CNC Turning with Live Tooling: Boost Speed and Complexity

TL;DR

CNC turning with live tooling is an advanced manufacturing process that integrates rotating cutting tools into a CNC lathe's turret. This allows the machine to perform milling, drilling, and tapping operations on a part while it is still in the lathe, all within a single setup. The primary benefit is a massive boost in efficiency, enabling the production of highly complex parts with features like off-center holes or milled flats faster, more accurately, and often at a lower cost by eliminating secondary machine setups.

What Is Live Tooling in CNC Turning?

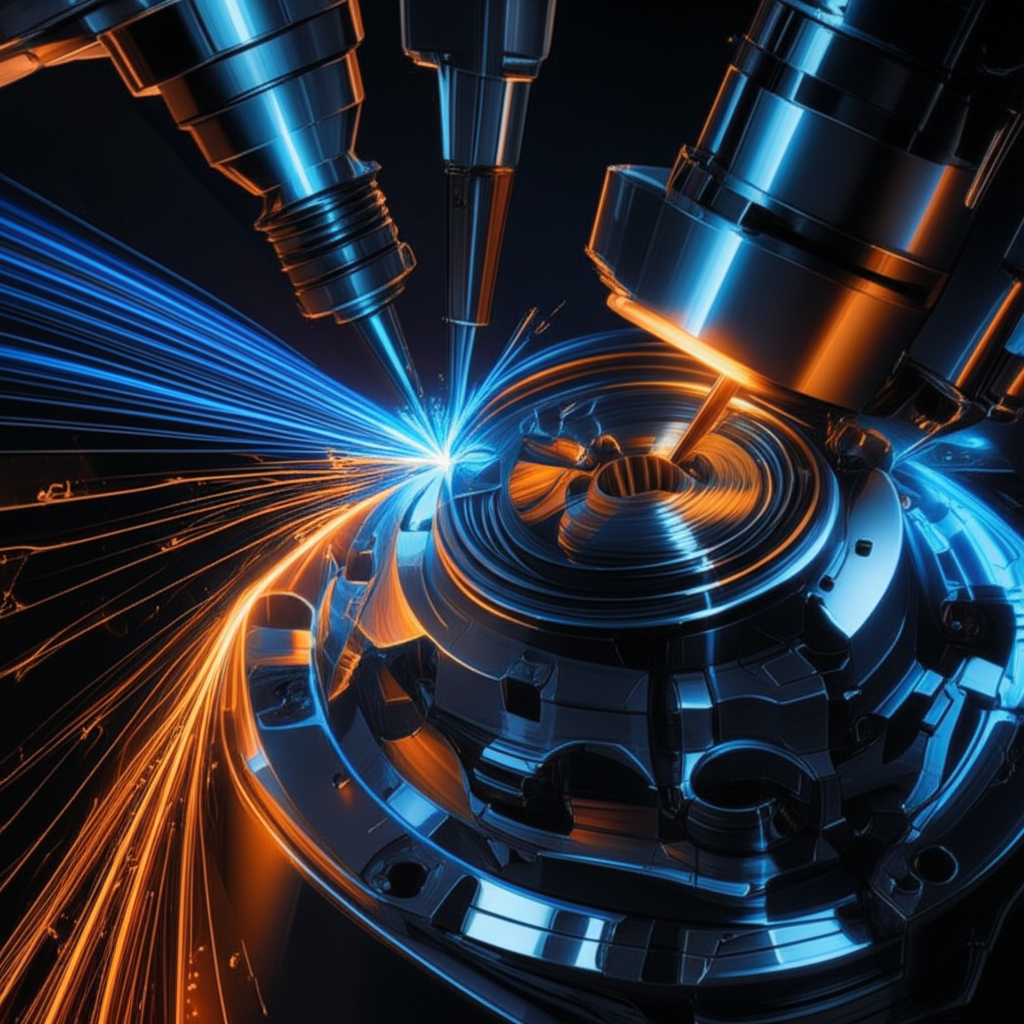

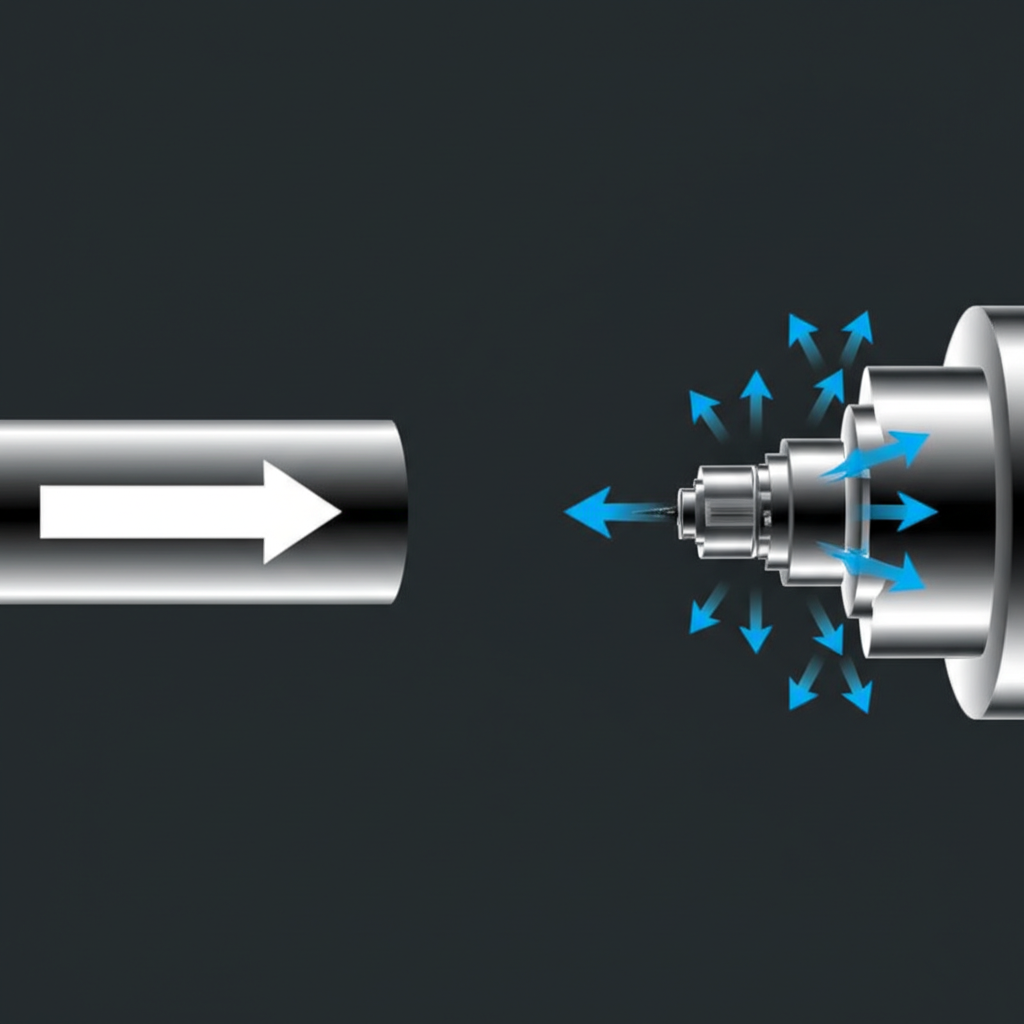

In the world of precision manufacturing, CNC turning has long been a foundational process for creating cylindrical parts. Traditionally, a CNC lathe operates by rotating a workpiece at high speed while a static, non-rotating cutting tool removes material. However, this method is limited to creating features that are symmetrical around the part's central axis. Live tooling, also known as driven tooling, fundamentally changes this dynamic by introducing powered, rotating tools into the lathe's turret.

Unlike conventional static tools, live tools have their own motor, allowing them to spin independently of the workpiece. As Sawyer Fabrication explains, this means the cutting apparatus is driven independently of the rotating workpiece, effectively turning a lathe into a multi-function machining center. This capability allows the machine to perform operations that would typically require moving the part to a separate milling machine or drill press. The workpiece can be stopped or indexed to a specific angle, and the live tool can then perform milling, drilling, or tapping operations.

The range of operations this technology enables is extensive. For instance, a live tooling lathe can drill holes perpendicular to the part's centerline (cross-drilling), mill flat surfaces onto a round shaft, cut keyways, or tap off-center threads. Essentially, it combines the capabilities of a lathe and a mill into one highly efficient process, performed in a single clamping of the material. This consolidation is the core innovation that makes live tooling so powerful.

Key Advantages: Why Use Live Tooling for Your Parts?

The decision to use a CNC turning center with live tooling is driven by significant advantages in efficiency, precision, and design freedom. By consolidating multiple machining processes into a single machine, this technology addresses several common manufacturing bottlenecks, ultimately delivering better parts faster and more cost-effectively. For engineers and procurement managers, understanding these benefits is key to optimizing production for complex components.

