Copper Door Secrets: Patina, Performance, And Real Costs

What the Cooper Door Means and How to Find What You Need

When you search for copper door, do you mean a stunning architectural entryway, or are you looking to book a table at a popular New Hampshire restaurant? Sounds simple, but this single phrase splits search intent into two very different directions. Let’s clear up the confusion so you can get straight to the information that fits your needs.

What a Copper Door Is in Architecture

In the world of design and construction, a copper door typically refers to an entry or interior door crafted from solid copper or clad in copper sheets. These doors are prized for their warm, timeless appearance and their ability to develop a unique patina over time. Architects and homeowners choose copper doors for their durability, corrosion resistance, and the elegant character they bring to both traditional and modern spaces. The natural antimicrobial properties of copper also make it a practical choice for high-touch surfaces. If you’re searching for inspiration or technical details about copper as a door material, you’re in the right place—just keep reading below for expert insights and design ideas.

The Copper Door Restaurant at a Glance

On the other hand, The Copper Door is also a well-known dining destination with two locations in New Hampshire—one in Bedford and another in Salem. The Copper Door Restaurant NH offers upscale comfort food in a welcoming atmosphere, making it a top pick for locals and travelers alike. If you’re looking for details about the copper door salem location, menus, or how to make a reservation, you’ll find direct links and resources in the restaurant-focused section below.

Why Most Copper Door Searches Miss the Mark

It’s easy to see why search engines get tripped up by the phrase copper door. With one term covering both high-end architectural products and a popular restaurant, users can end up in the wrong place, leading to confusion or unnecessary clicks. Whether you type "copper door nh," "the copper door restaurant," or just "copperdoor," the results can be a mix of design inspiration, technical articles, and dining guides. That’s why this guide is structured to help you self-select your path quickly.

Find Your Path Fast

- Homeowner or Designer: Want to learn about copper doors for your project?

- Architect or Builder: Need technical specs or sourcing tips?

- Diner or Foodie: Ready to book a table or browse the copper door restaurant nh menu?

- Traveler: Looking for directions to copperdoor salem nh or Bedford?

Key Insight: Search intent for "copper door" splits almost evenly between architectural products and the restaurant brand—so clear navigation is the fastest way to get users what they need and reduce bounce.

For restaurant hours, menus, or reservations, always verify details directly on official sites or trusted local directories. For design and material guidance, authoritative architectural resources and manufacturer sites offer the most accurate information. This approach ensures you find exactly what you’re after—whether it’s a statement entryway or a standout meal.

Why Copper Doors Stand Out

Why Designers Choose Copper for Exterior Doors

When you picture a copper door, you might imagine a grand entryway glowing with rich, reddish tones or a modern, minimalist panel with a subtle, brushed finish. But what makes copper such a compelling choice for doors—whether solid or copper-clad? The answer lies in its unique combination of beauty, durability, and natural performance advantages.

Architectural copper doors are typically constructed in two main ways: either as solid copper panels or as copper sheets clad over a wood or steel core. Both methods offer distinct benefits. Solid copper doors deliver unmatched longevity and a substantial, secure feel, while copper-clad doors provide the look and performance of copper with added structural flexibility and, often, lighter weight.

Designers and homeowners choose copper for exterior and interior doors because it:

- Develops a unique patina over time, evolving from warm salmon reds to deep browns and, eventually, to classic blue-green hues depending on exposure.

- Resists corrosion in most environments, thanks to the formation of a tough oxide-sulfate patina that protects the metal beneath.

- Offers antimicrobial properties, naturally reducing bacterial loads on high-touch surfaces—an advantage for both residential and commercial settings.

- Requires minimal maintenance compared to painted or coated metals, especially when used in exterior applications.

- Enables diverse design styles—from ornate traditional panels to sleek, contemporary slabs—thanks to copper’s malleability and compatibility with various finishing techniques.

Worried about finding the right information if you searched for "door copper," "cooper door," or even "coper door"? Rest assured, you’re in the right place—these are common variants, and the principles of copper door design apply no matter how you type it.

