Custom Aluminum Parts Manufacturer | Rapid & Precision Services

TL;DR

As a leading custom aluminum parts manufacturer, we specialize in delivering high-precision components for everything from rapid prototyping to high-volume production runs. Our online platform allows you to upload design files and receive instant quotes for CNC machined and fabricated parts. We are committed to providing exceptional quality with fast turnaround times to keep your projects on schedule.

Our Custom Aluminum Manufacturing Capabilities

We provide a comprehensive suite of manufacturing services tailored to the unique properties of aluminum. Our facility is equipped with advanced machinery to handle projects of any complexity, ensuring your components are produced to exact specifications. Whether you require a single prototype or a full production run, our team has the expertise to translate your designs into tangible, high-quality parts. We focus on precision, speed, and manufacturability to provide a seamless experience from start to finish.

Our core strength lies in our ability to offer a diverse range of processes under one roof, simplifying your supply chain and accelerating your product development lifecycle. From initial machining to final finishing, we maintain rigorous quality control standards to guarantee every part meets your requirements. This integrated approach allows for greater efficiency, consistent quality, and clear communication throughout the manufacturing process.

Precision CNC Machining

Our CNC machining services are at the heart of our operations. We utilize state-of-the-art 3, 4, and 5-axis CNC machining centers to produce complex geometries with exceptional accuracy. This technology allows us to machine aluminum parts with tight tolerances and intricate features that are impossible to achieve with conventional methods. We work with a wide array of aluminum alloys, optimizing tool paths and cutting parameters to suit the specific grade you've chosen, ensuring optimal strength and surface finish. For businesses that need high-precision custom parts fast, services like XTJ CNC Machining Services offer an excellent example of delivering rapid prototyping and volume production with lead times from just a few days.

Sheet Metal Fabrication

For components requiring enclosures, brackets, or panels, our aluminum sheet metal fabrication services provide a robust solution. We employ a range of techniques including precision laser cutting, waterjet cutting, CNC bending, and forming. Our processes are ideal for creating durable yet lightweight parts from popular alloys like 5052-H32, which is known for its excellent formability and corrosion resistance. We also offer hardware insertion and tapping to deliver assemblies that are ready for immediate integration into your final product.

Finishing and Anodizing Services

To enhance the functional and aesthetic properties of your aluminum parts, we offer a variety of finishing services. Anodizing is a popular choice for aluminum, as it creates a hard, corrosion-resistant, and non-conductive surface layer. We provide Type II anodizing for a durable finish in various colors and Type III (hardcoat) for applications requiring maximum wear resistance. Other available options include powder coating for a durable, colored finish and chromate conversion coating to improve corrosion resistance while maintaining electrical conductivity.

