304 Stainless Steel Vs 316 And 430: Make The Right Call Now

Understanding the Essentials of 304 Stainless Steel

What 304 Stainless Steel Means in Practice

Ever wondered why some kitchen sinks, food equipment, or architectural fixtures seem to last forever, resisting stains and rust? Chances are, you’re looking at 304 stainless steel. This material is the most widely used austenitic stainless steel, prized for its unique blend of corrosion resistance, workability, and versatility. Its austenitic crystal structure gives it excellent ductility and toughness, making it a top choice for forming and welding. Imagine shaping deep-drawn sinks or constructing sanitary piping—304 handles both with ease, which is why it’s found everywhere from appliances to industrial tanks.

Common Names and Global Equivalents

Sounds complex? It gets easier when you know the names. 304 stainless steel is often called 18/8 stainless steel because of its typical composition: about 18% chromium and 8% nickel. But that’s not all. Depending on where you are or the standards you follow, you might see it labeled as AISI 304 (American Iron and Steel Institute), SUS304 (Japanese standards), or by other designations in Europe and beyond.

- 18/8 Stainless Steel

- AISI 304 (USA)

- SUS304 (Japan)

- EN 1.4301 (Europe)

- UNS S30400

This global reach ensures that whether you’re specifying material for a food processing plant or architectural hardware, you’re likely working with the same reliable alloy. When someone asks, what is 304 stainless steel used for, the answer spans everything from cookware and fasteners to chemical tanks and building facades.

Why 18/8 Became the Go-To Alloy

So, why is type 304 stainless steel the default choice for so many applications? The answer lies in its balanced properties:

- Corrosion resistance: With both chromium and nickel, 304 resists rust and many chemicals, making it suitable for food, water, and mild chemical environments.

- Formability: Need to deep-draw or bend? 304 is highly formable, ideal for complex shapes.

- Weldability: It joins easily by most welding methods, though for heavy welds or thick sections, the low-carbon version (304L) is recommended to avoid carbide precipitation and maintain corrosion resistance.

- Non-hardenable by heat: Unlike some steels, 304 cannot be hardened by heat treatment. It does, however, become stronger and slightly magnetic when cold worked—so if you’re wondering, is 304 stainless steel magnetic, the answer is generally no in its annealed state, but yes after significant cold working.

For projects where welding is extensive, or where maximum corrosion resistance after welding is critical, consider 304L, the low-carbon variant. This helps prevent weld decay and intergranular corrosion, especially in food and chemical processing applications.

Key takeaway: 304 stainless steel is chosen for its unmatched combination of corrosion resistance, ease of fabrication, and global availability—making it the first call for multipurpose applications.

Whether you call it 304 stainless steel, 18/8 stainless steel, aisi 304, or sus304, this alloy stands as the backbone of countless industries. Next, we’ll dive deeper into its mechanical and physical properties so you can make informed design choices for your next project.

