CNC Turning vs Milling: Choosing the Right Process

TL;DR

The core difference between CNC turning vs milling lies in which part moves. In CNC turning, the workpiece rotates at high speed while a stationary cutting tool shaves away material, ideal for creating cylindrical or conical parts. Conversely, CNC milling involves a rotating cutting tool that moves across a stationary workpiece, allowing for the creation of more complex, flat, or angular shapes. Your choice depends entirely on the desired geometry of the final component.

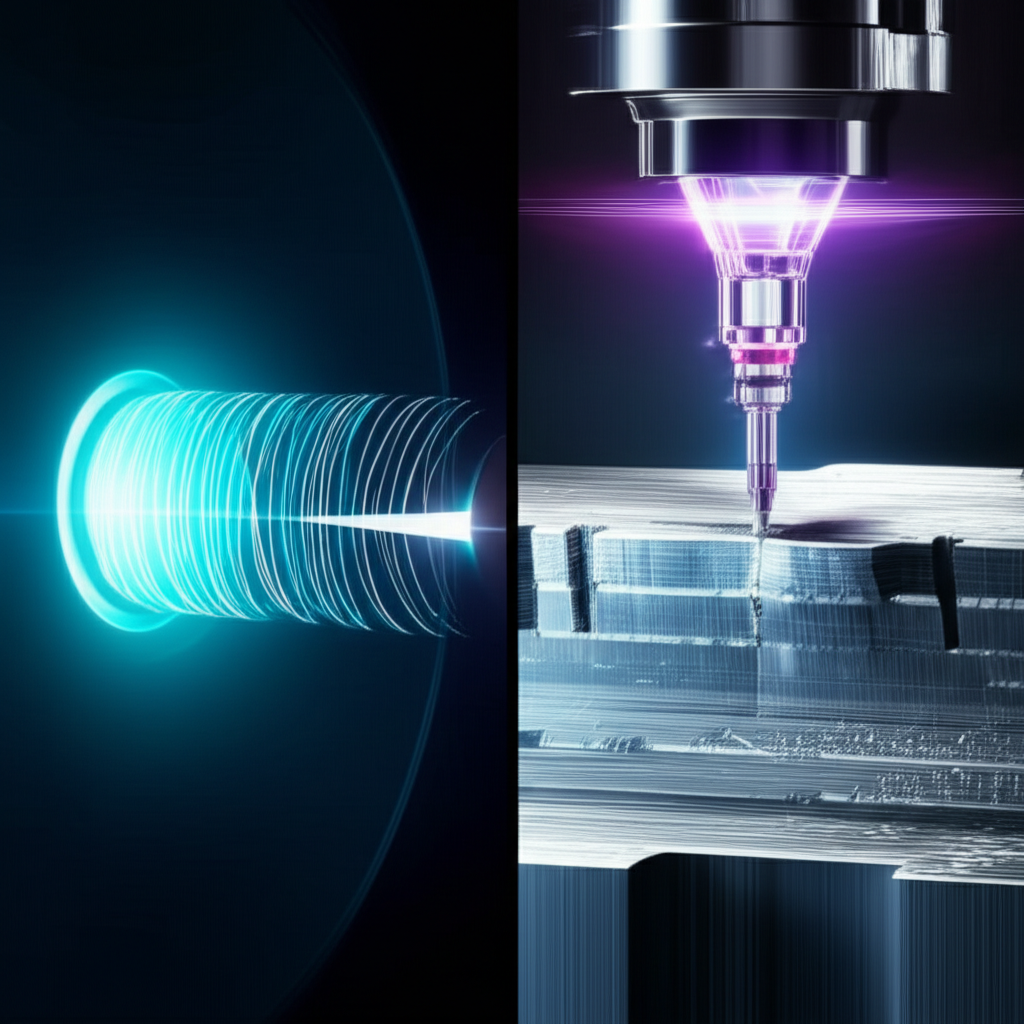

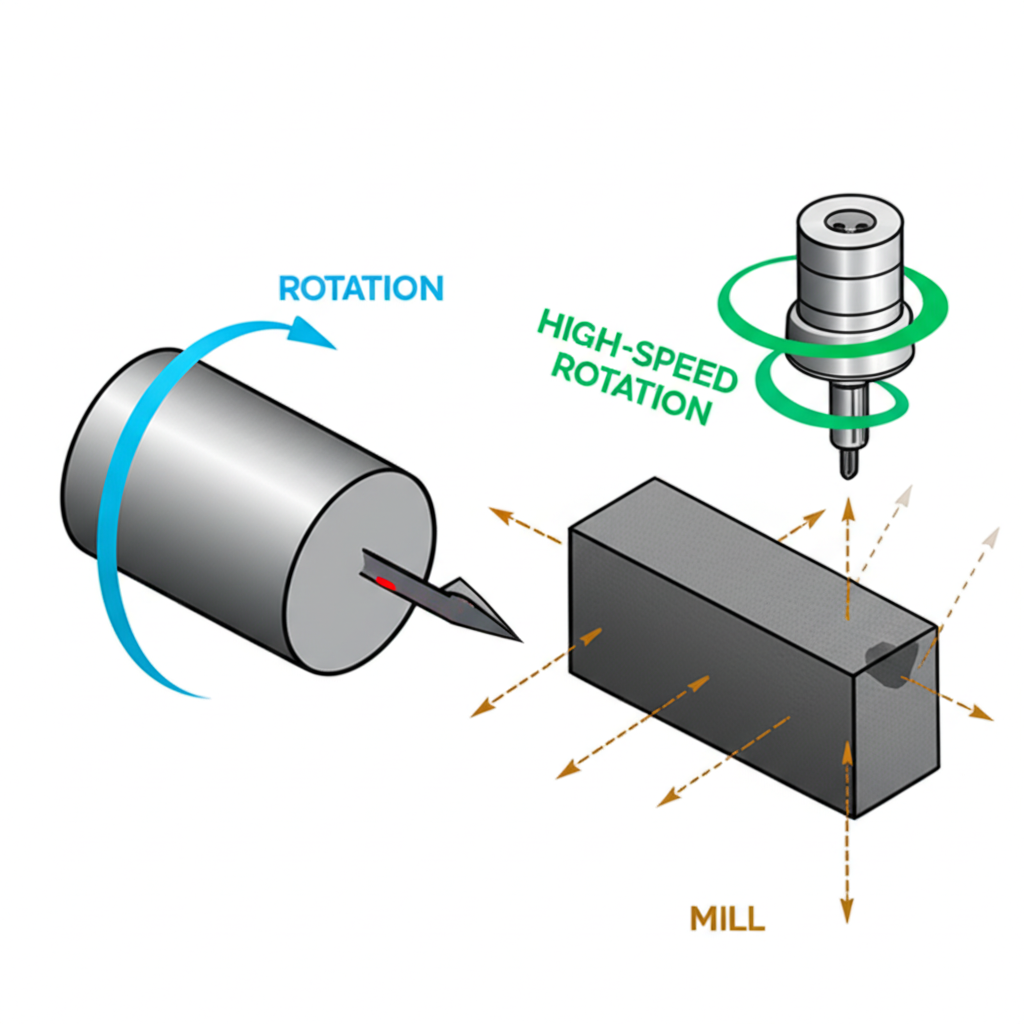

The Core Distinction: Workpiece vs. Tool Rotation

Understanding the fundamental mechanics of CNC turning and milling is the first step to selecting the right process for a manufacturing project. Although both are subtractive manufacturing methods—meaning they remove material to create a part—their approaches are opposites. This primary difference in motion dictates the types of parts each process can efficiently produce.

CNC turning is analogous to a potter working on a wheel. The process uses a machine called a lathe, which securely holds a piece of raw material (typically a round bar) in a chuck and rotates it at high speeds. A stationary, single-point cutting tool is then moved along the length and diameter of the spinning workpiece, precisely removing material to form a symmetrical, cylindrical shape. This method is exceptionally efficient for producing components like shafts, pins, bolts, and nozzles, where rotational symmetry is the key feature. As one expert source, Mastercam explains, the material itself spins while the tool advances into it.

