Essential Strategies for Machining Copper Components

TL;DR

Machining copper for electrical components requires specialized strategies to manage its unique properties. The process primarily involves precise techniques like CNC milling and turning to shape this highly conductive metal into parts such as busbars and connectors. Success depends on overcoming challenges related to copper's softness and high thermal conductivity by using extremely sharp tools, appropriate coolants, and optimized machine settings to prevent material buildup and ensure a high-quality surface finish.

Understanding Copper's Unique Properties for Machining

Copper is a cornerstone material in the electrical industry, prized for a unique combination of properties that make it ideal for conductive components but challenging to machine. Understanding these characteristics is the first step toward mastering the manufacturing process. Its high ductility and malleability, while beneficial for forming processes, can lead to a 'gummy' or 'stringy' response during cutting, causing material to stick to the tool rather than shearing away cleanly. This behavior complicates achieving tight tolerances and smooth surface finishes, which are critical for effective electrical contact.

The most defining feature of copper is its exceptional thermal and electrical conductivity, second only to silver. While its electrical conductivity is the primary reason for its use in components like busbars and connectors, its thermal conductivity presents a significant machining hurdle. Heat generated at the cutting point rapidly dissipates throughout the entire workpiece, rather than being carried away with the chip. This can lead to thermal expansion, potential warping of thin parts, and increased wear on cutting tools if not managed with an effective cooling strategy.

Furthermore, copper has a tendency to work-harden rapidly when subjected to mechanical stress. This means that inefficient cutting operations, where the tool rubs rather than cuts, can quickly increase the hardness of the material surface, making subsequent passes more difficult and increasing tool wear. This necessitates continuous, confident cuts with optimized feed rates to stay ahead of the hardening effect. The selection of a specific copper alloy also plays a crucial role; for instance, oxygen-free grades like C101 offer superior conductivity, while alloys like C110 are formulated for better machinability, presenting a critical trade-off between performance and manufacturing cost.

Essential Machining Techniques for Copper Components

Successfully shaping copper into high-performance electrical parts relies on a set of specialized machining techniques designed to handle its unique properties. The most common and effective methods are CNC (Computer Numerical Control) milling and turning, which offer the precision and control necessary for complex geometries. These processes are fundamental to producing everything from simple connectors to intricate heat sinks and busbars used in power distribution systems.

CNC Milling is a versatile process that uses rotating multi-point cutting tools to remove material from a stationary workpiece. It is ideal for creating complex features like slots, pockets, and holes required in many electrical components. For copper, precision milling with 4-axis or 5-axis machines can achieve extremely tight tolerances, which is vital for parts that must fit into larger assemblies. Because of copper's tendency to gum up, the tool paths and cutting parameters must be carefully programmed to ensure clean cuts and prevent material from adhering to the cutter.

CNC Turning is used to create cylindrical or conical parts by rotating the workpiece against a stationary single-point cutting tool. This method is highly efficient for producing components like pins, connectors, and custom fasteners. When turning copper, maintaining a constant cutting depth is important to manage the high thermal loads and prevent tool wear. The angle of the cutting tool is also critical; a sharp angle helps shear the soft material cleanly, preventing the smearing that can degrade the surface finish. For projects requiring these advanced capabilities, services like XTJ CNC Machining Services offer expertise in handling a wide range of materials, including various copper alloys, with high precision.

Beyond traditional methods, advanced techniques are sometimes employed for highly specialized applications. Electrical Discharge Machining (EDM) and water jet cutting are two such processes that can achieve intricate shapes without inducing mechanical stress, which is beneficial for delicate copper parts. EDM uses electrical sparks to erode material, allowing for the creation of complex internal features, while water jet cutting uses a high-pressure stream of water to slice through the metal, avoiding any heat-affected zones. These methods provide engineers with expanded design freedom for the most demanding electrical components.

