4 x 8 Aluminium Sheets: Alloy, Gauge, And Price Made Simple

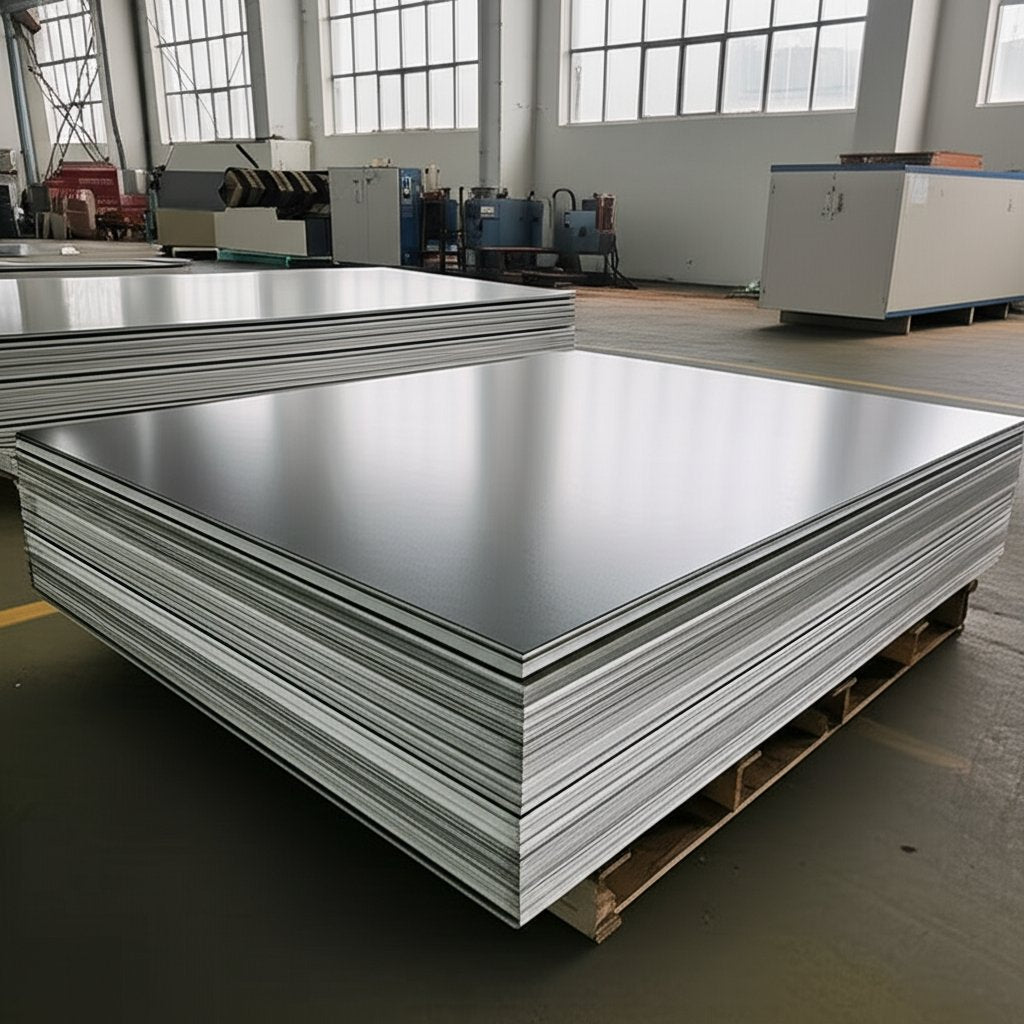

Understanding 4 x 8 Aluminium Sheets

When you hear someone mention “4 x 8 aluminium sheets,” what exactly do they mean? In the world of fabrication and supply, this term almost always refers to flat sheet aluminum measuring 48 inches by 96 inches—just like a standard piece of plywood. These sheets are prized for their manageable size, versatility, and ease of transport, making them a staple for projects large and small.

What 4 x 8 aluminium sheets include and exclude

Not every flat piece of aluminum qualifies as a 4 x 8 sheet. Here’s what’s typically included:

- Dimensions: A true 4x8 aluminum sheet is 48" wide by 96" long. You may also see these described as "aluminium sheet 8 x 4" or "aluminium sheet 8x4" in some markets, but the sizing is the same.