Patina, Finishes, and Longevity

One of the signature qualities of copper is its ability to transform visually as it ages. When first installed, copper doors exhibit a bright, metallic sheen—salmon red for pure copper, with subtle variations for copper alloys. Over months and years, environmental exposure triggers a natural oxidation process, shifting colors through oranges, russet browns, and, in time, to the recognizable blue-green or gray-green patina seen on historic buildings and monuments.

- Natural patina: Left untreated, copper develops a protective, self-healing surface that resists further corrosion and gives each door a one-of-a-kind appearance.

- Clear-coated: Preserves the initial color and luster for a period, but requires periodic reapplication—especially for exterior doors.

- Waxed or oiled: Enhances depth and slows patina formation; best for interior doors or areas where a dark, rich tone is desired.

- Brushed: Provides a soft, matte texture that diffuses light and conceals fingerprints.

- Hammered or embossed: Adds dimension and stiffness, making doors visually striking and resistant to surface dents.

Takeaway: The patina that forms on copper is not just beautiful—it’s a naturally protective layer that dramatically extends the life of the door in most climates.

Unlike many metals, copper corrodes at negligible rates in clean air and water, and its patina shields it from harsh weather and pollution. For example, copper roofing in rural areas corrodes at less than 0.4 mm in 200 years (reference). While doors are subject to different exposures, the same principle holds: copper’s surface evolves, but the underlying metal remains sound for generations.

Maintenance That Preserves Character

Worried about keeping a copper door looking its best? The good news is that copper requires less upkeep than most metals or painted finishes. In fact, it’s often the changing patina that owners cherish most. Here are practical tips:

- For exterior doors: Let the patina develop naturally, cleaning only as needed to remove debris or fingerprints. Avoid harsh chemicals that could disrupt the protective layer.

- For interior doors: If you prefer to maintain the initial color, periodic applications of wax or oil can enhance luster and slow oxidation. Use soft, non-abrasive cloths for cleaning.

- In coastal or industrial climates: Patina may form more quickly, and occasional rinsing with clean water can help remove salt or pollutants.

- For copper-clad doors on wood or steel cores: Ensure proper sealing at edges and hardware penetrations to prevent moisture ingress into the core material.

It’s also worth noting that copper’s antimicrobial qualities make it a smart choice for high-traffic areas—especially on handles and push plates. This can be particularly valuable in public buildings, healthcare settings, or anywhere hygiene is a priority.

Design Flexibility: From Heritage to Modern

Whether you’re envisioning a traditional, paneled "door copper" for a heritage restoration or a minimalist, brushed slab for a contemporary home, copper’s versatility supports nearly any design intent. Its ability to be shaped, textured, and finished makes it a favorite for both statement entryways and subtle interior accents. And for those searching for "copper door near me," local fabricators and specialty shops often offer custom options to match your project’s climate, style, and performance needs.

As you continue exploring, you’ll discover how copper doors are crafted—from hand-forged artistry to precision-machined panels—and how to choose the right fabrication and care approach for your project.

