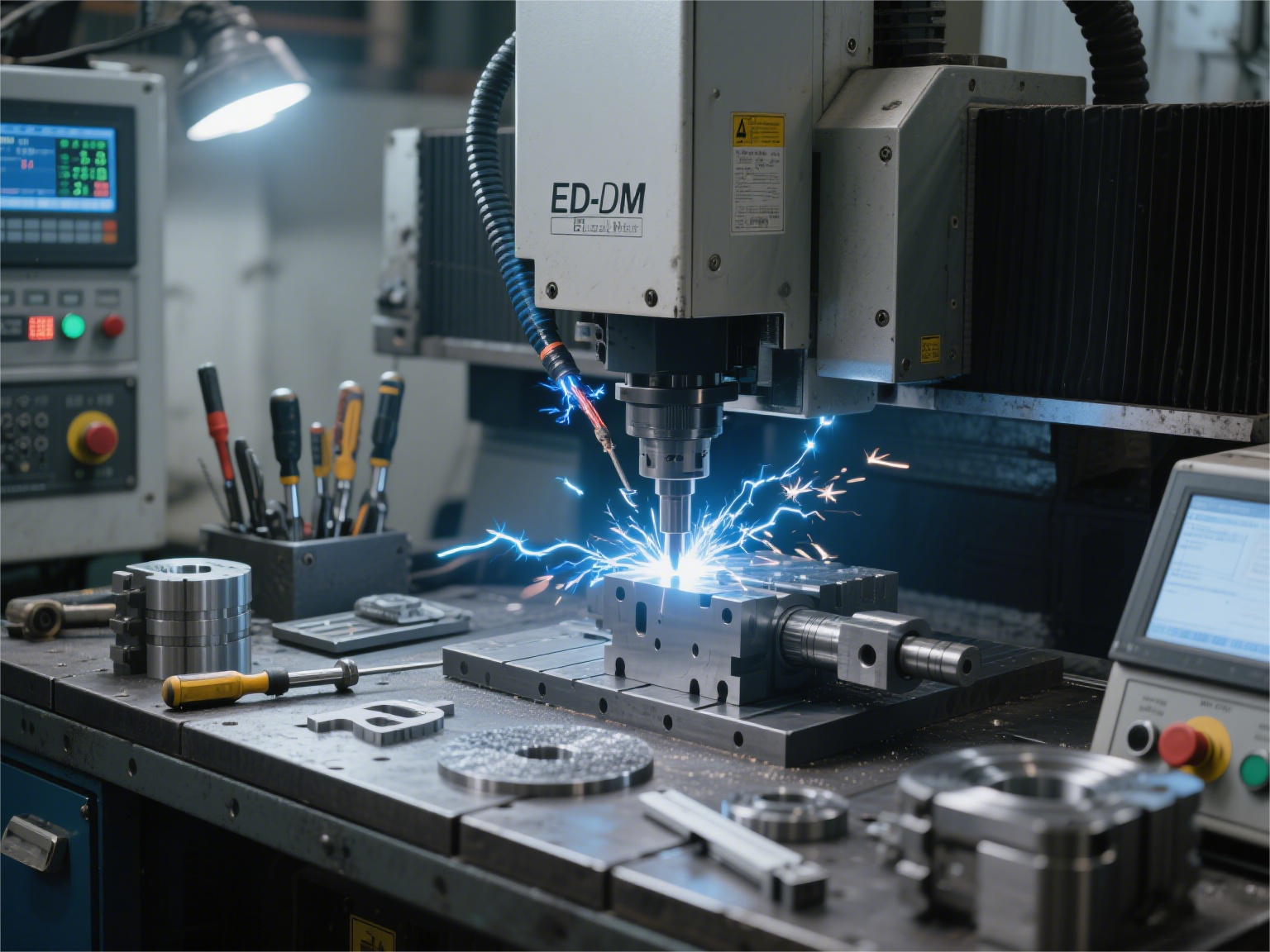

The Three Types of EDM Machining and Their Critical Differences

1. Technology Fundamentals

EDM removes material through controlled spark discharges (8,000–12,000°C) between electrode and workpiece in dielectric fluid. Unique advantages:

-

Processes any conductive material (hardened steel, carbide, Inconel)

-

Creates geometrically complex features (sharp corners, thin walls <0.1mm, deep cavities)

-

Generates zero mechanical stress

2. Sinker EDM (Ram/Cavity EDM)

Technical Principle

-

Electrode: Mirror-finished copper/graphite

-

Process: Vertical Z-axis plunge with dielectric oil

-

Surface Finish: Achieves Ra 0.1μm (mirror finish)

Applications

-

Injection mold cavities (automotive, consumer goods)

-

Blind features in aerospace alloys (Inconel 718)

-

Surface texturing (leather-grain patterns)

Limitations

-

Electrode fabrication increases lead time

-

Max material removal rate: 300 mm³/min

3. Wire EDM

Technical Principle

-

Electrode: Moving brass/molybdenum wire (Ø0.02–0.3mm)

-

Precision: ±0.001mm positioning, ±0.005mm corner control

-

Taper Cutting: Up to 30° angles

Critical Innovations

-

Constant wire tension (15–25N)

-

Adaptive flushing with deionized water

-

Multi-pass cutting (roughing → finishing)

Applications

-

Progressive dies (hardened tool steel)

-

Surgical blade contours (medical grade stainless)

-

Ejector pin holes (±0.002mm roundness)

4. Micro EDM

Technical Principle

-

Electrode: Rotating tungsten carbide tubes (Ø0.03–0.3mm; >2,000 RPM)

-

Accuracy: ±0.5μm with nanosecond pulses

-

Aspect Ratio: 100:1 for microholes

Breakthrough Capabilities

-

On-the-fly electrode dressing

-

Reverse drilling for high-aspect-ratio holes

-

Burr-free surfaces (Ra <0.1μm)

Applications

-

Fuel injector nozzles (Ø0.05–0.12mm)

-

Orthopedic implant porosity (50–200μm holes)

-

Cooling microchannels in semiconductor tools

5. Comparative Analysis

| Parameter | Sinker EDM | Wire EDM | Micro EDM |

|---|---|---|---|

| Accuracy | ±0.01mm | ±0.001mm | ±0.0005mm |

| Surface Finish | Ra 0.1μm | Ra 0.2μm | Ra 0.05μm |

| Electrode | 3D custom graphite | Moving wire | Rotating micro-tubing |

| MRR | Medium (300 mm³/min) | High (500 mm³/min) | Low (50 mm³/min) |

| Key Strength | 3D cavities | Contour precision | Micro-feature resolution |

6. Synergistic Implementation & Trends

Hybrid Manufacturing

Example: Turbine disk production

-

Roughing: 5-axis milling (bulk removal)

-

Semi-finishing: Sinker EDM (blade root slots)

-

Finishing: Wire EDM (profiles) + Micro EDM (cooling holes)

→ 40% cycle time reduction vs. conventional methods

Emerging Innovations

-

AI-Powered Gap Control: Real-time spark monitoring adjusts voltage/pulse

-

Dry EDM: Reduced environmental impact using gas dielectrics

-

Hybrid Machine Tools: Integrated milling-EDM platforms (e.g., Makino D200Z)

Conclusion

Selecting the optimal EDM process requires analyzing:

-

Feature geometry (3D vs. 2D vs. micro-scale)

-

Tolerances (±0.0005mm to ±0.01mm)

-

Material constraints (conductivity, hardness)

Sinker EDM dominates mold making, Wire EDM excels in precision contours, while Micro EDM enables micromachining impossible with conventional methods. The future lies in intelligent process integration and sustainability-driven innovations.