Is Aluminium a Metal? Properties, Alloys, And Smart Uses

Is Aluminium a Metal?

Yes, aluminium is a metal—by definition and in practice, it is one of the most widely used metals worldwide.

Featured answer: is aluminium a metal?

Wondering if aluminium (or aluminum, depending on where you are) is truly a metal? The answer is straightforward: aluminium is a metal, not a metalloid or a nonmetal. It is classified as a metallic element on the periodic table, and its properties—like high electrical conductivity, malleability, and metallic bonding—are classic hallmarks of metals. If you’ve ever asked, "is aluminum a metal or metalloid" or "is aluminum a metal or nonmetal," the scientific consensus is clear: aluminium is a metal, not a metalloid or a nonmetal.

- Conductivity: Aluminium efficiently conducts electricity and heat, a defining trait of metals.

- Malleability and ductility: It can be pressed or rolled into sheets and drawn into wires without breaking.

- Metallic bonding: Its atoms are held together by a sea of shared electrons, typical of metallic structures (reference).

Why aluminium is classified as a metal

Let’s break down the science. Aluminium sits in Group 13 of the periodic table and is considered a true metal by chemists. It forms metallic bonds—where electrons move freely between atoms—giving it its shiny appearance, ability to conduct electricity, and flexibility. Unlike metalloids, which have mixed properties, aluminium behaves consistently like a metal in both its pure and alloyed forms. It is not a metalloid, nor is it a nonmetal.

Some people wonder, "is aluminum a metal or a nonmetal?" The answer is that it’s a metal, through and through. It is also only weakly magnetic (technically paramagnetic), meaning it is very weakly attracted to strong magnets but for all practical purposes is considered non-magnetic.

Element versus alloy: what people really mean

Here’s where things get practical. Pure aluminium is a chemical element, not an alloy. However, most of the aluminium you encounter in the real world—whether in airplanes, beverage cans, or window frames—is actually an aluminium alloy. These alloys are made by mixing aluminium with small amounts of other metals (like copper, magnesium, or silicon) to boost strength, durability, or other properties.

So, when you hear "aluminum or aluminium," know that both spellings refer to the same element, and both pure aluminium and its alloys are metallic in nature. In upcoming sections, you’ll discover how its properties, alloys, and smart applications make it a staple in modern life.

Properties That Make Aluminium Unmistakably Metallic

Core properties that define aluminium

When you pick up a soda can or feel the frame of a laptop, you’re experiencing some of the most important qualities that set aluminium apart from other metals. But what exactly gives aluminium its unmistakably metallic character? Let’s break down the essentials:

| Property | Aluminium | Mild Steel | Copper |

|---|---|---|---|

| Density | 2.7 g/cm³ (low) | ~7.8 g/cm³ (high) | 8.9 g/cm³ (very high) |

| Melting Point | 660°C (1,220°F) | ~1,425°C (2,597°F) | 1,085°C (1,985°F) |

| Thermal Conductivity | High | Moderate | Very High |

| Electrical Conductivity | Excellent (62% of copper by area) | Moderate | Excellent (reference) |

| Corrosion Resistance | Excellent (forms oxide layer) | Poor (rusts easily) | Excellent (patinas) |

| Magnetic Behavior | Non-magnetic | Magnetic | Non-magnetic |

- Lightweight: With an aluminum density of just 2.7 g/cm³, it’s about a third the weight of steel or copper, making it the go-to choice for applications where weight savings matter (AZoM).

- Good strength-to-weight ratio: While pure aluminium is softer than steel, its alloys can be engineered for impressive strength.

- High thermal and electrical conductivity: Aluminium’s ability to transfer heat and electricity efficiently underpins its use in electronics, wiring, and heat sinks.

- Excellent corrosion resistance: It forms a thin, self-healing oxide layer that shields it from further corrosion—unlike iron, which rusts.

- Non-magnetic behavior: For anyone wondering, “is aluminum magnetic?”—the answer is no. Aluminium is not attracted to magnets in everyday situations.