How Copper Doors Are Fabricated

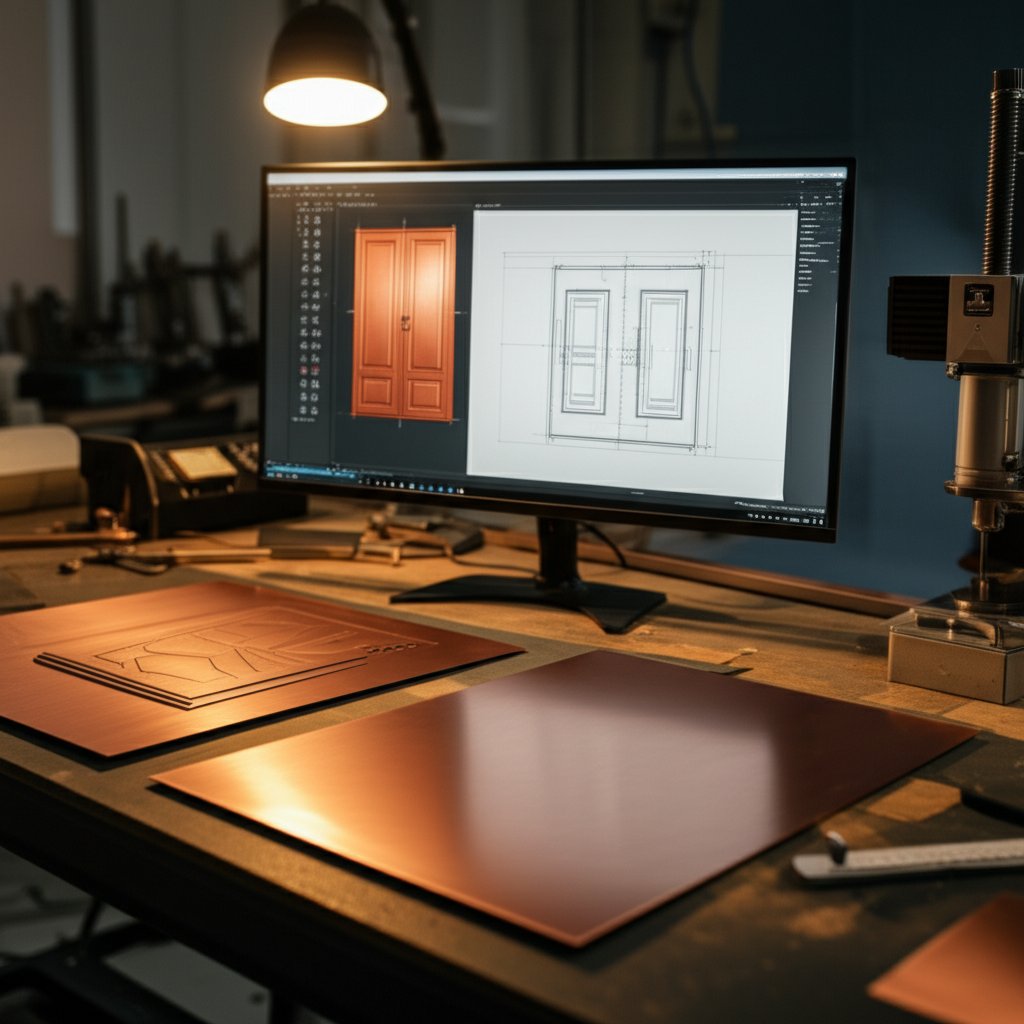

From Sheet to Statement Door

Ever wondered how a copper door transforms from a simple sheet of metal into a stunning work of art or a precision-engineered entry? The journey is a fascinating blend of old-world craftsmanship and today’s advanced technology. Whether you’re seeking a one-of-a-kind centerpiece for your home or specifying a series of doors for a commercial project, understanding the fabrication process will help you make informed decisions—and avoid surprises along the way.

Traditional Crafting vs. Modern Machining

Let’s break down the main fabrication methods used for copper doors. Each approach offers distinct advantages, depending on the design complexity, project scale, and desired finish. Here’s a comparison to help you visualize the options:

| Fabrication Approach | Complexity | Lead Time | Repeatability | Typical Use Cases |

|---|---|---|---|---|

| Hand-Forging & Chasing | High (Artistic, Custom Motifs) | Long (Made-to-order) | Low (Each piece unique) | Heritage restorations, luxury residences, sculptural entries |

| Casting (Lost Wax or Sand) | Medium-High (Ornate reliefs, hardware) | Medium (Mold prep required) | Medium (Repeatable with molds) | Decorative panels, custom pulls, escutcheons |

| Sheet Cladding on Wood/Steel Core | Medium (Flat/formed panels, edge treatments) | Short-Medium | High (Panelized systems) | Exterior/interior doors, commercial entries |

| Modern CNC Machining & Laser Cutting | Very High (Intricate patterns, tight tolerances) | Short (Digital workflow) | Very High (Precision batch production) | Contemporary designs, repeated motifs, engineered hardware |

