316 Stainless Steel: 9 Essential Points Engineers Rely On

Understanding the Foundations of 316 Stainless Steel

What Is 316 Stainless Steel?

Ever wondered what sets 316 stainless steel apart from the rest? If you’ve worked with process equipment, marine hardware, or medical devices, you’ve likely come across this material. In simple terms, 316 is an austenitic stainless steel—meaning it has a face-centered cubic crystal structure that delivers outstanding toughness and ductility. But what is 316 stainless really? It’s the go-to grade when you need reliable corrosion resistance, especially in environments where chlorides or harsh chemicals are present. Compared to the more common 304 grade, 316 stands out thanks to its addition of molybdenum, which significantly boosts its pitting and crevice corrosion resistance in salty or aggressive environments.

Why 316 Is Called Austenitic

316 stainless steel belongs to the austenitic family—think of it as the most widely used group of stainless steels. The term "austenitic" describes its internal structure, which is stable across a wide range of temperatures and gives this alloy its characteristic non-magnetic nature and excellent toughness, even at cryogenic temperatures. This structure is also why stainless steel ss 316 is so formable and weldable, making it a favorite for complex fabrications and demanding service conditions.

Typical Composition Ranges

If you’ve ever asked, “What’s the composition of 316 stainless steel?” you’re not alone. The alloy’s composition is tightly controlled to ensure consistent performance. Here’s a quick look at how standards define it:

| Standard Designation | UNS Number | Typical Composition (wt%) |

|---|---|---|

| AISI 316 | S31600 | Cr: 16.0–18.0, Ni: 10.0–14.0, Mo: 2.0–3.0, C: ≤0.08, Mn: ≤2.00, Si: ≤0.75, P: ≤0.045, S: ≤0.030 |

These ranges are specified in standards such as ASTM A240 and EN 10088-3. The addition of molybdenum is what truly separates 316 from other grades and gives it the "marine grade stainless steel" reputation [Wikipedia: Marine Grade Stainless].

- Superior resistance to chlorides and many chemicals

- Excellent toughness and ductility (even at low temperatures)

- Outstanding cleanability and hygiene

- Good weldability and formability

- Non-magnetic in the annealed condition

Where 316 Excels in Real Applications

Picture this: You’re designing a piece of equipment that will face salty air, splashing seawater, or corrosive chemicals. That’s where 316 stainless truly shines. Typical forms include sheet, plate, bar, tube, and fasteners. You’ll see it in:

- Marine hardware and fittings

- Chemical and pharmaceutical processing equipment

- Food and beverage production lines

- Medical components and surgical instruments

- Architectural elements in coastal or urban environments

The key advantage of 316 stainless steel lies in its molybdenum content, which enhances resistance to pitting and crevice corrosion—especially in chloride-rich and marine environments.

So, when you’re comparing the composition of 316 stainless steel to other grades, remember its unique blend of chromium, nickel, and molybdenum. This is what gives it the edge as a "marine grade stainless steel," though it’s not invincible in all seawater conditions. Later in this article, we’ll dig deeper into 316L and 316H variants, and explain how corrosion mechanisms like pitting and stress corrosion cracking can influence your material selection. For now, keep in mind that 316 stainless offers a robust, versatile solution for tough, corrosive applications where reliability matters most.

Choosing Between 304 and 316 for Your Environment

Core Differences Between 304 and 316

When you’re weighing your options for a project, you might wonder: Is there a real difference between 304 and 316 stainless steel? To the naked eye, both look almost identical, but the secret is in the chemistry. Both are austenitic grades—non-magnetic, easy to fabricate, and widely used. The main distinction is that 316 contains molybdenum (about 2–3%), while 304 does not. This addition gives 316 a significant edge in resisting corrosion from chlorides and harsh chemicals.

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Composition (approx.) | 18% Cr, 8% Ni | 16% Cr, 10% Ni, 2–3% Mo |

| Corrosion Resistance | Good in most environments | Excellent, especially to chlorides and acids |

| Weldability | Excellent | Excellent |

| Formability | Excellent | Excellent |

| Availability | Most common globally | Widely available, but less than 304 |

| Typical Applications | Kitchenware, food equipment, architectural trim | Marine, chemical, pharmaceutical, medical devices |

