Does Aluminium Rust? Choose Alloys And Coatings That Last

The Short Answer and What Rust Really Means for Aluminum

Aluminum does not rust like iron or steel; it corrodes by forming aluminum oxide, which is usually protective.

Short answer

If you have ever wondered, "does aluminium rust?"—the answer is clear: it cannot rust in the way iron or steel does. Rust is a specific type of corrosion that only affects iron-containing metals. Instead, when aluminum is exposed to air and moisture, it forms a thin, tough layer of aluminum oxide. This layer acts as a natural barrier, shielding the metal underneath from further attack. So, while you might see dull gray patches or even white, powdery spots on neglected aluminum, this is not the reddish-brown rust familiar from old steel tools or fences.

Rust versus corrosion in plain language

It’s easy to mix up the terms, especially when you see any kind of surface change on metal. Here’s how to keep them straight:

- Rust = Iron oxidation (iron or steel + water/oxygen → iron oxide, the flaky red stuff)

- Corrosion = The broader breakdown of metals by chemical or electrochemical reactions (can affect any metal)

- Aluminum oxidation = Formation of a thin, adherent alumina (aluminum oxide) layer, not rust

Think of corrosion vs oxidation like this: oxidation is the chemical reaction with oxygen, while corrosion is the larger process that causes metal to deteriorate. Rust is just one result—specific to iron. Aluminum, on the other hand, forms a protective oxide layer that usually prevents deeper damage, unless conditions are especially harsh.

What this means for real-world parts

Imagine leaving an aluminum window frame or roof out in the rain for years. You’ll notice it doesn’t flake away like old steel. That’s because the oxide coating forms quickly and seals the surface. This is why aluminum is popular for outdoor structures, siding, and enclosures—it’s lightweight and resists visible decay in most environments. However, it’s not invincible. Salt spray near the ocean, trapped water in tight joints, or contact with other metals can still cause aluminum rust-like damage (though technically it’s corrosion, not rust).

In harsh conditions, you might see white powdery spots or a dull film—signs of oxidized aluminum. These are reminders that, while aluminum is durable, it still needs the right design and care to last.

What you will learn next

- Why aluminum resists rust, but can still corrode

- How passivation and oxide layers work

- Which environments put aluminum at risk

- Design tips to prevent corrosion

- How to choose the right alloy and finish

- Maintenance and cleaning best practices

By understanding the difference between corrosion vs oxidation and knowing how to spot and prevent issues, you’ll be ready to make the most of aluminum’s strengths—and avoid surprises down the road.

Why Aluminium Does Not Rust But Can Corrode

Why doesn't aluminum rust?

Ever left a steel tool outside and watched it turn reddish-brown? That’s rust—iron oxide. But when you leave aluminum in the same spot, you’ll notice something different. Instead of flaking rust, you might see a thin, dull film or white powder. That’s because aluminum doesn’t rust like iron or steel. Instead, it undergoes a process called oxidation in aluminum, forming a protective layer of aluminum oxide that shields the metal underneath from further damage.

How passivation works

Sounds complex? It’s actually a natural defense mechanism. Here’s what happens step by step:

- Fresh aluminum surface reacts instantly with oxygen in the air or water.

- This reaction forms a thin, tightly-adhering layer of aluminum oxide on the surface.

- If the layer gets scratched or lightly damaged, it self-heals by reforming in the exposed area, limiting further attack.

This process, called passivation, is what gives aluminum its reputation for durability and makes it a popular choice for outdoor and industrial applications. The oxide layer is non-reactive and does not flake off, unlike rust on steel, so the metal beneath stays protected in most environments.

Common corrosion modes: when protection fails

But is aluminum invincible? Not quite. Certain conditions can defeat this natural barrier. Here’s what causes aluminum corrosion in real-world situations:

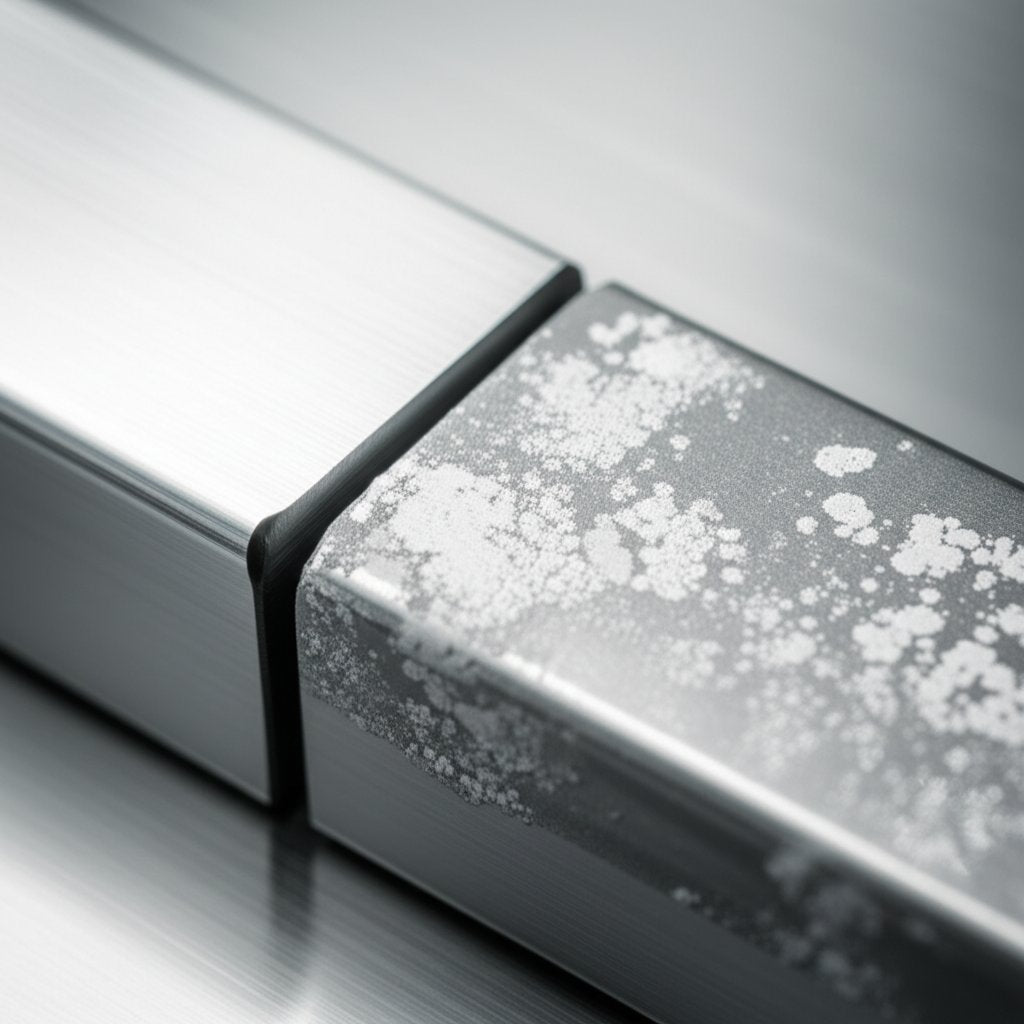

- Pitting corrosion: Localized spots—often tiny holes—form when chloride ions (like from road salt or seawater) break down the oxide layer.

- Crevice corrosion: Moisture trapped in overlaps, joints, or under fasteners creates hidden pockets where the oxide layer can’t reform, leading to accelerated attack.

- Galvanic corrosion: When aluminum touches a more noble metal (like brass or copper) in the presence of an electrolyte (such as water), electrons flow and aluminum corrodes quickly at the contact point.

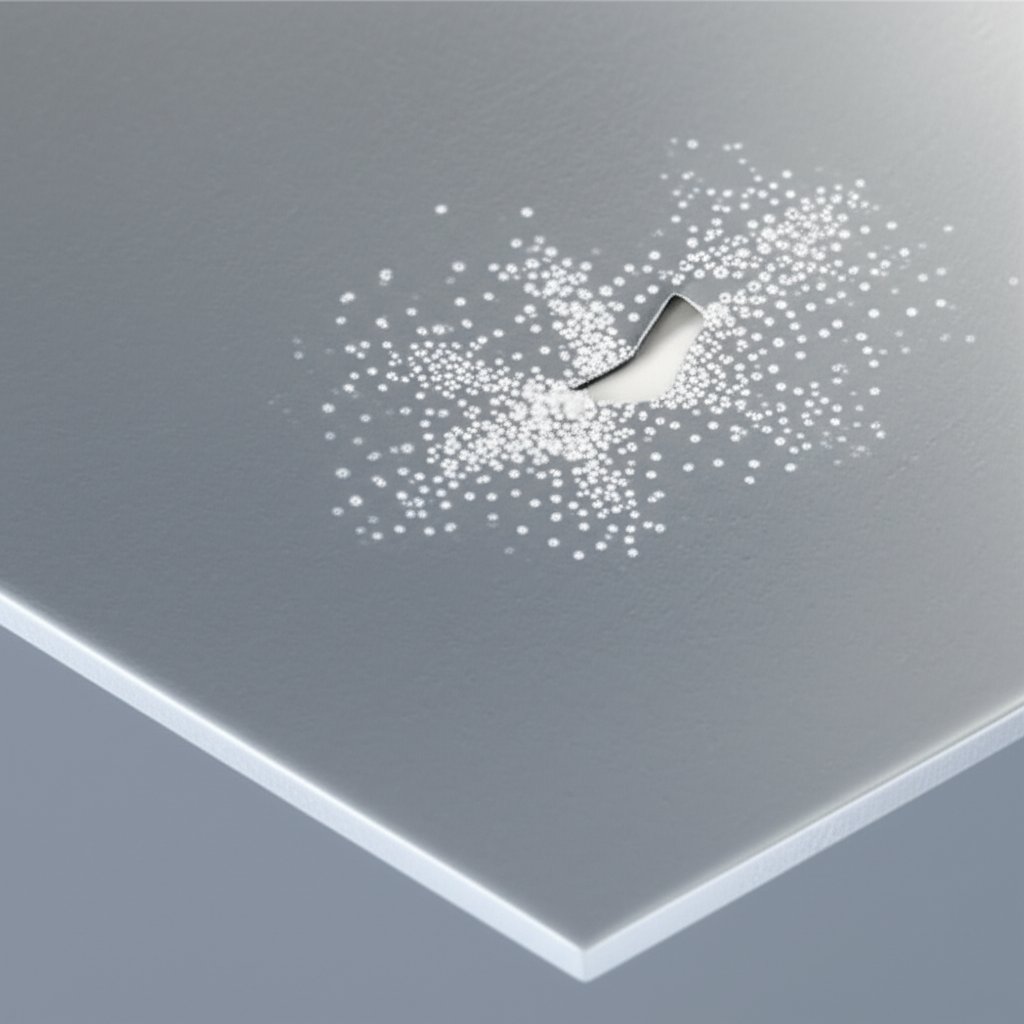

- Filiform corrosion: Under damaged paint or coatings, corrosion can spread like fine threads, especially in humid, salty environments.