For custom, hand-forged doors, artisans may heat and hammer copper into sculptural forms, adding chased or repoussé details for a tactile, old-world feel. Casting is ideal for hardware, relief panels, or when you want consistent decorative elements across multiple doors. Sheet cladding—where copper is formed over a wood or steel core—offers versatility for both traditional and modern door profiles, and is common in both residential and commercial settings.

Modern CNC machining and laser cutting have opened new creative possibilities. These technologies allow for intricate cutouts, perforations, or engraved motifs with high repeatability—perfect for commercial projects or when you need multiple doors with matching details. If you’ve seen copper door photos featuring geometric patterns or precise inlays, chances are they were produced with advanced digital tools.

Design Files That Speed Fabrication

Ready to bring your vision to life? Whether you’re working with a local artisan or a large fabrication shop, providing clear, vendor-ready drawings is the first step to a smooth project. Here’s a checklist to help you prepare:

- Accepted file formats (e.g., .dwg, .dxf, .step, .pdf for reference)

- Accurate dimensions (height, width, thickness, and core material)

- Finish notes (patina, brushed, hammered, clear-coated, etc.)

- Edge treatments (hemmed, wrapped, capped, or exposed)

- Hardware locations (hinges, locks, pulls, escutcheons)

- Panel layout (single slab, divided lite, decorative inlays)

- Tolerance expectations (if tight fits or alignment are required)

- Special requirements (fire rating, weatherstripping, glazing cutouts)

Supplying digital files with clear layer naming and callouts can save time and reduce costly back-and-forth. If you’re not sure which file type is best, most fabrication partners can advise based on their equipment and process.

Handling Misspellings and Search Variants

Noticed that people sometimes type “cooperdoor,” “copperdoor com,” or other variants when searching for fabrication resources or inspiration? Don’t worry—these are common slip-ups, and most reputable suppliers or image galleries will still surface relevant results. If you’re browsing for copper door photos or shop portfolios, try a few different spellings to see a wider range of examples. Just remember: the principles of quality fabrication and design apply no matter how you spell it.

In summary, whether you’re drawn to the artistry of hand-forged copper or the precision of modern machining, today’s fabrication landscape offers solutions for every style and scale. The next step? Explore how hardware, finishing, and thoughtful care routines can help your copper door age gracefully and perform beautifully for decades to come.

Hardware, Finishes, and Care

Hardware That Complements Copper

When you choose a copper door, every detail counts—including the hardware. Imagine a beautifully finished surface paired with hinges, locksets, and pulls that either blend in or stand out. The right hardware not only ensures smooth operation but also adds to the overall look and longevity of your entryway. For a cohesive design, many opt for copper alloy handles or knobs that echo the door’s finish. These can be polished for a subtle shine or left to patinate naturally, matching the evolving surface of the door itself.

- Hinges and pivots: Choose solid brass or copper-plated hardware for corrosion resistance and visual harmony.

- Locksets and pulls: Look for copper or bronze options, or select stainless steel for a modern contrast.

- Thermal breaks and weatherstripping: Essential for exterior copper doors, these hidden elements block drafts and moisture, preserving both comfort and the core materials.

- Glazing integration: If your copper door includes glass panels, specify compatible seals and trims to prevent leaks and maintain performance.

For inspiration, browsing the copper door photos or copper door salem photos online can spark ideas on hardware pairings and finishes that fit your style.

Finish Choices and Protective Coatings

Not sure which finish is right for your copper door? Each option offers a unique look and care routine. Let’s break down the most popular choices and what they mean for maintenance and appearance (reference):

- Natural patina: Embraces copper’s evolving color, from bright reds to deep browns and greens. Minimal upkeep—just occasional cleaning.

