What are the Processes in Aluminum Prototypes?

Aluminum is the most common material used for prototypes. Industries ranging from aerospace and medical to automotive require durable structural components. Aluminum prototypes are strong, have excellent weldability, and are also corrosion-resistant.

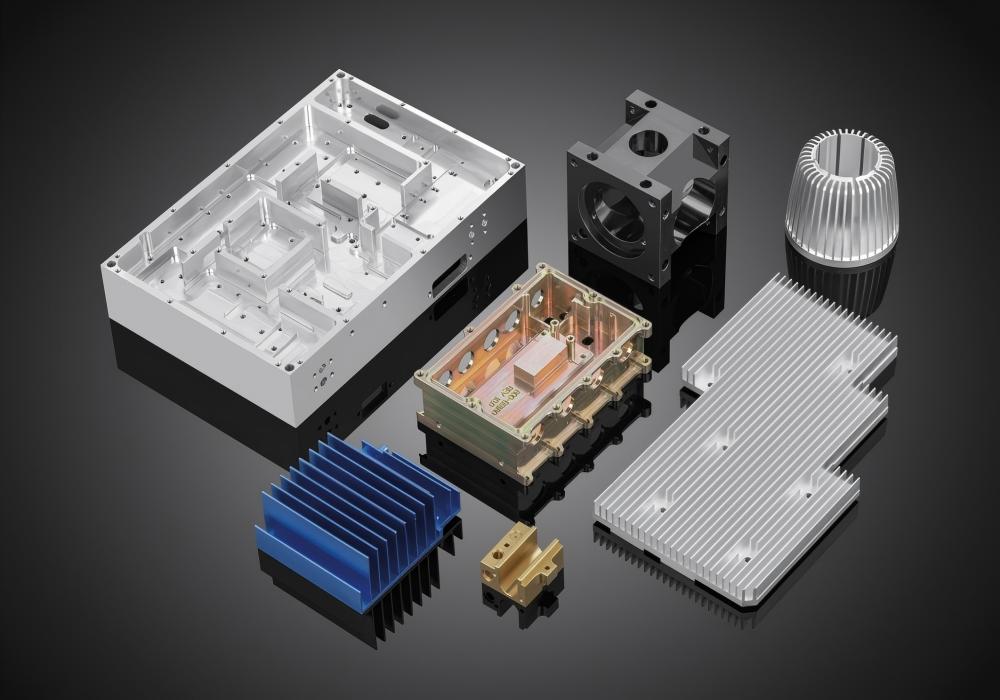

Manufacturers use different technologies to create aluminum prototypes. Depending on the part, quantity, or geometry, they may choose to use 3D printing, CNC machining, aluminum casting, extrusion, or sheet metal fabrication.

Let we look at these techniques to help you choose the best aluminum prototype manufacturing method.

3D Printing

Prototypes can be made using Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). For aluminum prototypes with complex structures, metal 3D printing can quickly and easily verify the feasibility of their structure and function.

CNC Machining

Most prototype manufacturers use CNC machining to produce aluminum prototypes. CNC machining can produce prototypes with great precision in almost the shortest possible time. CNC machining also uses 4- and 5-axis CNC machines to create complex parts with detailed features.

Sheet Metal Fabrication

This fabrication process involves the bending, cutting, and assembly of aluminum sheets. It is used to create functional prototypes such as casings and industrial parts.

When creating functional metal prototypes, manufacturers use laser cutting, stamping, bending, and welding processes. The downside of this technique is that it can be more expensive than other processes. For example, a single part might require a laser cutter and stamping machine, whereas with CNC machining, only one sort of machine is needed.

Aluminum Castings

Casting involves pouring molten aluminum into a mold to create a prototype. Because it requires specialized equipment, the mold-making process is expensive. So it's more suitable for mass production. Manufacturers can incorporate 3D printing and CNC machining into the casting process to reduce the production cost of metal prototypes.

Aluminum Extrusion

During the extrusion process, material is forced through a shaped, open die to produce a long, thin part. Examples of aluminum parts manufacturers can create through this process include metal rods, brackets, and connectors. However, due to the high cost, most extrusion companies focus on large-volume orders.

Summary

Due to its superior qualities, prototype manufacturers use aluminum in most of their processes. Depending on the part you need and your budget, you can choose between the aluminum prototype fabrication techniques listed above. You can contact Shenzhen XTJ, an ISO9001& IATF 16949 certified prototype company with over 20 years of experience. We will provide quality parts according to your specifications and designs.

-

Posted in

Aluminum Alloy, cnc machining, prototyping