Copper Still Buyer's Guide: Match Design, Heat, and Output

Why Copper Matters in Distillation

What Is a Copper Still?

Ever wondered what makes a copper still so special? Picture a traditional pot-shaped vessel, often with a graceful swan neck, that transforms raw ingredients—like botanicals or water—into something new through the process of distillation. A copper still is a piece of equipment, typically handcrafted, used to heat a liquid mixture and collect the purified vapor. While the term "moonshine still" might bring up images of old-timey bootleggers, today’s copper stills serve many lawful, creative, and scientific purposes.

Why Copper Improves Aroma and Flavor

So, why is copper the metal of choice for so many distillers, both past and present? Imagine you’re crafting an essential oil or a hydrosol. As vapor rises and contacts the copper surfaces inside the still, something remarkable happens. Copper acts as a catalyst, binding with sulfur and other unwanted compounds, which helps create a cleaner, smoother, and more aromatic final product. This is why many artisans seeking rich, characterful spirits or high-quality essential oils prefer copper over stainless steel.

- Superior heat transfer: Copper quickly and evenly distributes heat, allowing for precise temperature control during distillation.

- Reduces sulfur compounds: Copper actively binds sulfur compounds in the vapor, minimizing off-odors and harsh flavors.

- Repairability: Copper is malleable and can be repaired or reshaped more easily than other metals.

While stainless steel is prized for its durability and lower maintenance, it does not offer the same level of interaction with vapor as copper. This means the choice between copper and stainless steel can affect not just how often you clean your still, but also the subtle qualities of your end product.

Safety and Legal Considerations

Before using or purchasing a copper still for alcohol production, always verify local, state, and federal laws and permits. This guide is for educational purposes and covers only legal applications.

Owning a copper still is legal in most places, but how you use it matters. Distilling essential oils, hydrosols, or purifying water is generally permitted and does not require a special license in the US. However, distilling alcohol at home—even for personal use—remains illegal under federal law unless you have the proper permits. Some states may have additional rules, so always double-check before starting any new project.

- Essential oils: Safe and legal; follow manufacturer and fire safety guidelines.

- Hydrosols: Legal for home and small business use; use food-grade materials.

- Lab demonstrations: Great for science education; ensure adult supervision.

