The Critical Role of Fixtures in CNC Machining: Precision Enablers for Prototypes & Low-Volume Production

Introduction

In prototype and low-volume CNC machining, where every part counts and margins are tight, fixtures are the unsung heroes of manufacturing success. More than simple clamps, they are precision-engineered solutions that bridge design intent and machined reality. For engineers managing NPI (New Product Introduction) or small-batch production, understanding fixturing is non-negotiable.

Why Fixtures Matter Beyond Mass Production

While high-volume runs justify custom fixtures, prototypes/low volumes demand strategic flexibility. Key challenges fixturing solves:

-

Accuracy Assurance

-

Prevent deflection in thin-walled prototypes (±0.05mm tolerance loss common without proper support)

-

Maintain datum consistency across multiple setups

-

-

First-Part Success

-

Eliminate trial-and-error positioning (Critical for <50pcs batches)

-

-

Scalable Efficiency

-

Reduce setup time by 60-80% vs. manual positioning

-

4 Fixturing Strategies for Prototype/Low-Volume Success

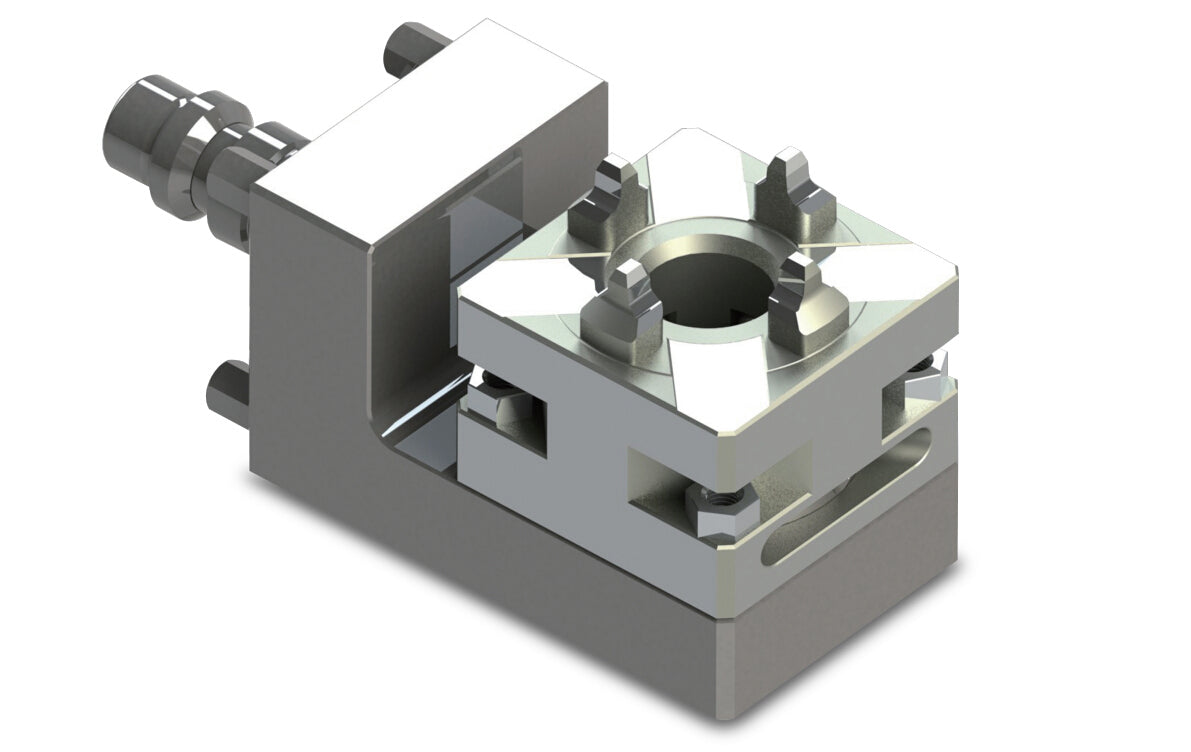

1. Modular Fixture Systems

-

Components: Mitee-Bite clamps, 80/20 aluminum frames, magnetic bases

-

Best For: Iterative design changes

-

Savings: Reconfigure in <15 minutes vs. 4+ hours for custom jigs

2. Vacuum Fixturing

-

Applications: Flat/thin parts (<3mm), composites, non-ferrous metals

-

Advantages:

-

Zero part obstruction (360° machining access)

-

Even pressure distribution (Prevents warping in aerospace prototypes)

-

-

Limitations: Unsuitable for heavy milling operations

3. Soft Jaws (Custom-Machined)

-

Process: Machine vise jaws to part contour during first-op

-

Precision: Achieve <0.01mm repeatability for second-op features

-

Cost: 70% cheaper than hardened custom fixtures

4. 3D-Printed Fixtures

-

Materials: High-temp resins (e.g., Carbon RPU), nylon composites

-

Use Cases:

-

Holding fragile medical prototypes

-

Complex organic shapes (Drones, automotive housings)

-

-

Lead Time: 8-24 hours vs. 5+ days for metal fixtures

The Hidden Costs of Poor Fixturing (Data-Driven Insights)

| Scenario | Prototype Impact (Per 10pcs Batch) |

|---|---|

| Manual repositioning | +3.5 hours setup time |

| Part vibration/deflection | 15-30% scrap rate |

| Inconsistent datum points | +$1,200 inspection/remachining costs |

*Source: SME Study on Low-Volume Machining Efficiency (2023)*

5 Fixture Design Principles for Engineers

-

Access > Rigidity

Prioritize toolpath clearance over excessive clamping (Use edge grips instead of top clamps where possible). -

Zero-Point Systems (ZPS)

Implement quick-change pallets (e.g., Erowa, System 3R) for multi-machine workflows. -

Metrology Integration

Design fixtures with probing access for in-process verification. -

Scalability Planning

Plan for future volumes: Can soft jaws be converted to PEEK molds? Does modular fixture allow rapid expansion? -

DFF (Design for Fixturing)

Collaborate with machinists early to add:-

3° draft angles for vacuum seals

-

Tool access channels

-

Temporary datum geometries

-

Real-World Case: Medical Device Prototype

Challenge: Machine titanium spinal implant (0.8mm thin walls) with 5µm surface finish.

Fixture Solution:

-

Vacuum plate with custom silicone gasket

-

3D-printed PETG support lattice

Outcome: -

Scrap rate reduced from 40% to 3%

-

Surface finish compliance: 100%

Conclusion: Fixturing as Strategic Investment

In prototype and low-volume CNC machining, fixtures are not expenses—they’re accuracy multipliers and risk mitigators. The right fixturing strategy delivers:

✅ First-article success rates >95%

✅ Per-part cost reduction up to 35%

✅ Scalability from 1 to 1,000 units

Partner with machinists who treat fixturing as a core engineering discipline, not an afterthought.

Ready to Optimize Your Next CNC Project?

XTJ specializes in fixture-driven precision for prototypes and low-volume batches.

Request a free fixturing assessment for your project:

hcc@xintianjian.com.cn

-

Posted in

CNC workholding, fixture, low-volume fixtures, machining accuracy, prototype CNC machining