- Clear-coated: Preserves the original luster for a while, but the coating will eventually wear and need reapplication. Offers some protection against fingerprints and stains.

- Waxed or oiled: Deepens color and adds a subtle sheen. Needs regular touch-ups, especially in high-traffic or exterior locations.

- Brushed or hammered: Adds texture, diffuses light, and hides small scratches. Maintenance depends on whether you allow patina or apply coatings.

| Finish Type | Pros | Cons |

|---|---|---|

| Natural Patina |

|

|

| Clear-Coated |

|

|

| Waxed/Oiled |

|

|

If you’re visualizing how these finishes change over time, consider an image gallery approach. Before-and-after copper door photos (with alt text like “exterior copper door with natural patina”) can help you see what to expect as your door matures.

Care Routines That Age Gracefully

Sounds complex? It doesn’t have to be. Regular, gentle care is the key to keeping your copper door looking its best—whether you love its bright shine or the deep character of aged patina. Here’s a simple routine:

- Dust weekly with a soft, dry cloth—especially if your entry is near a busy street or garden.

- Clean with mild soap and water, using a soft cloth. Avoid harsh chemicals or abrasive tools.

- Spot-treat stains with a gentle mix of lemon juice and baking soda, then rinse and dry thoroughly.

- If you prefer a lasting shine, apply a clear lacquer or wax as needed—especially if the original coating has worn off.

- For high-traffic doors, increase cleaning frequency and check for any signs of wear on finishes or hardware.

Remember, over-polishing can strip away the protective patina and diminish copper’s natural resilience. Gentle, regular care preserves both beauty and performance.

Key Insight: A copper door’s color will never be perfectly uniform—and that’s the point. Patina variation is part of its enduring appeal, making every door one of a kind.

As you plan your project, think about how your hardware, finishes, and care routines will shape the story your door tells over time. In the next section, we’ll explore where copper doors truly shine—from historic renovations to bold, modern statements.

Where Copper Doors Excel

Ever wondered where a copper door makes the biggest impact? Whether you’re restoring a historic entry, designing a boutique hotel, or looking to add warmth to a contemporary home, copper’s versatility and visual drama set it apart. Let’s explore where these doors shine—and why architects and homeowners alike keep choosing them for signature spaces in places as varied as copper door new hampshire or urban residences in copper door salem ma.

Historic Charm with Modern Performance

Imagine walking up to a building that’s stood for generations. The original entry may have faded, but a new copper door—crafted with time-honored techniques—restores both function and grandeur. Copper’s ability to develop a rich patina makes it a favorite for heritage renovations. Artisans use methods like metal repoussage, manual oxidation, and controlled erosion to create details that echo the past while standing up to today’s performance needs.

- Heritage Entrances: Copper doors are often specified for historic restorations, where their evolving surface and tactile quality revive the spirit of original craftsmanship. The patina develops character that fits seamlessly with aged brick, stone, or ornate facades.

Hospitality Entrances That Signal Quality

When you step up to a boutique hotel, winery, or restaurant, the entry sets the tone. Copper-clad doors, whether sculpted with celestial motifs or finished with a dramatic brushed texture, signal exclusivity and attention to detail. For hospitality projects, designers often pair copper with contrasting materials—think dark wood, stone, or glass—to create a memorable first impression. In cities like the copper door new hampshire or copper door concord nh, these entries become local landmarks.

- Hospitality and Retail: Statement copper doors at the front of hotels, bars, or retail spaces draw guests in and reinforce a brand’s unique identity. Their warmth and sheen make guests pause, reflect, and anticipate what’s inside.

Residential Statements with Texture and Tone

For homeowners, a front door is more than just an entry; it’s a personal statement. Copper doors offer a spectrum of design possibilities—from minimalist slabs with subtle patina to doors featuring intricate, hand-forged patterns. In modern builds, they’re often paired with stucco, concrete, or dark siding to create inviting contrast and curb appeal. Over time, each door’s surface tells a unique story, reflecting the climate and lifestyle of its setting.