Core Properties That Drive Design Choices

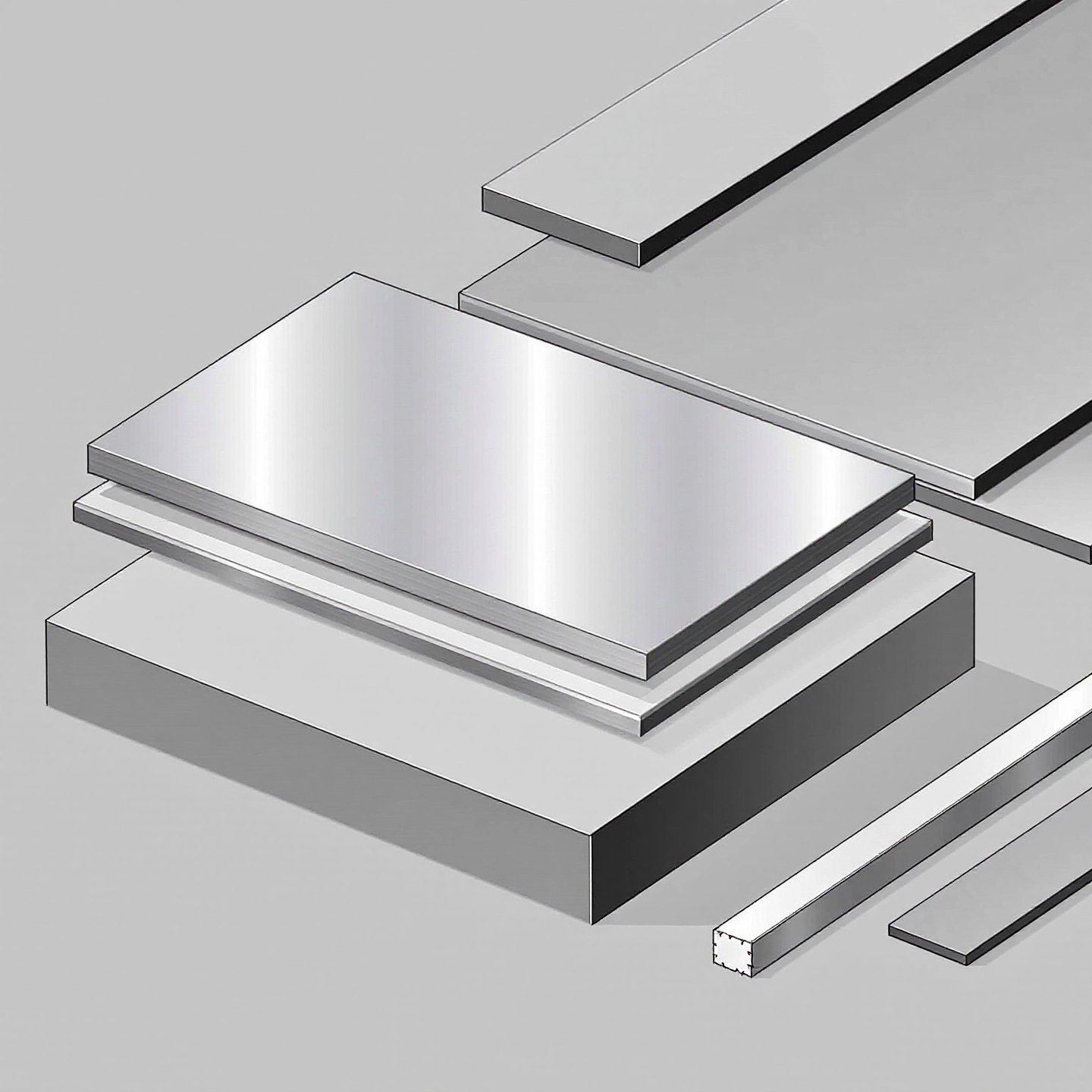

Mechanical Properties by Form and Condition

When you’re engineering with 304 stainless steel, understanding its mechanical performance is essential. But here’s a twist: these properties aren’t fixed—they vary by product form (like sheet, plate, or bar) and by whether the material is annealed or cold worked. Let’s break it down so you can choose wisely for your next project.

| Form/Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

| Sheet (Annealed) | 540 - 750 | 230 min | 45 min | 215 max |

| Plate (Annealed) | 520 - 720 | 210 min | 45 min | 215 max |

| Bar (Annealed) | 500 - 700 | 190 | 45 min | 215 max |

| Cold Worked (Any form) | Higher than annealed | Higher than annealed | Lower than annealed | Higher than annealed |

For exact figures in your application, always consult supplier datasheets or standards like ASTM or EN. Cold working increases both the 304 stainless steel yield strength and hardness, but reduces ductility (elongation). This is why cold worked 304 is chosen when higher strength is needed, but you’ll notice it becomes less formable.

Physical Properties You Should Track

Physical attributes matter just as much as mechanical ones—especially for thermal expansion, weight, and electrical performance. Here’s a quick-reference list of key ss 304 material properties you’ll want to track (ASM MatWeb):

- Density: 8.00 g/cm³ – a reliable benchmark for weight calculations (304 stainless steel density).

- Melting Point: 1400 – 1455°C (304 stainless steel melting point), making it suitable for high-temperature service.

- Modulus of Elasticity: 193 GPa (304 stainless steel modulus of elasticity), critical for deflection and stiffness calculations.

- Thermal Expansion: 17.2 x 10-6/K, important for assemblies exposed to temperature swings.

- Electrical Resistivity: 0.72 x 10-6 Ω·m.

These physical properties are consistent across most forms, but always confirm with your supplier for critical designs.

How Cold Work Changes Performance

Imagine you’re forming or rolling 304 stainless steel—what happens to its properties? Cold work (like bending, drawing, or rolling at room temperature) increases strength and hardness, but at the expense of ductility. So, if you need a tougher part, cold work is your friend. But if you need to keep things flexible for deep forming, stick with annealed material. Note that cold work can also make 304 slightly magnetic, a detail that matters in some applications.

Why does this matter? Because the way you process or specify 304 can change the final performance of your product. Need to maximize strength? Go for cold worked. Need high ductility and ease of forming? Annealed is your best bet.

Key takeaway: Always match the 304 stainless steel composition and processing condition to your design needs. Mechanical and physical properties can shift significantly with cold work, so check the latest datasheets for ss 304 material properties before finalizing your design.

Now that you know how the numbers stack up, let’s explore how 304 stainless steel stands up to real-world corrosion and what you can do to keep it looking and performing its best.

Corrosion Realities and How to Mitigate Them

Understanding Pitting and Crevice Risks

When you install or fabricate with 304 stainless steel, it’s easy to assume it’s immune to rust and corrosion. But is that always true? In most indoor, fresh water, and food-processing environments, 304 stainless steel corrosion resistance is outstanding. Its high chromium and nickel content form a passive oxide layer that protects against oxidation and many chemicals, making it a staple for kitchen equipment, architectural features, and piping.

However, when chlorides enter the picture—think de-icing salts, pool chemicals, or coastal air—the story changes. Even though 304 is robust, it has a practical chloride limit: up to about 100 ppm in fresh water, especially if crevices are present. Above this, pitting and crevice corrosion can occur, sometimes rapidly. This means that in marine or heavily salted environments, 304 may develop rust spots or deeper corrosion, particularly in shielded areas where water can stagnate.

Why does this happen? In chloride-rich settings, the protective film can break down locally, leading to tiny pits or under-the-surface attack in crevices. These forms of corrosion are often hidden until significant damage is done. So, if you’re wondering, does 304 stainless steel rust or can 304 stainless steel rust—the answer is yes, under the right (or wrong) conditions.