Magnetism and corrosion: what actually happens

There’s often confusion about whether aluminium is a magnetic metal or if it rusts like iron. Let’s clear these up:

- Is aluminum a magnetic metal? Pure aluminium is considered paramagnetic, which means it is effectively non-magnetic for practical purposes. It does not stick to magnets, making it ideal for applications where magnetic interference must be avoided—think MRI machines or sensitive electronics.

- Does aluminium rust? Unlike steel, aluminium doesn’t form red rust. Instead, it develops a hard, transparent oxide film (Al₂O₃) that protects it from further corrosion—even in harsh environments. This is why many outdoor structures and marine components are made from aluminium.

If you’ve ever wondered about the “melting temp of aluminum,” it’s relatively low for a metal—660°C (1,220°F)—which contributes to its versatility in manufacturing and recycling (Britannica).

Thermal and electrical behavior in practice

Aluminium’s metallic nature shines in how it handles heat and electricity. Its high thermal conductivity means it dissipates heat rapidly, making it a favorite for heat sinks, cookware, and radiators. Its electrical conductivity, while lower than copper’s by cross-sectional area, is still excellent for power lines and wiring—especially when weight matters.

- Fast heat dissipation: Ideal for electronics and automotive parts.

- Easy to form and shape: Thanks to its malleability and ductility, aluminium is rolled into sheets and drawn into wires for countless uses.

- Lightweight structures: From aircraft frames to ladders, aluminium’s low density enables efficient, strong designs.

Its specific heat of aluminum is also relatively high, meaning it can absorb a lot of heat before its temperature rises—another perk for thermal management applications.

To sum up, aluminium’s unmistakably metallic properties—light weight, high conductivity, corrosion resistance, and non-magnetic character—make it a staple in modern engineering. Next, we’ll see how alloying transforms these properties for even more demanding uses.

Aluminium Alloy Series Made Simple

Alloy series cheat sheet: 1xxx to 7xxx

When you’re choosing materials for a project, you’ll quickly realize that pure aluminium is rare outside of specialized uses. Most real-world applications rely on aluminium alloys—carefully designed blends of aluminium with other elements to fine-tune strength, corrosion resistance, and workability. But how do you make sense of all the numbers and series? Here’s a clear, at-a-glance guide to the major wrought aluminium alloy series you’ll encounter (Wikipedia):

| Series | Key Alloying Elements | General Traits | Heat-Treatable? | Typical Uses |

|---|---|---|---|---|

| 1xxx | None (99%+ pure aluminium) | Very soft, excellent conductivity, highest corrosion resistance | No | Electrical conductors, chemical equipment, foil |

| 2xxx | Copper | High strength, reduced corrosion resistance, tough, not easily welded | Yes | Aerospace, truck wheels, high-stress parts |

| 3xxx | Manganese | Moderate strength, good corrosion resistance, good workability | No | Cookware, roofing, beverage cans |

| 4xxx | Silicon | Lower melting point, good flow, used as filler/welding rod | No (except with Mg, then 6xxx) | Welding wire, automotive parts, die-casting |

| 5xxx | Magnesium | High corrosion resistance, moderate-to-high strength, excellent weldability | No | Marine, transport, pressure vessels, sheet/plate |

| 6xxx | Magnesium & Silicon | Good strength, highly versatile, easy to machine and weld | Yes | Extrusions, structural components, frames, architectural |

| 7xxx | Zinc (plus Mg, Cu) | Highest strength, lower corrosion resistance, tough, limited weldability | Yes | Aerospace, sports equipment, high-stress parts |

How alloying transforms aluminium

Sounds complex? Here’s why these differences matter. By adding carefully measured amounts of elements like copper, magnesium, or silicon, the properties of aluminium alloy material are tuned for specific jobs. For example, the 5xxx series—magnesium alloys—are celebrated for their corrosion resistance in marine environments, while 7xxx series alloys of aluminium deliver the highest strength for aerospace and performance gear.