Key Considerations: Tooling, Speeds, and Coolants

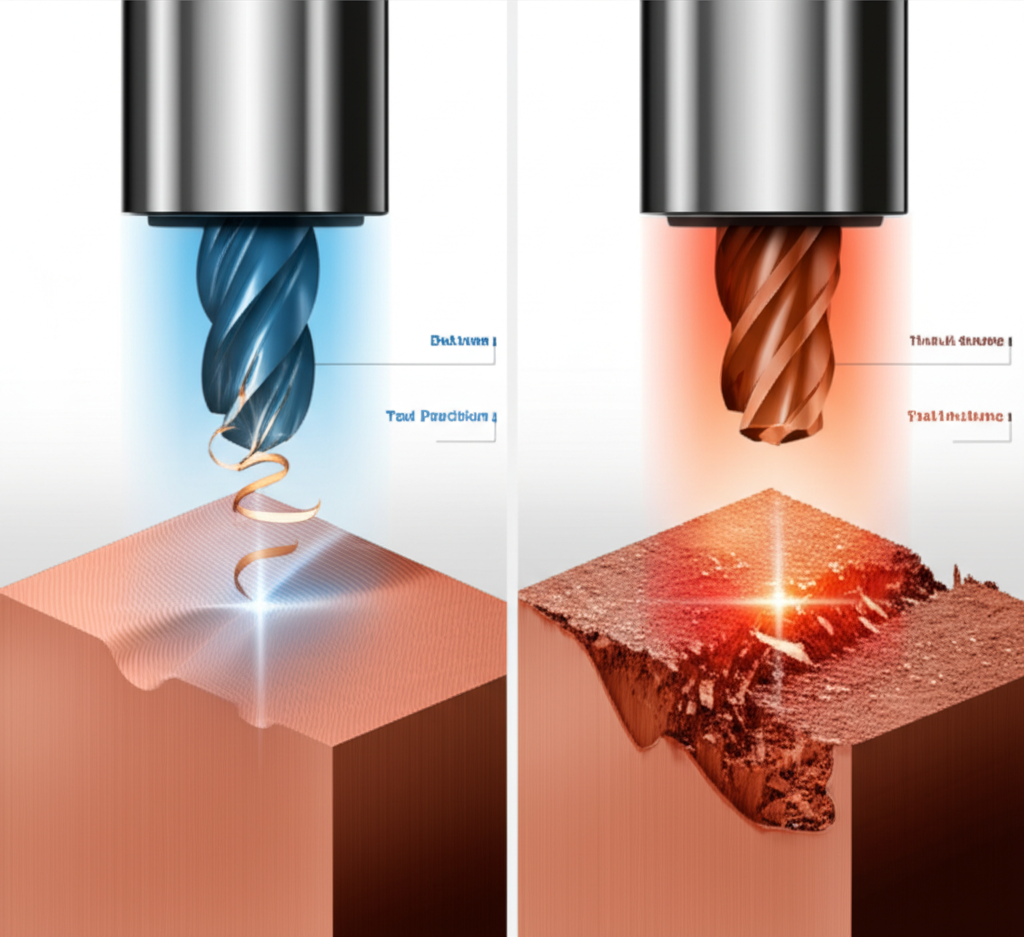

Achieving precision when machining copper for electrical components hinges on the careful management of three interconnected variables: the cutting tools, the machine speeds and feeds, and the coolant strategy. Neglecting any one of these can lead to poor surface finish, dimensional inaccuracies, and rapid tool failure. A methodical approach to these technical parameters is essential for producing high-quality, reliable parts.

Tool Selection

The choice of cutting tool is paramount. Due to copper's soft and sticky nature, tools must be extremely sharp to shear the material cleanly rather than pushing it. High-Speed Steel (HSS) is often recommended for its ability to maintain a very sharp cutting edge. For higher production volumes, cemented carbide tools with specialized coatings are used to provide superior wear resistance. The geometry of the tool is just as important as the material; high positive rake angles and sharp nose radii help reduce cutting forces, prevent material buildup on the tool edge, and minimize smearing on the part's surface.

Speeds and Feeds

Optimizing cutting speeds and feed rates is a delicate balance. Running the machine too slowly can cause the tool to rub against the workpiece, leading to work hardening and making the material more difficult to cut. Conversely, excessively high speeds can generate too much heat, leading to thermal expansion and potential part distortion. A common strategy is to use moderate cutting speeds combined with aggressive feed rates. This ensures the tool is constantly engaged in a true cutting action, efficiently forming and evacuating chips while minimizing heat buildup and tool wear. The goal is to make a clean chip and get it away from the cutting zone as quickly as possible.