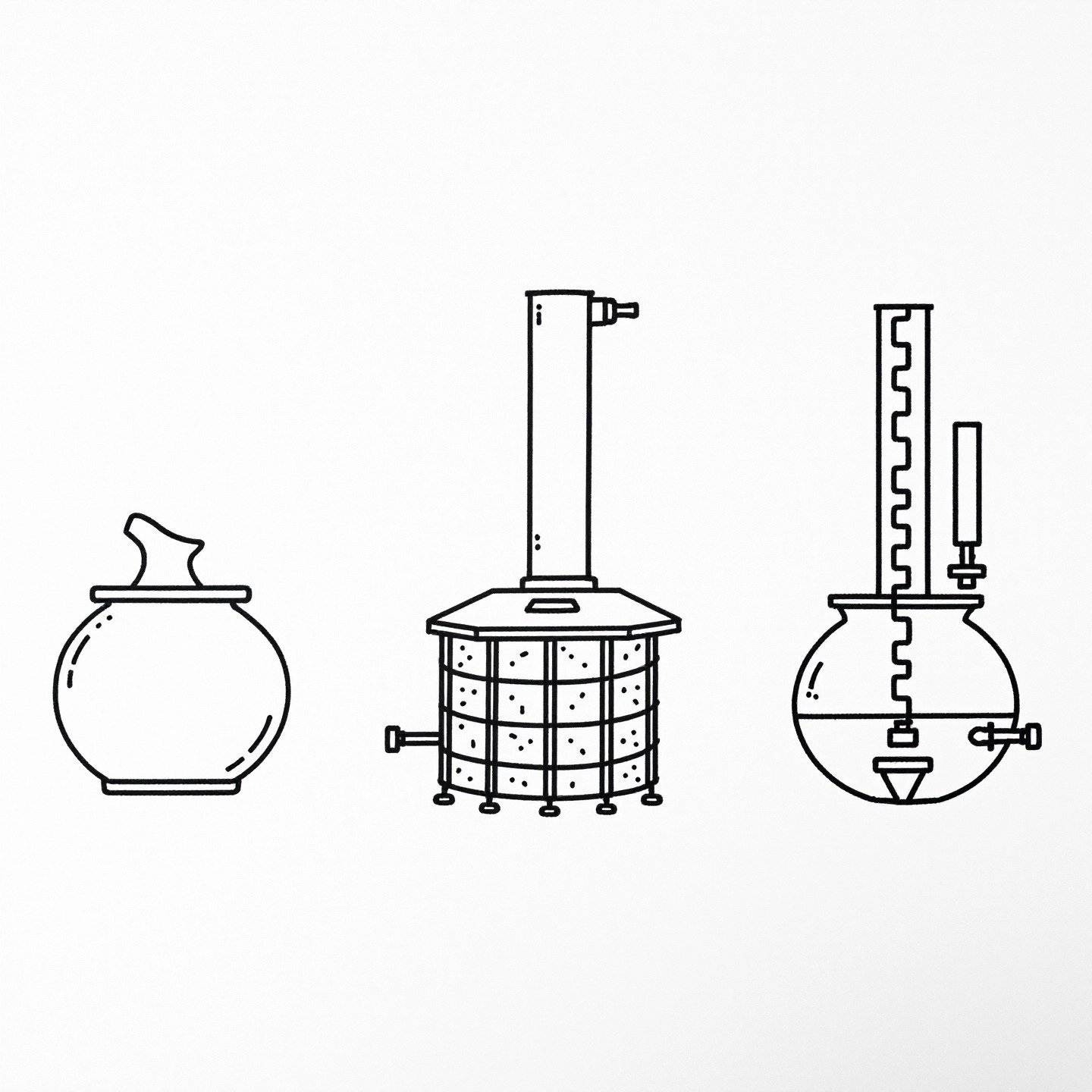

Configurations: Pot Still vs. Reflux Assemblies

You’ll find pot stills are ideal for producing flavor-rich products—think essential oils or traditional spirits (where legal). Reflux stills, on the other hand, are designed for higher purity output and are often chosen for water distillation or laboratory use. Both designs have their place, and your choice will depend on your goals and compliance requirements. If you’re curious about the history, the antique copper still remains a collector’s favorite, symbolizing centuries of distillation tradition.

This guide will walk you through the differences, safety tips, maintenance, and how to select a copper still moonshine setup for legal applications. Ready to dive deeper? Let’s explore the anatomy and features that matter most in the next section.