| Cost | Lower | Higher (due to Mo and Ni) |

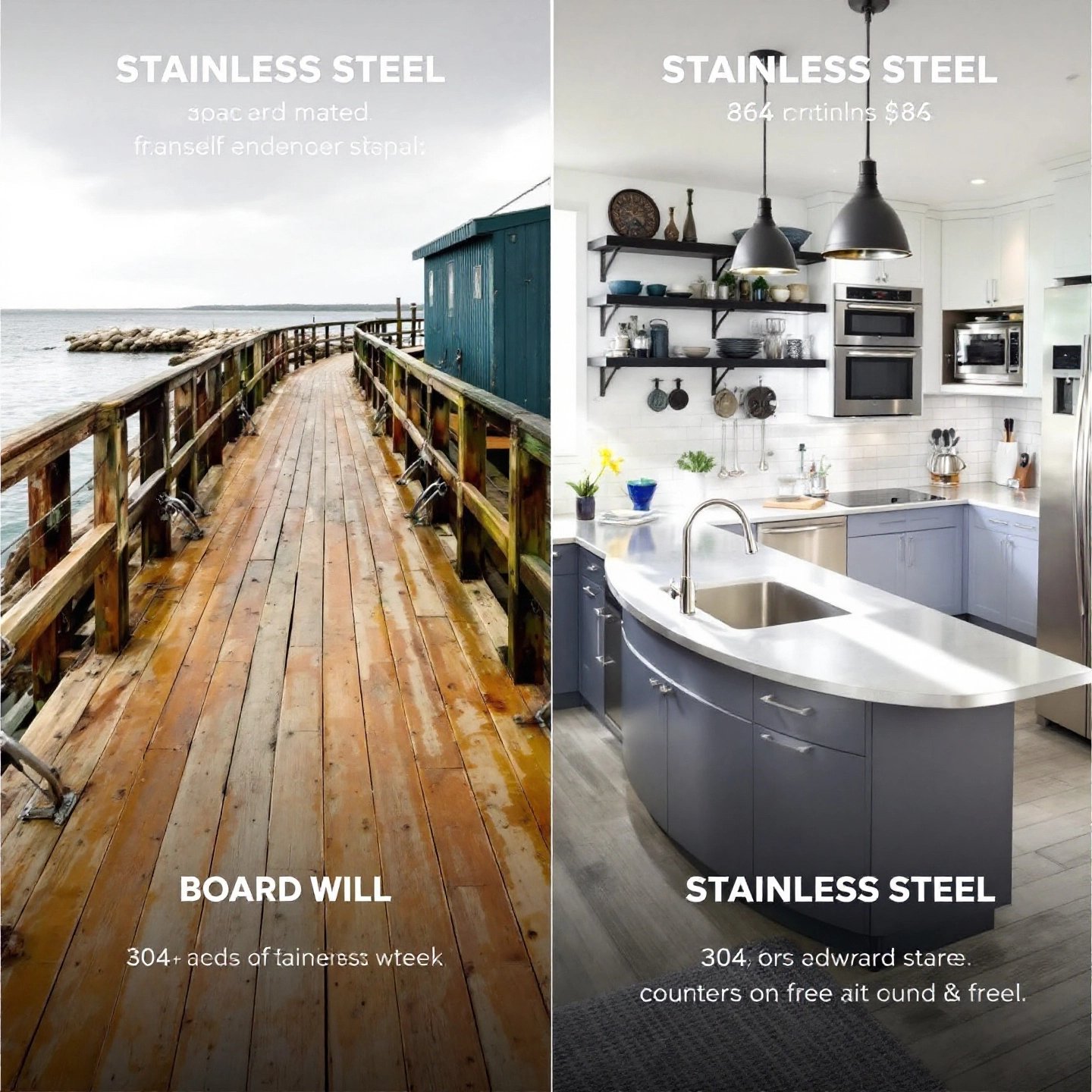

Corrosion and Chloride Exposure Considerations

Imagine you’re designing for a coastal boardwalk, a food processing plant, or a chemical tank. Here, the difference between 316 stainless steel and 304 is critical. 316 stands up to saltwater and de-icing salts, making it a staple in marine and chemical environments. The molybdenum in 316 helps prevent pitting and crevice corrosion where chlorides are present. In contrast, 304 is suitable for less aggressive settings and is the standard for kitchen equipment and architectural details not exposed to harsh chemicals.

- Near saltwater or de-icing salts? Choose 316.

- General indoor or dry architectural use? 304 is often sufficient.

- Frequent cleaning with strong chemicals? 316 offers extra peace of mind.

- Food contact? Both meet FDA requirements, but 316 is preferred for aggressive sanitizing agents.

When selecting between stainless steel 304 vs 316, environments with high chloride or chemical exposure should almost always drive you toward 316 for long-term reliability.

Cost Versus Risk and Service Life

Let’s talk numbers—without hard figures. 304 is less expensive and, for many benign environments, delivers excellent performance at a lower initial cost. However, if corrosion occurs, replacement or repair can quickly outstrip the upfront savings. In harsh environments, 316 often extends service life by years, justifying its higher initial investment. Lifecycle thinking means weighing not just purchase price, but also the cost of maintenance, downtime, and risk of failure.

When 304 Still Makes Sense

Sounds complex? It doesn’t have to be. For many indoor, dry, or mildly corrosive settings, 304 is a practical, economical choice. You’ll notice it’s the most widely used stainless grade worldwide for a reason. For food prep surfaces, general architectural trim, or hardware not exposed to aggressive chemicals, 304 stainless steel vs 316 stainless steel is often an easy decision: 304 suffices. But when in doubt—especially where chlorides or acids lurk—316 is the safer bet.

Up next, we’ll explore how 316’s variants—such as 316L and 316H—can further fine-tune your choice for welded assemblies and high-temperature applications.