- Thickness: Most 4 x 8 aluminium sheets fall between 0.2 mm and 6 mm thick, though North American standards may extend sheet thickness up to 6.35 mm (0.25 in). Thicker material is classified as plate, while thinner is considered foil.

- Tempers: Sheets are commonly supplied in a range of tempers—from soft (O) to harder (Hxx or Txx)—which affect both formability and strength.

- Surface: Finishes range from mill (bare) to brushed, painted, or anodized. Protective films are often applied to one or both sides to guard against scratches during handling and fabrication.

Buyers should not expect guaranteed flatness or dimensional tolerances unless these are specifically cited from recognized standards or provided on a mill test certificate (MTC). Always confirm critical requirements with your supplier.

Common finishes and tempers for general use

Most aluminum 4x8 sheet options come in finishes that suit their end use. For example, mill finish is standard for industrial and structural applications, while brushed or painted finishes are popular for signage and architectural cladding. Tempers like H32 or H14 are common for general-purpose work, balancing strength and bendability. If appearance or corrosion resistance is important, ask about anodized or coated surfaces.

Where 4 x 8 fits in the aluminum family

How do you know if you need a sheet, plate, or panel? Here’s a quick breakdown:

| Product | Typical Thickness Range | Formability | Typical Uses | Relevant Standards |

|---|---|---|---|---|

| Sheet | 0.2–6 mm (up to 6.35 mm in North America) |

High (easy to cut, bend, and shape) | Signage, enclosures, cladding, fixtures | ASTM B209, Aluminum Association |

| Plate | Above 6 mm (above 6.35 mm in North America) |

Lower (stiffer, less bendable) | Machined parts, heavy-duty panels, structural | ASTM B209, Aluminum Association |

| Panel | Varies (often sheet or plate with added layers or core) | Depends on construction | Architectural facades, insulated walls | Project-specific |

For most general fabrication, "sheet aluminum 4x8" is the go-to material. If your project needs more strength or thickness, you may need to look at plate. Panels, on the other hand, are often composite or insulated products for specialized uses.

Common applications for 4 x 8 aluminium sheets

- Signage and display boards

- Equipment enclosures and machine guards

- Trailer skins and truck bodies

- Architectural cladding and wall panels

- Fixtures, furniture, and cabinetry

- Marine and automotive panels

Imagine building a custom trailer, fabricating machine guards, or installing a modern facade—aluminum sheet 4x8 is likely the material you’ll reach for. Its combination of light weight, corrosion resistance, and easy fabrication makes it a favorite across industries—from construction and transportation to signage and home improvement.

Key standards for 4 x 8 aluminium sheets include ASTM B209 for both sheet and plate, as well as Aluminum Association alloy and temper designations. For any project where flatness, thickness, or surface quality matters, always verify tolerances and properties directly from mill datasheets or supplier MTCs—don’t rely on generic claims.

Align your choice of alloy, temper, and finish with what your project truly needs—corrosion resistance, machinability, surface appearance, or all three.

Ready to dig deeper? Up next, we’ll break down how to choose the right alloy and temper for your application, followed by guidance on gauge, weight, fabrication, and smart procurement for aluminium sheet 8 x 4. Stay tuned for practical tips to get the most value from every aluminium sheet 8x4 you buy.

Alloy and Temper Selection Made Simple

Ever wondered why one aluminium sheet bends easily while another feels stiff and tough to shape? Or why some panels hold up better against salt spray or harsh weather? It all comes down to alloy and temper—the backbone of every 4 x 8 aluminium sheet decision. Let’s break down the most popular choices so you can match the right material to your job, whether you’re building enclosures, marine panels, or CNC-machined brackets.

