Rapid Prototyping vs Production Machining: Key Differences

TL;DR

Rapid prototyping prioritizes speed and iterative design, using additive methods like 3D printing to quickly create models for testing and validation. In contrast, production machining focuses on cost-efficiency, precision, and consistency for manufacturing large volumes of the final product, typically using subtractive methods like CNC machining. The fundamental trade-off is between the flexibility of development in prototyping and the economies of scale achieved in mass production.

Core Distinctions: Purpose, Speed, and Scale

Understanding the difference between rapid prototyping and production machining begins with their distinct purposes within the product lifecycle. Rapid prototyping is fundamentally about exploration and validation. Its primary goal is to transform a digital design into a physical part as quickly as possible to test its form, fit, and function. This stage allows engineers and designers to identify flaws, make improvements, and iterate on a design before committing to expensive tooling. According to one report, this process can cut development time by as much as 42%. This speed is achieved through additive manufacturing processes, such as 3D printing (SLA, SLS, FDM), which build parts layer by layer directly from a CAD file without the need for custom tooling.

Production machining, on the other hand, is engineered for efficiency and repeatability at scale. Its purpose is not to test a design but to manufacture a finalized, validated product in high volumes—often thousands or millions of units. This process relies on subtractive manufacturing, where computer-controlled machines, like CNC mills and lathes, remove material from a solid block to create the final part. While the initial setup, which includes programming and creating specialized tooling and fixtures, can be time-consuming and costly, the per-unit cost drops significantly as volume increases, making it highly economical for mass production.

The concepts of speed and volume are where the two methods diverge most sharply. Rapid prototyping offers turnaround times measured in hours or days for single pieces or small batches (1-50 parts). This agility is crucial for iterative development. In contrast, production machining has a much longer lead time, often spanning several weeks or months, due to the extensive setup required. However, once operational, it can produce thousands of parts per day with exceptional consistency. The choice between them is therefore a strategic one, dictated by the project's stage and ultimate goals.

To clarify these differences, consider the following comparison:

| Factor | Rapid Prototyping | Production Machining |

|---|---|---|

| Primary Purpose | Design validation, form/fit testing, iteration | Mass manufacturing of final products |

| Process Type | Primarily Additive (e.g., 3D Printing) | Primarily Subtractive (e.g., CNC Machining) |

| Ideal Volume | 1 to 100+ parts | 1,000 to 1,000,000+ parts |

| Lead Time | 1-5 days | 4-12 weeks |

| Design Flexibility | High; easy to modify and iterate | Low; changes are costly and complex |

