316l stainless steel For Real-World Corrosion, Welding, And Cost

Understanding 316L Stainless Steel at a Glance

When selecting materials for demanding environments, the name 316l stainless steel often stands out. But what is 316l stainless steel, and why do engineers, fabricators, and designers turn to it again and again? If you’ve ever wondered about the real-world meaning behind "316 stainless" or what sets 316L apart, you’re in the right place. This opening section will clarify the basics, dispel common myths, and set the stage for a deeper dive into composition, performance, and application.

What Is 316L Stainless Steel

316L stainless steel is a low-carbon variant of the classic 316 austenitic stainless family. It’s engineered to provide excellent corrosion resistance, especially in environments rich in chlorides—think marine, chemical, or pharmaceutical settings. The "L" in 316L stands for "low carbon," a design tweak that dramatically reduces the risk of sensitization (also known as weld decay) during welding or high-temperature use. This means 316L is ideal for welded assemblies, heavy-gauge fabrications, and hygiene-critical components where corrosion at welds could otherwise be a concern.

Where 316L Excels Versus 316

Sounds complex? Imagine you’re specifying a tank or pipe for a salty, humid environment. Both 316 and 316L offer strong corrosion resistance thanks to their molybdenum content, but 316L’s lower carbon content means it withstands welding without losing its protective qualities. The broader 316 family includes several variants (like 316, 316L, 316H), each fine-tuned for specific needs. The main difference between 316 vs 316L boils down to carbon content and weld performance—not basic corrosion resistance in ambient conditions. You’ll often see multiple designations (e.g., AISI, ASTM, UNS) across standards, but the core 316 meaning remains: high corrosion resistance with tailored options for fabrication.

-

Immediate Benefits:

- Outstanding resistance to pitting and crevice corrosion in chlorides

- Excellent weldability—no post-weld heat treatment required for most cases

- Biocompatibility—widely used in medical and food-grade applications

-

Common Misunderstandings:

- Is 316 stainless magnetic? — Both 316 and 316L are generally non-magnetic, but may become slightly magnetic after cold working or welding

- "316L doesn’t rust" — While highly resistant, surface staining can occur in harsh marine or neglected environments

- "316L is always equivalent to 304" — Not true; 316L’s molybdenum content offers superior performance in chlorides compared to 304

Key Takeaways Before You Choose

Before you specify a grade, it’s crucial to understand the subtle but important differences within the 316 family. The "L" version is your go-to for welded or thick-section parts, while standard 316 stainless is often chosen for non-welded structures. Both share the same austenitic base, so their general resistance to corrosion, formability, and toughness are comparable. However, the real advantage of 316L emerges in welded assemblies or when hygiene and long-term durability are paramount.

Choose 316L first for welded assemblies or hygiene-critical components where low carbon content minimizes sensitization risk.

In the sections that follow, you’ll learn how the composition of 316L stainless steel drives its performance, how it compares to other stainless grades, and what to watch for in fabrication, machining, and real-world use. Whether you’re new to stainless alloys or looking to optimize your next project, understanding the 316 meaning is the first step toward smarter material selection.

Composition and Corrosion Behavior Explained

When you’re choosing materials for environments where corrosion is a real threat—think coastal structures, chemical processing, or food and pharma plants—the composition of your stainless steel is what truly makes the difference. So, what’s inside 316L stainless steel that gives it such a strong reputation? And how do its ingredients translate to performance in the real world? Let’s break it down step by step.

316L Composition and Why It Matters

At its core, 316L stainless steel composition is similar to standard 316, but with a crucial tweak: lower carbon. This subtle change helps prevent the formation of chromium carbides at grain boundaries during welding, which means 316L keeps its corrosion resistance even after fabrication. Both 316 and 316L are enriched with molybdenum—a key upgrade over 304 stainless steel—which is the secret to their superior resistance in chloride-rich settings.

Here’s a quick look at the main alloying elements in 304, 316, and 316L, based on ASTM and supplier data [Wikipedia]:

| Grade | Cr (Chromium) | Ni (Nickel) | Mo (Molybdenum) | C (Carbon) | N (Nitrogen) |

|---|---|---|---|---|---|

| 304 | 18.0–20.0% | 8.0–10.5% | - | ≤0.08% | - |

| 316 | 16.0–18.0% | 10.0–14.0% | 2.0–3.0% | ≤0.08% | ≤0.10% |

| 316L | 16.0–18.0% | 10.0–14.0% | 2.0–3.0% | ≤0.03% | ≤0.10% |

Notice how the composition 316L stainless steel closely matches 316, except for that lower carbon maximum. This is the heart of why 316L is so often dual-certified with 316, but it’s the low carbon that makes it the preferred choice for welded assemblies and hygiene-critical applications. The ss316 composition also stands out from 304 thanks to its added molybdenum, which is a game-changer for fighting off aggressive chlorides.

Chloride Resistance and Marine Environments

Ever wondered what is marine grade stainless steel? The answer usually points to 316 or 316L, as their molybdenum content dramatically improves resistance to pitting and crevice corrosion caused by saltwater. In fact, the term "A4" is widely used for fasteners made from these grades, signaling suitability for coastal or marine installations [Wikipedia].