Performance in Food Contact and Sanitary Systems

In food, beverage, and pharmaceutical settings, 304’s chemical compatibility is a major strength. It resists organic acids, cleaning agents, and most food ingredients, making it the default choice for sanitary piping, tanks, and prep surfaces. Here, the main enemy is not the food itself, but improper cleaning or the accumulation of chlorides from cleaning agents or hard water. Regular cleaning, good drainage, and avoiding stagnant water are essential to keep surfaces bright and corrosion-free.

But what about that occasional brown discoloration or “tea staining” you might see on outdoor railings or kitchen fixtures? This is often caused by surface contamination (like iron particles from tools or abrasive pads) or by exposure to harsh environments. While it looks like rust, it’s usually superficial and can be removed with proper cleaning and passivation—restoring the protective oxide layer.

Design and Maintenance to Prevent Staining

So, what can you do to prevent 304 stainless rust or discoloration? The best defense is a combination of smart design, good housekeeping, and proactive maintenance:

- Design out crevices: Avoid joints, overlaps, or tight corners where moisture and chlorides can collect.

- Choose the right surface finish: Smooth, polished finishes are less likely to trap contaminants and easier to clean.

- Plan for regular cleaning: Wash surfaces with clean water, especially after exposure to salts or harsh chemicals. Use mild detergents or specialized stainless cleaners as needed.

- Passivate after fabrication: Chemical passivation removes embedded iron and restores the protective layer, reducing risk of future staining or corrosion.

- Avoid contamination: Don’t use carbon steel tools or brushes on stainless steel surfaces.

- For high-chloride or coastal environments: Consider upgrading to molybdenum-bearing grades like 316, which handle much higher chloride levels before corrosion begins.

Key principle: Design out crevices and clean regularly in chloride service. Even the best alloys need maintenance to deliver long-term performance.

To sum up, will stainless steel 304 rust? In low-chloride, well-maintained settings, it’s highly resistant. But in salty, stagnant, or contaminated conditions, pitting and staining are real risks. If you’re working near the ocean or with aggressive chemicals, 304 may not be the right call—upgrading to a higher-alloy grade will pay off in the long run. Next, we’ll compare when to choose 304, 304L, 316, or 430 for your specific environment and application.