- Stress-corrosion cracking: Certain high-strength aluminum alloys can crack and fail if exposed to the right combination of stress, moisture, and corrosive agents.

Each type of aluminum corrosion has its own triggers and appearance, but all share a common theme: when the oxide layer is compromised or overwhelmed, corrosion can progress.

Aluminum ‘doesn’t rust’ because rust is iron oxide, but it can corrode—especially in saltwater, tight crevices, or when touching dissimilar metals.

Practical implications

If you’re designing or maintaining aluminum parts, here are some simple strategies to keep corrosion at bay:

- Shed water: Design parts and assemblies to drain easily and avoid water traps.

- Isolate dissimilar metals: Use plastic washers, gaskets, or coatings to prevent direct contact with more noble metals.

- Choose the right finishes: In salt-rich or polluted environments, select coatings or anodizing that reinforce the oxide barrier.

Understanding aluminum oxidation and the mechanisms behind does aluminum corrode helps you make smarter choices about material selection, design, and maintenance. In the next section, we’ll look at how different environments—from clean air to coastal zones—affect the risk and appearance of aluminum corrosion, and what you can do to mitigate it.

Environmental Factors That Accelerate Corrosion in Aluminum

Where aluminum thrives

Ever wondered why aluminum is the go-to choice for window frames, outdoor enclosures, or even poolside furniture? In many environments, especially those with clean air and good drainage, aluminum’s natural resistance shines. When placed in rural settings or suburban areas with low pollution, and when water is allowed to drain freely, you’ll find that aluminum surfaces stay clean and intact for years. The protective oxide layer forms and stays put, meaning does aluminum rust outside?—not in the traditional sense. Instead, you get a stable, low-maintenance material that’s ideal for most outdoor applications.

Where aluminum struggles

But what happens when conditions are less forgiving? Imagine installing a pool enclosure aluminum frame right next to a chlorinated pool, or using aluminum structures near the ocean. Coastal air is rich in salt (chlorides), and pool chemicals can be aggressive. In these settings, the oxide layer can be breached, leading to pitting or crevice corrosion. Likewise, in industrial urban zones, airborne pollutants and acid rain can accelerate attack, especially if surfaces are not regularly cleaned. Areas with frequent temperature swings or high humidity can also promote condensation—trapping moisture in joints or crevices and raising the risk of corrosion.

| Environment | Risk Level | Typical Issues | Mitigation Strategies |

|---|---|---|---|

| Clean rural/outdoor | Low | Minimal corrosion, stable oxide layer | Basic design, occasional cleaning |

| Freshwater exposure | Low to Moderate | Possible staining if water is trapped | Ensure drainage, avoid standing water |

| Coastal/marine | High | Pitting, crevice corrosion from salt spray | Use coatings/anodizing, rinse regularly, seal joints |

| Pool enclosures | Moderate to High | Chlorinated moisture, white powdery spots | Regular cleaning, protective finishes, ventilate |

| Industrial urban | Moderate to High | Deposits, acid/alkaline attack, surface dulling | Frequent cleaning, select resistant alloys, apply coatings |

So, does aluminum rust in water? Technically, it does not rust, but it can corrode if the water contains salts or if water is trapped in joints. Will aluminium rust in water? Not in the way iron does, but prolonged exposure—especially in pools or coastal zones—can lead to visible white powder (aluminum hydroxide) or dull, rough patches. If you’re asking, "can aluminum rust in water?"—the answer is no to rust, but yes to corrosion if the environment is aggressive enough.

What to watch for outdoors

When inspecting aluminum outdoors, look for:

- White, chalky deposits (signs of pitting or crevice corrosion)

- Dull or rough patches where the oxide layer is compromised

- Localized holes or spots, especially near fasteners or joints

- Staining under gaskets or at the base of enclosures

If you’re curious about what does aluminum corrosion look like, it’s often less dramatic than steel rust—think subtle powder, small pits, or a faded finish rather than flaking red rust.

Design notes

- Keep joints open and drainable to prevent water accumulation

- Seal overlaps and edges to keep out moisture and contaminants

- Avoid sharp crevices where water and debris can collect

- Specify compatible fasteners to minimize galvanic corrosion risk

Environment sets the baseline risk; design and maintenance determine outcomes.

Understanding how different environments affect aluminum means you can make smarter choices about installation, materials, and care. Next, we’ll explore specific design strategies to prevent galvanic attack and keep your aluminum structures resilient, even in tough conditions.

Design Practices to Prevent Galvanic Attack in Aluminum Assemblies

Isolate dissimilar metals

Ever wondered why mixing stainless steel and aluminum parts can sometimes lead to unexpected failures? The answer lies in galvanic corrosion—a process where two different metals in electrical contact, exposed to an electrolyte like water, form a tiny battery. In this setup, aluminum acts as the anode and corrodes faster, while the stainless steel or carbon steel acts as the cathode and stays protected. This is why stainless steel and aluminum corrosion is a real concern in many assemblies, especially outdoors or in damp environments.

So, does stainless steel react with aluminum? Yes—if you bolt them together without proper isolation, you set the stage for stainless to aluminum corrosion. But you can break this chain:

- Electrically isolate aluminum from stainless or carbon steel using non-conductive washers, sleeves, or specialized coatings between the metals.

- Seal joints and interfaces with approved gaskets or sealants to keep out moisture and block electrolyte paths.

- Consider using plastic or polymer fasteners and spacers where strength requirements allow.

Drain and ventilate joints

Imagine water sitting in a tight crevice between two metals—this is the perfect storm for corrosion. To minimize aluminum and steel corrosion, design your assemblies so water can’t get trapped. Here’s how:

- Shape joints and overlaps with drain paths so moisture flows out, not in.