Selecting Among 316 316L and 316H Grades

When to Choose 316L for Welded Assemblies

Imagine you’re fabricating a tank or piping system that will be repeatedly welded, or exposed to aggressive cleaning chemicals. In these scenarios, 316L stainless steel is the engineer’s top pick. Why? The lower carbon content in 316L (316l composition specifies a maximum of 0.03% carbon) minimizes the risk of carbide precipitation during welding. This means you avoid the dreaded sensitization and resulting intergranular corrosion at weld seams—a common failure mode in standard 316. The improved weldability and resistance to post-weld corrosion make 316L ideal for pharmaceutical, food, and chemical process equipment, especially when heavy-gauge or complex welded assemblies are involved.

Where 316H Makes Sense for Elevated Temperatures

Now, picture a heat exchanger, boiler, or steam piping system operating at sustained high temperatures. Here, 316H stainless steel comes into its own. With a higher carbon content (0.04–0.10%), 316H delivers increased strength and creep resistance at elevated temperatures. This makes it the go-to for power generation, petrochemical, and refinery applications where materials are expected to hold up under stress and heat over long periods. While 316H offers similar corrosion resistance to standard 316, its mechanical properties at high temperatures are what set it apart.

Decision Flow: 316 vs 316L vs 316H

Not sure which grade to specify? Use this step-by-step guide to match the right alloy to your application:

- Will your component be welded, and is minimizing sensitization critical? → Choose 316L stainless steel (316l stainless steel composition provides superior weldability).

- Is your service environment defined by continuous or high-temperature operation (above 500°C), with a need for long-term strength? → Opt for 316H stainless steel.

- Do you need robust general chloride resistance without specific weld or temperature demands? → Standard 316 is a reliable, cost-effective choice.

| Grade | Typical Use Case | Weldability | Temperature Focus | Common Standards |

|---|---|---|---|---|

| 316 | General corrosion resistance, process equipment, marine fittings | Good (post-weld annealing may be needed) | Ambient to moderate | ASTM A240, A312 |

| 316L | Welded assemblies, tanks, pipes, pharmaceutical & food equipment | Excellent (no post-weld anneal required) | Ambient to moderate | ASTM A240, A312 |

| 316H | High-temperature service: boilers, heat exchangers, refinery piping | Good (special techniques for thick sections) | Elevated (above 500°C) | ASTM A240, A312 |

Other Types Within the 316 Family

While 316, 316L, and 316H are the main variants, you may encounter others like 316Ti (stabilized with titanium for enhanced high-temperature corrosion resistance) in specialized European or legacy applications. However, for most engineering needs, the trio above covers the key decision points.

Always verify your grade selection against the project’s mechanical, corrosion, and code requirements—refer to the standards and datasheets discussed in Section 9 to ensure compliance and long-term reliability.

Understanding the differences in 316 vs 316l stainless steel and knowing when to specify 316h stainless steel empowers you to match your material to the job—whether that means tackling tough welds, withstanding high heat, or ensuring everyday durability in corrosive environments. Up next, we’ll explore how these grades perform under real-world corrosion mechanisms like pitting and stress corrosion cracking, and what you can do to maximize service life.

Corrosion Behavior and PREN Explained for 316

Understanding PREN and What It Indicates

When you’re specifying materials for harsh environments, a common question is: Will 316 stainless steel rust? While 316 stainless offers excellent corrosion resistance—especially in marine stainless steel applications—no alloy is completely immune. That’s where understanding the Pitting Resistance Equivalent Number (PREN) comes into play. PREN is a comparative tool for ranking the relative pitting corrosion resistance of stainless steels within the same family. It’s based on the alloy’s chromium, molybdenum, and nitrogen content, with each element contributing to the alloy’s ability to resist localized attack from chlorides and other aggressive ions. The higher the PREN, the better the expected resistance to pitting corrosion, but it’s not an absolute predictor for every real-world scenario. PREN values are best used to compare grades and guide initial selection, not as a guarantee of performance in every service condition.