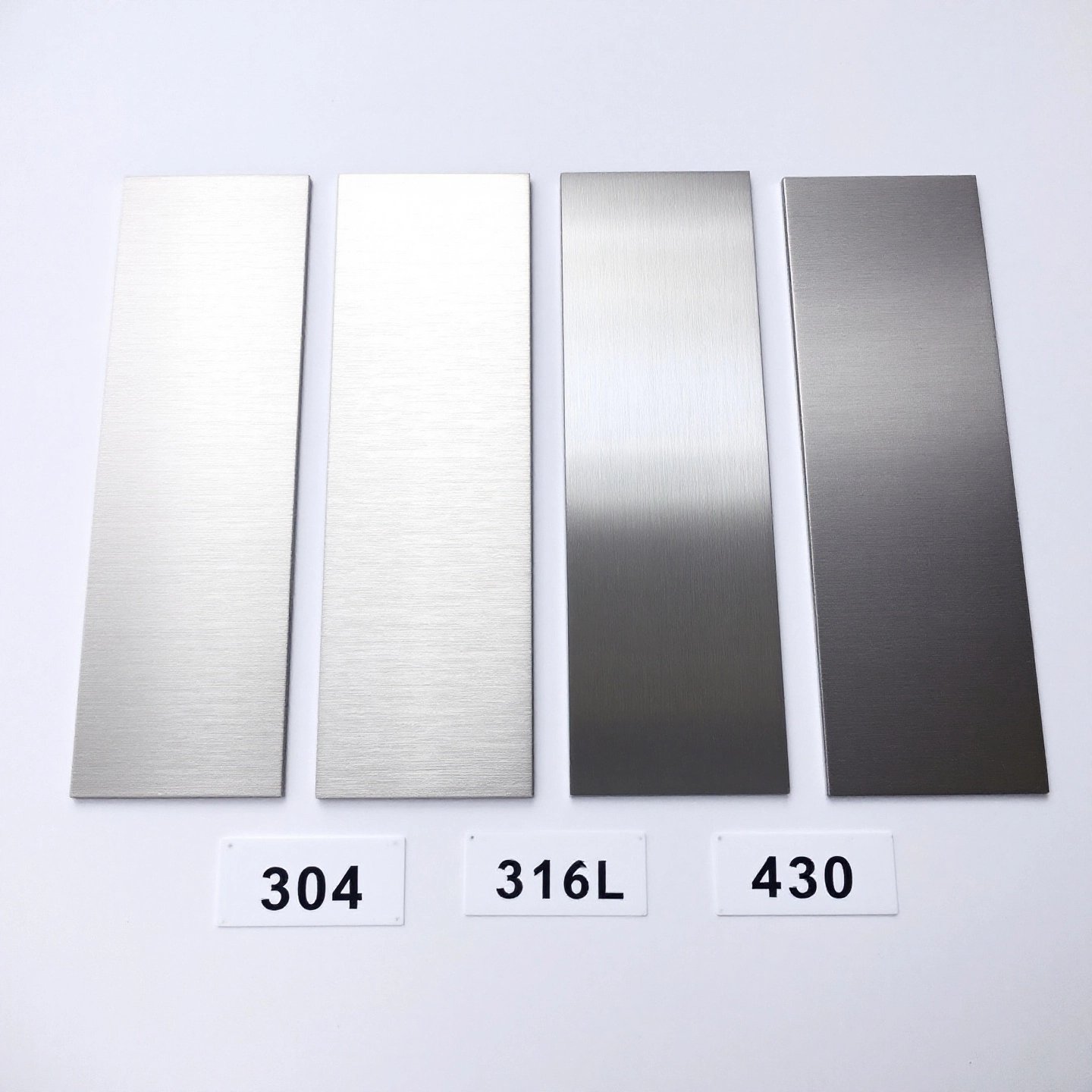

Selecting Between 304, 304L, 316, and 430 Stainless Steel Grades

When 304 Is the Right Fit

Ever paused at a material spec sheet and wondered which grade is really best for your job? Let’s break it down. 304 stainless steel is the industry’s all-rounder—austenitic, non-magnetic in its annealed state, and known for its excellent corrosion resistance, formability, and weldability. If you’re designing kitchen equipment, food processing tanks, architectural handrails, or general-purpose piping, 304 is often the first choice. It’s reliable in most indoor and mild outdoor environments where chlorides are low and hygiene or aesthetics matter.

But what about those edge cases—welding, aggressive chemicals, or tight budgets? That’s where its close relatives come in.

Why 316 Wins in Chlorides

Imagine your application faces salty air, de-icing salts, or chemical splash—think coastal railings, marine hardware, or chemical plant components. This is where the 304 vs 316 stainless steel debate gets real. 316 includes molybdenum, boosting its resistance to pitting and crevice corrosion in chloride-rich environments. In the stainless steel 304 vs 316 matchup, 316 is the clear winner for marine, pharmaceutical, or harsh chemical exposure, even though it comes at a premium price. If you’re weighing 316 stainless steel vs 304, ask: Will the part see salt, bleach, or high-chloride cleaning agents? If so, 316 is the safer bet for long-term durability.

304L for Welded Assemblies

Welding a lot of joints, thick sections, or constructing tanks and frames? Here’s where 304L stainless steel shines. The “L” stands for low carbon (max 0.03%), which prevents carbide precipitation and intergranular corrosion after welding. In the 304 vs 304L decision, 304L is ideal for welded structures in food, chemical, and architectural projects where post-weld heat treatment is impractical. It’s slightly lower in strength than standard 304, but the tradeoff is much easier fabrication and longer life in welded joints.

304 vs 430: When Cost and Magnetism Matter

Need stainless on a budget, or want magnetic properties for appliance panels or automotive trim? 430 stainless steel is a ferritic grade—lower cost, magnetic, and still offering decent corrosion resistance for indoor or mildly corrosive environments. However, 304 vs 430 stainless steel is a tradeoff: 430 is less resistant to acids and chlorides, and not as formable or weldable as 304. Use it for decorative trim, kitchen backsplashes, or non-critical parts where cost is key and exposure is limited.

Decision Matrix: Matching Grade to Application

| Environment / Application | 304 | 304L | 316 | 430 |

|---|---|---|---|---|

| General indoor, food, sanitary | Best | Best (if welding) | Better (overkill for most) | Good (if low corrosion risk) |

| Welded assemblies, tanks, piping | Good (may need post-weld treatment) | Best (no post-weld treatment needed) | Better | Fair (not recommended) |

| Marine, coastal, high-chloride | Fair (risk of pitting) | Fair (risk of pitting) | Best | Poor |

| Budget-sensitive, decorative, magnetic | Good (non-magnetic) | Good (non-magnetic) | Fair (expensive) | Best (magnetic, low cost) |

| Formability, deep drawing | Best | Best | Better | Good |

- 304: Balanced performance, best for most indoor and light outdoor uses.

- 304L: Go-to for welded assemblies and piping where corrosion after welding is a concern.

- 316: The right call for marine, pharmaceutical, and chemical processing—anywhere chloride attack is likely.

- 430: Choose for cost-driven, magnetic, or decorative applications with low corrosion risk.

Key takeaway: For most uses, 304 delivers the best mix of value and performance. But when welds, harsh chemicals, or tight budgets are involved, selecting between 304L, 316, or 430 ensures you get the right balance of corrosion resistance, formability, and cost.

Ready to specify your material? Next, we’ll cover how to match standards, finishes, and procurement details to get the right product for your project—whether you need stainless steel 304 vs 316, 304 vs 304L, or something else entirely.