In stark contrast, CNC milling operates more like a sculptor carving a block of stone. In this process, the workpiece is held stationary on the machine's bed. A multi-point cutting tool, held in a spindle, rotates at high speeds and moves along multiple axes (typically X, Y, and Z) to cut away material. This allows the machine to create a vast array of complex shapes, including flat surfaces, slots, pockets, and intricate 3D contours. Milling is performed on a milling machine or a CNC machining center and is the go-to process for parts like engine blocks, enclosures, and custom brackets that are not cylindrically based.

Detailed Comparison: A Side-by-Side Analysis

Beyond the fundamental difference in rotation, several key operational factors distinguish CNC turning from milling. These aspects influence everything from machine selection and setup complexity to production speed and final cost. A direct comparison highlights where each process excels and helps in making an informed decision for a specific application.

| Feature | CNC Turning | CNC Milling |

|---|---|---|

| Process | Workpiece rotates against a stationary tool. | Cutting tool rotates against a stationary workpiece. |

| Machine Used | Lathe or Turning Center | Milling Machine or Machining Center |

| Workpiece Movement | Rotates on its axis. | Remains stationary (bed may move on X/Y/Z axes). |

| Tool Movement | Moves linearly along the workpiece. | Rotates and moves along multiple axes. |

| Typical Part Geometry | Cylindrical, conical, round shapes. | Flat surfaces, complex shapes, pockets, holes. |

| Best For | Shafts, pins, bolts, pulleys, custom fasteners. | Enclosures, brackets, molds, engine components. |

Expanding on these points, setup and programming complexity often differ. Turning is generally considered easier to learn for basic operations, as the toolpaths are often simpler. In contrast, milling, especially 3-axis, 4-axis, or 5-axis milling, requires more advanced programming skills to create the complex toolpaths needed for intricate geometries. This complexity can also translate into longer setup times for milling jobs.