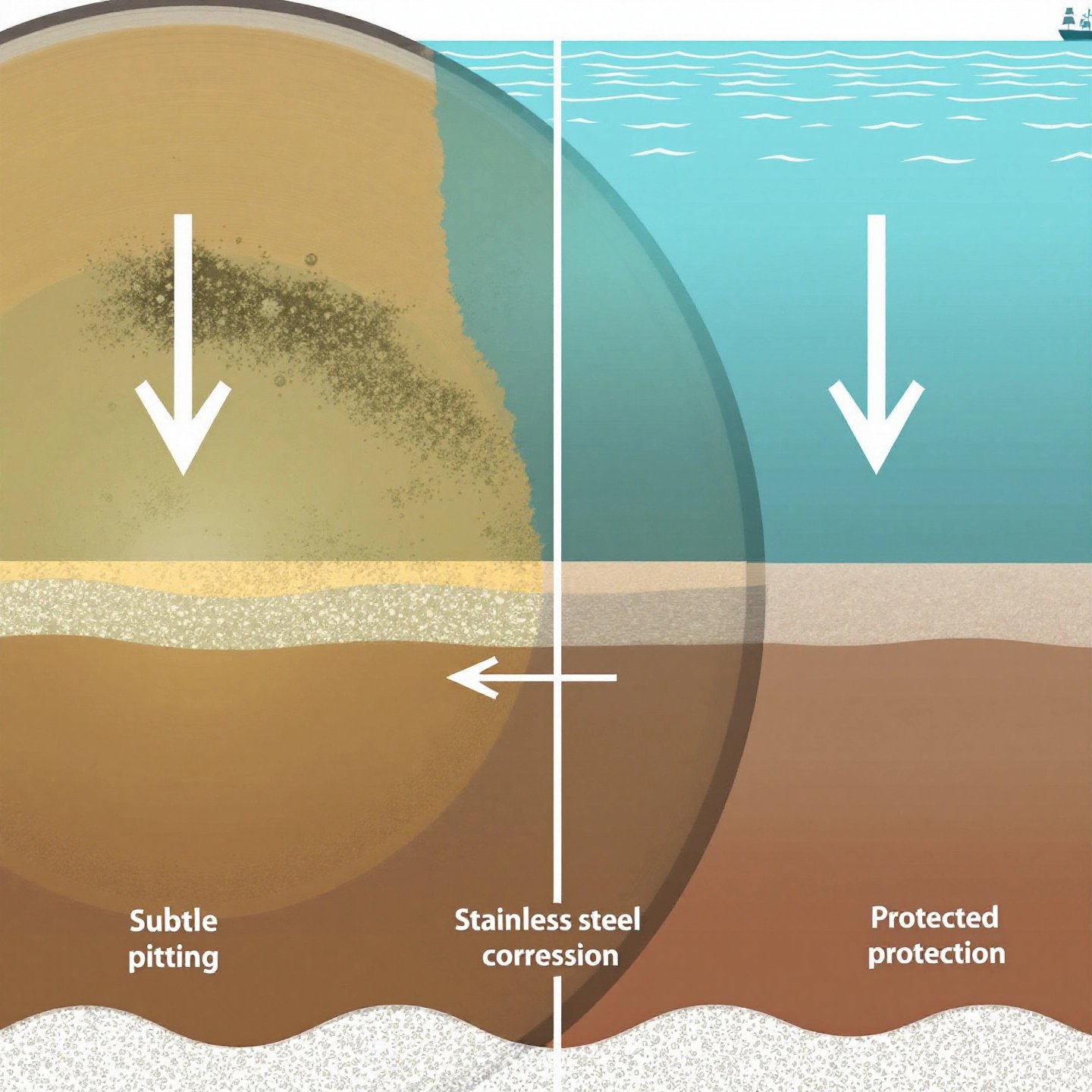

Pitting Versus Crevice Corrosion in Practice

Imagine a piece of marine stainless steel hardware exposed to salt spray. Over time, you may notice tiny, dark pits forming on the surface—classic signs of pitting corrosion. This type of attack is highly localized and often results from a breach in the protective oxide film, typically caused by chlorides. Now, picture a gasketed joint or a bolt with a washer: moisture and salts can become trapped in these crevices, leading to crevice corrosion. While both mechanisms are forms of localized corrosion, crevice corrosion is driven by stagnant microenvironments with low oxygen, which accelerates attack beneath deposits, gaskets, or fasteners. The geometry of the crevice—its depth and width—plays a major role in determining severity [British Stainless Steel Association].

Chloride SCC Risks and Prevention

Another concern with 316 stainless steel corrosion resistance is chloride stress corrosion cracking (SCC). SCC can occur when tensile stresses—either from service loads or residual fabrication stresses—combine with chloride-rich environments. This risk is heightened in warm, humid, or poorly ventilated spaces such as swimming pool enclosures or offshore structures. While 316’s alloying elements provide robust resistance, SCC can still occur if design and fabrication practices do not minimize stress or exposure. Preventative measures include reducing residual stresses (through proper fabrication and heat treatment), avoiding sharp bends or cold work in critical areas, and selecting the right grade for the environment.

Design features—like gasketed joints, deep crevices, and stagnant water zones—can have a bigger impact on corrosion performance than the alloy choice itself. Paying attention to detail is often the key to maximizing the corrosion resistance of 316 stainless steel in service.

Stepwise Field Diagnosis and Mitigation

So, does 316 stainless steel rust? In most cases, you’ll see only superficial discoloration or minor pitting if the alloy is well selected and maintained. However, if problems arise, a systematic approach helps you get to the root cause and restore performance. Here’s a practical troubleshooting workflow:

- Inspect for Symptoms: Look for pit morphology (small, deep pits for pitting; wide, shallow attack for crevice corrosion), staining, or under-deposit corrosion.

- Review Environment History: Note chloride sources (saltwater, de-icing salts, cleaning agents), temperature cycles, and cleaning schedules.

- Verify Material: Confirm the grade used is indeed 316 or a higher-alloyed variant suitable for marine stainless steel or similar aggressive service.

- Implement Corrective Actions: Consider design changes (eliminate crevices, improve drainage), upgrade to a smoother surface finish, apply passivation treatments, or substitute with a more resistant alloy if warranted.