The most significant benefits of incorporating live tooling include:

- Single-Setup Manufacturing: The primary advantage is the ability to complete a complex part in one continuous operation without moving it to another machine. Every time a part is unclamped and re-fixtured on a different machine (a secondary operation), there is a risk of introducing small alignment errors. As detailed in a comparison by Zintilon, eliminating these transfers preserves the part's original datum, leading to higher accuracy and consistency across a production run. This single-setup approach drastically reduces handling time, labor costs, and potential for human error.

- Enhanced Part Complexity: Live tooling unlocks the ability to create features that are impossible on a standard lathe. Components requiring off-center holes, milled flats, radial slots, or intricate surface features can be machined with ease. The addition of a Y-axis on some live tool lathes further expands this capability, allowing for even more complex milling operations on the workpiece. This gives designers greater freedom to create sophisticated, multi-functional parts that are optimized for performance rather than limited by manufacturing constraints.

- Improved Accuracy and Repeatability: By avoiding the need to re-fixture a part, live tooling ensures a higher degree of precision. The initial setup dictates the geometric relationships for all features, both turned and milled. This means that the location of a milled flat relative to the central bore will be exceptionally consistent from one part to the next. This level of repeatability is critical for industries like aerospace, medical, and automotive, where tight tolerances are non-negotiable.

- Reduced Cycle Times and Lead Times: Consolidating operations directly translates to faster production. The time spent moving parts between machines, setting them up, and waiting in queues for the next operation is eliminated. This reduction in overall cycle time means that finished parts are produced more quickly, shortening lead times for both prototypes and full production runs. For many projects, this speed can provide a significant competitive advantage.