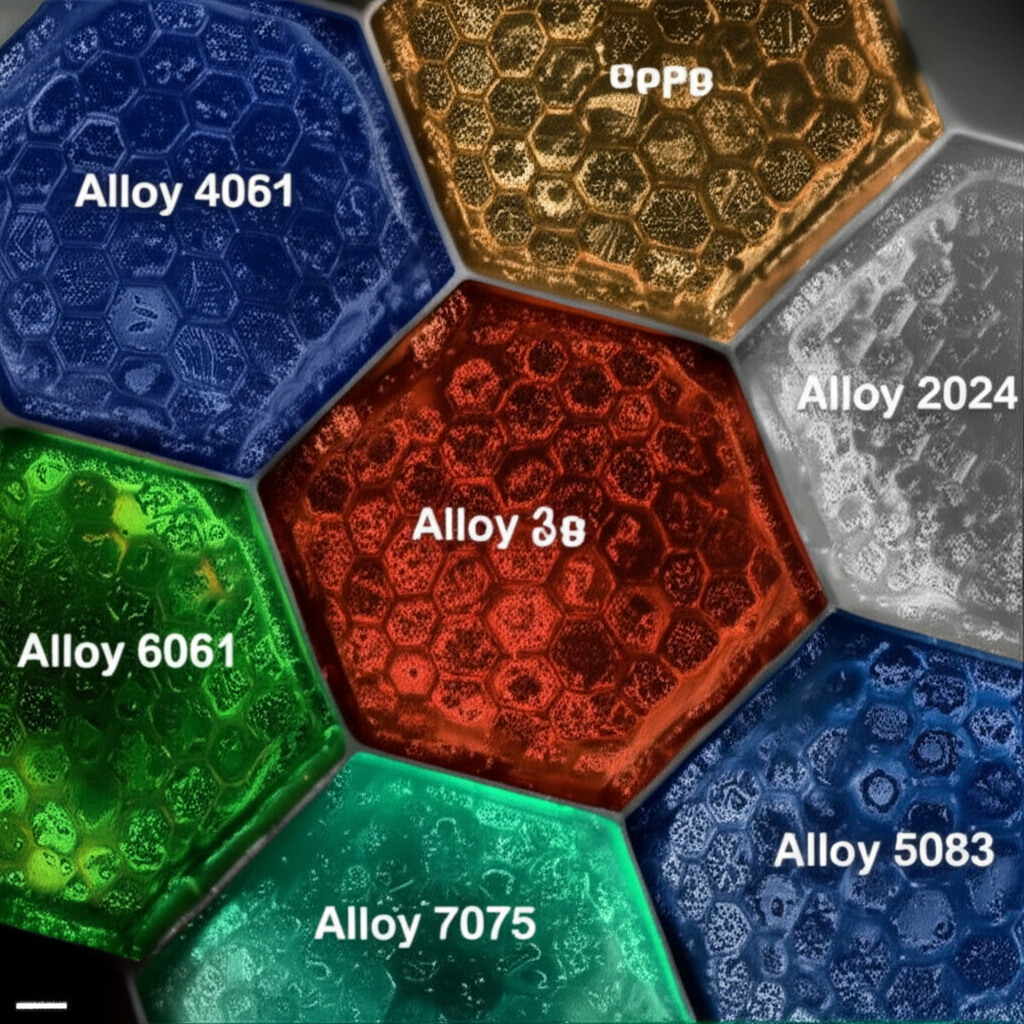

Aluminum Alloys We Work With

Selecting the right aluminum alloy is critical to the performance of your final product. Each alloy offers a unique combination of strength, weight, corrosion resistance, machinability, and cost. We stock a wide range of the most common and effective aluminum grades to meet diverse engineering requirements. Our team can provide guidance on the best material for your specific application, ensuring your parts have the optimal properties for success. The table below details some of the popular alloys we machine, drawing on specifications from industry leaders like Xometry and Protolabs.

| Aluminum Alloy | Key Properties | Common Applications |

|---|---|---|

| 6061-T6 | Excellent strength-to-weight ratio, good machinability, weldability, and corrosion resistance. | Structural components, bike frames, automotive parts, electronic enclosures. |

| 7075-T6 | Very high strength, good fatigue resistance, and fair machinability. | Aerospace components, high-stress parts, gears, rock climbing equipment. |

| 5052-H32 | Excellent corrosion resistance (especially in marine environments), good formability, not heat-treatable. | Sheet metal parts, fuel tanks, marine equipment, railings. |

| 2024-T3 | High strength and good fatigue resistance, but poor weldability and corrosion resistance. | Aircraft fittings, bolts, structural components under tension. |

| MIC-6 | Cast aluminum tool plate with excellent dimensional stability and flatness; no internal stresses. | Fixtures, assembly jigs, test structures, precision tooling. |

Our Simple 3-Step Process: From Design to Delivery

We have streamlined our manufacturing process to be as efficient and user-friendly as possible. Our goal is to minimize complexity and provide a clear path from your initial concept to the final delivered parts. This straightforward workflow ensures rapid quoting, transparent production, and reliable delivery, allowing you to focus on innovation.

-

Upload Your Design & Get an Instant Quote

The process begins when you upload your 3D CAD file (such as STEP or DXF) to our secure online portal. Our automated system analyzes your design's geometry to provide an instant, interactive quote. You can adjust materials, quantities, and finishing options in real-time to see how they affect the price and lead time, giving you full control over your project's budget and timeline.

-

Expert Review & Manufacturing

Once you approve the quote, your order moves to our engineering team for a design for manufacturability (DFM) review. This step ensures your design is optimized for the chosen process and material. After approval, your project is scheduled for production in our advanced manufacturing facility, where our skilled technicians and automated systems work to create your parts with precision and efficiency.

-

Quality Inspection & Fast Shipping

Quality is paramount. Every part undergoes a rigorous inspection process to ensure it meets your specifications and our high standards. We verify dimensions, finish, and overall quality before carefully packaging your components. Finally, your order is shipped directly to you, with options for expedited delivery to meet even the tightest deadlines.

Why Partner With Us for Your Aluminum Parts?

Choosing the right manufacturing partner is crucial for the success of your project. We are dedicated to providing more than just parts; we offer a reliable, responsive, and expert service designed to support your goals. Our commitment to technology, quality, and customer service sets us apart and makes us the ideal partner for your custom aluminum component needs.

-

Rapid Turnaround Times

In today's fast-paced market, speed is a competitive advantage. We have optimized every aspect of our process, from instant quoting to efficient production, to deliver your parts faster. We offer both rapid prototyping and scalable production runs with impressively short lead times, helping you accelerate your development cycle and get to market sooner.

-

Uncompromising Quality & Precision

We are committed to the highest standards of quality. Our operations are ISO 9001 certified, and we employ advanced inspection tools to ensure every part is manufactured to your exact specifications. With capabilities for tolerances as tight as +/- 0.005mm, we can handle the most demanding applications in industries from aerospace to medical devices.

-

Competitive, Transparent Pricing

Our instant online quoting engine provides full transparency. You receive a detailed cost breakdown immediately after uploading your design, with no hidden fees. This allows you to make informed decisions and manage your budget effectively. By leveraging automation and efficient processes, we offer competitive pricing for both single prototypes and large production volumes.

Frequently Asked Questions

1. How is aluminum manufactured into parts?

Aluminum parts are commonly manufactured through processes like extrusion, casting, rolling, forging, and CNC machining. CNC machining is a subtractive process where rotating tools cut material from a solid block to create a final shape. Sheet metal fabrication involves cutting, bending, and forming sheets of aluminum into the desired geometry.

2. How much does it cost to machine aluminum parts?

The cost of machining aluminum parts varies significantly based on complexity, size, quantity, tolerances, and the specific alloy used. Machining time is a primary cost driver. Simple parts in large quantities can be very affordable, while complex, single-prototype parts will have a higher per-unit cost. Using an instant online quoting tool is the best way to get an accurate price for a specific design.

3. Who is the largest manufacturer of aluminum in the US?

Alcoa Corporation is a global leader in the aluminum industry and one of the largest manufacturers in the United States. They are involved in various stages of aluminum production, from bauxite mining to producing finished aluminum products.

-

Posted in

aluminum fabrication, cnc machining, custom aluminum parts, rapid prototyping, sheet metal services