- Contemporary Homes: In neighborhoods from copper door salem ma to new developments across the country, copper doors bring warmth and artistry to otherwise clean, modern lines. They become the focal point that welcomes guests and anchors the home’s architectural character.

Key Insight: Pairing a copper door with materials like stone, stucco, or dark wood creates a high-impact facade—one that’s both timeless and tailored to its context.

From heritage buildings to hospitality venues and contemporary homes, copper doors excel wherever you want to combine artistry, performance, and a sense of place. As you plan your own project, consider how copper’s evolving patina and tactile finish can elevate your entryway—making it a conversation starter for years to come. Up next, we’ll guide diners and travelers to the right resources for the Copper Door Restaurant experience in New Hampshire.

Navigate The Copper Door Restaurant in New Hampshire

When you search for copper door salem nh or copper door bedford nh, you’re likely looking for an exceptional dining experience at one of New Hampshire’s most recognized restaurants—not a metal entryway. But with two distinct locations, a popular menu, and high demand for reservations, how do you make sure you’re headed to the right spot and get the most out of your visit? Let’s break it down so you can plan your meal with confidence—whether you’re a local, a traveler, or someone comparing bedford nh restaurants or restaurants salem nh for a special occasion.

Find The Copper Door in Bedford and Salem

Both Copper Door Restaurant locations—Bedford and Salem—offer their own unique ambiance, but share a commitment to upscale comfort food and welcoming service. To avoid confusion, verify which location fits your plans:

- Bedford: A popular choice for those searching for copper door bedford or "Bedford NH restaurants." Located conveniently off Route 101, it’s a go-to for lunch, dinner, and Sunday brunch.

- Salem: Sought out by diners using terms like the copper door salem nh, this location is easily accessible from I-93 and serves the southern New Hampshire and northern Massachusetts area.

- For up-to-date directions, use your preferred mapping tool or GPS app, as routes and traffic patterns can change.

Menus, Reservations, and What to Expect

Wondering what’s on the copper door menu or how to secure your table? Both locations offer seasonal menus featuring classic American dishes and inventive specials. Here’s how to make the most of your visit:

- Check the latest menu offerings, including brunch and seasonal items, on the official Copper Door website.

- For copper door reservations, book directly online for either Bedford or Salem. Reservations are accepted for the main dining room only, for parties up to 12 guests. Outdoor seating is first-come, first-served and cannot be reserved.

- Plan ahead for busy times, especially on weekends and holidays, as both locations are favorites among restaurants salem nh and bedford nh restaurants listings.

Parking, Accessibility, and Peak Times

Before you head out, it’s smart to confirm parking options, accessibility features, and peak dining hours. Here’s a quick checklist to ensure a smooth visit:

- Parking: On-site parking is available at both Bedford and Salem locations.

- Accessibility: The restaurant’s website details ongoing efforts to make facilities and online resources accessible to all guests. For specific accessibility questions or assistance, reach out via the contact information provided on their accessibility page.

- Contact: For questions about large parties, dietary restrictions, or special requests, use the contact form or phone numbers listed on the official site.

- Peak times: Expect higher demand during weekend evenings and special occasions. For real-time wait times or to confirm your reservation, call ahead or use online tools.

Before your visit, always check the official Copper Door website or trusted local directories for current menus, specials, and any dress code updates. Policies and offerings can change, so a quick confirmation ensures the best experience.

Traveling from another city? Instead of relying on fixed directions, use mapping apps for the most accurate, real-time routes to either copper door bedford nh or the copper door salem nh. This is especially helpful if you’re comparing options among bedford nh restaurants or exploring restaurants salem nh for your next meal out.

With a little planning, your Copper Door experience—whether in Bedford or Salem—will be memorable for all the right reasons. Next, we’ll help you compare fabrication paths for your copper door project, so you can move from inspiration to execution with confidence.

