize designs and production plans. Together, they form a integrated, customer-focused manufacturing service recognized for quality and reliability.

-

Posted in

CNC Machining Service, DFM, R&D