It’s important to note that while pure aluminium (1xxx) is an element, all the other series are true aluminium alloys. This means that when someone asks, “is aluminium an alloy?” the answer is: pure aluminium is not, but the vast majority of aluminum and aluminum alloys in use are, in fact, alloys of aluminium. The specific blend of elements and the way the metal is processed (including heat treatments like T6 or H32 tempers) can further adjust hardness, ductility, and performance for demanding applications (Wikipedia).

Common applications by series

To make this even more practical, here are some real-world examples of how each series is used:

- 1xxx: Power grid wiring, chemical tanks, and reflective surfaces where purity and conductivity matter most.

- 3xxx: Beverage cans and food packaging—where moderate strength and easy formability are key.

- 5xxx: Boat hulls, truck bodies, and storage tanks—ideal for wet, corrosive environments.

- 6xxx: Window frames, bicycle frames, and extruded architectural profiles—thanks to a balance of strength, machinability, and weldability.

- 7xxx: Aircraft wings and sporting equipment—where the highest strength-to-weight ratio is critical.

- For corrosion resistance near seawater, prioritize 5xxx series aluminium alloy.

- For higher strength and good machinability, consider the 6xxx series.

- For the highest strength and precision, especially in aerospace, 7xxx series alloys of aluminum are your go-to—just be mindful of their weldability and corrosion needs.

- Remember: tempers (like T6 for 6061-T6) can further fine-tune properties, which we’ll cover in the decision checklist later on.

In short, understanding the main series of aluminium alloy is the key to selecting the right aluminum alloy material for your next project. Next, we’ll look at how to identify aluminium in the field—so you can spot the difference even without lab equipment.

How to Identify Aluminium in the Field

Quick tests to identify aluminium

Ever found a piece of metal and wondered, “Is this aluminium or something else?” You don’t need fancy lab equipment to get a reliable answer. With a few simple field tests, you can confidently identify aluminium—even when it’s in the form of cast aluminum parts or thin aluminum foil metal. Here’s a step-by-step approach you can use almost anywhere:

- Magnet test: Grab a small magnet and touch it to the metal. Aluminium is not a magnetic material, so the magnet won’t stick. This instantly rules out most steels, but keep in mind some stainless steels are also non-magnetic.

- Weight and feel: Pick up the object. Aluminium has a much lower density than steel or copper—about 2.7 g/cm³—so it feels surprisingly light for its size. If you’re comparing two similar-sized items, the lighter one is likely aluminium. This low weight is why is aluminum malleable and easily shaped in so many products.

- Sound test: Tap the metal gently with a hard object. Aluminium gives off a dull thud, while steel rings with a clearer, higher-pitched sound. Cast aluminum parts might sound even duller due to their structure.

- Surface scratch observation: Use a key or a coin to lightly scratch an inconspicuous spot. Aluminium is softer than steel and scratches easily, revealing a bright, silvery streak beneath. This softness is another reason why is aluminium malleable and widely used in foil and sheet form.

- Spark test (with caution): If it’s safe, lightly file the edge of the metal and watch for sparks. Aluminium produces almost no sparks, while steel throws off bright, branching sparks. Always wear eye protection and avoid this test on finished or valuable parts.

Visual and tactile clues that rarely fail

Sometimes, your senses can tell you a lot. Aluminium often has a matte, silvery-gray appearance, especially when oxidized. It’s cool to the touch and quickly matches room temperature. Thin aluminum foil metal is extremely flexible and can be crumpled by hand—another sign of its malleability. Cast aluminum may show a rougher texture or small casting marks, while rolled sheets are smooth and uniform.

When coatings make identification tricky

What if the metal is painted, anodized, or coated? Coatings can mask aluminium’s natural color and texture, but a careful scratch test in a hidden spot can reveal the bright metal underneath. Anodized aluminium may appear darker or colored, and the surface can be harder than bare metal. Cast aluminum also behaves differently from wrought alloys when scratched or filed, sometimes producing a powdery residue instead of a clean, bright streak.

- Avoid harsh chemicals—these can damage both the metal and any protective coatings.

- Anodized surfaces may darken or resist scratching; test only in inconspicuous areas.

- Cast aluminum can differ in texture and hardness from rolled or extruded alu sheets.