But here’s the catch: even marine grade 316 stainless steel isn’t invincible. Environmental factors like stagnant water, high temperatures, lack of rinsing (especially under overhangs), or tight crevices can all increase the risk of localized corrosion. That’s why real-world performance depends on more than just the alloy’s name or composition of ss 316.

-

Design Tips for Marine and Chloride-Rich Environments:

- Avoid tight crevices and overlapping joints—these trap chlorides and moisture.

- Specify a smooth or polished finish to minimize initiation sites for corrosion.

- Design for drainage—standing water accelerates attack.

- In splash zones, routine freshwater rinsing helps reduce salt buildup.

Pitting and Crevice Corrosion Basics

Here’s where the science comes in. Pitting and crevice corrosion are localized forms of attack that can occur even when the rest of the surface looks perfect. The risk is highest in the presence of chlorides (like seawater or de-icing salts) and increases with temperature or poor design features.

To compare resistance between grades, engineers use the Pitting Resistance Equivalent Number (PREN)—a formula that factors in chromium, molybdenum, and nitrogen content. The higher the PREN, the better the resistance to pitting. While specific PREN values vary depending on the exact chemistry, the trend is clear: 316/316L outperforms 304 in chloride environments, but even 316L can be challenged in hot, stagnant, or crevice-prone areas.

Engineers also consider Critical Pitting Temperature (CPT), which is the lowest temperature at which pitting begins in a standardized test. Again, molybdenum-rich grades like 316L provide a higher CPT than 304, but geometry, finish, and maintenance remain crucial to long-term durability.

In chloride-rich service, the Mo-bearing chemistry of 316/316L delivers a step-change over 304, but geometry, finish, and temperature still govern real-world outcomes.

Next, we’ll explore how these material choices translate into mechanical performance, helping you specify the right grade for strength, formability, and service temperature—because choosing the right composition is just the first step in smart stainless steel design.

Mechanical Properties for Smarter Design

When you’re choosing a material for demanding applications, understanding 316 stainless steel properties is crucial. But what do these numbers and terms really mean for your design? Let’s break down the mechanical behavior of 316L and its close cousin, 316, so you can make confident, informed choices—whether you’re building process equipment, medical devices, or marine structures.

Typical Strength and Ductility Ranges

Sounds complex? Here’s the good news: both 316 and 316L offer a balance of strength and ductility that makes them versatile for forming, welding, and in-service use. In the annealed (soft) condition, 316l stainless steel properties include moderate tensile and yield strengths, high elongation (good stretch before break), and excellent toughness. According to supplier and standard data:

| Condition | Tensile Strength (min) | Yield Strength (min) | Elongation (min) | Hardness (max) |

|---|---|---|---|---|

| Annealed (ASTM A240 Plate/Sheet/Strip) | 70000 psi (485 MPa) | 25000 psi (170 MPa) | 40% | 217 Brinell / 95 HRB |

| Annealed (316) | 75000 psi (515 MPa) | 30000 psi (205 MPa) | 40% | 217 Brinell / 95 HRB |

| Cold-Worked (varies by reduction) | Insert values from authoritative datasheets; do not extrapolate. | |||

What does this mean for you? In the annealed state, 316L is easy to form and bend, and it resists cracking even in tough service. The slightly lower strength of 316L compared to 316 is due to its reduced carbon, but for most applications, these differences are minor. Both grades maintain their ductility and toughness—key ss 316 properties—even at low temperatures.

Cold Work Effects on Hardness

Imagine you’re rolling, drawing, or bending 316L sheet for a structural or medical component. You’ll notice it gets harder and stronger with each pass—a phenomenon called strain hardening. This is a hallmark of austenitic stainless steels. As 316L is cold worked, its yield and tensile strength increase, but its ductility (stretch before break) drops. This is why specifying the right condition (annealed vs. cold-worked) is so important for your project’s needs [Praiseworthy Prize].

-

Key takeaways about cold work:

- Cold-worked 316L offers higher strength and hardness, but less formability.

- Annealed 316L is easier to bend, punch, or deep draw—ideal for complex shapes.

- For fatigue-sensitive parts, annealed material often performs better due to retained ductility.

Always check the stainless 316 properties for the exact product form and condition you plan to use—mechanical values can shift significantly with processing. For example, 316 stainless hardness in the annealed state is typically below 217 Brinell, but cold work can push it much higher.

Temperature and Cryogenic Considerations

Will your design see extreme heat or cold? One of the most valuable stainless steel material properties 316 is its ability to maintain toughness even at cryogenic temperatures. Unlike some metals that become brittle in the cold, 316L and 316 remain ductile and strong, making them suitable for applications like LNG piping or cryogenic vessels. At elevated temperatures, both grades retain their strength better than many competing alloys, though prolonged exposure above 800°F (427°C) can affect their microstructure and mechanical performance (especially for non-L grades).

Thermal expansion, modulus, and conductivity should also be considered for precision assemblies or high-temperature service. Always consult datasheets and standards for the specific numbers relevant to your application.

| Checklist for Engineers: Mechanical Properties Selection |

|---|

|

Use mechanical-property values from the exact product form and condition you will procure—standards and supplier datasheets govern the numbers.

Next, we’ll explore how these mechanical characteristics influence welding and fabrication, helping you avoid pitfalls and ensure your 316L assemblies perform as intended.