Anatomy of Copper Stills

Essential Copper Still Parts and Functions

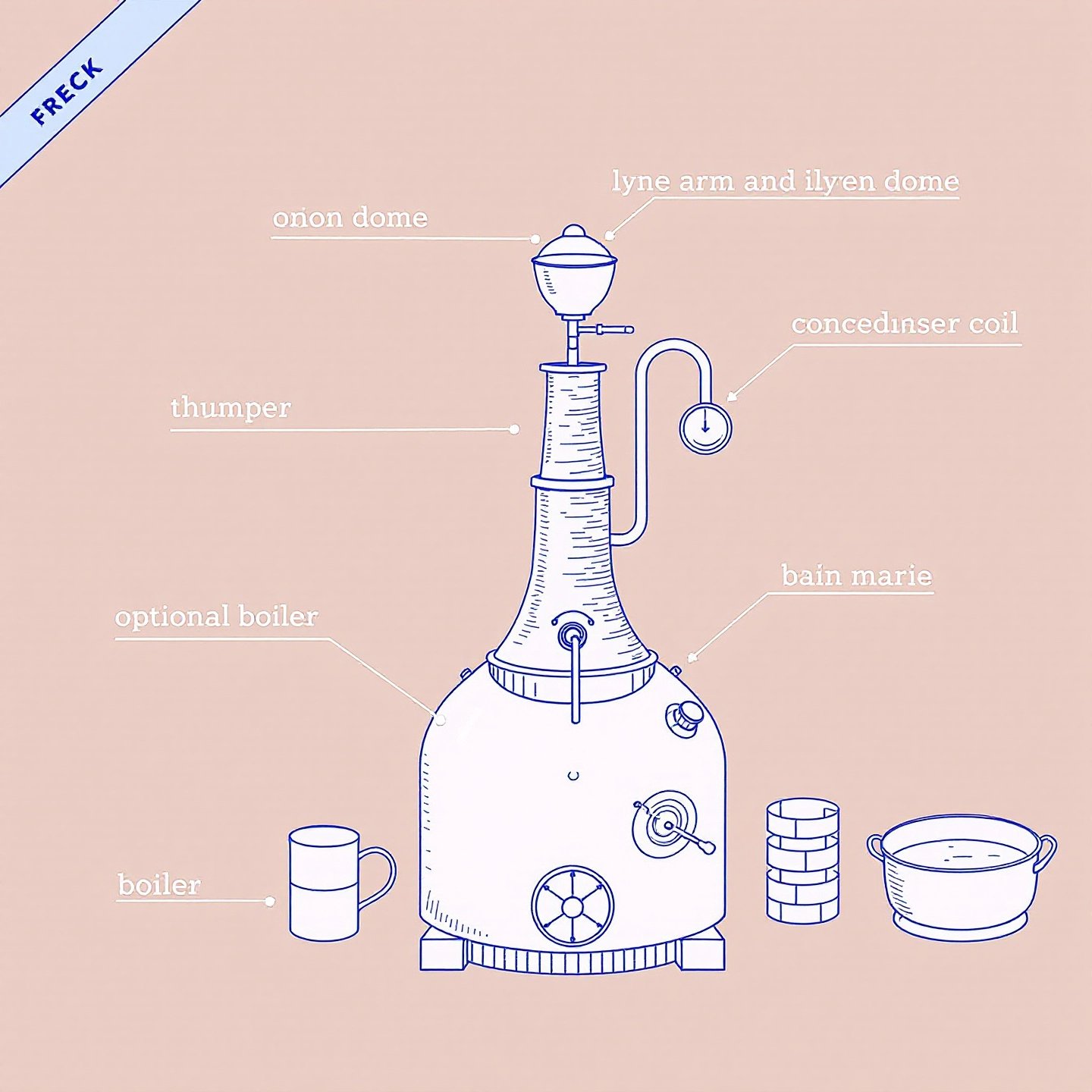

When you look at a copper still—whether it’s a classic copper pot still or a more modern setup—it might seem like a maze of pipes and chambers. But each part has a clear purpose, and knowing what they do can help you choose the right still parts, troubleshoot issues, or plan upgrades. Imagine you’re looking at a moonshine still diagram: each labeled section is crucial for performance, safety, and the flavor of your final product.

- Boiler (Pot): The main vessel where your mash, wash, or botanicals are heated. Usually made from thick copper for even heat distribution and durability.

- Onion/Helmet (Copper Helmet): A bulbous dome that sits atop the boiler. It helps separate heavier compounds and can enhance the richness of character spirits.

- Lyne Arm: A sloping or horizontal tube that channels vapor from the head to the condenser. Its angle can influence flavor carryover.

- Condenser: Where hot vapor is cooled and converted back to liquid. Common types include the worm, Liebig, and shotgun (see comparison table below).

- Thermometer Ports: Allow for temperature monitoring at key points—essential for repeatable, safe distillation.

- Tri-Clamp Ferrules: Stainless or copper fittings that provide secure, leak-resistant connections between still modules.

- Gaskets: Food-safe seals (usually PTFE or silicone) preventing vapor leaks at joints.

- Thumper (Thumper Still): An optional secondary vessel for additional purification or flavor modification—especially popular in traditional American distilling.

- Gin Basket: A chamber for holding botanicals, allowing vapor infusion for gin and aromatic hydrosols.

Pot Head vs Reflux Column

Choosing between a pot still head and a reflux column depends on your goals. A pot still head, often topped with a copper helmet, is ideal for capturing robust flavors—think whiskey or essential oils. The design is straightforward, with vapor moving directly from the boiler to the condenser, preserving more congeners and aromatic compounds (source).

A reflux column, on the other hand, features a tall, packed column (often filled with copper mesh or ceramic rings). As vapor rises, some condenses and falls back, creating multiple mini-distillations within the column. This process strips out more impurities, resulting in higher purity—ideal for neutral spirits or lab applications. Packing material and take-off controls allow you to fine-tune purity and output.

Condenser Types and Cooling Basics

Condensers are where vapor becomes liquid again, and the design you choose affects cooling efficiency, cleaning, and even the footprint of your setup. Here’s a quick comparison:

| Condenser Type | Footprint | Cooling Water Needs | Ease of Cleaning | Typical Applications |

|---|---|---|---|---|

| Worm | Large (coil in tub) | Moderate | Challenging (coils can trap residue) | Traditional pot stills, rustic setups |

| Liebig | Moderate (straight tube) | Low to moderate | Easy | Small copper pot stills, home use |

| Shotgun | Compact (multi-tube) | Higher flow for large volumes | Moderate (multiple tubes) | High-output setups, commercial or advanced hobbyists |

Each condenser style has its place. For example, a shotgun condenser is great for high-volume, efficient cooling, while a Liebig is simple and easy to clean.

-

Safety-critical seals and fittings to verify:

- Tri-clamps for secure, tool-free connections

- PTFE (Teflon) or high-temp silicone gaskets for food safety

- Brazed or lead-free soldered joints to prevent contamination

When assembling or upgrading your moonshine still parts, always check that all seals are tight, gaskets are intact, and joints are free from leaded solder. This is especially important for any still used in aromatic or essential oil production.

Understanding these components—and how they fit together—makes it easier to read a moonshine still diagram, spot upgrade opportunities, and ensure safe, efficient operation. Next, we’ll help you match your goals to the right still configuration, so you can select a setup that fits your space, batch size, and desired results.