Coolant Strategy

An effective coolant or lubrication strategy is non-negotiable when machining copper. Its high thermal conductivity means heat quickly spreads from the cutting zone into the tool and the workpiece. A high-volume flood coolant serves two critical functions: it dissipates heat to prevent thermal damage and it lubricates the cutting interface to prevent chips from welding to the tool. This lubrication is vital for achieving a good surface finish and extending tool life. The choice of coolant can range from soluble oils to synthetic fluids, selected based on the specific operation and copper alloy being machined.

Ensuring Peak Performance: Best Practices for Electrical Parts

Synthesizing the unique properties of copper with precise machining techniques is crucial for manufacturing electrical components that deliver optimal performance and reliability. Adhering to a set of best practices ensures that the material's inherent conductivity is preserved and that the final part meets stringent design specifications. Following these guidelines can make the difference between a functional component and a point of failure in an electrical system.

- Select the Appropriate Copper Grade: The choice of material is the foundation of the project. While pure, oxygen-free copper (like C101) offers the highest electrical conductivity, it is also more challenging to machine. For many applications, an alloy like C110 provides a better balance of good conductivity and superior machinability, often resulting in a more cost-effective solution without a significant performance trade-off.

- Prioritize Tool Sharpness and Geometry: Never use a dull or worn tool on copper. An extremely sharp cutting edge is essential to cleanly shear the material and prevent the gummy buildup that leads to poor finishes and tool failure. Use tools with high positive rake angles to reduce cutting pressure and facilitate smooth chip evacuation.

- Maintain Consistent and Confident Cuts: Due to copper's tendency to work-harden, avoid dwelling or rubbing the tool against the workpiece. Program toolpaths for continuous engagement with aggressive, consistent feed rates. This approach minimizes hardening, reduces cycle times, and improves the overall quality of the cut.

- Implement Aggressive Heat Management: Copper's thermal conductivity requires a robust cooling strategy. Use a high-volume flood of quality coolant to continuously draw heat away from both the tool and the workpiece. This prevents thermal expansion, which can compromise dimensional accuracy, and helps lubricate the cutting zone for a smoother finish.

- Design for Manufacturability (DFM): Simplify designs where possible to improve machinability and reduce costs. Avoid unnecessarily deep pockets or sharp internal corners with small radii. Maintain a minimum wall thickness of around 0.5 mm to prevent warping and ensure structural integrity during machining.

- Focus on Surface Finish and Deburring: The surface quality of an electrical component is critical for ensuring low-resistance contact. Post-machining processes like polishing or electropolishing can enhance the surface and improve corrosion resistance. Thorough deburring is also essential, as any small fragments or rough edges can interfere with electrical connections.

Frequently Asked Questions

1. What grade of copper is used for machining?

Two of the most common grades are C101 (Oxygen-Free Copper) and C110 (Electrolytic Tough Pitch Copper). C101 is 99.99% pure and offers superior electrical conductivity, making it ideal for high-performance applications. However, C110 is generally easier and more cost-effective to machine, providing an excellent balance of conductivity and manufacturability for a wide range of electrical components.

2. What materials cannot be CNC machined?

While CNC machining is very versatile, certain materials are not suitable. These typically include very soft or flexible materials like silicone rubber and some soft polymers that deform under the cutting tool. Other challenging materials include hard ceramics, carbon fiber composites, and hardened glass, which can shatter or cause extreme tool wear. Extremely soft metals and foam-like materials are also difficult to clamp and cut cleanly.

3. What is the hardest material to CNC?

Among the most challenging materials to machine are nickel-based superalloys like Inconel, which are known for their extreme strength and heat resistance. These properties cause rapid tool wear and require specialized machining strategies. Other difficult materials include titanium alloys, hardened steels, and advanced ceramics, all of which demand specific tools, slow cutting speeds, and rigid machine setups to be processed effectively.