Welding and Fabrication Essentials for 316L Stainless Steel

Welding 316l stainless steel—whether for a sanitary 316l pipe, a pressure vessel, or a custom bracket—demands more than just technical know-how. Why? Because the real-world performance of ss316l hinges on the right welding practices, filler selection, and post-weld care. If you’re aiming for reliable, corrosion-resistant joints and want to avoid costly rework, this section is your fabrication playbook.

Welding Risks and Sensitization Control

When you weld austenitic stainless steels like 316 l stainless, the big risk is sensitization. Sounds technical? Imagine chromium—the element that gives 316l its corrosion resistance—being pulled out of solution at the grain boundaries during welding. This forms chromium carbides, creating zones vulnerable to intergranular corrosion. The low carbon content in 316l stainless (UNS S31603) is specifically designed to minimize this risk, letting you weld without worrying about weld decay or loss of corrosion resistance in the heat-affected zone.

But even with 316 l steel, you still need to control heat input and avoid lingering too long in one spot. Overheating can cause warping, distortion, or even weaken the joint. That’s why experienced welders always monitor interpass temperatures and use proper joint designs to spread heat evenly.

Recommended Filler Metals

Choosing the right filler metal is critical for maintaining the corrosion resistance and mechanical properties of t316l stainless steel welds. For most applications, you’ll want a 316L filler—this matches the base metal’s chemistry, especially the low carbon and molybdenum content, and prevents weak spots in the weld. Common designations include:

- ER316L (GTAW/TIG and GMAW/MIG wires)

- E316L (SMAW/stick electrodes)

For welding 316l pipe or tube to carbon steel, a 309 filler is usually specified. Always confirm the exact filler designation with AWS A5.x standards and supplier recommendations to ensure compliance with project requirements.

Step by Step Post‑Weld Best Practices

Want to avoid the most common welding failures with ss 316l? Follow this practical, field-tested checklist for every weld:

- Joint Preparation and Cleanliness: Remove all grease, oil, dirt, and especially iron particles from the weld area. Any contamination can cause localized rust or reduce corrosion resistance.

- Control Heat Input: Use the lowest amperage and voltage practical for the joint. Avoid excessive heat buildup to reduce distortion and prevent sensitization.

- Monitor Interpass Temperature: Keep interpass temperatures within recommended limits (typically below 150°C/300°F) to minimize grain growth and preserve toughness.

- Shielding and Back Purging: For tubes, piping, or sanitary welds, use inert gas shielding (argon is common) on both sides of the weld to prevent oxidation and discoloration inside the joint.

- Post-Weld Cleaning and Passivation: Remove all weld discoloration (heat tint) and restore the passive chromium-rich surface layer. Use mechanical methods (abrasive pads, brushing), followed by chemical pickling and passivation per ASTM A380/A967 [BSSA].

-

Process Tips by Welding Method:

- GTAW/TIG: Ideal for thin sanitary tubing and critical welds. Produces clean, precise joints but is slower and more skill-intensive.

- GMAW/MIG: Good for productivity and thicker sections. Faster than TIG, but requires careful parameter control for quality results.

- SMAW/Stick: Suitable for field repairs or hard-to-access joints. Portable, but produces more slag and requires more cleanup.

Always validate your welding parameters and procedures with a qualified WPS (Welding Procedure Specification) and PQR (Procedure Qualification Record) to ensure repeatable results and code compliance.

Don’t forget: post-weld heat treatment (PWHT) is generally not required for austenitic grades like ss316l. However, in rare cases—such as thick, highly stressed weldments or when specified by codes—a solution anneal or stress-relieving treatment may be called for. Check ASM Handbooks or project specs for guidance.

After welding, cleaning and passivation are as critical as filler choice—surface chemistry governs corrosion performance.

By following these best practices, your 316 l stainless assemblies will not only meet but exceed expectations for durability, hygiene, and long-term corrosion resistance. Next up, we’ll cover how to machine, form, and finish 316l for cost-effective, high-quality fabrication results.