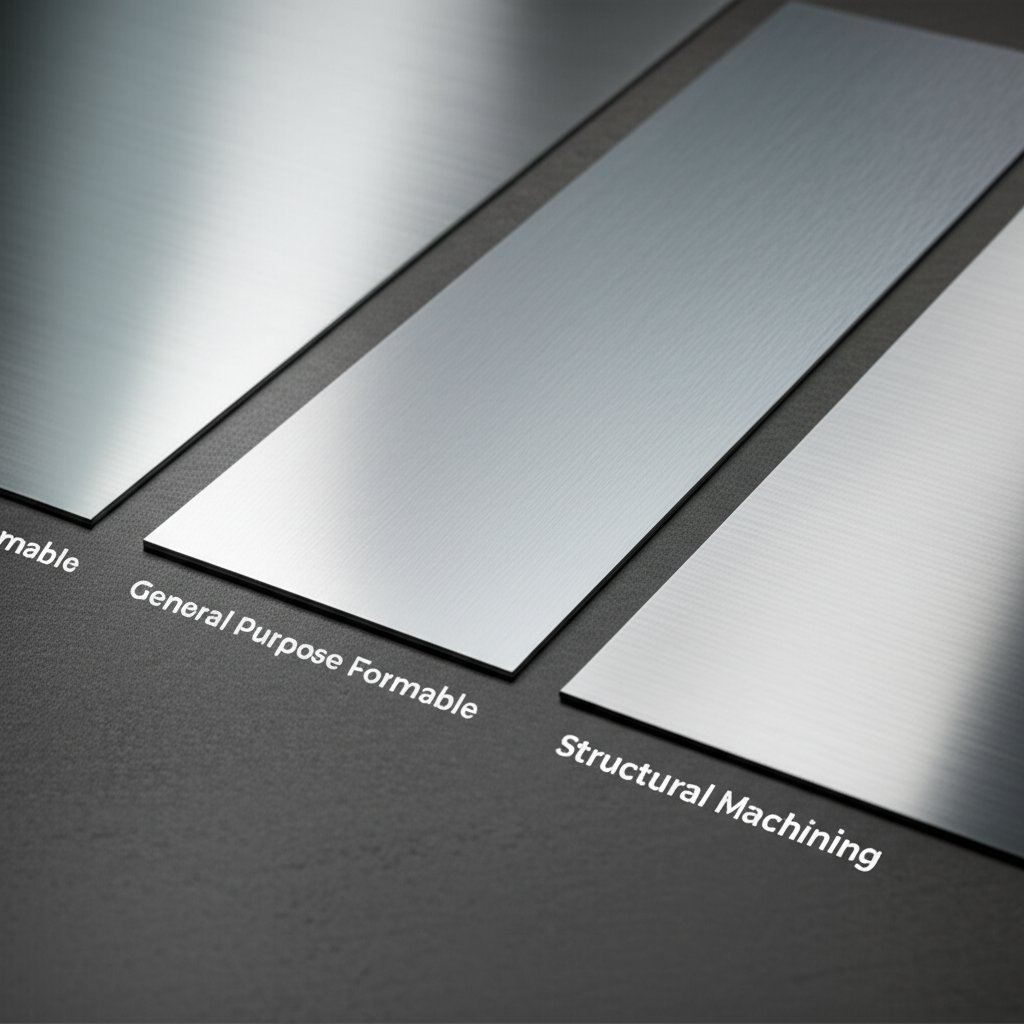

Formable General-Purpose Choice: 3000 Series (3003 Aluminum)

If you need a sheet that’s easy to bend, punch, or shear for signage, enclosures, or light-duty panels, 3003 aluminum is your go-to. This alloy is praised for its excellent formability and good corrosion resistance—especially in humid or mildly corrosive environments. It’s a non-heat-treatable alloy, so its strength comes from cold working, not heat treatment. The most common temper you’ll find is H14, which strikes a balance between softness and strength, making it ideal for projects that require lots of forming or shaping.

Marine-Grade Corrosion Resistance: 5000 Series (5052 Aluminum Sheet)

Working near saltwater or in demanding transport applications? 5052 aluminum sheet stands out for its superior corrosion resistance—especially in marine, automotive, and outdoor environments. Thanks to its magnesium content, 5052 is tougher than 3003 and resists attack from salt and chemicals. It’s still highly formable and weldable, but offers better strength for demanding applications. This makes it a favorite for boat hulls, trailer skins, and fuel tanks. Common tempers like H32 are chosen for a blend of strength and workability.