Standards, Forms, and Smart Procurement for 304 Stainless Steel

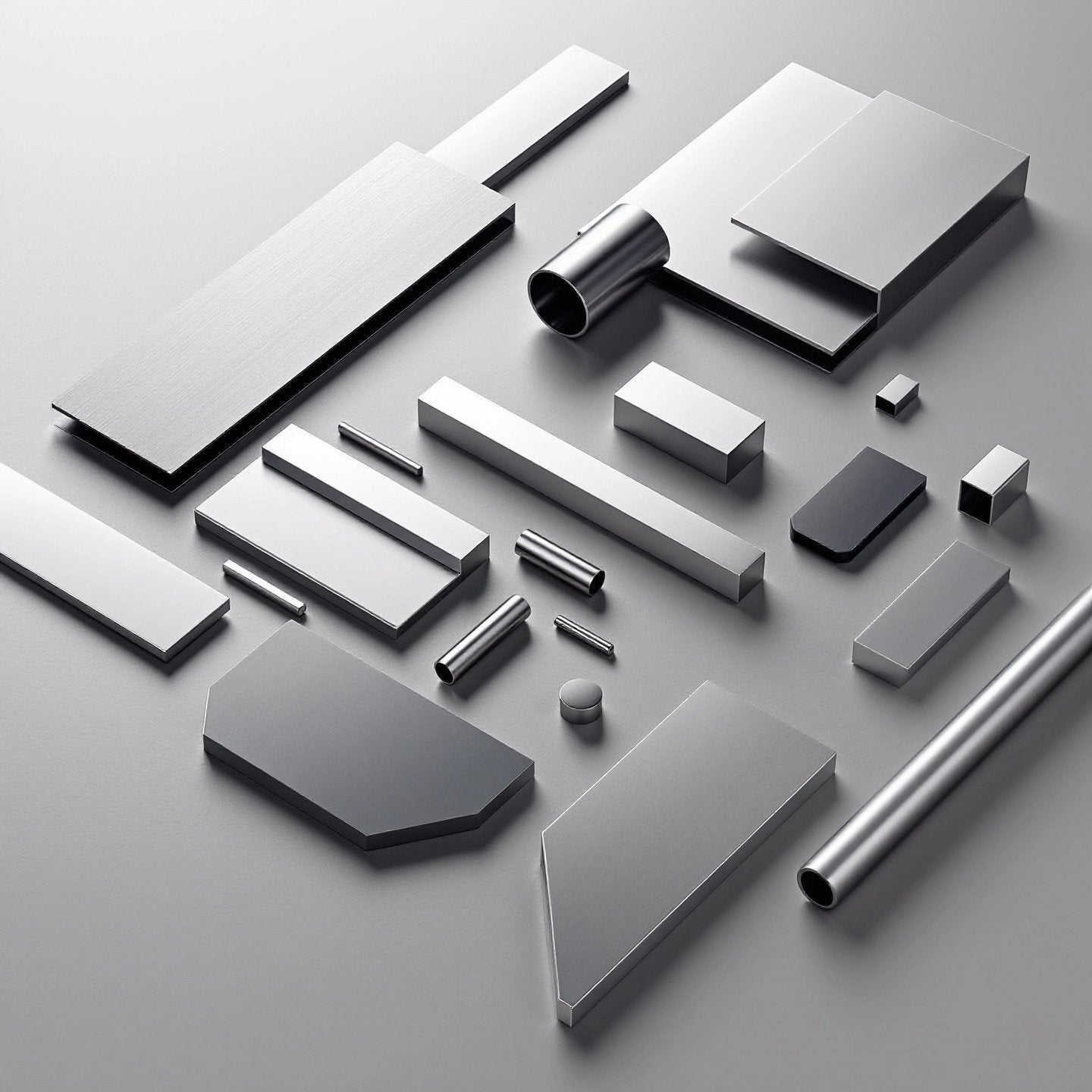

Mapping Standards to Product Forms

When you’re ready to buy 304 stainless steel, it’s not just about picking a grade—it’s about making sure you specify the right form, standard, and finish for your project. Sounds complex? Let’s break it down with some practical examples and a handy mapping table so you can see how 304 stainless steel sheet, plate, bar, and pipe line up with industry standards and finishes.

| Product Form | Common Standards | Typical Finishes | Notes |

|---|---|---|---|

| Sheet | ASTM A240, ASTM A666 | No. 2B (general), No. 4 (brushed), BA (bright annealed) | Most popular for architectural and hygienic uses |

| Plate | ASTM A240 | No. 1 (hot rolled, annealed, pickled), 2B | Used for structural and heavy-duty applications |

| Bar | ASTM A276, ASTM A479 | Cold drawn (bright), hot rolled (pickled) | Ideal for machined components and fasteners |

| Pipe/Tube | ASTM A312 (pipe), ASTM A554 (ornamental tube) | Polished, annealed, pickled | Hygienic and architectural piping, handrails |

| Strip | ASTM A240, ASTM A666 | 2B, polished, custom | Precision applications, springs, gaskets |

For example, if you’re sourcing 304 stainless steel sheets for an elevator wall or kitchen backsplash, you’ll likely specify ASTM A240 with a No. 4 brushed finish. If you need a 304 stainless steel bar for machining, ASTM A276 with a cold drawn finish is a good fit. And for sanitary piping or architectural handrails, stainless steel tube per ASTM A554 with a polished finish will keep things both hygienic and visually appealing.

What to Put on the Purchase Order

Ever get tripped up by missing paperwork or unclear requirements? You’re not alone. To avoid headaches and ensure you get what you need, here’s a checklist for your next procurement of 304 stainless steel pipe, sheet, bar, or plate:

- Material Test Reports (MTRs): Confirms chemistry and mechanical properties match ASTM 304 stainless steel requirements.