- Always use proper safety gear—eye protection and gloves—especially when filing or cutting.

By combining these quick tests and observations, you’ll be able to spot aluminium—whether it’s in sheets, cast parts, or even household foil. Understanding these clues not only answers the question “is aluminium a metal” in practical terms, but also sets you up for smart material selection and safe handling. Next, we’ll explore how aluminium’s corrosion resistance works—and what to watch out for in mixed-metal assemblies.

How Aluminium Really Handles the Elements

Why aluminium doesn’t rust like iron

Ever noticed how old aluminium window frames or soda cans rarely show the flaky red rust you see on steel? That’s because aluminium behaves differently when exposed to air and moisture. Instead of rusting, aluminium forms a thin, invisible layer of aluminium oxide almost instantly. This oxide layer is hard, chemically inert, and sticks tightly to the surface, acting as a natural shield against further corrosion.

So, does aluminum rust? Technically, no—because “rust” is iron oxide, and aluminium contains no iron. But can aluminum rust in the sense of corroding? Yes, but the process and result are very different. Instead of red flakes, you’ll see a whitish or dull surface film that protects the metal underneath. This is one of the signature aluminum metal properties that makes it ideal for outdoor use and in environments where other metals might fail.

Understanding galvanic corrosion in assemblies

Sounds complex? Imagine you’re building a boat, a deck, or a machine, and you need to fasten aluminium to another metal. If those metals are different—say, aluminium and copper, or aluminium and stainless steel—and water is present, you could set up a tiny battery. This is called galvanic corrosion. In this situation, aluminium acts as the “anode” and will corrode faster than normal, while the more “noble” metal (like copper or stainless) stays protected.

Where is this most likely to happen? Galvanic corrosion is a real risk in wet, salty, or humid environments—think marine hardware, outdoor railings, or HVAC systems. Bare aluminium in direct contact with copper, brass, or carbon steel is especially vulnerable. Even stainless steel fasteners can cause problems if not properly isolated, although with good design and sealing, they’re often acceptable.

Key insight: Always keep dissimilar metals electrically isolated in wet or salty environments to prevent galvanic corrosion.

Simple ways to prevent galvanic attack

Worried that your aluminium will rust or corrode away in mixed-metal assemblies? The good news is, you can prevent most issues with a few smart steps. Here’s a checklist you can use when working with aluminium and other metals:

- Isolate metals with nonconductive washers or gaskets: Simple nylon or plastic washers break the electrical path between metals.

- Use compatible fasteners: Whenever possible, choose fasteners made from the same material as your aluminium parts. If you must use stainless steel, add isolation and sealants.

- Apply barrier coatings or primers: Powder coating, paint, or specialized primers add a physical and electrical barrier. Focus on coating the more noble metal if only one can be coated.

- Design for drainage and drying: Avoid trapping water between metal surfaces. Good drainage and ventilation reduce the risk of corrosion.

- Consider anodizing or powder coating: Anodizing thickens the protective oxide layer, making it tougher and more resistant to attack. But remember—if the coating is scratched or damaged, corrosion can still occur underneath.

- Use sacrificial anodes in marine settings: In boats, a small piece of zinc (the sacrificial anode) will corrode instead of your aluminium hull or parts.

It’s important to note: while anodizing greatly improves corrosion resistance, your fastener and joint strategy still matters. Even the best coating can’t protect areas where bare metals touch and water is present.

In summary, while aluminium won’t rust like iron, it’s not invincible. By understanding the unique properties of aluminum and taking steps to prevent galvanic corrosion, you can ensure your projects last for years—even in tough environments. Next, let’s look at how to join and fabricate aluminium for strong, reliable assemblies.

Fabricating and Joining Aluminium the Right Way

Welding choices and heat sensitivity

Ever tried welding aluminium sheet metal or an aluminum plate and found it trickier than expected? You’re not alone. Aluminium’s high thermal conductivity and low melting point mean it dissipates heat rapidly, which can lead to distortion, burn-through, or weak welds if not managed carefully. Here’s how to approach welding for success:

Pros

- Provides high structural strength—essential for frames, aluminum channels, and critical joints.