Matching Your Copper Still to Your Goals and Space

Choosing the Right Copper Still for Your Goals

When you’re looking for a copper still for sale, it’s easy to get overwhelmed by options. Are you a home hobbyist, a craft spirit enthusiast, or maybe someone interested in botanical extractions? The right choice comes down to your intended use, batch size, and desired level of control. Imagine you want to experiment with a mini still for essential oils—your priorities will be very different from someone seeking a full-scale whiskey still for sale for small-batch production.

| User Type | Typical Volume Range | Recommended Configuration | Condenser Type | Control Complexity |

|---|---|---|---|---|

| Home Hobbyist | 1–5 gallons | Pot still or micro alembic | Liebig or small worm | Simple (manual heat, basic thermometer) |

| Small-Batch Craft | 6–16 gallons | Pot still or hybrid (pot/reflux) | Larger Liebig or shotgun | Moderate (heat control, extra gauges) |

| Lab/Aromatics | 0.5–2 gallons | Mini still or column still for sale | Liebig or compact condenser | Simple to moderate (precision temp control) |

Size, Throughput, and Run-Time Expectations

Sounds complex? It doesn’t have to be. Start by thinking about how much product you want per run and how often you’ll distill. Smaller stills—like a 1- to 5-gallon mini still—are perfect for test batches, home experiments, or learning the basics. Larger setups (8, 16, or even 26 gallons) are better if you want to produce enough for a group, or if you’re eyeing a moonshine still kit for more ambitious projects.

Keep in mind, more volume means longer heat-up and run times, bigger cooling demands, and more attention to safety. For example, an 8-gallon still might take an hour or more just to reach temperature, and the run could last several hours depending on your wash and heating method. Portability and ceiling height matter, too—can you safely move and operate your still in your chosen space?

What Reputable Sellers Disclose

Before you buy, ask yourself: what details are available about the still? Reliable vendors of any liquor distilling kit, pot still for sale, or column still for sale should clearly list:

- Copper thickness (affects durability and heat distribution)

- Grade or purity of copper used

- Joint construction (soldered, brazed, or welded—and if lead-free)

- Gasket material (should be food-safe, like PTFE or high-temp silicone)

- Warranty terms and after-sales support

Missing specs, vague descriptions, or a lack of warranty are red flags. Accessories also add up—don’t forget hoses, pumps, hydrometers, and a safe, stable heat source. If you’re investing in a whiskey still for home or small business use, these details are just as important as the base price.

- Is the copper thickness specified?

- What grade of copper is used?

- Are joints lead-free and professionally finished?

- What’s the warranty or return policy?

- Are all necessary accessories included or listed?

By focusing on your goals and verifying these details, you’ll set yourself up for safe, satisfying results—whether you’re starting with a mini still or scaling up to a full moonshine still kit. Next, let’s examine how material quality and build standards can impact performance and longevity.

Material Quality and Build Standards That Matter for Copper Stills

How Copper Sheet and Thickness Affect Longevity

When you’re shopping for a copper still, have you ever wondered why some last for decades while others dent or wear out quickly? Much of this comes down to the quality of the copper sheet used and how thick it is. Thicker sheet copper provides better resistance to dents and warping, especially under frequent heating and cooling cycles. Imagine picking up an old copper moonshine stills—the ones that stand the test of time are almost always built from robust, heavy-gauge copper. Thin copper may look shiny at first, but it’s more prone to damage and may not distribute heat as evenly, which can affect both performance and safety.

| What to Look For | Why It Matters | How to Verify |

|---|---|---|

| Stated copper thickness (gauge or mm/inch) | Ensures durability, dent resistance, and even heat transfer | Check seller specs or request written confirmation |

| Uniform, clean seams (soldered or brazed) | Prevents leaks, indicates skilled craftsmanship | Inspect product photos or request close-up images |

| Food-grade copper (pure, not decorative alloy) | Safety for consumables and aromatics; avoids contamination | Look for material declarations or certifications |

Lead-Free Joints and Food-Safe Materials

Ever noticed how some stills advertise "lead-free" or "food-safe" construction? That’s not just a buzzword. Joints soldered with lead or fluxes containing harmful chemicals can leach toxins into your distillate, especially when the still is heated repeatedly. Always look for copper still kits or finished products that specify lead-free solder and food-safe fluxes. If the vendor doesn’t mention this, ask for written assurance or certifications. Avoid any decorative copper distiller or imported still that doesn’t clearly state its material safety—these are often made from alloys not intended for repeated food contact.

- Warning signs to watch for:

- Uneven seams or blobs of solder (may indicate poor workmanship or unsafe materials)

- No mention of copper grade or solder type (could be mystery alloys)

- Imported or decorative stills without food-contact certification

Copper vs Stainless for Performance and Care

So, should you choose a copper steel or a stainless still? Here’s the trade-off: copper is unbeatable for removing sulfur compounds and providing rapid, even heat transfer. This is why most traditional copper moonshine stills are prized for flavor-rich spirits and artisanal distillation. Stainless steel, on the other hand, is less expensive, more durable, and easier to clean. It won’t tarnish like copper, and it’s less likely to suffer accidental dents. However, stainless does not remove sulfur on its own, so many modern stainless stills include copper mesh or plates inside the column to compensate.