- Heat Numbers: Traceability for each batch or lot.

- Surface Finish Codes: Specify No. 2B, No. 4, BA, or custom as needed for your application.

- Certifications: Ask for ISO 9001 or other quality certificates to ensure supplier reliability.

- Dimensions/Tolerances: Clearly state thickness, width, length, and any special tolerances.

- Product Form: Specify sheet, plate, bar, tube, or pipe.

- Order Quantity: Indicate total weight or number of pieces.

- Special Requirements: Such as edge condition, flatness, or special packaging.

Research shows that clear communication can significantly reduce procurement delays and quality issues, with some industry reports estimating that as many as 40% of these issues are related to poor communication.

Surface Finish and Tolerance Considerations

Why does finish matter? The right surface finish not only enhances appearance but also impacts corrosion resistance and cleanability. For architectural and hygienic applications, a smoother finish (like No. 4 or BA) resists fingerprints and is easier to sanitize. For heavy-duty or structural uses, a No. 1 or 2B finish is often sufficient.

Tolerances—how close the actual size is to what you specified—matter too. Tight tolerances on thickness or flatness can affect downstream fabrication, especially if you’re laser cutting, bending, or welding stainless steel sheets or 304 stainless steel pipe. Always double-check that your supplier can meet your project’s tolerance requirements, particularly for automated manufacturing or precision assemblies.

Key takeaway: The success of your project depends on matching the right product form, standard, surface finish, and tolerances to your application—and on clear, complete communication with your supplier.

With your procurement checklist in hand, you’re ready to move from specification to fabrication. Next, we’ll dive into best practices for welding, heat treatment, and forming to help you get the most out of your 304 stainless steel parts.

Welding, Heat Treatment, and Forming Best Practices for 304 Stainless Steel

Welding Practices and Filler Selection

When you’re fabricating with 304 stainless steel, the right welding approach can make or break your project’s durability and corrosion resistance. Sounds complex? Let’s simplify it. Both 304 and 304L are highly weldable using standard processes like TIG, MIG, and stick welding. But the key difference lies in how each handles heat and post-weld corrosion.

Pros of Welding 304L vs 304

- 304L (low carbon): Greatly reduces the risk of sensitization (chromium carbide precipitation at grain boundaries), which can cause intergranular corrosion after welding.

- No need for post-weld heat treatment in most cases—saves time and cost, especially for thick sections or complex assemblies.

- Often dual-certified as both 304 and 304L, offering flexibility in sourcing and fabrication.

Cons of Welding 304 vs 304L

- 304 (standard carbon): More susceptible to sensitization when welded, especially in thicker gauges or when heat input is high.

- May require post-weld annealing to restore corrosion resistance—this is not always practical for large or assembled parts.

For filler metal, use grade 308 for 304, and 308L for 304L. This ensures the weld metal matches the base metal’s corrosion resistance and mechanical properties. If you’re welding heavy sections or expect high stress, consult supplier datasheets for specific recommendations to match your project’s 304 stainless steel material properties.

Post Weld Cleaning and Passivation

Ever noticed discoloration or dullness near a weld? That’s not just cosmetic—it can signal reduced corrosion resistance. After welding, it’s essential to clean and passivate the area to restore the protective oxide layer. Here’s a practical workflow:

- Mechanical cleaning: Use stainless-only brushes or abrasives to remove slag, spatter, or heat tint. Avoid cross-contamination from carbon steel tools.

- Chemical passivation: Apply a passivation solution (like nitric acid or pickling paste) to remove free iron and contaminants. This step is vital for restoring corrosion resistance, especially in demanding environments (TIG Brush).

- Rinse thoroughly: Wash with clean water to remove all chemical residues.

- Dry and inspect: Ensure the surface is clean, bright, and free of discoloration before putting the part into service.

Modern electrolytic weld cleaning (like the TIG Brush) offers a safer and faster alternative to traditional acid methods, making it easier to achieve a fully passivated surface without hazardous chemicals.

Heat Treatment and Forming Considerations

Thinking about heat treatment for extra strength? Here’s the catch: 304 stainless steel cannot be hardened by heat treatment due to its austenitic structure. Instead, it’s typically annealed to relieve stress and restore ductility after cold forming or welding. Annealing is performed by heating to 1010–1120°C (1850–2050°F) followed by rapid cooling—usually by water quenching.

| Process | Temperature Range | Purpose |

|---|---|---|

| Annealing | 1010–1120°C (1850–2050°F) | Restore ductility, relieve stress, optimize corrosion resistance |

| Post-weld anneal (304 only) | Same as above | Remove sensitization in welded joints |

| Rapid cooling (quenching) | Water quench | Prevent carbide precipitation |

Cold working (bending, drawing, rolling) is the main route to increase 304 stainless hardness and strength. However, as you increase strength and 304 ss hardness, ductility and formability decrease. This means you might encounter higher springback and need to use larger bend radii or intermediate annealing steps to avoid cracking during forming.

Practical tip: Always verify forming parameters and heat treatment cycles with up-to-date supplier data, as small changes in process can significantly affect 304l stainless steel properties and part performance.

Key takeaway: Match your welding, cleaning, and forming processes to the specific needs of 304 or 304L. Use 304L for welded assemblies to avoid sensitization, prioritize thorough post-weld cleaning and passivation, and remember: heat treatment restores ductility, but only cold work will increase hardness. For the best results, always check the latest data for your chosen product form and application.