Strong and Machinable: 6000 Series (6061 Aluminum Sheet)

When your project demands more strength, precise machining, or structural performance, the 6061 aluminum sheet is a top pick. This alloy combines magnesium and silicon, resulting in a material that can be heat-treated for higher strength. The T6 temper is especially popular for CNC-machined plates, brackets, and structural assemblies where rigidity and dimensional stability matter. While it’s less formable than 3003 or 5052, its machinability and weldability are excellent, making it a staple for high-performance parts.

| Alloy | Typical Uses | Formability | Weldability | Corrosion Resistance | Machinability | Recommended Tempers |

|---|---|---|---|---|---|---|

| 3003 | Enclosures, signage, kitchen equipment, light-duty panels | Excellent (ideal for bending and forming) | Good | Very good (humid, mild chemical exposure) | Fair | H14 (half-hard), H24 |

| 5052 | Marine panels, trailer skins, tanks, transport equipment | Very good (can be formed and bent) | Excellent | Excellent (saltwater, harsh environments) | Fair | H32 (standard), H34 |

| 6061 | Structural brackets, CNC-machined plates, frames | Moderate (less bendable, better for machining) | Good | Good | Excellent | T6 (heat-treated), T651 |

- 3003 aluminum: Great for enclosures, signage, and projects needing lots of bends or shaping.

- 5052 aluminum sheet: Go-to for marine, transport, and outdoor applications where corrosion resistance is a must.

- 6061 aluminum sheet: Best for structural brackets, CNC-machined parts, and components that require higher strength or tight tolerances.

Imagine you’re fabricating an outdoor sign (choose 3003 for easy bending), building a boat hull (5052 for corrosion resistance), or CNC-machining a bracket (6061 for strength and precise cuts). That’s how alloy and temper shape your decision—and your finished result.

Always check bend radius and forming guidance for your chosen alloy-temper before committing to tight bends. Tempers like H14 or H32 boost strength but may reduce bendability—consult supplier charts or datasheets for best results.

Before you order, request certifications that match your specified alloy and temper. This ensures your aluminium 4x8 sheet meets expectations and avoids costly substitutions. The right choice here sets the stage for easier fabrication, better finishing, and longer service life for all types of aluminium sheets.

Next, we’ll tackle how thickness, gauge, and temper interact to determine real-world strength and formability—so you can confidently specify the perfect 8 x 4 aluminium sheet for your needs.

Standards, Tolerances, and Documentation Essentials

Core product standards you should cite

Sounds complex? When you’re sourcing aluminum sheet metal 4x8 for your next project, it’s easy to get overwhelmed by technical jargon. But the truth is, most buying headaches can be avoided by knowing which standards to reference and what documentation to request. For most aluminum sheet 4 x 8, ASTM B209 is the go-to product standard in North America. It covers both sheet and plate, laying out requirements for alloy composition, mechanical properties, and, crucially, aluminum sheet thickness and flatness. The Aluminum Association also publishes alloy and temper designations that appear on every legitimate sheet of aluminum you buy. Internationally, you might see EN or ISO equivalents—always confirm these align with your project’s requirements and local codes. For specialty finishes (like anodizing or painting), reference the relevant finishing standard at the time of order.

Certifications and what they actually cover

Imagine you receive a stack of aluminum sheet material and need to prove it meets your spec. That’s where certifications come in. ISO 9001 and IATF 16949 are quality management system certifications—they tell you the supplier is organized and follows documented processes, but they do not guarantee the properties of the metal itself. For that, you want a Mill Test Report (MTR) or Material Test Certificate (MTC). These documents, issued by the mill or distributor, confirm the alloy, temper, chemistry, and mechanical properties of your aluminum sheet metal 4x8. Each MTR includes a unique heat number, tying your order back to the exact production batch for full traceability. This is essential for code compliance and quality audits—especially in regulated industries like transportation, marine, or food processing.

What to request in your paperwork

Here’s a quick checklist to keep your aluminum sheet 4 x 8 order on track:

- Cite ASTM B209 (or equivalent) for sheet and plate

- Specify alloy and temper using Aluminum Association designations

- Request MTR/MTC with heat number, chemistry, and mechanicals

- Ask for dimensional tolerances (thickness, flatness, squareness) per standard or supplier datasheet

- State surface finish and finishing standard if required (e.g., for anodized or painted sheets)

Supply 4 x 8 aluminum sheet per ASTM B209, alloy-temper as specified, with MTR showing heat number and mechanicals. No substitutions without written approval.