- Permanent and seamless joins, especially with TIG or MIG welding.

Cons

- Requires careful heat control due to rapid heat dissipation—easy to overheat thin alu sheets.

- Aluminium’s oxide layer must be removed before welding for a strong bond.

- Not all alloys weld equally—some (like 2xxx and 7xxx) are more challenging and may require advanced techniques.

Tip: For thin aluminum sheets, pulse welding or controlled preheating can help prevent warping. Always clean the oxide layer just before welding.

Fasteners, rivets, and isolation best practices

Not every project needs welding. For many assemblies—think modular frames, enclosures, or when you want to disassemble later—mechanical fastening is the go-to. But there are a few tricks to getting it right with aluminium sheets and plates:

Pros

- Simple, cost-effective, and reversible—perfect for DIY or modular builds.

- Great for joining thin alu sheets without heat distortion.

- Blind rivets are ideal for quick, strong joins in places you can’t reach from both sides.

Cons

- May require careful hole alignment and sizing to avoid slippage or weak joints.

- Direct contact with dissimilar metals (like steel or copper) can cause galvanic corrosion—always use isolation washers or sealants.

- Less seamless appearance compared to welded or bonded joints.

Tip: For outdoor or marine projects, combine aluminum fasteners with nonconductive washers to prevent corrosion. Always check the compatibility of your fasteners with your aluminum channel or plate.

Adhesive bonding and surface prep that works

Prefer a clean, heat-free join? Modern adhesives make it possible to bond aluminum sheets, plates, or even channels with surprising strength. Here’s what you need to know:

Pros

- No heat input—no risk of warping or heat-affected zones.

- Distributes stress evenly across the joint, reducing fatigue.

- Excellent for joining thin panels or dissimilar materials without fasteners.

Cons

- Requires meticulous surface prep—clean, degrease, and lightly abrade both surfaces to remove the oxide layer (Permabond).

- Cure times may slow down assembly compared to welding or riveting.

- Some adhesives (like structural epoxies or acrylics) can be expensive for large areas.

Tip: For best results, use a dedicated metal to metal glue or structural adhesive designed for aluminium. Always follow the manufacturer’s instructions on surface preparation and curing.

Machining tips for clean finishes

When you need to cut, drill, or mill aluminum sheets or plates, a few smart choices can make all the difference. Imagine you’re machining a batch of alu sheets for a custom enclosure—what should you watch for?

- Use sharp, uncoated carbide cutters—these stay sharp longer and reduce aluminum build-up.

- Choose two-flute or three-flute tools for better chip evacuation—especially important for deep pockets or channels.

- Keep feed rates high enough to avoid rubbing, but not so high as to break the tool—find the sweet spot for your machine and material thickness.

- Use compressed air or coolant to clear chips and keep the workpiece cool.

- Secure workpieces firmly—aluminium’s softness means it can shift or vibrate if not clamped tightly.

By following these machining tips, you’ll get cleaner cuts, better tolerances, and longer tool life—whether you’re working with aluminum channels, plates, or thin sheets.

In summary, fabricating and joining aluminium successfully comes down to understanding its unique properties and choosing the right method for your application. Whether you’re welding, fastening, bonding with metal to metal glue, or machining alu sheets, careful prep and smart technique will ensure your assemblies are strong, reliable, and built to last. In the next section, you’ll learn how to choose the best aluminium alloy and temper for your specific needs.

Which Aluminium Should You Use?

When aluminium beats other materials

Ever wondered why aluminium is everywhere—from aircraft and cars, to window frames and consumer electronics? The answer lies in its unique balance of strength, lightness, and corrosion resistance. If your project calls for lightweight metals with strong performance, aluminium often comes out on top. Compared to steel, it’s about a third the weight, making it ideal for structures where reducing mass is key. And when you compare aluminum vs aluminum alloy, you’ll find that alloys can be tailored for even higher strength or better corrosion resistance, expanding your options.