In terms of production speed and cost, turning often has an advantage for the right type of part. According to Pioneer Service Inc., turned parts are usually quicker and more efficient to produce than milled parts. The continuous cutting action on a lathe allows for rapid material removal on round stock. While milling is more versatile, creating a simple round shaft on a milling machine would be far less efficient and more costly than producing it on a lathe. However, modern multi-axis turn-mill centers can combine both processes, offering the best of both worlds by machining complex parts in a single setup, which can reduce overall production time.

Applications and Use Cases: When to Choose Each Process

The decision between CNC turning and milling ultimately comes down to the specific design requirements of the component. Each process is tailored to a distinct set of geometries and finds its home in different industrial applications. Understanding these use cases provides a practical guide for engineers, designers, and hobbyists alike.

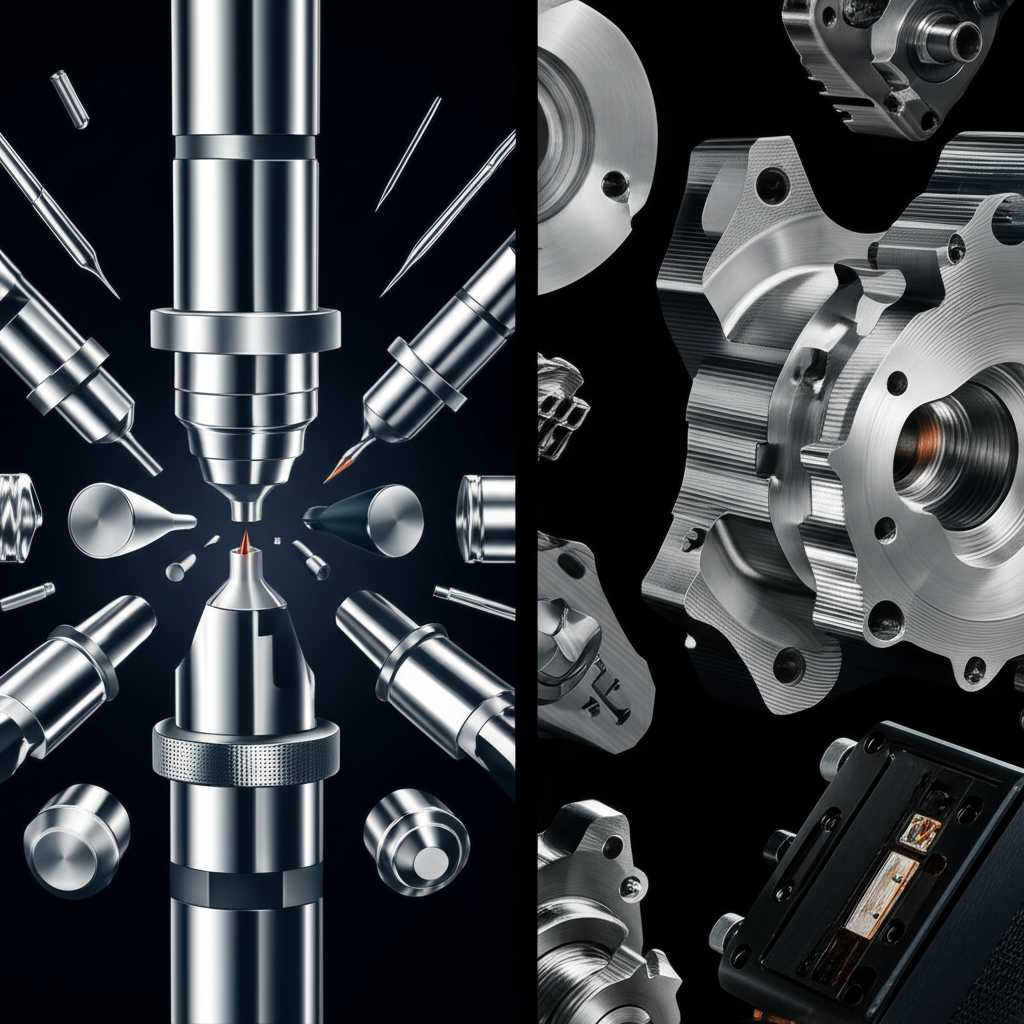

Typical Applications for CNC Turning

Because it excels at creating parts with rotational symmetry, CNC turning is indispensable for producing a wide range of common and specialized components. If you can draw the part's cross-section and rotate it around a central axis to form the final shape, turning is likely the right choice. Common examples include:

- Shafts and Axles: The foundational components in countless machines, from electric motors to vehicle transmissions.