- Design out crevices and stagnant water traps wherever possible

- Ensure proper drainage and ventilation to minimize moisture retention

- Specify suitable surface finishes—smoother surfaces resist corrosion better

- Use passivation and regular cleaning to restore the protective oxide film

- Consider higher alloy alternatives if continuous immersion or extreme chloride exposure is unavoidable

Ultimately, the corrosion resistance of 316 stainless steel is a synergy between alloy selection, design detail, fabrication quality, and maintenance. While it is often called a marine stainless steel for its reliable performance in salt-laden environments, even the best alloys benefit from thoughtful design and proactive care. In the next section, we’ll connect these corrosion mechanisms to the physical and mechanical properties you can specify to ensure your design stands the test of time.

Properties and Design Data You Can Specify with Confidence

Mechanical Properties Overview

When you’re narrowing down material choices, understanding the mechanical properties of 316 stainless steel is crucial. Sounds complex? It doesn’t have to be. Whether you’re specifying a sheet for a pressure vessel or a bar for a structural frame, you’ll notice consistent performance in terms of strength, ductility, and toughness. Let’s break down the key mechanical properties you’ll encounter most often:

| Product Form | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

| Bar & Section (up to 160mm) | 500–700 | 200 min | 40 min | 215 max |

| Sheet (up to 8mm) | 500–700 | 200 min | 40 min | - |

| 316H Bar | 520–670 | 220 min | 45 min | - |

These figures are typical for annealed material and represent minimum requirements for most engineering applications. Remember, cold working increases both the 316 stainless steel yield strength and hardness, but may reduce ductility.

Temperature Effects on Strength and Ductility

Imagine a component exposed to high process temperatures. As temperature rises, you’ll notice a gradual reduction in yield and tensile strength, as well as possible changes in elongation. For example, standard 316 may lose significant strength above 500°C, which is why 316H is preferred for elevated temperature service. Conversely, at cryogenic temperatures, the austenitic structure ensures toughness is retained, making 316 stainless steel suitable for low-temperature applications.

Keep in mind: mechanical properties can also vary between annealed and cold-worked conditions. Cold work boosts hardness and strength but may impact formability and fatigue resistance.

Density and Thermal Characteristics

Why does 316 stainless steel density matter? It’s essential for weight calculations and thermal management. The typical density of stainless steel 316 is around 8.00 g/cm3. This value is consistent across most product forms and is a key factor in structural and thermal design.

| Property | Typical Value | Unit |

|---|---|---|

| Density | 8.00 | g/cm3 |

| Thermal Conductivity | 16.3 | W/m·K |

| Thermal Expansion | 15.9 × 10-6 | K-1 |

| Young's Modulus | 190–205 | GPa |

Thermal conductivity of stainless steel 316 is moderate, supporting its use in process equipment where temperature gradients exist. The young's modulus of stainless steel 316 (also referred to as 316 stainless steel young's modulus) typically falls in the range of 190–205 GPa, which is vital for stiffness and deflection calculations [AZoM Properties].

Design Allowables and Standards

Here’s a practical tip: Always use code-approved values for design allowables, especially for pressure-containing components. For example, ASME Boiler and Pressure Vessel Code or EN standards specify allowable stresses based on rigorous testing and safety factors. Never substitute generic handbook values for these critical applications.

For pressure vessel and piping design, allowable stresses must be taken directly from governing codes such as ASME BPVC or EN standards—not from general datasheets or handbooks.

Fatigue and creep properties are also important for cyclic or high-temperature service. While 316 stainless steel properties are robust for most static applications, elevated temperatures or repeated loading may require careful review of code limits and supplemental testing.

- Use vendor datasheets or code books for precise property values and test methods.

- Account for temperature effects in strength and expansion calculations.

- Consider cold work if higher strength is needed, but review the impact on ductility and fatigue.

- For critical service, verify material certification against relevant standards.

By understanding and applying these 316 stainless steel properties, you can specify materials with confidence—balancing performance, safety, and long-term reliability. Next, we’ll explore welding and fabrication best practices to ensure your chosen grade delivers optimal results in the shop and in service.

Welding and Fabrication Best Practices for 316

Weld Prep and Joint Design Principles

Ever tried welding a 316 stainless steel sheet and ended up with unexpected distortion or discoloration? The foundation for a successful, corrosion-resistant weld starts long before the arc is struck. Surface prep is critical: all joint edges should be free of oil, grease, dust, and moisture. Even small particles can compromise weld integrity or lead to corrosion down the line. For best results, work in a clean, controlled environment—but if that's not possible, meticulous cleaning before and during welding is a must.

- Degrease and dry all surfaces before assembly

- Use dedicated stainless tools to avoid cross-contamination

- Fit-up joints tightly to minimize gaps and ensure consistent penetration

- Design joints to allow for good access and shielding, especially for 316 stainless steel plate and thicker sections

Filler Metal Selection for 316 and 316L

Choosing the right filler metal is essential for maintaining the corrosion resistance of your welds. For both standard 316 and t316l stainless steel, a matching or slightly over-alloyed filler (such as 316L or a designated 316-type electrode) is typically recommended. This ensures the weld metal retains the same resistance to pitting and chemical attack as the base material. Using a compatible filler also helps prevent issues like weld decay and intergranular corrosion, which can occur if carbon content or alloy balance is mismatched.