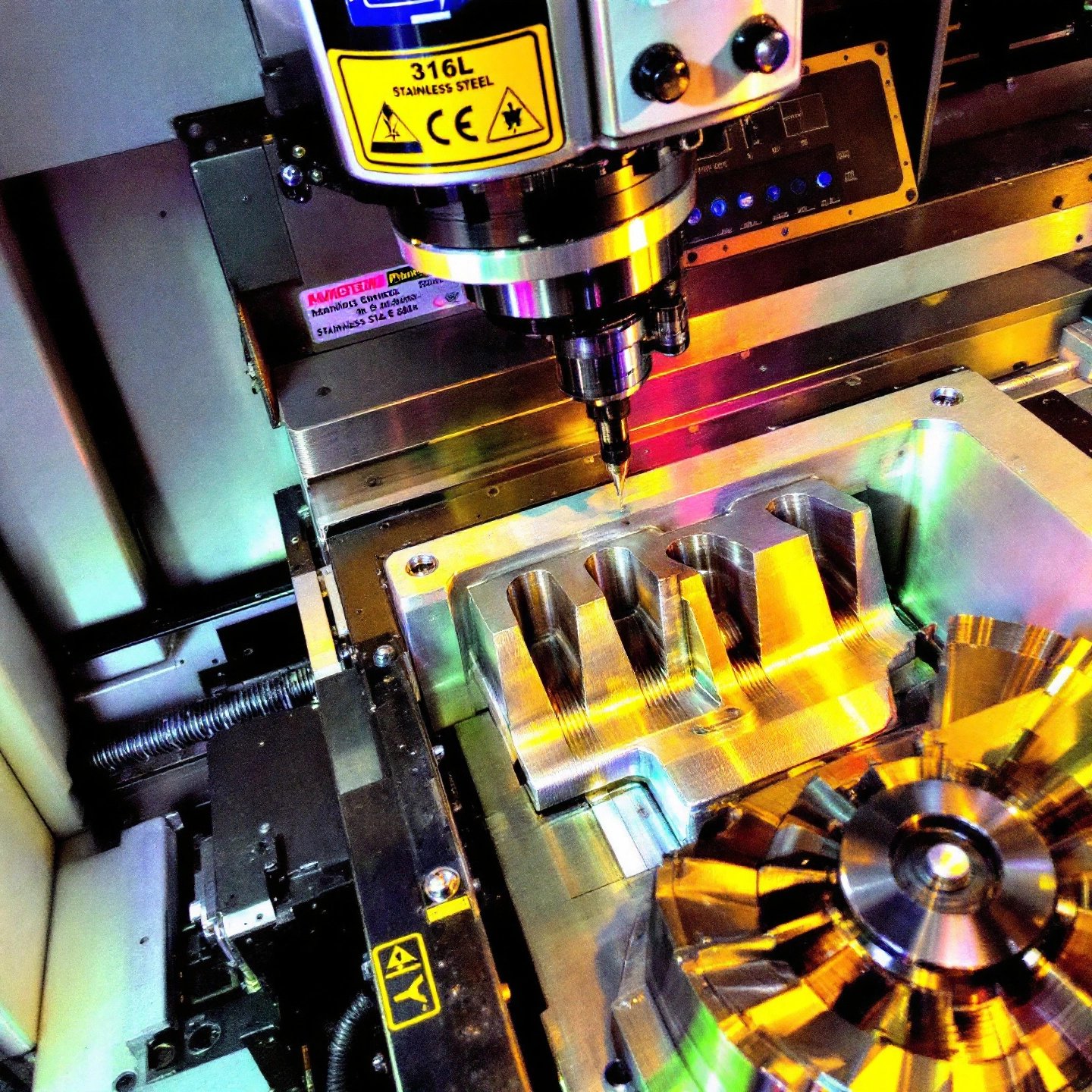

Machining and Forming Best Practices for 316L Stainless Steel Sheet and Plate

Machining Work-Hardening and Tooling

Ever wondered why machining 316l stainless steel sheet sometimes feels like a battle against your own tools? The answer lies in the alloy’s strong work-hardening tendency. As you cut, the surface hardens quickly—meaning each pass gets tougher, and tool wear accelerates. To stay ahead, use sharp, rigid tooling (preferably carbide with heat-resistant coatings) and maintain steady, consistent feeds. Avoid rubbing or lingering with the tool, as this only deepens the hardened layer and shortens tool life.

Surface speeds should be slower than those for free-machining steels, and aggressive, continuous cuts are preferred over light, repetitive passes. High-pressure coolant is a must—helping manage heat buildup in the cutting zone and flushing away chips before they can scratch or mar the finish. If you’re working with thin 316l sheet or intricate parts, keep setups as rigid as possible to minimize vibration and dimensional drift.

- Minimize tool dwell—keep the tool moving to avoid excessive work hardening.

- Use coated carbide tools for improved productivity and longer tool life.

- Keep fixtures and setups rigid to reduce chatter and maintain accuracy.

- Clear chips frequently—stringy chips can damage both the tool and the 316 ss sheet surface.

- Apply abundant, well-directed coolant to control temperature and prevent built-up edge.

Forming and Bending Practices

When it comes to forming or bending 316 stainless steel sheet and plate, you’ll notice it’s both ductile and strong—but that work-hardening behavior means you need to plan ahead. Generous bend radii are your friend: tight bends increase the risk of cracking or springback, especially on thicker or cold-worked 316 ss plate. For heavy forming, consider intermediate anneals to restore ductility and reduce internal stress. Always pay attention to grain direction in sheet—bending against the grain can require more force and may lead to surface imperfections.

- Use larger radii for thicker or work-hardened material to avoid cracking.

- Plan for springback—overbend slightly to achieve your final shape.

- For tight bends or complex forms, intermediate annealing may be necessary.

- Protect the surface during forming to maintain finish quality and corrosion resistance.

Surface Finish and Passivation

Surface finish isn’t just about looks—on 316l stainless steel plate, it can make or break corrosion resistance and cleanability. For sanitary or food-grade applications, aim for a smooth, low-roughness finish (often below Ra 0.8 μm), achieved through fine machining, polishing, or even electropolishing. Structural uses may tolerate rougher finishes, but smoother surfaces always resist corrosion better and are easier to clean.

After machining or forming, always specify final passivation—this chemical process removes contaminants and restores the protective chromium oxide layer, ensuring your 316 stainless sheet or plate delivers its full corrosion resistance. For aggressive environments, electropolishing can further enhance durability and hygiene by smoothing microscopic peaks and valleys.

- Match surface roughness targets to your application—sanitary vs. structural.

