Machining PEEK: Essential High-Temperature Techniques

TL;DR

Machining PEEK (Polyether Ether Ketone) for high-temperature applications is highly effective due to the material's ability to retain its mechanical strength and stability at continuous temperatures up to 250°C (482°F). However, successful machining hinges on meticulous heat management. Because PEEK has low thermal conductivity, machinists must use sharp tooling, appropriate coolants, and optimized speeds and feeds to prevent thermal deformation and cracking, ensuring the final part meets precise specifications.

Understanding PEEK's High-Temperature Properties

Polyether Ether Ketone, or PEEK, is a high-performance thermoplastic renowned for its remarkable stability in extreme environments. Its semi-crystalline structure gives it a unique combination of thermal, mechanical, and chemical resistance properties that make it a preferred alternative to metals in demanding applications. Understanding these core characteristics is the first step toward mastering its machining process.

The primary advantage of PEEK is its high operating temperature. With a melting point of 343°C (649°F), it can be used continuously at temperatures up to 250°C (482°F) without significant loss of its physical properties. This allows machined PEEK components to function reliably in environments like automotive engine compartments, aerospace systems, and downhole oil and gas equipment. Unlike many other polymers, PEEK maintains its excellent tensile and flexural strength even when exposed to high heat, steam, or corrosive chemicals.

However, a critical property for machinists to consider is PEEK's low thermal conductivity. While metals quickly dissipate heat away from the cutting tool, PEEK tends to trap it. This localized heat buildup can raise the material's temperature above its glass transition point (around 143°C), leading to softening, deformation, or even melting if not properly managed. This thermal sensitivity is the central challenge that dictates the best practices for machining PEEK.

| Property | Typical Value |

|---|---|

| Melting Point | ~343°C (649°F) |

| Continuous Service Temperature | ~250°C (482°F) |

| Glass Transition Temperature (Tg) | ~143°C (289°F) |

| Tensile Strength | 90 - 120 MPa |

| Thermal Conductivity | Low (~0.25 W/m·K) |

Essential Machining Techniques and Parameters for PEEK

Successfully machining PEEK requires a strategy that prioritizes heat control and stress reduction. While PEEK's stability allows for high machining speeds, these must be balanced with techniques that prevent thermal damage and maintain dimensional accuracy. Before any cutting begins, it is highly recommended to anneal the PEEK stock. This heat treatment process relieves internal stresses from manufacturing, significantly reducing the risk of cracking or warping during machining.

Tool Selection and Geometry

The choice of cutting tool is critical. For unfilled PEEK, sharp carbide tools with a polished surface are often sufficient. However, for reinforced grades like glass-filled or carbon-filled PEEK, which are highly abrasive, Polycrystalline Diamond (PCD) tooling is strongly recommended to resist rapid tool wear and achieve a superior surface finish. To prevent contamination, especially for medical or electronic applications, tools used for PEEK should not be used on metals. Positive rake angles and high clearance angles help produce a clean shearing action rather than pushing the material, which reduces heat generation.