For the best of both worlds, some distillers opt for a stainless boiler with a copper column or copper inserts. This hybrid approach balances cost, maintenance, and performance, especially for those who want the reliability of stainless with the reactivity of copper.

Finally, don’t overlook gasket materials. For any copper distiller, gaskets should be made from PTFE (Teflon) or high-temp silicone—both are designed for repeated food contact and high temperatures. Avoid rubber or unknown plastics, which can degrade or leach chemicals.

By focusing on these material and construction standards, you’ll set yourself up for safer, longer-lasting results—whether you’re assembling your own copper still kits or investing in a finished piece. Next, let’s explore how your choice of heating method can further impact performance and safety.

Heating Methods and Control Strategies for Your Copper Still

Choosing a Heat Source for Your Still

When you’re ready to fire up your copper still, the choice of heat source matters more than you might think. Should you go with an electric still, a gas burner, or even induction? Each method has its own safety requirements, power needs, and impact on your workflow. Imagine you’re setting up in a home kitchen versus a garage workshop—the right decision can make your process smoother and safer.

| Heat Source | Typical Use-Case | Control Finesse | Ventilation Needs | Maintenance |

|---|---|---|---|---|

| Electric Element (120 volt / 240 volt) | Home setups, indoor use, small to medium stills | Excellent (precise with controllers) | Low (no combustion) | Low (few moving parts) |

| Gas Burner (Propane/Natural Gas) | Outdoor or well-ventilated spaces, larger or traditional stills | Good (manual flame adjustment) | High (requires strong ventilation) | Moderate (inspect for leaks, clean burners) |

| Induction Plate | Small electric stills, modern spaces, quick setup | Very good (digital controls possible) | Low (no open flame) | Low (easy to clean) |

Electric vs Gas vs Induction: What to Consider

Let’s break down the options in plain terms. Electric heating—especially with a 120 volt or 240 volt element—offers clean, steady, and easily adjustable heat. Most homes are wired for 120 volts (sometimes written as 120 vac or 120 v), which supports smaller electric stills and basic setups. If you want to run a larger still or speed up your process, you’ll notice that 240 volt circuits (sometimes called double pole or 240-120) deliver more power, supporting higher wattage elements for faster warm-up and greater throughput.

Wondering about 120v vs 240v? The difference is capacity and efficiency. A 240 volt system can handle twice the wattage on the same wire size as 120 volts, making it ideal for bigger stills or when you want shorter heat-up times. However, installing or modifying 240 volt circuits should always be left to licensed electricians to ensure safety and code compliance.

Gas burners—using propane or natural gas—are a classic choice for larger stills or outdoor distillation. They heat quickly and can handle heavy loads, but require stable mounting, constant flame supervision, and, most importantly, excellent ventilation to prevent carbon monoxide buildup. Never use an open flame indoors or near alcohol vapors, and always check for leaks before lighting up (source).

Induction heating is gaining ground for small-batch or tabletop setups. It’s fast, responsive, and safe—there’s no open flame, and the cooktop cools quickly after use. However, you’ll need to confirm your still’s material is compatible with induction (most copper stills require a stainless base or an induction adapter).

Control and Safety Essentials

Regardless of your heat source, safety and control are non-negotiable. Here’s what you should always have in place:

- GFCI (Ground Fault Circuit Interrupter) protection for electric stills—prevents shock hazards.

- Stable mounting for all heating elements and burners—no tipping or shifting during operation.

- CO (carbon monoxide) detectors if using gas indoors or in semi-enclosed spaces.

- No open flames near alcohol vapors or flammable materials—keep fire extinguishers nearby.

- Routine inspections for leaks, damaged wires, or worn connections before every run.

For finer control, consider using a power controller (for electric) or a needle valve (for gas) to dial in your heat. This helps maintain a steady vapor rate and prevents surges that could compromise safety or product quality.

Imagine you’re scaling up from a small 120 volt tabletop still to a larger 240 volt setup. It’s not just about plugging into a different outlet—you’ll need to confirm your circuit can handle the load, and that all wiring meets local codes. If you’re unsure, always consult a qualified electrician before making changes to your setup.

By selecting the right heat source and following these control and safety strategies, you’ll ensure your distillation process is not only efficient but also safe for you and your workspace. Next, we’ll explore the maintenance routines that keep your copper still in top shape, so you can enjoy clean, consistent results for years to come.

Maintenance Routines and Troubleshooting for a Long-Lasting Copper Still

Routine Cleaning and Copper Care

Ever wonder why some copper moonshine stills stay shiny and efficient year after year, while others develop off-flavors or leaks? It all comes down to regular, gentle maintenance. Whether you use a home still for essential oils or a classic stovetop still, a simple cleaning routine is your best defense against tarnish, buildup, and unwanted flavors. Here’s a straightforward protocol that works for any still for alcohol or botanical distillation:

- Disassemble the still—separate the pot, condenser, and any removable parts for thorough access.