Ready to translate your knowledge into manufacturable parts? Next, we’ll explore machining and forming strategies that help you get the most out of stainless steel 304 304L—without sacrificing quality or productivity.

Practical Machining and Forming Playbook for 304 Stainless Steel

Machining Strategies that Reduce Work Hardening

Ever struggled with tool wear or tough chips when machining t304 stainless steel? You’re not alone. This alloy’s high ductility and tendency to work harden can turn a routine job into a test of patience and skill. But with the right approach, you can machine ss304 parts efficiently and achieve a clean finish every time.

- Use sharp, rigid tooling: Carbide or high-speed steel (HSS) tools with positive rake angles help slice through 304 metal before it work hardens.

- Maintain consistent chip load: Avoid light cuts and interruptions. Steady, moderate feed rates prevent surface hardening and extend tool life.

- Apply high-quality coolants: Flood the cutting zone with water-soluble oil or synthetic coolants to dissipate heat and flush chips, minimizing thermal buildup and galling.

- Rigid setups are essential: Secure workpieces firmly to reduce chatter and vibration, especially when milling or drilling 304 steel sheet or bar.

- Optimize speeds and feeds: Start with lower cutting speeds and moderate feeds, then adjust based on tool wear and surface finish. Too slow increases work hardening; too fast overheats the tool.

For complex geometries, tight tolerances, or rapid prototyping of t304l stainless steel parts, advanced CNC machining is a game changer. Services like XTJ offer 4 and 5-axis machining, ultra-tight tolerances, and dedicated engineering support to help you tackle work hardening and DFM challenges—an asset when producing intricate or high-precision 304 components.

Sheet Metal and Tube Forming Tips

Forming 304 stainless steel sheet or tubing? Imagine you’re bending a kitchen backsplash or fabricating a sanitary tube run. The key challenge is springback—ss304 naturally wants to return to its original shape after bending, and it hardens quickly if overworked.

- Account for springback: Overbend sheet or tube slightly to compensate for elastic recovery. The exact angle depends on thickness and bend radius.

- Choose appropriate bend radii: For annealed sheets, aim for a minimum inside bend radius equal to the material thickness. For harder or cold-rolled sheets, use 1.5–2x thickness to avoid cracking.

- Use the right tooling: Urethane or plastic dies minimize galling and surface scratches. For tube bending, mandrel or rotary draw benders preserve wall integrity and cosmetic finish.

- Lubricate to prevent galling: Apply suitable lubricants to reduce friction and extend tool life, especially when forming polished or visible surfaces.

- Plan for dimensional accuracy: Use simulation software or prototype first to verify springback and fit, especially for complex bends or assemblies.

When working with t304l stainless steel, consider annealing between forming steps if the material becomes too hard or prone to cracking. This restores ductility and makes subsequent bends easier.

Finishing Steps to Protect Against Corrosion

After machining or forming, finishing is your last line of defense against corrosion and surface defects. Wondering what’s the best way to finish 304 metal parts? Follow this workflow:

- Deburr: Remove sharp edges and burrs using stainless-only abrasives or brushes. This prevents injury and improves fit in assemblies.

- Clean: Wash parts with degreaser to remove cutting fluids and debris. For sanitary or food-grade applications, this step is critical.

- Passivate: Use a chemical passivation treatment (like nitric acid or citric acid solutions) to remove free iron and restore the protective oxide layer—essential for long-term corrosion resistance.

- Inspect: Check for surface defects, discoloration, or incomplete passivation. Rework as needed to meet cosmetic or hygiene standards.

For high-performance or visible applications, additional polishing or electropolishing can enhance appearance and further boost corrosion resistance.

Vendor Spotlight: CNC Machining for T304 and T304L Stainless Steel

| Vendor | Strengths for 304/304L Machining | Considerations |

|---|---|---|

| XTJ CNC Machining | 4/5-axis machining, ultra-tight tolerances, rapid turnaround, ISO/IATF certified, DFM support for work hardening and complex 304 metal parts | Best for prototypes, complex parts, or high-precision runs; minimum order quantities or lead times may apply for large-scale production |

Whether you’re producing a single prototype or scaling to full production, choosing the right partner for machining stainless steel t304 or t304l stainless steel ensures your parts meet performance and quality standards—without costly surprises.

Key takeaway: Successful machining and forming of 304 stainless steel hinges on sharp tooling, steady feeds, robust setups, and diligent finishing. For demanding parts, leverage expert CNC services and always finish with thorough passivation to unlock the full potential of your 304 or 304L components.

With your parts expertly machined and formed, you’re ready for the final step: building a robust sourcing and inspection checklist to guarantee every batch of 304/304L meets your expectations—covered in the next section.

Selection and Sourcing Checklist with Next Steps

Material Selection Checklist for Engineers

When you’re faced with a maze of stainless options, how do you confidently select between 304, 304L, 316, or 430? The trick is to match the 304 stainless steel material to your project’s environment, fabrication method, and budget. Here’s a practical checklist to guide your decision:

- Define the Environment: Will your part face chlorides, marine air, or harsh chemicals? If so, 316 may be worth the upgrade. For most food, beverage, or indoor architectural uses, 304 or 304L is ideal.