If you need specific tolerances for thickness or flatness, always reference the relevant clause in ASTM B209 or your supplier’s datasheet. Don’t rely on generic promises—request the numbers in writing on your order or MTR. Here’s a sample of what to clarify:

| Parameter | How to Specify | Where to Find |

|---|---|---|

| Thickness | Decimal value with tolerance | ASTM B209 or supplier datasheet |

| Flatness | Maximum allowable deviation | ASTM B209 or supplier datasheet |

| Squareness | Maximum out-of-square | ASTM B209 or supplier datasheet |

Finally, remember: if your project involves painting, anodizing, or other finishing, make sure your supplier knows your surface quality requirements before production. This ensures your aluminum sheet material arrives ready for its next step, without costly surprises. Up next, we’ll clarify how gauge, decimal thickness, and temper affect the real-world performance of your sheet of aluminum—and how to specify what you need, every time.

Thickness Gauge and Strength Clarified

Gauge versus Decimal Thickness

Ever wondered why a “16 gauge” aluminum sheet isn’t the same thickness as a 16 gauge steel sheet? Sounds confusing, right? That’s because gauge numbers are not universal—they vary by material type and can even differ between suppliers. When you’re working with aluminum sheet gauge, it’s easy to get tripped up if you rely on just the gauge number.

To avoid confusion, always specify the decimal thickness (such as 0.040 inch or 1.02 mm) for your project. This approach aligns with ASTM B209 and supplier best practices, ensuring everyone is on the same page from design through fabrication and delivery. If you’re referencing a supplier chart, double-check that it’s for aluminum—not steel—since the same gauge number means different thicknesses for each metal. For a quick reference, here’s a table with common aluminum sheet gauges, their decimal thicknesses, and notes on formability, based on industry-standard charts:

| Gauge | Decimal Thickness (inches) | Formability Notes |

|---|---|---|

| 22 | 0.025" | Very easy to form; ideal for thin aluminum sheet metal, signage, and cladding |

| 20 | 0.032" | Still flexible; good for enclosures and light covers |

| 18 | 0.040" | General fabrication; balances formability and stiffness |

| 16 | 0.050" | Stiffer; suitable for panels and moderate-duty guards |

| 14 | 0.064" | Much stiffer; used for structural panels and heavy-duty trays |

| 11 | 0.090" | Thick aluminum sheet metal; best for high-strength or machined parts |

Specify decimal thickness and acceptable tolerance in your RFQ; avoid gauge-only specs.

Why Temper Matters for Bendability

When you’re planning to bend or form a thin aluminum sheet, the alloy’s temper is just as important as its thickness. The temper describes the material’s hardness and ductility, which directly affect how easily it can be bent without cracking. For example, softer tempers (like O or H14) are much easier to form, while harder tempers (like H32 or T6) provide more strength but can be prone to cracking if bent too sharply.

- Thin aluminum sheet metal (such as 0.025"–0.040") is ideal for tight bends, but always check the minimum bend radius for your chosen alloy and temper.

- Springback—the tendency of aluminum to return slightly toward its original shape after bending—is more pronounced in harder tempers and thicker gauges.

- Consult your supplier’s bend allowance chart or datasheet for precise recommendations, as generic rules of thumb can lead to mistakes.

Imagine you’re making a custom bracket: choosing 5052-H32 for a 0.040 aluminum sheet will let you achieve a tight radius, but try the same with 6061-T6 and you risk cracks unless you use heat or increase the bend radius.

Choosing Thickness for Stiffness and Strength

How do you know if you need a thin or thick aluminum sheet metal for your project? It depends on the balance of stiffness, weight, and intended use. Here’s how to think about it:

- Thin sheet (22–18 gauge, up to 0.040") is perfect for easy forming, cladding, and decorative panels. It’s lightweight and simple to cut or bend.

- Mid-range thickness (16–14 gauge, 0.050"–0.064") is suited for general fabrication, moderate-duty panels, and enclosures where extra stiffness is needed.

- Thick aluminum sheet metal (11 gauge and up, 0.090"+) is best for structural parts, heavy-duty guards, or applications where machining, tapping, or high load capacity is required.

Stiffness increases dramatically with thickness, but so does weight. For projects where weight is a concern—think trailers or aircraft—using the thinnest material that meets your stiffness and strength needs is key.

Remember: the minimum inside bend radius grows with both thickness and hardness. Always check whether your protective film or painted finish will affect your bend radius or require special tooling. Taking the time to verify these details up front will save you from costly rework or scrap down the line.