- Rinse all parts with warm (not boiling) water to remove leftover residues.

- Wash each section using a mild, unscented detergent and a soft-bristled brush. Avoid abrasive pads—they can thin the copper and shorten the lifespan of your equipment.

- Citric acid rinse: Mix a solution of citric acid and warm water. Soak interior surfaces and condenser coils to dissolve mineral deposits and restore copper’s luster. For stubborn buildup, let it sit briefly, then gently scrub.

- Thoroughly flush all parts with fresh water to remove any cleaning residues.

- Dry completely before reassembling or storing to prevent tarnish and corrosion.

For light tarnish, a paste of baking soda and water works well. For extra shine, polish with a little lemon juice and salt, then buff with a soft cloth. After polishing, a thin layer of mineral oil can help slow future oxidation.

Leak Detection and Minor Fixes

Imagine you’re running your alcohol still and notice a faint wisp of vapor or a drop of liquid where it shouldn’t be. Early detection is key to avoiding bigger problems down the line. Here’s how to spot and address common issues before they escalate:

- Pinhole leaks: Look for vapor wisping or tiny droplets on seams or joints. Small leaks are often caused by corrosion or thin spots—temporary fixes include food-safe pipe repair tape or epoxy putty, but permanent solutions may require professional soldering or replacing the damaged section.

- Loose ferrules or clamps: If you see drips at connections, check that all fittings are tight and gaskets are seated properly. Hand-tighten clamps or ferrules—never overtighten, as this can damage seals.

- Worn gaskets: Cracked, flattened, or discolored gaskets can cause leaks or loss of pressure. Replace with food-safe silicone or PTFE gaskets as soon as wear is visible.

- Kinked tubing: If your condenser isn’t cooling efficiently or you notice poor liquid flow, inspect hoses for kinks or blockages. Straighten or replace as needed.

A safe way to check for leaks after cleaning or before any production run is to assemble your still, fill it with water, and heat gently. Watch for any escaping vapor or drips—this water run is a simple, non-invasive leak test that protects your workspace and your next batch.

-

Common symptoms and fixes:

- Leak at joint: Check gasket, tighten clamp, or use food-safe sealant for temporary repair.

- Poor condenser knockdown: Clean coils, check coolant flow, and remove any debris.

- Off-odors or flavors: Deep clean with citric acid, flush thoroughly, and inspect for hidden residue.

Gasket and Condenser Upkeep

Gaskets are the unsung heroes of any copper moonshine still or stovetop still. Over time, heat and pressure can wear them down, so regular inspection and timely replacement are essential for safe, leak-free operation. Here’s a quick guide to common gasket materials and their suitability for your setup:

| Gasket Material | Temperature Tolerance | Compatibility |

|---|---|---|

| Silicone | Up to 400°F (204°C) | Flexible, food-safe, fits most home stills |

| PTFE (Teflon™) | Up to 500°F (260°C) | Highly chemical-resistant, best for high-temp or repeated use |

| Buna-N | Up to 250°F (121°C) | Budget-friendly, suitable for cool-side joints only |

Check gaskets every few runs—replace them at the first sign of wear, flattening, or hardening. For the condenser, soak coils in citric acid to prevent scale buildup and flush with water to keep them clear. This ensures maximum cooling efficiency and consistent output from your still for alcohol or aromatics.

By making these routines second nature, you’ll extend the life of your copper still, avoid costly breakdowns, and enjoy pure, flavorful results every time. Next, let’s look at how different still designs and accessories impact performance and flavor, so you can get the most from your investment.

How Still Design and Accessories Shape Your Results

Flavor and Purity by Still Design

When you choose a copper still, you’re not just picking a piece of equipment—you’re deciding how much character, purity, and versatility you want in your final product. Ever wondered why a traditional pot distillery produces such rich, flavorful spirits, while a modern reflux column turns out crisp, neutral alcohol? The secret lies in the way each design manages congeners (flavor compounds) and purity.

| Still Type | Flavor Retention | Achievable Purity | Learning Curve | Typical Use-Cases |

|---|---|---|---|---|

| Pot Still | High (lots of congeners retained) | Moderate (single run: 60–80%) | Beginner-friendly | Whiskey, rum, brandy, essential oils, still for gin |

| Reflux Column | Low (most congeners removed) | Very high (up to 95%+ with proper packing) | Intermediate (requires tuning) | Vodka, neutral spirits, lab-grade distillation, clean hydrosols |

| Pot Still + Thumper | Medium-High (some flavor, higher proof) | Higher than pot still alone (second distillation effect) | Moderate (extra setup/steps) | Traditional American spirits, custom flavors, aromatic infusions |

With a classic pot still, you’ll notice robust aromas and deep flavors—ideal for those who want their copper still distillery to capture every nuance of the original mash or botanicals (source). Reflux columns, by contrast, use internal packing and a controlled reflux ratio to remove impurities and lighten the taste, making them perfect for high-purity spirits or delicate hydrosols.