So, what is aluminum used for most effectively? Think transport (cars, planes, trains), construction (frames, panels), consumer goods (laptops, phones), and packaging (cans, foil). Its combination of formability, conductivity, and resistance to rust makes it a staple in modern engineering. If you’re searching for what elements have the lowest densities of metals, aluminium is among the leaders—explaining its popularity in weight-sensitive applications.

Simple decision checklist to pick your alloy

Sounds complex? Let’s break it down. Choosing the right aluminium (or alternative) starts with your project’s core needs. Use this checklist to guide your selection:

- Required strength and stiffness: Will the part bear heavy loads or need to resist bending?

- Weight targets: Is minimizing mass critical for efficiency or handling?

- Corrosion exposure: Will your part face moisture, salt, or chemicals?

- Form factor: Are you using sheet, plate, or extrusions (like channels and profiles)?

- Welding or finishing needs: Will you weld, paint, anodize, or bond the metal?

- Cost and lead time: Is budget or fast delivery a top concern?

- Compliance: Are there industry or regulatory standards to meet?

Once you answer these, you can narrow your choice. For example, corrosion-prone environments (like marine or outdoor) point to 5xxx series alloys. If you need parts that are easy to machine and weld, 6xxx is a strong candidate. For the highest strength—think aerospace or performance gear—7xxx series is best, though it may require extra verification and care in joining. High formability or electrical conductivity? Look to 1xxx or 3xxx series. This is how you match what is the element aluminum used for with the right alloy family.

Applications and trade-offs that matter

Imagine you’re designing a lightweight bridge, a boat, or a set of electronic enclosures. The table below compares aluminium, steel, and copper on the traits that usually matter most. This at-a-glance view helps you weigh the trade-offs for your application:

| Material | Weight | Formability | Corrosion Resistance | Conductivity | Cost (relative) | Common Uses |

|---|---|---|---|---|---|---|

| Aluminium | Low | High | High | High | Medium | Transport, construction, electronics, packaging |

| Steel | High | Medium | Low (unless coated) | Medium | Low | Structural, automotive, tools |

| Copper | Very High | Medium | High | Very High | High | Electrical wiring, plumbing, heat exchangers |

What is aluminum used for, then? In construction, it’s chosen for window frames, cladding, and roofing panels—where corrosion resistance and light weight are prized. In transportation, it’s used for car bodies, aircraft skins, and train panels, saving fuel and boosting payloads. For electronics, its conductivity and ease of forming make it a go-to for heat sinks and casings. These are just a few uses of aluminium metal that show its versatility.

When deciding between aluminum vs aluminum alloy, remember that pure aluminium (1xxx) is best for conductivity and formability, while alloys are engineered for greater strength, toughness, or corrosion resistance. For thick, load-bearing parts, aluminum plate is preferred; for profiles and channels, extrusions are ideal; and for enclosures or panels, sheet is the go-to.

In summary, matching your needs to the right aluminium alloy ensures your project is efficient, durable, and cost-effective. By weighing the trade-offs and understanding what is the element aluminum used for in different contexts, you’ll make smarter choices—whether you’re building bridges, gadgets, or anything in between. Ready to bring your aluminium design to life? The next section will help you move from concept to finished part with confidence.

Bring Your Aluminium Design to Life

From design to finished aluminium parts

Ready to turn your aluminium sheet, plate, or custom extrusion into a finished product? Whether you’re prototyping a new device, building structural components, or designing sleek aluminum windows, the journey from concept to reality hinges on choosing the right manufacturing partner. The complexity of today’s aluminium alloys and the need for tight tolerances mean that not all machining shops are created equal. So, what should you look for to ensure your parts meet demanding specs on time and within budget?

- Axis capability: Can the shop handle 4-axis or 5-axis machining for intricate geometries and multi-sided parts?

- Tolerances: Are they equipped to deliver ultra-tight tolerances (as close as ±0.005 mm for critical features)?

- Certifications: Look for ISO 9001 and IATF 16949 certifications as signals of consistent quality and process control.

- Material expertise: Do they have experience with a range of aluminum alloys, from 6061 and 7075 to specialized grades for aerospace or electronics?