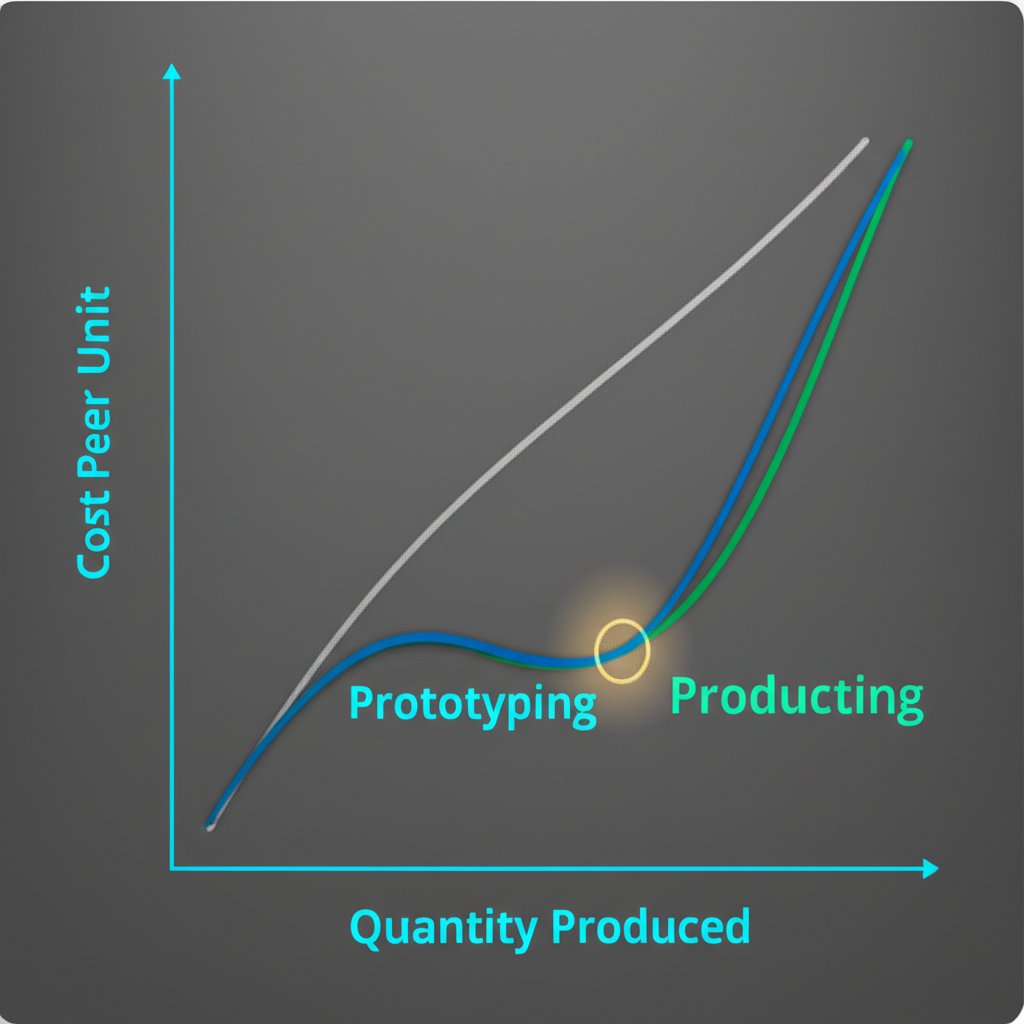

Economic Analysis: Cost Structure and Volume Economics

The financial considerations of rapid prototyping versus production machining are governed by a classic trade-off between upfront investment and per-unit cost. Rapid prototyping is characterized by a very low initial investment. Since it typically involves additive manufacturing, there are no costs for custom tooling, molds, or complex fixtures. The primary expenses are material and machine time, making it highly accessible for creating one-off parts or small batches. However, this model results in a relatively high cost per part, which does not decrease significantly with quantity. For example, a single prototype might cost anywhere from $200 to $2,500, depending on its complexity and material.

Conversely, production machining operates on the principle of economies of scale. The process requires a substantial upfront investment in tooling, which can range from thousands to hundreds of thousands of dollars. This initial cost must be amortized over the entire production run. Once this setup is complete, the automated and optimized nature of CNC machining allows for a very low cost per part, often dropping to between $5 and $50. This makes it incredibly efficient for high-volume manufacturing, where the initial tooling cost is spread across a vast number of units.

This economic divergence creates a break-even point. For very low quantities, rapid prototyping is the undisputed cost-effective choice. As the required volume increases, there is a point at which the total cost of production machining (including tooling) becomes lower than the total cost of producing the same number of parts via prototyping. Industry analyses suggest this break-even point typically occurs between 500 and 2,000 parts. Financial planning is therefore critical; a company must accurately forecast demand to determine when the investment in production tooling becomes justifiable. Choosing the wrong process for a given volume can lead to either excessive per-unit costs or a wasted investment in tooling.

Technical Comparison: Precision, Materials, and Technology

Beyond economics and purpose, rapid prototyping and production machining differ significantly in their technical capabilities, including precision, material selection, and the underlying technologies. Production machining, dominated by CNC technology, is the benchmark for precision. Because it carves parts from a solid block of material, CNC machining can achieve extremely tight tolerances, often as precise as ±0.01mm, and produce superior surface finishes. This is crucial for functional parts that require high accuracy for assembly and performance, such as engine components or medical implants.

Rapid prototyping technologies, while advancing rapidly, generally offer lower precision, with typical tolerances around ±0.1mm. The layer-by-layer construction method of additive manufacturing can also result in a rougher surface finish that may require post-processing. However, its key advantage is design freedom. Additive processes can create highly complex internal geometries, intricate lattices, and organic shapes that are impossible to produce with traditional subtractive methods. This makes it ideal for parts where complex form is more critical than ultimate precision.

Material selection is another key differentiator. Production machining works with a vast range of solid materials, including various metals (aluminum, steel, titanium) and engineering-grade plastics, ensuring that the final parts have the desired mechanical properties like strength and durability. Rapid prototyping primarily uses resins, powders, and filaments (like nylon and photopolymers), which may simulate the properties of production materials but often don't match their strength or temperature resistance. This is why prototypes are excellent for form and fit checks but may be unsuitable for rigorous functional testing under real-world stress. For projects requiring high-quality prototypes with a wide range of material options and expert design feedback, utilizing comprehensive formative manufacturing services can bridge the gap between initial concept and functional testing, ensuring prototypes meet precise engineering requirements.