- Choose polishing or electropolishing for maximum corrosion resistance.

- Always include passivation as a final step after machining or forming.

Specify the end condition in the PO—finish and passivation details drive corrosion performance and validation.

By following these machining, forming, and finishing best practices, you’ll unlock the full potential of 316l stainless steel sheet and plate—delivering parts that perform reliably, look great, and stand up to the harshest environments. Up next, we’ll connect these fabrication insights to real-world applications and design considerations for demanding industries.

Applications and Design Considerations for 316L Stainless Steel

When you’re choosing a material for projects that demand reliability, safety, and long-term performance, it’s not just about the alloy—it’s about how you apply it. Where does 316l stainless steel truly shine? Let’s walk through the most common (and critical) real-world uses, from saltwater docks to surgical implants, and see how smart design choices amplify the strengths of this versatile alloy.

Marine and Coastal Hardware

Ever wondered why marine grade stainless steel is the go-to for docks, boat fittings, and coastal fasteners? It’s all about resisting relentless salt spray and corrosion. 316L stainless steel, with its added molybdenum and low carbon, is the backbone of marine stainless steel hardware—from handrails and shackles to underwater piping and A4 fasteners. But it’s not just the alloy that matters. Imagine a dock where water sits trapped in tight corners—these crevices become hotspots for corrosion, even with the best materials.

-

Design for durability:

- Use 316/316L or A4 fasteners for maximum resistance in saltwater environments.

- Avoid stagnant crevices—design joints and connections to drain freely.

- Specify smooth, polished finishes to reduce initiation sites for corrosion.

- In splash zones, recommend routine freshwater rinsing to clear away salt buildup.

Even in the harshest marine settings, the right combination of material, finish, and maintenance can extend the life of your installations well beyond what lesser alloys offer.

Chemical and Pharmaceutical Equipment

When hygiene, cleanability, and resistance to aggressive chemicals are non-negotiable, 316L is the default choice for process equipment, piping, and tanks. Its smooth surface and resistance to pitting make it ideal for pharmaceutical reactors, food-grade tanks, and chemical dosing lines. But you’ll notice, it’s not just about the steel grade—it’s about ensuring every weld, seal, and surface finish meets strict standards.

- Verify all wetted parts use 316L, especially in contact with chlorides or cleaning agents.

- Specify post-weld passivation to restore corrosion resistance after fabrication.

- Consult compatibility tables (NACE/ASM) to confirm resistance to specific chemicals and temperatures.

- Demand smooth, low-roughness finishes for easy cleaning and to prevent bacterial growth.

By combining the right alloy with careful fabrication and validation, you’ll minimize contamination risks and ensure process reliability.

Medical, Jewelry, and Hygiene‑Critical Uses

Imagine a surgical implant or a piece of body jewelry—wouldn’t you want the best stainless steel grade hypoallergenic material available? That’s why 316l surgical stainless steel is trusted for implants, surgical instruments, and jewelry. Its low carbon and carefully controlled nickel content make it a low-allergy option, widely accepted for direct body contact. Still, you may wonder: is stainless steel hypoallergenic? Or more specifically, is 316l stainless steel hypoallergenic?

- 316L is considered hypoallergenic for most people, thanks to its low nickel release and clean surface finish.

- For medical implants and surgical tools, always verify compliance with relevant standards (such as ISO 5832).

- For jewelry, finish quality matters—polished surfaces reduce the risk of skin reactions.

- Remember: while 316L minimizes allergy risks, no material is 100% reaction-proof for everyone. Always test or specify appropriately for sensitive applications.

So, is surgical stainless steel hypoallergenic? In most cases, yes—316L is the industry benchmark for minimizing allergic reactions, which is why it’s so prevalent in medical and jewelry uses.

| Requirement | Design Action |

|---|---|

| Chloride exposure | Choose Mo-bearing grade (316/316L) and specify smooth finish |

| Welds in sanitary lines | Use 316L filler and specify post-weld passivation |

| Disinfection chemicals | Consult compatibility tables for temperature and concentration limits |

| Body-contact or jewelry | Specify 316L, polished finish, and validate hypoallergenic performance |

Material choice plus geometry, finish, and maintenance determine service life more than alloy designation alone.

As you can see, leveraging the strengths of 316l stainless steel is about more than just picking a grade—it’s about smart design, careful fabrication, and ongoing care. In the next section, we’ll tackle troubleshooting and maintenance strategies to help you get the most from your stainless investments.

Troubleshooting Corrosion and Failures

Ever spotted mysterious brown stains on your supposedly “rust-proof” stainless steel 316l? Or noticed unexpected pitting on a marine railing or pharmaceutical tank? Even the best alloys can falter if the environment or maintenance isn’t right. This field-ready guide breaks down common failure modes and gives you practical steps to keep your 316l ss performing as intended.

Spotting Pitting and Crevice Corrosion

When you see small, dark spots or rough patches on your stainless steel 316l, you might wonder: will 316 stainless steel rust? While true red rust is rare on 316l, localized corrosion like pitting and crevice attack can occur—especially in salty, stagnant, or poorly maintained environments. Here’s how to diagnose the problem before it spreads:

- Identify the environment: Is the part exposed to chlorides (saltwater, deicing salts), high humidity, or elevated temperatures? These factors dramatically increase the risk of pitting and crevice corrosion.