- Lead time: Can they deliver rapid prototypes or production runs with short turnaround times?

- Engineering support: Will you get help reviewing your CAD files and optimizing for manufacturability?

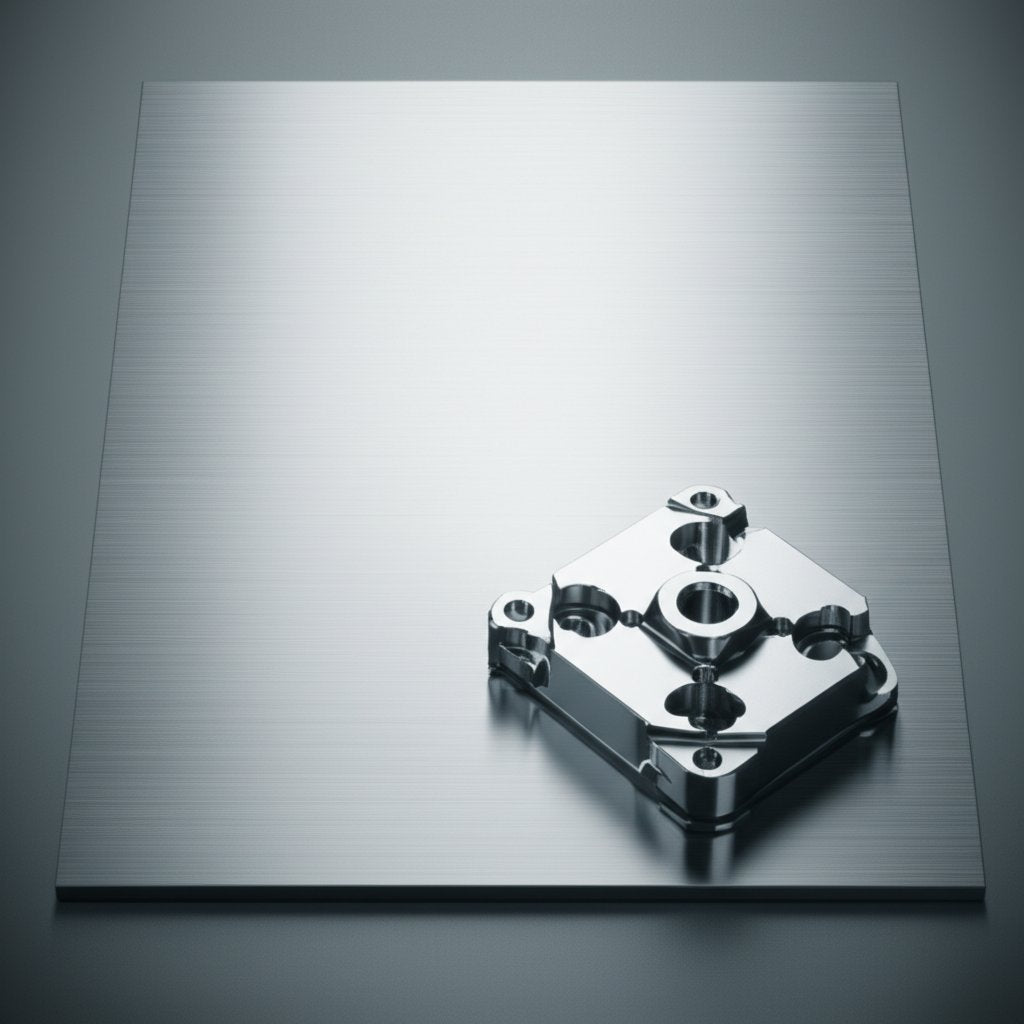

Precision machining for alloys and complex shapes

Imagine you’ve selected the ideal aluminum alloy for your application. Achieving the full potential of that material—whether it’s a lightweight enclosure, a high-strength bracket, or a custom aluminum window frame—often requires advanced CNC machining. But what does that mean in practice?