- Ventilate enclosed spaces to prevent condensation buildup.

- Seal lap joints and edges to block chloride ingress, especially in marine or poolside environments.

- Break capillary crevices by using larger radii or spacers—sharp, tight corners are trouble spots.

Choose compatible fasteners

Fasteners are often the weak link in aluminum assemblies. Mixing metals without a plan can accelerate steel on aluminum corrosion. To avoid this, match fastener materials as closely as possible to the base metal, or ensure robust isolation. Stainless fasteners can be used with aluminum, but only if they’re properly separated by isolators and sealed against water ingress.

| Design Step | Best Practice |

|---|---|

| Identify dissimilar contacts | Map all stainless, steel, and aluminum interfaces early in design |

| Specify isolation hardware | Use non-conductive washers, sleeves, and sealants |

| Define coatings and sealing | Apply primers, choose compatible topcoats, seal edges before assembly |

| Provide drainage/venting | Incorporate drain holes and open joints to shed water |

| Document maintenance access | Ensure joints and fasteners are accessible for inspection and resealing |

- Identify all points where dissimilar metals will touch.

- Specify isolation hardware (washers, sleeves) and compatible sealants.

- Define your coating stack: primer, topcoat, and edge sealing.

- Design in drain/vent features to keep joints dry.

- Document how maintenance will be done—easy access is key.

Galvanic corrosion needs a metal pair, an electrolyte, and electrical contact; break any link and risk falls sharply.

Practical notes and honest tips

- Stainless fasteners are fine with aluminum if isolated and sealed. Over-torquing can crush isolators—use proper torque settings.

- Always check that your sealants and isolators are compatible with both your coatings and the expected temperature range.

- If you’re unsure about material compatibility, consult a galvanic series chart or reach out to a materials expert for guidance.

By following these design strategies, you can dramatically reduce the risk of corrosion stainless steel and aluminum assemblies face, even in challenging environments. Next, we’ll look at how choosing the right aluminum alloy can further boost your corrosion resistance and make your projects last longer.

Choosing the Right Aluminium Alloy for Corrosion Resistance

How alloying changes corrosion behavior

When you’re selecting aluminum for your next project, have you ever wondered why some grades last for decades outdoors, while others need extra protection? It all comes down to alloying. Pure aluminum is naturally corrosion resistant, but it’s also soft and not very strong. By adding elements like magnesium, copper, silicon, or zinc, manufacturers can tailor aluminum’s properties for different applications—but these changes also affect how well the alloy stands up to harsh environments.

Sounds complex? Here’s the simple truth: higher purity and magnesium content usually boost corrosion resistance, while copper and zinc can reduce it. That’s why understanding aluminum alloy corrosion resistance is key to getting the durability you need, especially in marine or industrial settings.

Common series at a glance

Let’s break down the most common aluminum alloy families and see how they stack up for corrosion resistance, weldability, and typical uses. This table gives you a quick, practical overview:

| Alloy Series | Corrosion Resistance | Common Uses | Weldability | Best Environment Fit |

|---|---|---|---|---|

| 1xxx (Pure) | Very High | Enclosures, electrical bus bars, chemical handling | Excellent | General outdoor, electrical, food/chemical |

| 3xxx (Manganese) | High | Heat exchangers, cookware, automotive trim | Good | General outdoor, mild industrial |

| 5xxx (Magnesium) | Very High | Marine, transportation, building panels | Excellent | Marine, de-icing, harsh outdoor |

| 6xxx (Magnesium & Silicon) | Moderate to High | Structural frames, extrusions, automotive, consumer electronics | Good | General outdoor, structural, moderate marine |

| 2xxx (Copper) | Lower | Aerospace, high-strength components | Poor | Protected, dry, or coated environments |

| 7xxx (Zinc) | Lower | Aerospace, sports equipment, high-stress parts | Poor to Moderate | Needs robust coating if exposed |

Match alloy to environment

Still not sure which is the best corrosion resistant aluminium for your application? Use these quick tips to guide your selection:

- For marine or de-icing salt exposure: Choose a 5xxx series alloy (like 5052 or 5083) and pair it with proper finishing for maximum aluminum corrosion resistance.

- For general outdoor structures and extrusions: 6xxx series (such as 6061 or 6063) offers a great balance of strength and corrosion resistance. It’s widely used for frames, enclosures, and consumer products.

- For high-strength, critical components: 2xxx and 7xxx series deliver exceptional strength but have lower corrosion resistance. Always specify robust coatings or limit use to protected environments.

- For excellent formability and resistance: 1xxx and 3xxx alloys are ideal for enclosures, cookware, and chemical handling, thanks to their high aluminium corrosion resistance and easy fabrication.

By matching your alloy choice to the environment and application, you can ensure long-lasting performance and minimize maintenance headaches. Remember, corrosion resistance of aluminum alloys isn’t just about the base metal—it’s about the right alloy, finish, and design working together. Next, we’ll look at how protective coatings and surface treatments can further extend the life of your aluminum parts in challenging conditions.

Finishes and Coatings That Protect Aluminium in Demanding Environments

Anodizing for Durable Oxide Protection

When you want to make sure your aluminum parts stay looking sharp and last for years, the right surface treatment makes all the difference. Imagine you’ve installed a sleek aluminum railing by the ocean or built enclosures that see constant rain—how do you keep them from dulling or developing aluminium tarnish? That’s where anodizing comes in.