- Inspect geometry: Look for tight crevices, overlapping joints, or areas where water and debris collect—these are prime sites for attack.

- Examine welds: Check heat-affected zones for discoloration (heat tint), cracks, or roughness—these can signal sensitization or early corrosion.

- Verify surface finish and passivation: Has the passive layer been properly restored after fabrication? Dull or stained areas may indicate insufficient passivation.

- Review cleaning and exposure cycles: Are aggressive cleaners, bleach, or high-chloride water used regularly? Frequent exposure without thorough rinsing can damage even the best 316l properties.

-

Likely causes to consider:

- Insufficient or damaged passivation layer

- Iron contamination from tools or shop debris

- Improper filler metal or excessive heat input during welding

- Stagnant chloride-rich water trapped in crevices

- Use of incompatible cleaning chemicals

Intergranular Attack After Welding

Imagine you’ve just finished welding a sanitary line or marine fixture using 316l ss. Weeks later, you notice brown lines or cracks along the weld. This could be intergranular corrosion—where chromium carbides form at grain boundaries due to excessive heat or improper welding technique. The low carbon content of 316l stainless helps prevent this, but poor practices or contamination can still cause trouble.

- Look for discoloration (heat tint) or roughness in the heat-affected zone.

- Check if the weld area was properly cleaned and passivated per ASTM A380/A967.

- Review whether the correct filler metal was used and if welding parameters were within recommended limits.

Preventive Actions and Maintenance

Want to avoid costly failures or ugly tea staining on your stainless steel 316l? Here’s a practical checklist for prevention and remediation:

- Thorough cleaning: Routinely clean surfaces with mild, chloride-free detergents and rinse with fresh water, especially in marine or chemical environments.

- Repassivation: If surface iron contamination or corrosion is found, restore the passive layer using chemical passivation treatments as specified in ASTM A380/A967.

- Eliminate crevices: Redesign joints and assemblies to allow for drainage and minimize areas where salts can collect.

- Upgrade finish or alloy: For the most demanding environments, specify smoother finishes or consider higher-alloy materials if repeated failures occur.

- Document issues: Take photos and record details of any failures to help guide future remediation and material selection.

Even 316/316L can show rust tea staining in marine air—deposits and crevices are the usual culprits.

Keep in mind, the risk of pitting and crevice corrosion rises with higher chloride concentration, temperature, and poor oxygen supply. There’s no universal “safe” chloride limit—so regular inspection and maintenance are your best defense. By understanding these failure modes and acting early, you’ll extend the service life and reliability of your 316l stainless steel investments.

Ready to ensure your next project is specified right from the start? In the next section, we’ll cover the essential standards and specifications that keep your 316l ss projects on track and performing as expected.

Specifications and Standards That Matter for 316L Stainless Steel

Ever been confused by the alphabet soup of designations and standards when sourcing 316l stainless steel? You’re not alone. Whether you’re in procurement, engineering, or QA, getting the right alloy—and documenting it correctly—is the key to performance, compliance, and cost control. Let’s break down what each code means, how to match them to your needs, and what to specify on your purchase order to avoid costly surprises.

UNS and AISI Designations

First things first: what’s the difference between UNS and AISI numbers? You’ll often see both on datasheets, but they serve different purposes.

- UNS S31600 – This is the Unified Numbering System designation for standard 316 stainless.

- UNS S31603 – This marks the low-carbon 316L variant.

- AISI 316 and AISI 316L – These are traditional American Iron and Steel Institute (AISI) numbers. They’re widely used in literature and commerce ("aisi 316 stainless steel" or "aisi 316 ss"), but aren’t precise enough for procurement—since chemistry and mechanical property requirements can vary by product form and standard. Always pair AISI with the correct UNS and ASTM spec for clarity.

In practice, you’ll also encounter EN and DIN designations (like 1.4401 for 316 and 1.4404 for 316L), especially in European supply chains. For global projects, cross-reference these with UNS and AISI numbers to ensure you’re getting the right material.

Common ASTM Product Standards

Now, let’s talk about the standards that really matter when ordering astm 316 stainless steel or type 316 stainless steel. ASTM (American Society for Testing and Materials) standards define the chemistry, mechanical properties, and testing methods for each product form. Here are the most frequently used ones for 316/316L:

- ASTM A240 – Plate, sheet, and strip (often dual-certified as 316/316L)

- ASTM A276 – Bars and shapes (hot-finished or cold-finished)

- ASTM A479 – Bars and shapes for pressure vessels

- ASTM A312 – Seamless and welded pipe

- ASTM A213 – Seamless tubes for heat exchangers and condensers

- ASTM A193 – Bolting materials for high temperature or pressure service

Always confirm the exact standard and revision with your supplier—requirements can change, and not all standards are interchangeable. For example, A240 covers t316 stainless steel sheet and plate, while A312 is for pipe. Using the wrong standard can lead to compliance issues or unexpected failures.