Compare Fabrication Paths for Your Copper Door Project

Ready to turn inspiration into a real copper door? Choosing the right fabrication path can make all the difference—whether you’re a homeowner wanting a statement entry, an architect specifying a large project, or a builder looking for reliable repeatability. Should you work with a local artisan, order a stock product, or partner with a precision machining service for custom panels and hardware? Let’s break down your options so you can move forward with confidence.

Choosing the Right Fabrication Path

Imagine you need a copper door that stands out for its quality, fit, and finish. The fabrication method you select shapes everything from lead time and budget to the final look and performance. Here’s a comparison to help you weigh your options:

| Fabrication Option | Features | Lead Time | Finish Consistency | Quality Control | Best For |

|---|---|---|---|---|---|

| XTJ CNC Machining Services |

|

As fast as 3 days | Excellent—digital workflow ensures matching parts | High—certified processes, robust inspection | Custom pulls, escutcheons, decorative panels, production runs |

| Local Artisan Shop |

|

Several weeks to months | Varies—unique patina and marks for each piece | Medium—depends on artisan’s process | Heritage restorations, sculptural entries, single doors |

| Stock or Semi-Custom Door Manufacturer |

|

1–4 weeks (varies by supplier) | Good—consistent finish for standard options | High—factory QC protocols | Budget-driven projects, quick replacements |

Notice how precision CNC machining stands out for projects that demand repeatability and perfect fit—especially when coordinating multiple components, like matching copper door pulls, trims, or custom panels. For example, if you’re comparing fabrication paths for a commercial entry or a series of residential doors, digital manufacturing can reduce rework and speed up installation, even for complex designs.

When Precision Machining Adds Value

Wondering if CNC machining is right for your copper door project? Here’s when it really shines:

- Prototype pulls or escutcheons: Need to test fit and finish before a full order? CNC allows rapid iteration with tight tolerances.

- Small-batch or production runs: For hotels, offices, or multi-unit residences, digital files ensure every piece matches, reducing surprises on site.

- Complex decorative panels: Intricate motifs, perforations, or engraved details are possible with 4- and 5-axis machining, delivering crisp results that hand tools can’t match.

- Finish coordination: Need brushed, patinated, or bead-blasted copper to match throughout a project? Digital machining and surface finishing can deliver uniformity across dozens—or hundreds—of parts.

XTJ’s digital workflow and rapid lead times (as fast as 3 days for some parts) help keep projects on schedule. Their engineering team can review your drawings and offer DFM (Design for Manufacturability) feedback to optimize both cost and performance. This is particularly valuable when your design calls for copper alloys like oxygen-free copper or beryllium copper, which require special handling for both machining and finishing (see their 5-axis machining capabilities).

Coordinating Finish Consistency Across Parts

You’ll notice that one of the biggest challenges in multi-part copper door projects is achieving consistent color and texture—especially if you’re sourcing panels, trims, and hardware from different vendors. Precision machining services like XTJ can help by:

- Applying the same finishing process (brushed, bead-blasted, patinated) to all parts in a single batch

- Documenting finish specs for future reorders or replacements

- Matching hardware and panels to your door’s main surface, reducing visual mismatch

- Delivering parts that are ready for installation, minimizing on-site adjustments

For custom projects, provide detailed drawings and finish notes up front. This ensures that even if you’re ordering in phases—say, prototype pulls first, then a full set for installation—your copper door’s components will look and fit as intended.

Practical Tip: For commercial or multi-unit projects, digital manufacturing not only speeds up production but also ensures every copper door, panel, and hardware piece matches perfectly—saving time and reducing costly rework.

As you weigh your options, consider what matters most: artisan uniqueness, fast turnaround, budget, or finish consistency. Reading copper door reviews or consulting with project managers who have handled installations in places like copper door manchester nh can also provide real-world insights into what fabrication method best fits your project goals. Next, we’ll wrap up with actionable steps and resources to help you move from idea to finished entryway.