Anodizing is a process that thickens and toughens the natural oxide layer on aluminum. Instead of adding a separate coating, anodizing uses the metal itself to create a porous, hard, and aluminium corrosion resistant surface. This layer not only fends off most forms of corrosion but also resists wear and fading. Hard anodizing, a specialized form, builds an even thicker barrier for high-wear or harsh settings. The result? Less does aluminum tarnish, more longevity—especially in architectural, automotive, or marine uses.

Conversion Coatings as Primers

Sounds technical? Conversion coatings are simply chemical treatments that prepare aluminum for further finishing. They act as a primer, improving the bond between the base metal and any paint or powder you might apply next. Chromate-free options are now widely used for environmental safety. While these coatings offer some aluminum corrosion protection on their own, their real value is in boosting the durability and adhesion of topcoats. If you’re planning to paint or powder-coat your parts, a conversion layer is a smart first step.

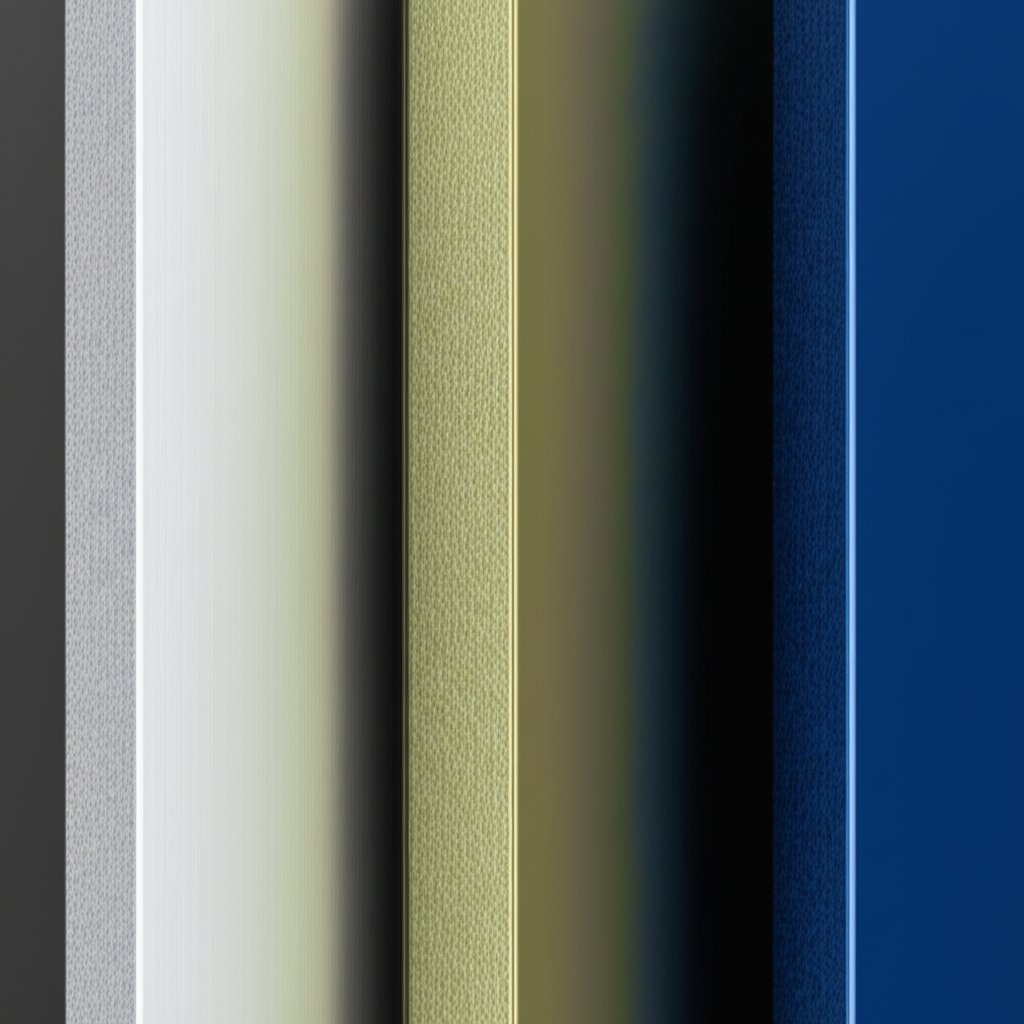

Paint and Powder Coating Systems

For barrier protection and aesthetics, paint and powder coatings are the go-to solutions. Picture a pool enclosure or an outdoor sign—these finishes shield aluminum from splashes, salts, and sun, while letting you pick from a rainbow of colors. Powder coating, in particular, creates an even, tough layer that resists chipping and fading. Both systems can be applied over anodized or conversion-coated surfaces for maximum aluminium corrosion protection.

But remember: no paint or powder can do its job if water sneaks under the surface. That’s why sealing edges and fastener holes is critical—especially in joints and corners where moisture likes to hide. Without good sealing, even the best aluminium protective coating can fail prematurely.

| Finish Type | Key Benefits | Best-Use Environments | Edge Sealing & Maintenance |

|---|---|---|---|

| Anodizing | Durable, integral oxide; wear & corrosion resistant | Architectural, marine, high-wear parts | Seal edges for max life; easy to clean |

| Conversion Coating | Improves paint adhesion; baseline protection | Under paint or powder, electronics, mild outdoor | Seal after topcoat; inspect for scratches |

| Powder Coating | Thick, uniform barrier; color options; chip resistant | Outdoor furniture, railings, signage | Seal fastener holes; periodic cleaning |

| Liquid Paint | Low cost; many colors; hides surface flaws | Low-budget, low-wear, or indoor parts | Check for peeling; reseal as needed |

How to Choose the Right Protection System

- Assess your environment and how often you’ll inspect the part (marine, poolside, industrial, or mild outdoor?).