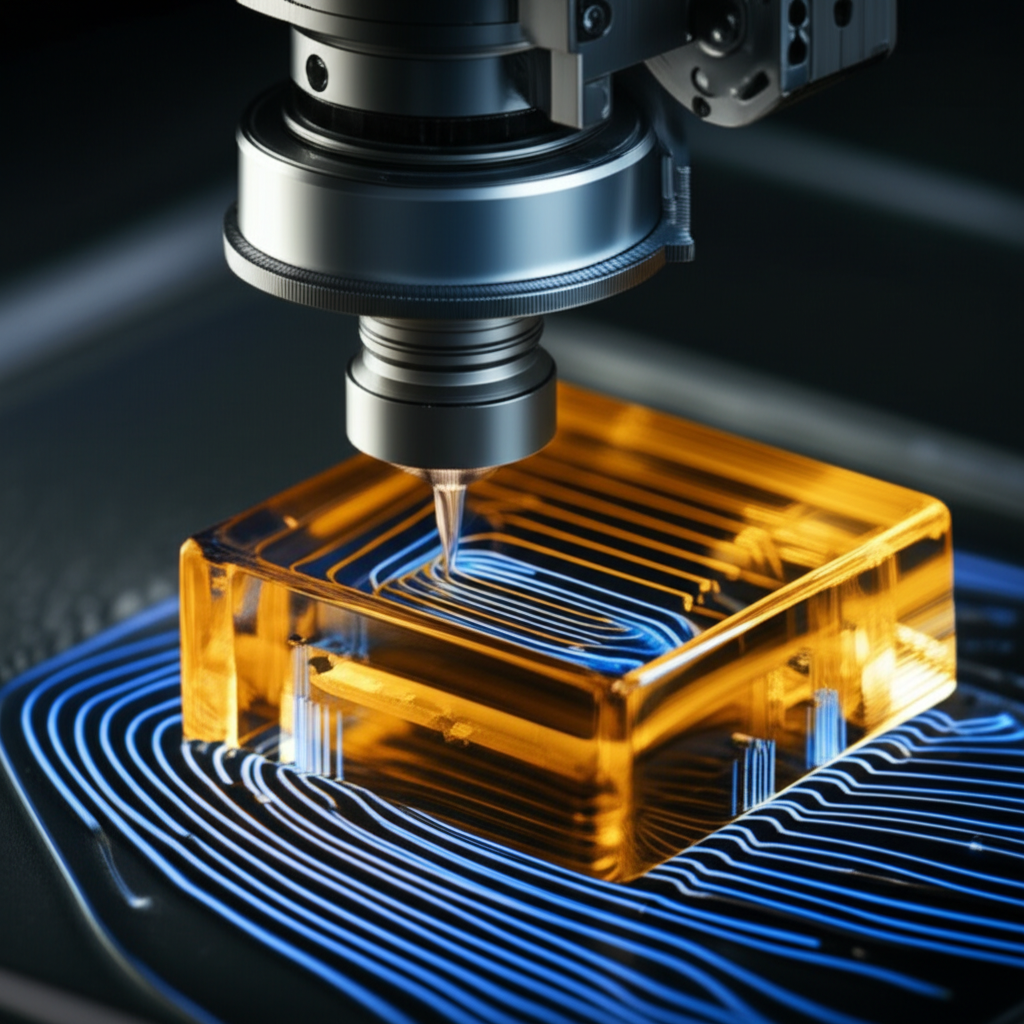

Heat Management and Cooling

Because PEEK does not dissipate heat well, a coolant is almost always necessary. A flood of standard water-soluble coolant is effective for removing heat and clearing chips from the cutting zone. For medical-grade PEEK components where liquid coolants could compromise biocompatibility, compressed air or a cold air gun is a viable alternative. This method helps cool the tool and workpiece while keeping the part dry. Effective cooling prevents the material from softening and ensures dimensional stability throughout the machining process.

Speeds and Feeds

High cutting speeds and feed rates are generally possible with PEEK, which contributes to efficient production. However, these parameters must be carefully calibrated. An overly aggressive approach can generate excessive frictional heat, while a feed rate that is too slow can cause the tool to rub against the material, also increasing heat. It is best to start with manufacturer-recommended parameters, such as those provided by material suppliers like Ensinger, and adjust based on the specific application, tool, and machine rigidity. For projects demanding the highest precision, partnering with a specialized service may be beneficial. For instance, providers of advanced CNC machining services often utilize 4 and 5-axis centers and have extensive experience optimizing parameters for high-performance polymers like PEEK to achieve tolerances as tight as +/- 0.005mm.

Overcoming Common Challenges in PEEK Machining

Even with the right techniques, machinists can encounter several common challenges when working with PEEK. Anticipating these issues and knowing how to address them is key to producing high-quality, reliable parts.