| Designation | Meaning/Use | Notes |

|---|---|---|

| UNS S31600 | 316 (standard carbon) | Used for general 316 stainless; matches A240, A276, A312, etc. |

| UNS S31603 | 316L (low carbon) | Preferred for welded, thick, or hygiene-critical parts |

| AISI 316 / AISI 316L | Traditional American designations | Common in specs and commerce; always pair with UNS/ASTM for procurement |

| ASTM A240 | Plate, sheet, strip | Dual-certified 316/316L is common |

| ASTM A276 | Bars, shapes | Check for finish (hot/cold) and condition |

| ASTM A312 | Seamless/welded pipe | Pressure-rated; used in process piping |

| DIN 1.4401 / 1.4404 | European 316 / 316L equivalents | Match to UNS S31600 / S31603 for global sourcing |

What to Put on the Purchase Order

Ready to order? Here’s a practical checklist to ensure your PO is bulletproof—no matter if you’re sourcing aisi 316l stainless steel, dual-certified plate, or pipe for a regulated project:

| PO Checklist for 316/316L Stainless Steel |

|---|

|

It’s always smart to include any special requirements—such as dual certification (316/316L), specific heat/lot traceability, or compliance with pressure vessel codes—up front. This avoids ambiguity and ensures you get the exact aisi 316 ss or aisi 316l stainless steel product your project demands.

Specifications control quality—list the exact UNS, product standard, condition, and finish to avoid ambiguity.

With your specs in order, you’re ready to move from paperwork to production. Next, we’ll show you how to turn those requirements into precision parts—covering vendor selection, DFM tips, and how to streamline sourcing for 316L components.

Selecting between 316 and 316L

When you’re faced with the choice—316 vs 316L stainless steel—it can feel like splitting hairs. But the subtle differences between these two grades have a big impact on weld reliability, long-term corrosion resistance, and ease of fabrication. So, when should you reach for 316, and when is 316L the clear winner? Let’s break down the facts so you can make the right call for your project.

When To Choose 316 vs 316L

Imagine you’re specifying material for a process tank, a marine railing, or a pharmaceutical line. Both 316 and 316L offer robust corrosion resistance—especially in environments exposed to chlorides or harsh chemicals. However, the choice comes down to how you’ll fabricate and use the material:

- Welded assemblies: 316L is almost always preferred. Its lower carbon content minimizes sensitization, reducing the risk of intergranular corrosion and weld decay.

- Non-welded structures: Both grades perform similarly. You can choose either, but confirm the specification with your supplier.

- Heavy-gauge or thick sections: 316L is safer if post-weld heat treatment isn’t feasible, as it maintains corrosion resistance even after welding.

- Extreme chloride or marine environments: Both grades are suitable, but design details (like crevice avoidance and surface finish) matter more than the minor differences between 316 and 316L.

In short, if your part will be welded—or if you need maximum reliability at joints—316L is the smart, low-risk choice. For purely structural or non-welded applications, either grade can deliver excellent performance.

Composition Differences In Practice

Sounds technical? Here’s the practical breakdown: the main distinction between 316 versus 316L is carbon content. 316L contains less carbon (max 0.03%) than standard 316 (max 0.08%). This tweak means 316L resists forming chromium carbides during welding, so it keeps its corrosion resistance right at the welds.

| Property | 316 | 316L | Notes |

|---|---|---|---|

| Carbon Content (max) | 0.08% | 0.03% | Lower in 316L to prevent sensitization |

| Weld Performance | Risk of weld decay if not heat treated | Excellent, no post-weld heat treatment needed | 316L preferred for welded assemblies |

| Typical Applications | Structural, construction, non-welded parts | Pharma, food, marine, welded tanks, piping | 316L for hygiene and corrosion-critical uses |

| Mechanical Strength | Slightly higher | Slightly lower | Difference is minor for most uses |

It’s easy to see why, in the debate of 316 ss vs 316l, the “L” grade is the default for welded or hygiene-critical applications. For most other uses, the two are functionally interchangeable—just check your specs and compliance requirements.

Cost And Availability Considerations

Worried about cost or lead times? Good news: both 316 and 316L are widely available in sheet, plate, bar, pipe, and tubing. They’re often dual-certified, meaning a single batch meets both specs. Pricing trends for 316l vs 316 are generally similar, with any premium driven by local demand or specific certifications—not the chemistry itself.

Here’s a quick decision flow to help you choose:

- Welded sanitary systems: Go with 316L.

- Thick welded sections or no post-weld heat treatment: 316L is safer.

- Non-welded structural applications: Either 316 or 316L; confirm with your supplier.

- Extreme chloride exposure: Consider design upgrades (better drainage, smoother finish) or, for severe cases, a higher-alloy grade.

In summary, the question of 316l ss vs 316 ss is less about price or basic corrosion resistance, and more about how you’ll fabricate and use the final part.

If welding is on the print, default to 316L unless a qualified procedure justifies otherwise.

Now that you know how to select between these two workhorse grades, the next step is turning your design into finished parts. Up next: practical strategies for sourcing, vendor qualification, and design for manufacturability—so you get the most from your 316L investment.

Sourcing Precision 316L Machined Parts

Turning your 316l stainless steel design into a finished part isn’t just about picking the right alloy—it’s about making smart decisions at every stage, from drafting your drawings to selecting a vendor. With 316l steel’s unique work-hardening and corrosion-resistant properties, a little extra planning goes a long way toward avoiding costly surprises. So, how do you ensure your stainless 316l parts are manufactured right the first time?