- Assess Welding Needs: If welding is extensive or you’re fabricating tanks, piping, or frames, choose 304L to avoid post-weld corrosion—this is the key difference in the 304 stainless steel vs 304l debate.

- Consider Hygiene and Cleanability: For sanitary or pharmaceutical settings, prioritize smoother finishes and low-carbon grades (304L or 316L) to minimize contamination risk.

- Balance Cost and Performance: For budget-sensitive, non-critical, or decorative uses, 430 may suffice. But for robust corrosion resistance and versatility, 304/304L is the safer bet.

- Check Local and Industry Standards: Make sure your grade and finish match project or regulatory requirements (e.g., ASTM A240 for sheet/plate, A312 for pipe).

- Verify Dual Certification: Many suppliers offer dual-certified 304/304L—giving you flexibility for both standard and welded applications.

Tip: For welded assemblies, 304l vs 304 stainless steel comes down to corrosion risk after welding—304L is almost always the safer, lower-maintenance choice.

Procurement and Inspection Essentials

Ready to place an order? Imagine receiving a shipment that doesn’t match your spec, or worse, fails in service. Avoid these headaches by building a robust procurement and inspection checklist. Here’s what to request and verify every time you source 304 stainless steel material or its variants:

- Material Test Reports (MTRs): Confirm chemical composition and mechanical properties—essential for verifying 304/304l compliance.

- Heat Numbers: Ensure traceability from mill to finished product.

- Surface Finish Codes: Specify No. 2B, No. 4, BA, or custom as needed for hygiene or appearance.

- Dimensions and Tolerances: State all critical measurements and allowable variation.

- Product Form: Sheet, plate, bar, pipe, or tube—be specific.

- Quantity and Packaging: Define order size and packaging requirements to prevent transit damage.

- Inspection Criteria: Visual inspection for defects, dimensional checks, and surface quality review.

- Certifications: Ask for ISO 9001 or other quality certificates for supplier credibility.

Always cross-check all numeric properties against the MTRs provided with each batch—this is your safeguard against off-spec material or substitutions.

From Prototype to Production: Sourcing Partners for 304/304L Stainless Steel

Navigating the supplier landscape can be daunting. Whether you’re sourcing for a one-off prototype or a full production run, it pays to partner with suppliers who understand the nuances of 304/304l fabrication and inspection. Here’s a shortlist of vetted service types to consider, with a focus on machining and quality control:

- XTJ CNC Machining – Pros: 4/5-axis machining, ultra-tight tolerances, rapid lead times, ISO/IATF certified, engineering support for DFM and 304/304L work hardening issues. Cons: Minimum order quantities or specific lead times may apply for large-scale runs.

- Global Stainless Distributors – Pros: Wide inventory, multiple grades, value-added services. Cons: May require longer lead times for custom forms or finishes.

- Regional Service Centers – Pros: Local support, quick delivery, custom processing. Cons: May have limited stock of specialty finishes or dual-certified stainless steel 304l.

- Third-Party Inspection Agencies – Pros: Independent verification of specs, packaging, and documentation. Cons: Adds cost, but reduces risk of non-compliance.

For projects where precision, rapid prototyping, or complex 304 vs 304l stainless features are required, XTJ’s engineering support and advanced machining capabilities can help you move smoothly from design to finished part.

Key takeaway: A thorough selection, procurement, and inspection process is your best defense against costly surprises. Always verify specs, demand full traceability, and partner with suppliers who offer technical support and proven quality systems for every batch of stainless steel 304l or 304/304l you buy.

By applying these checklists and partnering with trusted providers, you’ll ensure every batch of 304 stainless steel material meets your expectations—whether you’re building a sanitary assembly, fabricating a welded structure, or scaling up production for a critical application.

Frequently Asked Questions about 304 Stainless Steel

1. What are the disadvantages of 304 stainless steel?

304 stainless steel is not suitable for environments with high levels of salt, chlorine, or strong chemicals. In marine or heavily chlorinated settings, it may experience pitting or crevice corrosion. For these applications, higher-alloy grades like 316 are recommended for better resistance.

2. What is 304 stainless steel used for?

304 stainless steel is widely used in kitchen equipment, food processing, architectural hardware, sanitary piping, and industrial tanks. Its corrosion resistance, formability, and weldability make it ideal for applications requiring durability and hygiene.

3. Is 304 stainless steel magnetic?

In its annealed state, 304 stainless steel is generally non-magnetic. However, after significant cold working (such as bending or rolling), it can become slightly magnetic due to changes in its crystal structure.

4. Can 304 stainless steel rust?

While 304 stainless steel is highly resistant to rust in most environments, it can develop rust or staining in chloride-rich or coastal areas, especially where water stagnates or crevices exist. Regular cleaning and proper design help minimize this risk.

5. How do I choose between 304, 304L, 316, and 430 stainless steel?

Select 304 for general use, 304L for welded structures to avoid post-weld corrosion, 316 for superior chloride resistance, and 430 for cost-sensitive or magnetic applications in mild environments. Always match the grade to your specific environment, fabrication needs, and budget.

-

Posted in

304 stainless steel, corrosion resistance, fabrication tips, material selection, stainless steel grades