- Use 316L filler for both 316 and 316L base metals, especially for welded assemblies

- Consult AWS or ASTM filler specifications to confirm compatibility

- For heavy sections or critical service, verify filler selection against project codes

Heat Input Control and Distortion Management

Welding ss316 isn’t just about joining metal—it’s about managing heat and movement. Because 316 stainless doesn’t conduct heat as efficiently as mild steel, it’s prone to overheating and warping if welders linger too long in one spot. Excessive heat can reduce corrosion resistance and cause distortion, especially in thin 316 stainless sheet or large 316 stainless steel plate fabrications.

- Use lower heat input and faster travel speeds to minimize distortion

- Control interpass temperature and allow the joint to cool between passes

- Clamp and support assemblies to prevent movement during welding

- For complex joints, consider back purging with inert gas to protect the root

- Prepare: Clean and fit-up the joint; set up clamping and shielding.

- Tack: Tack weld at intervals to hold alignment and prevent distortion.

- Weld: Use the specified filler and technique (TIG for best appearance, MIG for speed, Stick for economy).

- Cool: Allow controlled cooling between passes to avoid heat buildup.

- Finish: Inspect welds for defects and prepare for postweld cleaning.

Postweld Cleaning, Pickling, and Passivation

Imagine completing a flawless weld on a 316 ss sheet—only to see rust stains appear weeks later. This is often due to heat tint or contamination left behind. Postweld cleaning is not optional; it’s essential for restoring the full corrosion resistance of ss316 weldments. Heat tint, a visible discoloration from welding, can locally deplete chromium and reduce corrosion resistance. According to the British Stainless Steel Association, all visible heat tint deeper than pale yellow should be removed, especially for applications involving water or food contact [BSSA].

- Mechanically remove scale or discoloration (grinding, brushing, or blasting)

- Follow with acid pickling (nitric or mixed acid) to dissolve oxide layers

- Finish with passivation (nitric acid or citric acid) to restore the protective oxide film

- Always follow supplier instructions for chemicals and contact times

- Don’t overlook inside weld faces, especially for pipe and vessel work

Even a small amount of embedded iron or residue from chloride-based cleaners can undermine the corrosion resistance of 316 stainless steel after fabrication. Always use dedicated stainless tools and avoid cross-contamination for best results.

These best practices apply whether you’re assembling a t316l stainless steel tank, a sanitary 316 ss sheet enclosure, or a heavy-duty 316 stainless steel plate structure. By controlling surface prep, filler selection, heat input, and postweld cleaning, you ensure your fabrications deliver the long-term performance and reliability expected from ss316. In the next section, we’ll explore how machining and forming techniques can further influence the performance and longevity of your 316 components in demanding applications.

Machining and Forming 316 Without Headaches

Controlling Work Hardening with Smart Toolpaths

Ever started machining a 316 stainless steel rod and noticed the cutting gets tougher with every pass? That’s work hardening in action—one of the main reasons sus316 machining can be so challenging. When you cut or form this alloy, the surface hardens quickly, making each subsequent operation more difficult and potentially wearing out your tools faster. The trick is to stay ahead of the hardening. This means planning your toolpaths so the cutter is always engaging fresh material, not repeatedly skimming over the same spot. Consistent, steady feeds and avoiding “dwelling” in one area will help you avoid excessive hardening. For example, when turning or milling a 316 stainless steel round bar, maintain a constant tool engagement and use as few passes as possible to reach the final shape. This approach minimizes the risk of surface hardening and keeps your tool life in check.

- Always use sharp, high-quality cutting tools—dull tools accelerate work hardening.

- Plan toolpaths to avoid “rubbing” or light cuts on previously machined surfaces.

- Set up operations so the tool enters the workpiece in a single, continuous motion.

- Monitor for signs of hardening: increased cutting force, tool wear, or surface discoloration.

Coolant, Lubrication, and Chip Management

Heat is the enemy when machining 316 stainless steel bar. The alloy’s low thermal conductivity means heat builds up at the cutting edge, increasing the risk of tool wear, dimensional inaccuracies, and poor surface finish. That’s why abundant, well-directed coolant is a must for every operation, especially on ss 316 rod or 316 ss rod stock. High-pressure coolant not only keeps temperatures in check but also helps break up chips and flush them away, preventing recutting and surface scratching.

- Use copious coolant—flood or high-pressure systems work best for deep cuts.

- Choose coolants or lubricants specifically formulated for stainless steel machining.

- Ensure chipbreakers are used on inserts to control chip size and prevent entanglement.

- Clear chips frequently to avoid heat buildup and tool damage.

Galling Prevention in Forming and Assembly

Ever had fasteners seize or threads strip when assembling 316 stainless steel components? That’s galling—a form of cold welding that happens when two stainless surfaces slide under pressure. It’s especially common with fine threads or high-torque applications, such as assembling 316 stainless steel rod into mechanical systems. To prevent galling during forming and assembly:

- Apply suitable lubricants or anti-seize compounds to threads and mating surfaces.

- Use coarse threads when possible to reduce surface contact and friction.

- Keep threads clean and free from debris; even small particles can trigger galling.