What a Thumper Really Does

Curious about what is a thumper on a still and what does a thumper do on a still? Imagine adding a secondary chamber between your boiler and condenser. As hot vapor passes through the thumper, it bubbles through a liquid (often low wines or a flavored wash), undergoing a second distillation. This boosts proof, refines the spirit, and allows for creative flavor additions—all in a single run. Thumpers are especially valued for producing spirits with higher alcohol content and enhanced character, without the need for multiple distillation cycles.

Botanical Infusion with a Gin Basket

If you’re aiming for a still for gin or want to experiment with vapor infusions, a gin basket is your go-to accessory. Picture a chamber—inline or offset—placed in the vapor path, filled with botanicals. As vapor rises, it extracts essential oils and flavors from the herbs, spices, or fruits, resulting in a light, aromatic spirit. This method is favored for its ability to produce clear, smooth, and nuanced gins or aromatic hydrosols without heavy residues or color carryover.

-

Variables affecting run time and output:

- Charge volume (how much wash or mash you start with)

- Heat rate (how quickly you bring the still up to temperature)

- Ambient temperature (affects cooling efficiency)

- Condenser capacity (how fast you can condense vapor back to liquid)

- Wash composition (alcohol content and impurities)

- Accessory use (thumper, gin basket, etc.)

The best copper still setup is the one that matches your flavor goals, batch size, and legal requirements. Always choose your design and accessories based on the results you want—and the regulations in your area.

Whether you’re building a pot distillery for full-bodied spirits, a reflux system for ultra-clean distillate, or adding a thumper or gin basket for creative infusions, understanding these performance trade-offs will help you get the most from your copper still. Next, we’ll discuss how precision fabrication and custom parts can further fine-tune your results and make maintenance a breeze.

Custom Parts and Precision Fabrication for Copper Stills

When Custom Parts Make Sense

Ever tried to upgrade your copper still, only to find that off-the-shelf parts just don’t fit—or that leaks persist no matter how much you tighten a clamp? That’s where custom fabrication steps in. Imagine you’re building a hybrid copper alembic with a stainless boiler, or you want to add a sight-glass, tri-clamp ferrules, or even a gin basket for botanical infusions. These aren’t just aesthetic upgrades; they’re about precision, safety, and making your copper distillation kit easy to maintain for years to come.

Custom components—like condenser tube sheets, copper tees for vapor routing, or a copper whiskey thief for sampling—often need tolerances tighter than what basic hand tools can achieve. When you want leak-free joints, repeatable performance, and parts that swap out smoothly, it’s time to consider professional machining.

CNC Precision for Leak-Free Assemblies

So, why does CNC machining matter for copper still parts? The answer is repeatable accuracy. CNC machining uses computer-controlled tools to cut, drill, and shape copper or stainless to exact specifications. This means parts like flanges, adapters, or complex copper tees can be made to fit perfectly—no gaps, no guesswork, and no post-assembly leaks. For example, using CNC-milled ferrules or tube sheets ensures your gaskets seal properly and the still can be disassembled for cleaning without damaging the copper.

When you need ultra-tight tolerances, rapid turnaround, or documentation for food-contact safety, working with a shop that specializes in copper is key. Services like XTJ's CNC machining services offer 4/5-axis machining, tolerances down to +/- 0.005mm, and support for over 30 materials—including copper and stainless steel. With ISO 9001:2015 and IATF16949 certifications, you’ll know your parts meet strict quality standards and can be scaled from prototype to production as your needs grow.

| Sourcing Path | Typical Tolerance/Fit | Materials Supported | Lead Time | Documentation | Scalability |

|---|---|---|---|---|---|

| XTJ CNC Machining | Ultra-tight (+/- 0.005mm) | Copper, stainless, 30+ others | Fast (as little as 3 days) | Full (drawings, certifications) | Prototype to full production |

| Local Fabricator | Moderate (manual or semi-CNC) | Usually copper, stainless, brass | Varies (1–4 weeks typical) | Basic (drawings, sometimes certs) | Small batches |

| DIY (Hand Tools) | Low (fit varies, more leaks) | Copper, sometimes brass | Slow (depends on skill/tools) | None | One-off only |

For critical joints—like those joining copper still parts to a stainless condenser—tight tolerances from CNC machining help preserve the integrity of food-contact surfaces. This reduces the risk of leaks and makes cleaning much easier.

How to Brief a Machine Shop

Thinking about commissioning a custom copper distillation kit or just a single adapter? Here’s a quick checklist to get the most from your fabricator—whether you’re ordering a batch of copper tees or a unique copper whiskey thief for sampling:

- Provide detailed drawings or sketches with all dimensions and tolerances called out.