Live Tooling vs. Secondary Operations: A Technical Comparison

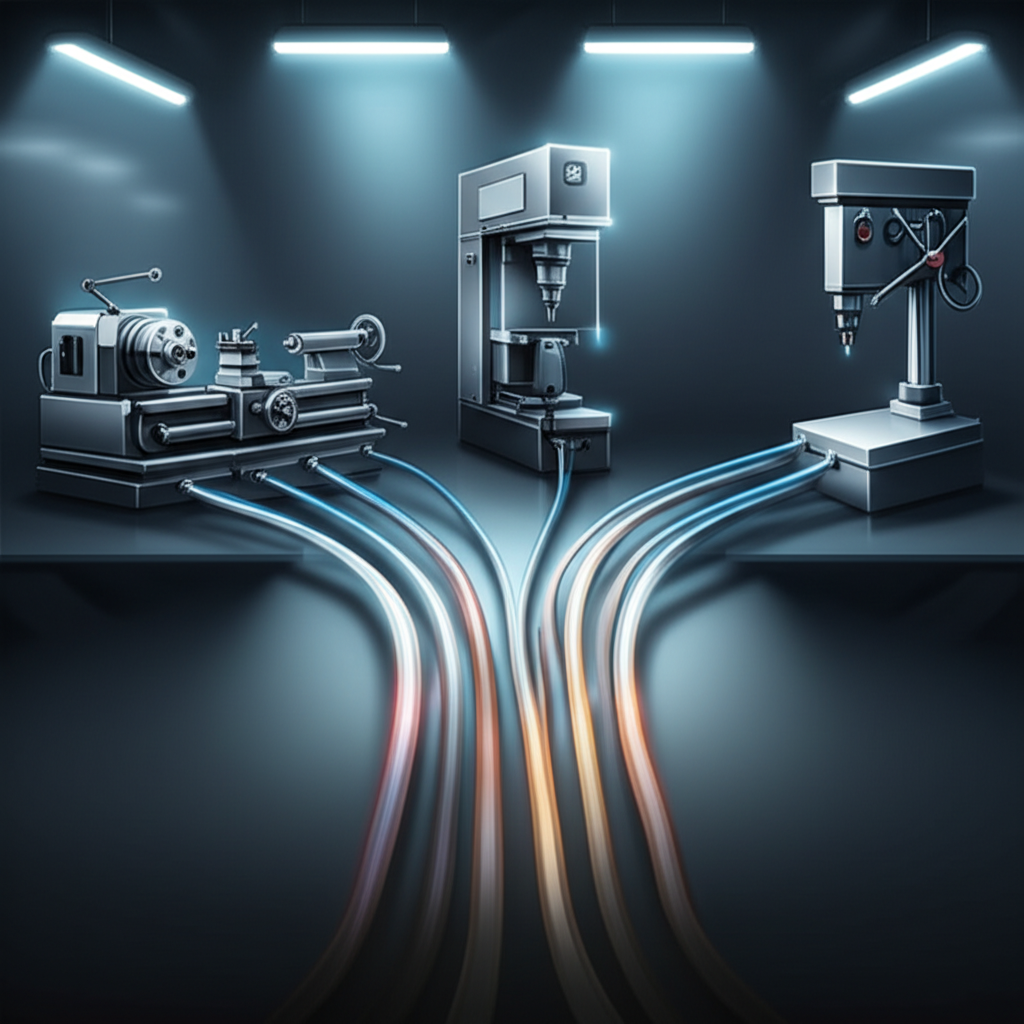

Choosing between a single-process workflow on a live tooling lathe and a multi-process approach involving a standard lathe plus secondary operations is a critical decision in manufacturing. While the latter may seem viable for shops without advanced equipment, a direct comparison reveals significant differences in speed, cost, and quality. The traditional method involves turning the part on a lathe, then moving it to a milling machine for features like flats or holes, and potentially to a third machine for tapping or drilling.

The live tooling approach, by contrast, completes all these steps in a single chucking. This 'done-in-one' philosophy is a cornerstone of modern lean manufacturing. As Southern Fabricating Machinery Sales highlights, if you are currently turning workpieces and then setting them up in a milling machine, a live tooling lathe can more than offset its initial investment through reduced process time and increased accuracy.

The following table provides a clear comparison of the two workflows across key performance metrics:

| Factor | Live Tooling Lathe | Standard Lathe + Secondary Operations |

|---|---|---|

| Setup Time | One initial setup for all operations. | Multiple setups; one for the lathe, another for the mill, etc. |

| Cycle Time | Significantly shorter due to the elimination of part transfer and queue times. | Longer overall cycle time due to manual handling and multiple machine queues. |

| Accuracy & Consistency | Higher precision as all features are machined relative to a single datum. Excellent repeatability. | Risk of tolerance stacking and re-fixturing errors with each new setup. Consistency can vary. |

| Labor Cost | Lower, as one operator manages a single, more automated process. | Higher, requiring labor for part transfer, inspection, and setup on multiple machines. |

| Scrap Rate | Lower, due to reduced handling and higher process control. | Potentially higher, as each additional setup introduces another opportunity for error. |

In summary, while the initial equipment cost for a live tooling lathe is higher, the long-term savings in labor, reduced scrap, and faster lead times make it a far more efficient and reliable solution for producing complex parts. The traditional method becomes progressively less efficient as part complexity and production volume increase.

Applications and Part Examples: What Can You Make with Live Tooling?

The true value of CNC turning with live tooling becomes evident when looking at the specific parts and features it can produce. This technology is not just an incremental improvement; it enables the creation of components that would be difficult, time-consuming, or prohibitively expensive to make otherwise. Its applications span nearly every industry, from aerospace and automotive to medical and consumer electronics, wherever complex, multi-feature cylindrical parts are needed.

Common examples of parts ideally suited for live tooling include shafts with keyways, bolts with cross-drilled holes for safety wires, and hydraulic fittings with milled wrench flats. As Komacut points out, the process excels at making a variety of components like pins, flanges, bushings, and connectors that require precise rotational features combined with other machined elements. For instance, a single machine can turn the outer diameter of a shaft, mill a keyway along its length, and drill and tap holes on its end face, all in one go.

Beyond simple features, live tooling makes it possible to machine complex geometries. Consider a part like a custom valve stem, which may require a turned sealing surface, threaded sections, a milled hexagonal head for actuation, and cross-drilled ports for fluid flow. Producing this part with secondary operations would involve multiple machines and careful inspections at each stage. With live tooling, all these features are machined with high precision in a single, automated sequence. This capability is invaluable for parts where the geometric relationship between features is critical for function. For companies needing high-precision custom parts quickly, services leveraging advanced 4 and 5-axis CNC machining centers can deliver complex components with tight tolerances in a variety of materials, from rapid prototypes to full production runs.

Is Live Tooling the Right Choice for Your Project?

CNC turning with live tooling offers a powerful solution for manufacturing complex parts with unparalleled efficiency and precision. By integrating milling, drilling, and tapping capabilities into a single lathe setup, it eliminates the need for secondary operations, thereby reducing lead times, minimizing the potential for error, and lowering labor costs. This 'done-in-one' approach is particularly advantageous for components that feature a combination of cylindrical and asymmetrical features, such as flats, off-center holes, or keyways.

The decision to specify live tooling ultimately depends on part complexity, production volume, and tolerance requirements. For simple, purely cylindrical parts, a traditional CNC lathe remains a cost-effective choice. However, as soon as a part requires any non-turned features, the benefits of live tooling become compelling. It streamlines the entire production workflow, enhances design freedom for engineers, and delivers a higher-quality, more consistent final product. For any project demanding both speed and complexity, CNC turning with live tooling stands out as the superior manufacturing method.