- Control installation speed—slower is better to minimize heat buildup.

- Mix nut and bolt grades (e.g., 304 nut with 316 bolt) where mechanical properties allow, as this can reduce galling tendency.

Tolerancing, Deburring, and Inspection Tips

Imagine completing a batch of precision 316 stainless steel round bar components—only to find burrs or rough edges that could compromise sealing or assembly. Achieving tight tolerances and smooth finishes requires more than just careful machining; it’s about the whole process chain. Here’s a practical setup checklist to help you get it right, every time:

| Step | Action |

|---|---|

| 1. Tool Selection | Choose carbide or coated tools designed for austenitic stainless; ensure sharpness. |

| 2. Fixturing | Use rigid, vibration-free setups to minimize chatter and deflection. |

| 3. Machining | Maintain steady feed rates and avoid light skimming passes. |

| 4. Chip Control | Utilize chipbreakers and clear chips frequently. |

| 5. Coolant Application | Apply abundant, targeted coolant to reduce heat and improve finish. |

| 6. Deburring | Inspect and remove all burrs, especially on sealing or mating surfaces. |

| 7. Final Inspection | Check for dimensional accuracy, surface finish, and edge integrity. |

Surface finish and post-process passivation are not just cosmetic—these steps can make or break the corrosion performance of your 316 stainless steel components in service.

With the right strategy, machining and forming 316 stainless steel bar or rod becomes a process you can control—not a headache you have to endure. Up next, we’ll explore how advanced CNC capabilities and quality-focused partners can help you achieve reliable, high-precision results on your most demanding 316 stainless projects.

Precision CNC Options for Reliable 316 Parts

Why Precision CNC Matters for 316 Components

Ever tried to machine a complex s316 stainless steel bracket or a tight-tolerance valve seat, only to struggle with tool wear or inconsistent results? You’re not alone. Stainless steel 316 is prized for its corrosion resistance and durability, but those same properties make it a challenge to machine with precision. Its high work-hardening rate, tough austenitic structure, and tendency to gall or distort demand more than just basic shop tools—they require advanced CNC technology and know-how.

Imagine producing intricate t316 stainless steel parts for medical, marine, or process equipment. Even the smallest dimensional error or surface defect can lead to costly rework or performance failures. That’s why multi-axis CNC machining—especially with 4- and 5-axis centers—has become the gold standard for complex stainless 316 projects. These machines allow for continuous tool engagement, optimized toolpaths, and access to difficult geometries, all while minimizing the risk of work hardening and distortion.

Capabilities to Look For in a Machining Partner

So, what should you look for when selecting a CNC partner for your next cres 316 or type 316 stainless job? Not all machine shops are created equal—especially when it comes to handling demanding materials like s316 stainless steel. Here’s a checklist of must-have capabilities:

- Multi-axis machining (4- and 5-axis): Enables efficient, accurate machining of complex shapes and minimizes setup changes.

- Stable, rigid fixturing: Prevents vibration, tool deflection, and dimensional drift—critical for maintaining tight tolerances on stainless 316 parts.

- Advanced toolpath programming: Reduces work hardening by keeping the cutter engaged with fresh material and optimizing chip evacuation.

- High-pressure coolant systems: Essential for controlling heat, improving surface finish, and extending tool life—especially for t316 stainless steel and other tough alloys.

- In-process inspection and quality control: Regular checks during production catch issues early, ensuring every part meets spec.

- Material expertise: Experience working with stainless steel 316, cres 316, and similar grades means your parts are less likely to suffer from galling, burrs, or unexpected distortion.

For example, advanced CNC machining services like those offered by XTJ combine state-of-the-art 4- and 5-axis centers, ultra-tight tolerances down to +/- 0.005mm, and robust in-house inspection. These features are exactly what you want when your stainless 316 project can’t afford surprises or delays.

Quality Systems and Lead Time Considerations

Quality and speed go hand in hand—especially when you’re racing a deadline or working in regulated industries. Before committing to a machining partner for your type 316 stainless components, ask about their certifications and process controls:

- ISO 9001:2015 and IATF16949 certifications: These signal a commitment to process discipline and quality management, reducing the risk of non-conforming parts.

- Rapid lead times: Look for partners who can deliver prototypes or production runs in days, not weeks—without sacrificing quality.

- Engineering support: Access to DFM (design for manufacturability) guidance and material selection advice can help you avoid costly mistakes early on.

- Comprehensive material library: The ability to source and machine a wide range of metals—including stainless steel 316, t316 stainless steel, and cres 316—means fewer delays and more flexibility as your project evolves.

Choosing a CNC machining partner with proven experience in s316 stainless steel, multi-axis capabilities, and rigorous quality systems is the surest way to achieve reliable, high-precision results—especially for demanding stainless 316 applications.

By focusing on these core capabilities, you’ll not only minimize the headaches associated with machining type 316 stainless, but also set your project up for consistent, repeatable success. In the final section, we’ll bring it all together with a crosswalk of standards, a practical selection checklist, and the key references you need for confident sourcing and specification.