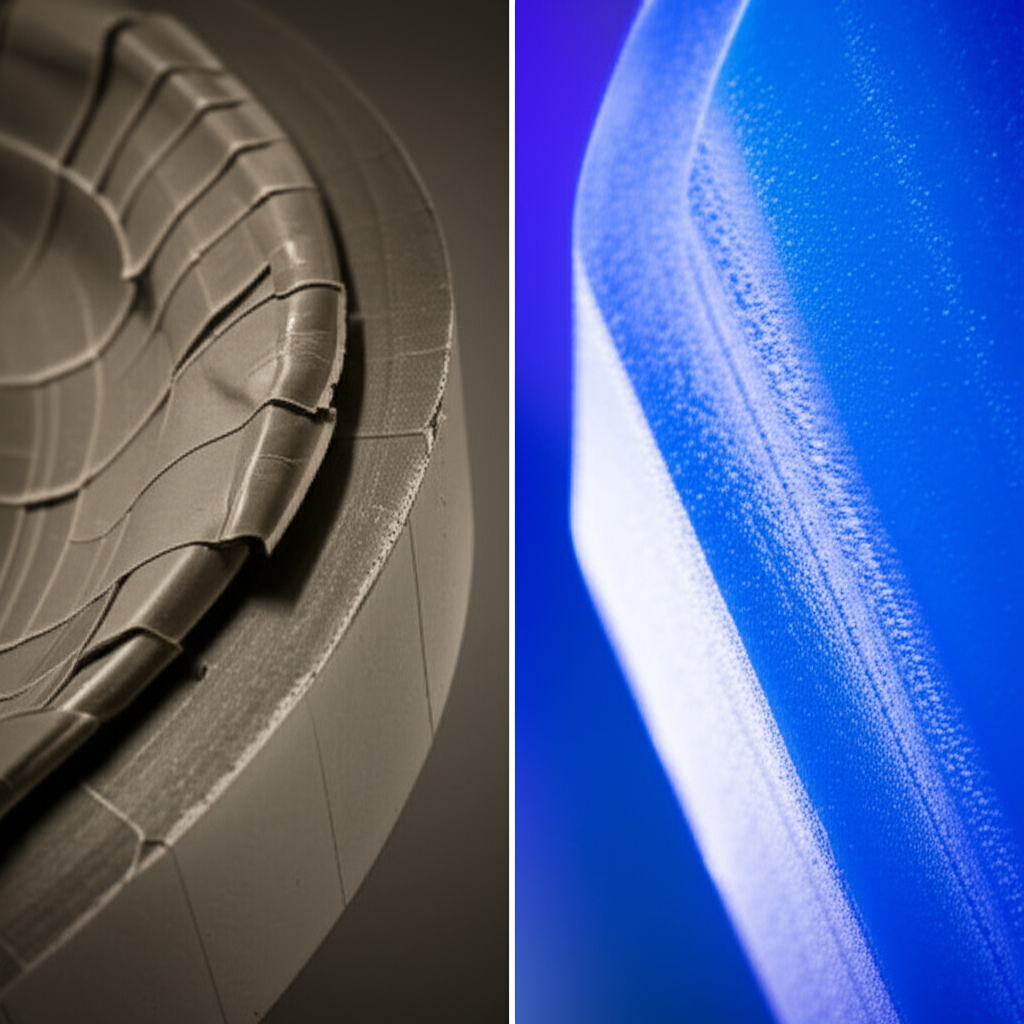

Challenge 1: Thermal Deformation and Stress Cracking

The most prevalent issue is damage from heat buildup. If the cutting zone gets too hot, the material can soften, leading to dimensional inaccuracies once it cools. In severe cases, internal stresses can cause micro-cracks, compromising the part's structural integrity. The solution lies in a multi-faceted approach: use sharp tools with appropriate geometry, apply consistent and ample cooling, and ensure the PEEK stock has been properly annealed before machining to relieve internal stresses.

Challenge 2: Burr Formation

Achieving a clean, burr-free edge is crucial, especially for medical devices and components with sealing surfaces. Burrs form when the material deforms plastically instead of shearing cleanly. This can be mitigated by using extremely sharp cutting tools with a high positive rake angle. Climb milling is often preferred over conventional milling as it helps produce a cleaner cut and directs cutting forces into the body of the material. A final, light finishing pass can also help remove any minor burrs.

Challenge 3: Managing Abrasive Filled Grades

PEEK grades reinforced with glass or carbon fibers offer enhanced stiffness and wear resistance but are highly abrasive on cutting tools. Using standard carbide tools on these materials will lead to rapid wear, resulting in poor surface finish and loss of dimensional accuracy. The only effective solution is to use harder, more durable tooling. As mentioned, PCD tools are the industry standard for machining filled PEEK grades, as their exceptional hardness allows them to maintain a sharp cutting edge for much longer, justifying their higher initial cost through improved part quality and tool life.

Real-World High-Temperature Applications of Machined PEEK

The exceptional properties of machined PEEK make it indispensable across several advanced industries where high temperatures, aggressive chemicals, and extreme mechanical stress are the norm. Its versatility allows it to replace metal components, offering weight savings and improved performance.

- Aerospace: In the aerospace industry, every gram matters. PEEK's high strength-to-weight ratio and thermal stability make it ideal for components like bushings, seals, and electrical insulators inside jet engines and structural parts that must withstand significant temperature fluctuations.

- Medical: Medical-grade PEEK is biocompatible and can be repeatedly sterilized without degradation. Its radiolucency (invisibility on X-rays) is a major advantage for orthopedic implants, such as spinal fusion cages and trauma fixation devices, as it allows surgeons to clearly assess the surgical site post-operation. More details on medical applications can be found in guides from specialists like AIP Precision Machining.

- Automotive: Under the hood, PEEK parts thrive. They are used for thrust washers, seal rings, and bearings in transmission and braking systems, where they reduce friction and withstand high temperatures and aggressive fluids, contributing to improved vehicle efficiency and reliability.

- Semiconductor & Electronics: The high purity and excellent dielectric properties of PEEK make it suitable for manufacturing semiconductor wafer handling equipment and high-frequency electrical insulators. It maintains its integrity during high-temperature fabrication processes.

Frequently Asked Questions

1. What are the limitations of PEEK?

While PEEK has excellent resistance to a wide range of chemicals, it can be attacked by concentrated sulfuric acid and some other aggressive chemicals like methylene chloride. It is also susceptible to degradation from prolonged exposure to high levels of UV radiation, which can cause discoloration and embrittlement if not properly protected for outdoor applications. Finally, its cost is significantly higher than that of more common engineering plastics, so its use is typically reserved for applications where its high performance is a necessity.

2. Is PEEK better than Delrin for machining?

Whether PEEK or Delrin (Acetal) is better depends entirely on the application's requirements. Delrin is an excellent, cost-effective choice for general-purpose mechanical parts that require low friction and good dimensional stability, and it is very easy to machine. However, Delrin lacks the high-temperature and chemical resistance of PEEK. PEEK is the superior material for applications exposed to continuous temperatures above 100°C, harsh chemical environments, or those requiring medical biocompatibility. For high-stress, high-temperature scenarios, PEEK's performance justifies its higher cost and more demanding machining process.

-

Posted in

cnc machining, high-temperature polymers, PEEK machining, polymer engineering, thermoplastic machining