- Specify the gasket type (PTFE, silicone, etc.) and size for each joint.

- Call out copper thickness and grade—C110 is popular for machinability and food safety.

- Request finish requirements—do you want a mirror polish, matte finish, or electropolishing for easier cleaning?

- Ask for documentation, especially for food-contact or pressure-rated parts.

By investing in precision fabrication for your copper alembic or hybrid still, you ensure not just a better fit, but a safer, more reliable setup that’s easier to maintain and upgrade. Up next, we’ll wrap up with actionable next steps and trusted resources to guide your copper still journey.

Trusted Resources and Final Steps for Copper Still Buyers

Your Next Steps

When you reach the end of your copper still research, it’s natural to wonder—what should I actually do next? Whether you’re eyeing copper stills for sale online or dreaming of finding copper stills near me for hands-on inspection, the path to a safe, high-quality setup is more straightforward than it seems. Let’s break it down so you can move forward with confidence and clarity.

- Source precision components responsibly: For custom adapters, ferrules, or condenser plates, consider CNC machining services that offer 4/5-axis capabilities, copper and stainless options, ISO-certified quality, and rapid turnaround. This is especially valuable if you need exact-fit parts for a hybrid build or want to upgrade safety-critical joints.

- Define your goals: Are you interested in essential oils, hydrosols, or water purification? Or are you seeking a classic setup reminiscent of old moonshine stills for sale? Clarifying your primary use will help you shortlist the right configuration.

- Verify specifications: Check for copper thickness, grade, and joint method. Reliable sellers of copper stills and copper alembic stills for sale should provide clear, written details about materials and construction. Don’t hesitate to ask for documentation.

- Plan heat and cooling: Assess your available utilities and space. Will you use electric, gas, or induction? Do you have enough ventilation and water flow for safe operation?

- Confirm legal requirements: Laws around distillation vary widely. Before you buy a still or attempt any alcohol production, contact local authorities or industry associations to ensure you’re in compliance. For non-alcoholic uses, such as an alembic essential oil distiller, most states allow ownership and operation without a permit—but always double-check.

Quality and Compliance First

Imagine finding the perfect still—only to discover it doesn’t meet food safety standards or your local code. That’s why it’s important to verify every claim, from solder type to gasket material. If you’re considering custom modifications or upgrades, professional machining can make your build safer and more reliable for years to come.

Where to Source Precision Components

For many, the final hurdle is sourcing those last few critical parts—especially if you’re restoring old moonshine stills for sale or building a hybrid system. Here’s where options like CNC machining services shine: you can get copper or stainless parts made to exact specs, with full engineering support and documentation. This is especially valuable if you’re assembling a kit or need replacements for rare or antique components.

The best copper still is one that matches your goals, meets all safety and legal standards, and is built to last. Always prioritize quality, compliance, and responsible sourcing—your results and peace of mind depend on it.

With these steps, you’re ready to move from research to action—confident that your investment in a copper still will deliver both performance and safety, whether you’re producing botanicals, water, or simply preserving a piece of distilling history.

Copper Still FAQs

1. Can you buy a copper still?

Yes, you can legally purchase a copper still in most regions, especially for uses like essential oil extraction, hydrosol production, or laboratory applications. However, using a copper still for alcohol distillation at home typically requires federal and sometimes state permits. Always verify local laws before buying or operating a still for any purpose.

2. Are copper stills better than stainless steel stills?

Copper stills are favored for their superior heat transfer and ability to bind sulfur compounds, resulting in cleaner aromas and flavors. Stainless steel stills are more durable and require less maintenance but lack copper's chemical benefits. Many distillers use hybrid systems to combine the strengths of both materials.

3. Why are stills illegal?

Distilling alcohol without proper permits is illegal under federal law in the US, regardless of whether the product is for personal use. This regulation is intended to ensure safety and prevent unregulated alcohol production. Non-alcohol uses, like making essential oils or water purification, are generally legal but still require compliance with local regulations.

4. What should I look for when buying a copper still?

Prioritize food-grade copper, lead-free joints, and clear details on copper thickness. Reliable sellers should specify gasket materials, joint methods, and offer warranties. Consider your intended use, batch size, and whether you need custom parts or accessories. Professional CNC machining services can provide precision components for leak-free, safe operation.

5. How do I maintain a copper still for long-term use?

Regularly clean all parts with mild detergent and citric acid to prevent tarnish and buildup. Inspect for leaks, worn gaskets, and ensure all fittings are tight. Replace gaskets as needed and keep condenser coils clear. A water run before each use helps detect leaks safely, ensuring your still remains efficient and safe for years.

-

Posted in

copper still, copper vs stainless, distillation equipment, moonshine still, still maintenance