For straightforward shapes, 3-axis CNC machining may suffice, efficiently producing slots, holes, and profiles in aluminum sheet or plate. However, as your designs get more complex—think multi-angled surfaces, deep cavities, or intricate channels—4-axis and 5-axis machining become essential. These technologies allow simultaneous movement and rotation, enabling the machine to reach every face of a part in one setup. The result? Higher accuracy, fewer errors, and faster production, especially for challenging parts used in aerospace, automotive, or electronics.

If your project demands ultra-tight tolerances, such as precision housings or high-performance mechanical components, be sure your partner can consistently deliver within the required range—down to ±0.005 mm for critical features. This level of precision is especially valuable for applications where fit, function, and assembly reliability are non-negotiable.

| Provider | Axis Capability | Tolerances | Certifications | Lead Time | Engineering Support |

|---|---|---|---|---|---|

| XTJ CNC Machining Services | 4-axis, 5-axis | ±0.005 mm | ISO 9001, IATF 16949 | From 3 days | Dedicated team, DFM review |

| Other Specialist Shops | 3-axis, 4-axis, 5-axis (varies) | ±0.01 mm or as quoted | ISO 9001 (varies) | 1–3 weeks typical | Varies (often by request) |

If you need complex aluminium parts with multi-sided features, tight tolerances, or quick turnarounds, consider XTJ CNC Machining Services as a practical next step. Their advanced 4 and 5-axis machining, ISO-certified processes, and rapid lead times are especially valuable for aluminium sheet, plate, and intricate channels where precision and speed are critical.

How to prepare your CAD and drawings

Before sending your design to a manufacturer, a little preparation goes a long way. Start with a 3D CAD model—this is the foundation for generating CNC toolpaths and visualizing your part’s geometry. But don’t stop there: include a detailed 2D drawing alongside your 3D file. Why? The 2D drawing specifies physical dimensions, tolerances, hole sizes, surface finishes, and other critical features the machinist needs to deliver the part you envision.

- Always provide both 3D and 2D files for the most accurate quotation and manufacturing result.

- Clearly call out any critical dimensions, tight tolerances, or surface finish requirements.

- Specify the exact aluminum alloy and temper (e.g., 6061-T6, 7075-T73) to avoid material mix-ups.

- Highlight any special features, such as threads, channels, or deep pockets, that may require special tooling.

Finally, be open to feedback from your machining partner. Experienced engineers can often suggest small tweaks that improve manufacturability, reduce cost, or enhance performance—without compromising your design intent.

By following these steps and partnering with a qualified CNC provider, you’ll transform your aluminium sheet, plate, or custom profile into a finished part that meets your exact requirements. Whether you’re building a prototype or moving to production, the right approach ensures your ideas become reality—precisely, efficiently, and with confidence.

Frequently Asked Questions About Aluminium as a Metal

1. Is aluminum 100% metal?

Aluminium is a pure metallic element on the periodic table, represented by the symbol Al. In its pure form, it is entirely metal, but most items you encounter are aluminium alloys, which combine aluminium with other metals for enhanced properties.

2. Is aluminium a metal or steel?

Aluminium and steel are both metals, but they are different elements with unique properties. Aluminium is lighter, more corrosion-resistant, and non-magnetic, while steel is heavier, magnetic, and can rust without protection. Aluminium is often chosen where weight and corrosion resistance are priorities.

3. Is aluminium a metal or metalloid?

Aluminium is classified as a metal, not a metalloid. It exhibits metallic bonding, high electrical and thermal conductivity, and malleability. Unlike metalloids, aluminium does not show mixed nonmetallic and metallic traits.

4. Can aluminum rust or corrode?

Aluminium does not rust like iron, but it can corrode. It forms a protective oxide layer that prevents red rust. However, in certain environments, especially when in contact with other metals and moisture, galvanic corrosion can occur, so isolation and coatings are recommended.

5. How can I tell if a metal is aluminium?

You can identify aluminium by its light weight, non-magnetic nature, silvery appearance, and dull thud when tapped. A magnet won’t stick, it feels lighter than steel, and a small scratch reveals a bright, silvery metal beneath.

-

Posted in

aluminium alloys, aluminium properties, corrosion resistance, is aluminium a metal, metal identification