- Pick a foundation treatment: anodize for durability, or conversion coat if you’ll paint or powder-coat.

- Decide if you need a barrier topcoat—especially important if you expect splashes, salts, or heavy wear.

- Specify edge sealing and fastener isolation to prevent underfilm attack.

- Define a simple cleaning routine to keep the finish in top shape.

Coatings work as systems; surface prep, primers, and edge sealing often matter more than coat thickness alone.

By combining the right treatments—anodizing, conversion coatings, and barrier finishes—you can create truly aluminium corrosion resistant parts that shrug off harsh weather, chemicals, and daily wear. Next, we’ll walk through inspection and maintenance steps to keep those finishes performing for years to come.

Inspection, Cleaning, and Repair Workflow for Aluminum Corrosion

Routine Inspections: Spotting Problems Early

Ever noticed a white, chalky film or dull spots on your aluminum railing, window frame, or equipment? That’s often the first sign of oxidation on aluminium or early-stage corrosion. Regular inspections are your best defense against long-term damage. In harsh or high-moisture environments—like near pools, coastlines, or industrial sites—set a routine to check all exposed aluminum surfaces at least once per quarter.

- Look for white powdery deposits, bubbling or blistered paint, and streaks near fasteners and seams.

- Pay extra attention to joints, overlaps, and areas where water may collect or drain slowly.

- Note any aluminum stain or discoloration that wasn’t there before—these can be early warning signs of deeper issues.

Cleaning and Corrosion Removal: Step-by-Step

When you spot corrosion, don’t panic—most cases of cleaning corroded aluminum are manageable with the right approach. Here’s a practical workflow that works for everything from window frames to cookware:

- Rinse with Freshwater: Start by rinsing the affected area with clean water to remove loose salts, dirt, and debris. This helps prevent further abrasion during cleaning (UL Prospector).

- Use a pH-Neutral, Aluminum-Safe Detergent: Mix a gentle, non-abrasive cleaner with water and apply with a soft brush or cloth. Avoid harsh chemicals or alkaline cleaners that can damage the oxide layer.

- Never Use Steel Wool or Stainless Brushes: These can embed iron into the surface, leading to rust on aluminum or galvanic spots. Stick to non-ferrous pads or soft sponges.

- Localized Corrosion Removal: For stubborn spots, gently abrade the area with a non-ferrous, fine-grade abrasive pad—always move with the grain to avoid scratches. Wipe clean with a damp cloth.

- Dry Thoroughly: After cleaning, use a dry cloth to remove all moisture and prevent new water stains or oxidation on aluminium.

For cookware, specialty items, or heavily oxidized surfaces, you may use a paste of baking soda and lemon juice, or a commercial aluminum brightener. Let the paste sit for up to 10 minutes before wiping away.

Repair and Reseal: Restoring Protection

Once you’ve completed aluminum corrosion removal, it’s time to restore protection and keep the problem from returning:

- Apply a Conversion Treatment: For bare or abraded areas, use a chromate-free conversion coating or primer designed for aluminum. These products help the new finish adhere and provide a corrosion-inhibiting base. Always follow manufacturer instructions for dwell times and application.

- Recoat with Primer and Topcoat: Once the conversion treatment is dry, apply a compatible primer and then a durable topcoat (paint or powder) if the item is exposed outdoors. Be sure to seal all edges, seams, and fastener heads to block moisture ingress.

- Document and Recheck: Keep a maintenance log of all cleaned and recoated areas. Re-inspect after exposure to harsh weather or chemicals to catch any recurrence early.

| Essential Materials for Aluminum Maintenance |

|---|

| Aluminum-safe detergent |

| Soft brushes or microfiber cloths |

| Non-ferrous abrasive pads |

| Chromate-free conversion treatment |

| Compatible primer and topcoat |

| Sealant for edges and fasteners |

Do not mix stainless brushes or carbon-steel tools with aluminum surfaces; embedded iron can create rust-like staining and galvanic sites.

With these steps, corrosion removal on aluminum becomes a regular, manageable part of your maintenance routine. By staying proactive, you’ll extend the life of your aluminum parts and keep them looking their best—no matter the environment. Next, we’ll see how industry standards and testing methods help verify your corrosion control strategy works as intended.

Standards and Test Methods for Verifying Aluminum Corrosion Resistance

Accelerated Exposure Tests: Salt Spray and Beyond

When you want to know if your aluminum parts will withstand years of tough service, waiting for real-world results isn’t practical. That’s where accelerated exposure tests come in. Ever heard of the salt spray test? Imagine putting your aluminum samples in a chamber filled with a fine mist of salty water—mimicking the harshness of coastal air or winter roads, but at lightning speed. This is the backbone of comparative testing for corrosion aluminium performance.

The most widely recognized standards for this are ASTM B117 and ISO 9227. These procedures specify how to prepare the salt solution, control the temperature, and assess the results—ensuring that every lab’s results are consistent and reliable. Salt spray testing is especially useful for ranking the relative durability of different coatings or alloys, helping you spot weaknesses before your product ever leaves the factory.

- ASTM B117 / ISO 9227: Neutral salt spray test for evaluating corrosion resistance of metallic coatings and alloys

- ASTM G85: Modified salt spray methods for cyclic, acidified, or more aggressive exposures

Keep in mind: these tests are fast and severe—they focus on salt-driven attack, which is only one type of aluminum corrosion. While they’re invaluable for comparison, they don’t predict exact service life in every environment.