- Pins, Bolts, and Screws: Custom fasteners with precise threads and dimensions.

- Bushings and Bearings: Cylindrical parts designed to reduce friction between moving components.

- Nozzles and Couplings: Fluid and gas handling components that require precise internal and external cylindrical features.

Typical Applications for CNC Milling

Milling's ability to create complex, non-symmetrical shapes makes it one of the most versatile manufacturing processes. It is used to produce everything from simple flat plates with mounting holes to highly intricate, three-dimensional parts. For projects requiring highly complex geometries, such as those in the aerospace or medical fields, partnering with a specialized service is often necessary. For instance, providers like XTJ CNC Machining Services utilize advanced 4 and 5-axis milling centers to produce intricate components from over 30 materials with extremely tight tolerances, offering rapid prototyping for such demanding applications. Common milled parts include:

- Enclosures and Housings: Custom boxes for electronics or mechanical assemblies.

- Brackets and Mounts: Structural components designed to hold other parts in a specific orientation.

- Engine Components: Parts like engine blocks, cylinder heads, and intake manifolds with complex internal and external features.

- Molds and Dies: Tooling used in other manufacturing processes like injection molding or die casting.

Material and Precision Considerations

Beyond part geometry, the choice between turning and milling can also be influenced by the material being used and the required levels of precision and surface finish. Both processes can work with a wide range of materials, including metals like aluminum, steel, and titanium, as well as various plastics. However, their distinct mechanics affect efficiency and final part quality in different ways.

Material Removal and Efficiency

When it comes to removing large amounts of material from round stock, turning is generally the more efficient process. The continuous engagement of the cutting tool with the rotating workpiece allows for high material removal rates, making it faster and more cost-effective for roughing out cylindrical shapes. Milling can also remove material quickly, but setting up a milling operation to turn a round bar into a smaller diameter cylinder would be inefficient. However, as noted by some machinists, for very tough or ductile materials, milling might offer better chip control, which is a crucial factor in maintaining a stable and reliable machining process.

Accuracy and Surface Finish

Both CNC turning and milling are capable of achieving exceptionally tight tolerances and fine surface finishes. The final quality depends heavily on the machine's rigidity, the quality of the cutting tools, and the programmed speeds and feeds. Turning naturally produces a very smooth, uniform surface on cylindrical diameters because the cutting action is continuous. Any imperfections tend to be helical, following the tool's path. In milling, the finish is created by the intermittent cuts of the rotating tool's multiple cutting edges. This can sometimes leave behind subtle tool marks, or scallops, on the surface, especially on large, flat faces. Achieving a mirror-like finish with milling often requires specific finishing passes with specialized tools.

Frequently Asked Questions about CNC Machining

1. Is milling the same as turning?

No, they are fundamentally different. In turning, the workpiece rotates while the tool is stationary, which is ideal for creating cylindrical parts on a lathe. In milling, the cutting tool rotates while the workpiece is stationary, which is used to create a wider variety of complex shapes on a milling machine. The key distinction is which element—the part or the tool—spins.

2. Is milling or turning harder?

The difficulty depends on the complexity of the part. Basic turning is often considered easier to learn than basic milling. However, advanced turning with complex profiles can be very challenging. Milling, particularly 3D and 5-axis milling, generally requires more advanced programming knowledge and setup skills to manage complex toolpaths and multiple axes of movement, making it harder to master for intricate parts.

3. What are the disadvantages of CNC turning?

The primary disadvantages of CNC turning are its geometric limitations; it is mainly suitable for cylindrical parts. Another drawback is the generation of waste material, as it is a subtractive process that carves a smaller part from a larger piece of stock. Finally, high-precision CNC lathes can have a high initial investment cost, and there can be size restrictions on the diameter of the workpiece the machine can handle.

4. Is a lathe milling or turning?

A lathe is the specific type of machine tool used for turning operations. While some modern lathes, known as turn-mill centers, incorporate rotating tools to perform some milling operations, the primary function of a standard lathe is turning. Therefore, a lathe is fundamentally a turning machine. You can find more information from sources like Auburn Bearing & Manufacturing.

-

Posted in

cnc machining, CNC milling, CNC turning, manufacturing processes, subtractive manufacturing