The table below summarizes the key technical differences:

| Technical Aspect | Rapid Prototyping (e.g., 3D Printing) | Production Machining (e.g., CNC) |

|---|---|---|

| Typical Tolerance | ±0.1mm to ±0.3mm | ±0.01mm to ±0.05mm |

| Surface Finish | Visible layer lines, often requires finishing | Smooth, high-quality finish as-machined |

| Material Properties | Good for form/fit; may lack strength of final material | Excellent; uses true production-grade metals and plastics |

| Geometric Complexity | Very high; can create complex internal structures | Limited by tool access and part geometry |

The Modern Workflow: When to Combine Both Technologies

The most effective modern product development strategies no longer treat rapid prototyping and production machining as an either/or decision. Instead, they are viewed as complementary stages in a seamless workflow. This hybrid approach leverages the strengths of each process to accelerate time-to-market, reduce financial risk, and improve the final product. By integrating both, companies can move from concept to mass production with greater confidence and efficiency. This strategic combination is detailed in resources like the guide from JLCCNC on combining both technologies.

The typical workflow begins with rapid prototyping. Engineers use 3D printing to create multiple design iterations quickly and cheaply. These early-stage prototypes are used for visual evaluation, ergonomic testing, and basic fit checks. This allows the design team to fail fast and learn quickly, refining the product's geometry and features without investing in costly tooling. This iterative loop can significantly de-risk the entire project by ensuring the design is thoroughly vetted before moving forward.

Once the design is largely finalized through additive prototyping, the process transitions to CNC machining for high-fidelity functional prototypes. These machined parts are made from production-grade materials and have the required precision and strength for rigorous real-world testing. This step validates the product's mechanical performance and ensures it meets all technical specifications before committing to mass production. After successful functional testing, the same CNC technology is then used to create the final tooling (e.g., injection molds) for production, ensuring a smooth and predictable transition to manufacturing at scale. This staged approach, moving from low-cost additive to high-precision subtractive methods, is now the standard for efficient and successful product development.

Making the Right Manufacturing Choice

Choosing between rapid prototyping and production machining is not a simple matter of preference but a critical strategic decision based on your project's specific stage, goals, and constraints. Rapid prototyping is the ideal choice for the early phases of development, where speed, flexibility, and the ability to iterate are paramount. It allows for creative exploration and design validation at a minimal initial cost. Production machining is the clear winner for mature, validated designs ready for market, where cost-efficiency at scale, precision, and repeatability are the primary drivers.

Ultimately, the most successful manufacturers recognize that these two processes are not competitors but partners in the journey from idea to reality. By implementing a hybrid workflow that leverages the speed of prototyping to refine a design and the power of production machining to scale it, companies can optimize their development cycle, minimize costly errors, and bring superior products to market faster.

Frequently Asked Questions

1. What are the differences between conventional machining and rapid prototyping?

The primary difference lies in the manufacturing approach. Rapid prototyping typically uses additive manufacturing, building a part layer by layer from a digital file, which is ideal for creating complex models quickly. Conventional machining, such as CNC, is a subtractive process that removes material from a solid block to shape a part, offering higher precision and strength. As noted by Proto MFG, prototyping is often more automated for model creation, while conventional machining is a broader, human-controlled process for production.

2. How is RP technology compared to CNC technology?

Rapid Prototyping (RP) technology, like 3D printing, excels at creating parts with complex internal geometries and features that are difficult or impossible to machine, such as deep, narrow channels. CNC technology, however, has the advantage in precision, achieving sharper edges, smoother finishes, and tighter tolerances. CNC is generally superior for functional parts requiring high strength and durability, as it works with solid blocks of production-grade materials.

3. What is the basic difference between manufacturing and rapid prototyping?

The fundamental difference is one of intent and scale. Rapid prototyping is focused on creating a small number of parts quickly to validate a design concept before mass production. Its goal is iteration and learning. Manufacturing, particularly production machining, is focused on producing a large volume of identical, finalized parts efficiently and cost-effectively to meet market demand. It prioritizes consistency, cost control, and speed at scale.

-

Posted in

additive manufacturing, cnc machining, product development, production machining, rapid prototyping