Alloy Susceptibility Tests: Digging Deeper Into Material Behavior

Not all aluminum alloys react the same way to corrosive conditions. Some are more prone to intergranular or exfoliation attack, especially high-strength grades. Specialized tests help pinpoint what is aluminum corrosion for your chosen alloy:

- ASTM G66 / G67: Assess intergranular corrosion in 5xxx series aluminum-magnesium alloys. G66 uses visual assessment after exposure, while G67 measures mass loss after nitric acid immersion.

- ASTM G34: Exfoliation corrosion susceptibility, especially for 2xxx and 7xxx series alloys used in aerospace or high-stress parts.

These methods help you select alloys and tempers that are less likely to suffer hidden or catastrophic corrosion in aluminum structures, especially in critical applications.

Electrochemical and Galvanic Evaluation: Testing Metal Pairings

Ever worried about mixing aluminum with stainless steel or other metals? Electrochemical and galvanic tests reveal how quickly corrosion aluminium can occur at these junctions. Standards like ASTM G71 guide the setup and interpretation of galvanic corrosion tests in electrolytes—helping you design safer, more durable assemblies. For stainless behaviors in mixed-metal assemblies, ASTM G48 is commonly referenced.

- ASTM G71: Conducts and evaluates galvanic corrosion tests between different metals in electrolytes

- ASTM G48: Pitting and crevice corrosion resistance testing for stainless steels (useful when pairing with aluminum)

These tests are essential for confirming that your chosen fasteners, coatings, and joint designs won’t create unexpected corrosion of aluminum when exposed to moisture or salts.

Salt spray and cyclic tests are comparative screening tools, not direct predictors of service life; they help rank systems under controlled conditions.

Consulting the Right Standards: A Quick Reference List

- ASTM B117 / ISO 9227 – Neutral salt spray (fog) test

- ASTM G85 – Modified, cyclic, or acidified salt spray

- ASTM G66 / G67 – Intergranular corrosion susceptibility (5xxx alloys)

- ASTM G34 – Exfoliation corrosion (2xxx, 7xxx alloys)

- ASTM G71 – Galvanic corrosion evaluation

- ASTM G48 – Stainless steel pitting/crevice (for mixed assemblies)

For a more exhaustive list of relevant standards, visit the ASTM Corrosion Standards Resource.

By applying these recognized standards, you can confidently verify the corrosion aluminium resistance of your parts and coatings—ensuring your design choices hold up in the real world. Next, we’ll compare aluminum to stainless and carbon steel, so you can make the best material choice for your next project.

Aluminium Versus Stainless and Carbon Steel

When aluminum is the right choice

Ever wondered, "what metal does not rust" when exposed to the elements? While no metal is truly immune to all forms of corrosion, aluminum comes impressively close for many everyday uses. Thanks to its natural oxide layer, aluminum resists atmospheric corrosion and won’t develop the flaky red rust seen on iron or steel. Its lightweight nature also makes it ideal for applications where weight reduction is a priority—think transportation, window frames, and outdoor enclosures. If you need a metal that doesn’t rust in typical outdoor conditions and is easy to shape, aluminum often stands out as the best fit.

When stainless makes sense

But sometimes, you need more than just lightweight and rust resistance. Stainless steel shines in environments where hygiene, chemical resistance, or frequent cleaning are essential—such as kitchens, medical equipment, or chemical plants. The chromium oxide layer in stainless provides robust protection against many forms of corrosion, including those that can challenge aluminum. However, stainless is heavier and often more expensive, so it’s best reserved for situations where its unique strengths are needed. If you’re comparing “what metal will not rust” in aggressive chemical or saltwater settings, stainless steel is a top contender—just remember that aluminum steel corrosion can occur if the two metals are joined without proper isolation.

When carbon steel is viable

Looking for strength on a budget? Carbon steel is widely used for its toughness and low cost. It’s a workhorse in construction, machinery, and automotive frames. However, does alloy steel rust? Yes—unless it’s protected by coatings or galvanization, carbon steel will rust quickly in moist or outdoor environments. This means regular maintenance and finishing are a must. Will alloy steel rust indoors? It’s less likely if kept dry, but vigilance is key. For projects where cost is the main concern and exposure to moisture is limited, carbon steel can be a smart pick.

| Attribute | Aluminum | Stainless Steel | Carbon Steel |

|---|---|---|---|

| Weight | Very light | Moderate to heavy | Heavy |

| Corrosion Behavior | Resists atmospheric corrosion, forms protective oxide | Highly corrosion resistant (chromium oxide layer) | Rusts rapidly without coatings |

| Maintenance Needs | Low (routine cleaning) | Low to moderate (cleaning, rare passivation) | High (regular painting, inspection) |

| Finishing Options | Anodizing, powder/paint, conversion coatings | Polishing, passivation, paint (if desired) | Galvanizing, painting, powder coating |

| Common Applications | Windows, enclosures, transport, electronics | Kitchens, medical, marine, architectural | Beams, frames, machinery, infrastructure |

Quick selection cues

- Choose aluminum for weight-sensitive structures and good general corrosion performance—especially when you want a metal that doesn't rust in typical outdoor use.

- Choose stainless steel where hygiene, aggressive chemicals, or saltwater are present, and when you need a material that resists nearly all forms of rust.

- Choose coated carbon steel for budget-driven projects in dry or controlled environments, but plan for ongoing maintenance.

Is aluminum waterproof? While no metal is truly waterproof, aluminum’s oxide layer means it won’t rust or degrade in rain or humidity the way untreated steel will. Still, for submerged or harsh chemical environments, proper alloy and finish selection is vital.

Choosing the right metal isn’t about finding the one that never rusts—it’s about matching each material’s strengths to your project’s real-world demands.