Actionable Next Steps and Helpful Resources for Copper Door Projects and Dining

Key Takeaways for Architectural Projects

Durability, evolving beauty, and craftsmanship make copper doors a standout choice for both heritage and modern spaces. The right fabrication path—whether artisan, stock, or precision CNC—will shape your experience from design through installation.

When you’re ready to move forward with a copper door project, clarity and preparation are your best allies. Imagine having every detail in place: finish targets, hardware specs, and installation requirements. This not only streamlines fabrication but also ensures your vision translates perfectly from drawing board to finished entryway.

- Finalize your design specs and material choices—patina, brushed, or hammered?

- Gather detailed drawings, including hardware and glazing locations.

- Confirm finish targets and note any special climate or performance needs.

- Verify installation requirements—core type, edge treatments, and on-site conditions.

If your design calls for custom pulls, escutcheons, or precision-matched panels, consider partnering with a machining specialist like XTJ CNC Machining Services. Their expertise with copper and ability to deliver ultra-tight tolerances can help you achieve repeatable results—especially for projects where finish consistency and engineered fit are non-negotiable. Sharing your drawings and finish requirements up front allows for actionable DFM (Design for Manufacturability) feedback and accurate lead times, so you can avoid costly surprises and keep your project on track.

Quick Links for Diners and Visitors

For the best Copper Door Restaurant experience, always check official sources for the latest menus, hours, and reservation policies.

- Browse the copper door menu for seasonal offerings, brunch, and chef specials.

- Review copper door salem reservations and copper door bedford reservations online—main dining room only, parties up to 12.

- Check copper door hours and parking options before your visit.

- For recent guest feedback, see the copper door reviews on trusted platforms.

- Planning a midday meal? The copper door lunch menu highlights classic and contemporary options.

Remember, policies and offerings can change. For the most reliable information—especially around holidays or special events—consult the official website or call ahead. This is especially important for diners heading to the copper door bedford nh or the Salem location, where demand can be high and menus may feature limited-time specials.

From Idea to Finished Entryway

Feeling inspired? Whether you’re envisioning a signature entry for your home, a multi-door commercial project, or simply planning your next meal at a beloved New Hampshire restaurant, a little preparation goes a long way.

- Architects and homeowners: Confirm your specs, coordinate with your chosen fabricator, and schedule site checks before installation.

- Diners: Reserve your table, review the latest menu, and check copper door hours to ensure a seamless visit.

Every copper door—whether literal or culinary—tells a story of quality, tradition, and attention to detail. With the right resources and a bit of planning, you’ll enjoy results that stand the test of time.

Copper Door FAQs

1. What are the benefits of choosing a copper door for my home or business?

Copper doors offer natural patina, corrosion resistance, and antimicrobial properties, making them durable and low-maintenance. Their evolving appearance adds character to both traditional and modern spaces, while their robust construction ensures long-term performance.

2. How do I maintain the appearance of a copper door?

To maintain a copper door, clean it regularly with a soft cloth and mild soap, avoid harsh chemicals, and let the natural patina develop. For those who prefer a shinier look, clear coatings or wax can be applied, but these require periodic reapplication.

3. Where are the Copper Door Restaurant locations in New Hampshire?

Copper Door Restaurant has two locations: one in Bedford, NH, and another in Salem, NH. Both offer upscale comfort dining and accept reservations. Always check the official website for current menus, hours, and reservation policies.

4. What is the difference between solid copper doors and copper-clad doors?

Solid copper doors are made entirely of copper, providing a substantial feel and long lifespan. Copper-clad doors use copper sheets over a wood or steel core, offering similar aesthetics with added structural flexibility and lighter weight.

5. How can I ensure finish consistency across multiple copper door components?

For consistent finishes on pulls, trims, and panels, work with precision machining services like XTJ CNC. Providing detailed drawings and finish specifications upfront ensures all parts match in color and texture, reducing rework and installation issues.

-

Posted in

architectural doors, copper door, Copper Door Restaurant NH, custom door fabrication, door finishes