Design For Manufacturability In 316L

Sounds complex? Imagine you’ve specified a critical component in 316ss material for a marine, medical, or high-purity application. You’ll want your design to not only perform but also be cost-effective to produce. Here’s where Design for Manufacturability (DFM) becomes essential—especially with material 316l and 316l plate forms that are prone to work hardening and require careful handling.

- Specify finish and passivation: Clearly call out surface finish (e.g., Ra value, polish level) and post-machining passivation. A well-defined finish ensures both corrosion resistance and hygiene.

- Plan for work hardening: 316l steel work-hardens rapidly. Use generous tolerances where possible, and indicate critical features that require extra attention, such as thin walls or tight radii.

- Confirm product standards: On your PO, match the UNS designation (e.g., S31603 for sus 316l), ASTM standard (e.g., A240 for 316l plate, A312 for tubing), and required mechanical properties. This prevents confusion and ensures compliance.

- Minimize secondary operations: If possible, design parts to reduce the need for heavy post-machining—complex features may drive up cost and risk in 316l steel sheets and plates.

Lock surface finish and passivation in drawings to avoid ambiguity across vendors.

Vendor Qualification Checklist

When sourcing 316l material components, not all machine shops are created equal. The right partner will have proven experience with stainless 316l, the right equipment for tight tolerances, and robust quality systems. Here’s a practical checklist to help you qualify vendors—whether you’re ordering 316l steel sheets, custom 316l plate, or high-precision parts:

| Qualification Criteria | What to Look For |

|---|---|

| Experience with 316/316L machining | Portfolio of similar projects or case studies, especially with complex or tolerance-critical parts |

| 4/5-axis CNC capability | Ability to handle complex geometries and maintain tolerances on challenging features |

| Quality certifications | ISO 9001:2015 and IATF16949 for regulated industries (medical, automotive, aerospace) |

| Material traceability | Full documentation from mill certs to final inspection; ability to provide heat/lot traceability for each batch of 316l steel |

| Surface treatment and passivation | In-house or certified partners for finishing, passivation, and validation per ASTM A380/A967 |

| Engineering support | Ability to advise on DFM for 316l steel sheets and plate, including tolerance, finish, and cost trade-offs |

For projects requiring rapid turnaround or ultra-tight tolerances, partnering with a specialist can make all the difference. For example, XTJ offers advanced 4 and 5-axis CNC machining specifically suited for 316L’s work-hardening challenges, with ISO/IATF certifications and engineering support to optimize your design for manufacturability and cost. This level of capability helps de-risk projects where precision and compliance are non-negotiable.

From Prototype To Production

Once you’ve locked in your design and qualified your vendor, the path from prototype to full-scale production in 316l material is all about process control and communication. Here’s how to keep things on track:

- Prototype with intent: Start with a standard finish and adjust only if your functional or regulatory requirements demand it. Over-specifying surface finish or tolerance can drive up costs unnecessarily.

- Validate machining strategy: 316l steel requires slower feeds, sharp carbide tooling, and abundant coolant to manage heat and work hardening. Confirm your vendor’s process plan includes these best practices.

- Document and inspect: Require detailed inspection reports, including dimensional checks and surface finish validation. For critical parts, request full material traceability and passivation certificates.

- Plan for scale: As you move to production, work with your vendor to optimize toolpaths, batch sizes, and inspection routines for efficiency without sacrificing quality.

By following these steps, you’ll ensure your 316l steel sheets, plate, or machined parts deliver the performance, durability, and compliance your application demands. The result? Fewer surprises, lower total cost, and components that stand up to even the harshest environments.

Frequently Asked Questions about 316L Stainless Steel

1. Is 316L stainless steel hypoallergenic and safe for sensitive skin?

316L stainless steel is widely regarded as hypoallergenic and is commonly used in medical devices, jewelry, and body piercings. Its low nickel release and smooth surface finish minimize skin irritation, making it a preferred choice for sensitive skin. However, individual reactions can vary, so high-polish finishes and proper cleaning further reduce allergy risks.

2. What is the main difference between 316 and 316L stainless steel?

The key difference is carbon content: 316L has a lower maximum carbon level than 316, making it less prone to sensitization and intergranular corrosion after welding. This means 316L is ideal for welded or hygiene-critical assemblies, while both grades offer similar corrosion resistance in most environments.

3. Does 316L stainless steel rust in marine or coastal environments?

316L stainless steel is highly resistant to rust and corrosion, especially in chloride-rich environments like marine or coastal areas. However, improper design, surface contamination, or lack of maintenance can lead to localized staining or pitting. Regular cleaning and proper drainage help maintain its corrosion resistance.

4. How should 316L stainless steel be specified on a purchase order?

A complete specification should include the UNS designation (S31603 for 316L), the relevant ASTM product standard (such as A240 for plate or A312 for pipe), required condition (annealed or cold-worked), surface finish, any mechanical property requirements, and details for passivation or special testing. This ensures clarity and quality in procurement.

5. What are best practices for machining and welding 316L stainless steel?

For machining, use sharp carbide tools, slow cutting speeds, and steady feeds to minimize work hardening. When welding, use 316L filler metals, control heat input, and always clean and passivate welds to restore corrosion resistance. Partnering with experienced vendors and specifying finish requirements on drawings are essential for optimal results.

-

Posted in

316l stainless steel, corrosion resistance, machining best practices, marine grade stainless, welding and fabrication