Standards Crosswalk References and Smart Next Steps

Standards and Designations Crosswalk

Ever found yourself puzzled by all the different names for 316 stainless steel? You’re not alone. Whether you see it listed as AISI 316, UNS S31600, or even a4 stainless steel, these designations all point to the same robust, corrosion-resistant alloy. Understanding how these names connect to global product standards is key to specifying the right material for your project.

| Common Name | Designation | Typical Standards | Product Forms |

|---|---|---|---|

| AISI 316 | UNS S31600 / S31600 | ASTM A240 (plate/sheet), ASTM A276 (bar), ASTM A312 (pipe/tube) | Sheet, Plate, Bar, Pipe, Tube |

| A4 Stainless Steel | Equivalent to AISI 316 | EN 10088-1, ISO 3506 (fasteners) | Fasteners, General Components |

For more details on chemical composition and mechanical properties, refer to the datasheets provided by suppliers or standards organizations such as ASTM and ISO. You’ll notice that type 316 stainless steel is recognized across industries for its reliability in demanding environments.

Practical Selection Checklist for 316 Grades

Choosing the right 316 grade for your application doesn’t have to be overwhelming. Here’s an actionable checklist to help you cover all the bases:

- Environment: Will the part face chlorides, saltwater, or aggressive chemicals? If so, a4 stainless steel (AISI 316/UNS S31600) is a solid bet.

- Temperature: Is the service temperature elevated? Consider high-temperature variants like 316H for prolonged exposure.

- Fabrication: Will the part be welded? If yes, 316L is preferred to minimize sensitization and intergranular corrosion.

- Regulatory Codes: Do industry codes (ASME, ASTM, ISO) specify a certain grade or standard? Always check before finalizing your spec.

- Lifecycle Cost: Weigh initial material cost against expected lifetime, maintenance, and replacement frequency.

Following this checklist helps ensure you’re not just picking a material, but making a smart, standards-backed decision for your project.

Authoritative References and Datasheets

Need to validate numbers or dig deeper into application specifics? Here’s a curated list of trusted references for type 316 stainless steel and its variants:

- ASM Handbook: Stainless Steels (see A4 Stainless Steel Properties)

- ASTM A240, A276, A312, and other product standards for UNS S31600

- UPMET 316/316L Technical Datasheet

- ASME Boiler and Pressure Vessel Code (for design allowables and fabrication guidance)

- ISO 3506 and EN 10088-1 for international fastener and product standards

- NACE MR0175/ISO 15156 for oil & gas and sour service requirements

Always pull numeric values—such as allowable stress, yield strength, or corrosion rates—from the cited standards or supplier datasheets. Avoid relying solely on generic summaries or marketing brochures for critical design decisions.

Next Steps for Prototyping and Production

Ready to move from specification to reality? If your project demands tight tolerances or rapid turnaround on 316 stainless steel components, it’s wise to partner with a machining specialist who understands the nuances of a4 stainless steel and related grades. For instance, XTJ offers advanced CNC machining services that align with global quality certifications and can deliver high-precision 316 parts on a rapid timeline—ideal for prototypes or production runs where reliability and accuracy are paramount.

By cross-referencing standards, following a structured selection process, and tapping into authoritative resources, you can confidently specify and source type 316 stainless steel for your next engineering challenge. Whether you’re designing for marine, chemical, or medical applications, these steps ensure your material choice stands up to both technical scrutiny and real-world demands.

Frequently Asked Questions about 316 Stainless Steel

1. Which is better, SS 304 or 316?

316 stainless steel is generally preferred over 304 in environments exposed to chlorides, saltwater, or harsh chemicals due to its superior corrosion resistance, thanks to added molybdenum. For indoor or less aggressive settings, 304 is cost-effective and performs well, but for marine, chemical, or food processing applications, 316 offers greater durability and reliability.

2. What is the main difference between 316 and 316L stainless steel?

The main difference is carbon content: 316L has a lower carbon level than standard 316, which greatly improves its resistance to sensitization during welding. This makes 316L ideal for welded assemblies in industries like pharmaceuticals and food processing, where corrosion resistance at welds is critical.

3. Can 316 stainless steel rust or corrode?

While 316 stainless steel is highly resistant to rust and corrosion, especially in chloride-rich and marine environments, it is not completely immune. Factors such as design details (crevices, stagnant water), improper cleaning, or contamination can lead to localized corrosion like pitting or crevice corrosion. Proper fabrication and maintenance are essential for optimal performance.

4. What are the typical applications of 316 stainless steel?

316 stainless steel is widely used in marine hardware, chemical processing equipment, food and beverage facilities, medical devices, and architectural components exposed to coastal or urban conditions. Its excellent corrosion resistance, weldability, and cleanability make it a top choice for demanding environments.

5. How do I ensure the best results when machining or welding 316 stainless steel?

For machining, use sharp tools, steady feeds, and ample coolant to control work hardening and heat. For welding, select compatible fillers like 316L, control heat input, and perform thorough postweld cleaning and passivation. Partnering with advanced CNC machining services can further ensure precision and quality, especially for complex or tight-tolerance parts.

-

Posted in

316 stainless steel, corrosion resistance, machining stainless steel, material selection, stainless steel grades