With this comparison, you can confidently weigh the pros and cons of each option for your next design. Up next, we’ll see how smart manufacturing and finishing choices lock in corrosion resistance from the drawing board to the final part.

From Design to Finished Parts

Design for Corrosion and Manufacturability

When you’re planning a new aluminum part, it’s easy to focus on shape, fit, or function—but what about long-term durability? Imagine investing in a sleek enclosure or structural frame, only to discover months later that crevice corrosion or galvanic attack is eating away at your investment. Sounds complex? The good news is, you can lock in strong corrosion resistance right from the design stage, especially when working with precision CNC machining partners who understand both manufacturability and real-world performance.

Early collaboration is key. By considering corrosion risks at the CAD level, you can select the right alloy, specify protective features, and ensure every detail—from edge radii to fastener holes—supports a robust, is aluminum corrosion resistant outcome. For example, choosing an alloy like 5083 or 6061 for marine or outdoor use gives you a solid foundation, but only if you also plan for drainage, isolation, and surface treatment.

- Material and alloy guidance: Match alloy and temper to the project’s exposure—marine, architectural, or industrial. Not all aluminum alloys are created equal, and some, like 7075, may need extra protection if used outdoors.

- Machined features for drainage and isolation: Design open joints, sloped surfaces, and built-in spacers to shed water and prevent moisture traps where aluminium will rust or corrode over time.

- Surface roughness targets: Specify finishes that align with your protective coating—smoother surfaces help paints and anodizing adhere, while rougher textures may be needed for grip or bonding.

- Documentation of sealants and fasteners: Clearly note which sealants, gaskets, or isolators to use at assembly to avoid galvanic reactions, especially where aluminum might contact stainless steel or other metals.

Strong corrosion performance starts at the CAD level and is locked in on the shop floor.

Surface Prep and Finishing in the Workflow

Think of surface prep and finishing as the final shield for your design. Even the best alloy can fail if the surface isn’t properly cleaned, prepped, and coated. For CNC-machined parts, this means removing machining lubricants, smoothing burrs, and applying conversion coatings or anodizing before any paint or powder finish. Each step builds another layer of protection—helping ensure your aluminum stays is aluminum rust proof in even demanding environments.

Edge sealing and fastener isolation matter too. Will cast aluminum rust if left unprotected? Not in the traditional sense, but cast or machined surfaces with rough edges or exposed pores can trap moisture, leading to localized attack. That’s why careful finishing—plus documentation of touch-up procedures for field repairs—makes a real difference over the life of the part.

Quality and Speed Without Compromising Protection

How do you balance fast delivery with uncompromising corrosion resistance? The answer lies in integrating corrosion control into every stage of manufacturing. Leading CNC shops, like XTJ CNC Machining Services, offer guidance on alloy selection, design for manufacturability, and finishing options all under one roof. This means you can optimize for both speed and quality—ensuring your parts arrive ready for harsh environments, not just the assembly line.

XTJ specializes in high-complexity projects, machining various grades of aluminum with ultra-tight tolerances. Their engineering team can help you specify features like drain paths, isolation details, and surface prep steps that make your parts more is aluminum corrosion resistant from the start. Whether you need a rapid prototype or a full production run, integrating these best practices ensures every part is built to last.

| Integration Point | Why It Matters for Corrosion Resistance |

|---|---|

| Alloy & Temper Selection | Ensures best fit for environment; some alloys need extra protection |

| Drainage & Isolation Features | Prevents water traps and galvanic attack at joints or fasteners |

| Surface Prep & Finishing | Promotes adhesion of protective coatings; reduces risk of underfilm corrosion |

| Assembly Documentation | Specifies sealants, gaskets, and maintenance for long-term durability |

By integrating corrosion control from the earliest design sketches through to final manufacturing, you can confidently answer questions like "does aluminum alloy rust" or "can aluminium rust in my application" with practical, proven solutions. The result: parts that look great, perform reliably, and stand up to real-world challenges—year after year.

Frequently Asked Questions about Aluminium Rust and Corrosion

1. How long does it take for aluminum to rust or corrode?

Aluminum does not rust like steel, but it can corrode over time if exposed to harsh conditions such as saltwater, chlorinated environments, or when in contact with dissimilar metals. The protective oxide layer forms instantly, but in aggressive settings, pitting or white powdery corrosion can appear in months or years if not properly maintained.

2. Can aluminum rust if it gets wet?

Aluminum will not rust when wet because rust is specific to iron, but it can corrode if water contains salts or pollutants. Prolonged moisture, especially if trapped in joints or crevices, may lead to white, powdery corrosion spots on aluminum surfaces.

3. What does aluminum corrosion look like?

Aluminum corrosion often appears as a dull gray film or white, powdery deposits instead of the red-brown rust seen on steel. In severe cases, small pits or rough patches may develop, especially near fasteners or in areas exposed to salt or chemicals.

4. How can I prevent corrosion between aluminum and stainless steel?

To prevent galvanic corrosion between aluminum and stainless steel, use non-conductive washers, sleeves, or coatings to electrically isolate the metals. Sealing joints and ensuring proper drainage also reduces corrosion risk in assemblies combining these materials.

5. Which aluminum alloys are most corrosion resistant?

Alloys in the 5xxx series (magnesium alloys) offer the highest corrosion resistance, especially in marine or salty environments. Pure aluminum (1xxx) and 3xxx series are also highly resistant, while 2xxx and 7xxx series may need protective coatings for outdoor use.

-

Posted in

aluminium rust, aluminum corrosion, aluminum maintenance, corrosion resistant alloys, galvanic corrosion