Up next, we’ll show you how to estimate the weight and coverage of your aluminum sheets for smarter planning and freight calculations.

Weight and Coverage Calculations Made Easy

Ever stood in the warehouse, wondering how much a stack of 4x8 sheet of aluminum weighs—or how many you’ll need for your next project? Whether you’re planning freight, budgeting for installation, or simply want to avoid surprises, knowing how to estimate aluminum weight and coverage is essential. Sounds complex? It’s actually straightforward when you break it down step by step.

How to Calculate Weight by Area

Imagine you’re ordering a 1 8 inch aluminum sheet or a full bundle of aluminum sheet 4x8 1 8 for a fabrication job. Here’s the universal formula you’ll use for any flat aluminum sheet:

- Convert all dimensions to consistent units. For 4 x 8 aluminium sheets, that’s 48 inches by 96 inches. If you’re working in feet, multiply feet by 12 to get inches.

-

Calculate the area:

Area = Length × Width

For a 4x8 sheet: 48 in × 96 in = 4,608 in² -

Calculate the volume:

Volume = Area × Thickness

If you have a 1 8 inch aluminum sheet (0.125 in thick):

4,608 in² × 0.125 in = 576 in³ -

Multiply by density:

Aluminum density varies by alloy, but a typical value is about 0.097 lb/in³. Always check your supplier’s datasheet for the exact alloy-temper density.

576 in³ × 0.097 lb/in³ ≈ 55.8 lbs for one sheet of 1/8 aluminum. -

Convert to your desired units:

If you need kilograms, divide pounds by 2.2046.

Tip: This method works for any thickness—just swap in your decimal value. For thinner or thicker sheets, repeat the calculation with the appropriate thickness.

Weight per Sheet Versus Per Square Foot

Sometimes you’ll need to compare options or plan for shipping. Here’s a handy way to estimate weight for common alloys and tempers. (Always confirm with your supplier’s density if you need exact figures.)

| Alloy | Temper | Thickness (in) | Weight per Sq Ft (lbs) | Weight per 4x8 Sheet (lbs) |

|---|---|---|---|---|

| 3003 | H14 | 0.040 | 0.56 | ~17.9 |

| 5052 | H32 | 0.063 | 0.88 | ~28.2 |

| 6061 | T6 | 0.125 | 1.73 | ~55.9 |

Editor: Populate weights using density values from Aluminum Association data or mill datasheets for your specific alloy and temper.

Note: If your sheet of 1/8 aluminum (or any other thickness) comes with a protective film or coating, add a small percentage to your total weight for accurate freight planning.

Coverage Planning for Projects

How many sheets of aluminum 4x8 do you need to cover a roof, wall, or enclosure? It’s not just about area—real-world projects require careful planning for fit and finish. Here’s a quick checklist:

- Include overlaps—especially for roofing or siding to ensure weatherproof seams.

- Allow for kerf loss—the material lost to saw or cutting blade width.

- Account for trim and edge cuts—for neat finishes and to fit around openings.

- Check directional grain—on brushed or patterned surfaces, align sheets for a consistent look.

Imagine you’re cladding a trailer or building a canopy. You’ll want to order a little extra to cover mistakes, offcuts, and the inevitable trim at edges and corners. For large projects, consulting with your supplier or installer can help you optimize your order and minimize waste.

Before you finalize freight or handling plans, always verify your calculated aluminum weight against supplier quotes. Small differences in alloy density, coatings, or packaging can add up quickly when you’re shipping a full pallet of 4x8 sheet of aluminum.

Next, we’ll dive into fabrication best practices—so your aluminum arrives not only at the right weight but ready for clean, efficient processing.

Fabrication Best Practices for Clean Results

Ever tried cutting or bending a big 4 x 8 aluminium sheet and ended up with warping, rough edges, or a less-than-perfect finish? You’re not alone. With the right techniques, though, you can turn aluminum sheet metal into crisp, professional parts—whether you’re building a trailer skin, a machine guard, or a set of painted aluminum sheets 4x8 for architectural cladding. Let’s break down each step so you can avoid costly mistakes and get results you’re proud of.

Cutting Choices Without Warping

Choosing the right cutting method is the first step to clean fabrication. Imagine you’re preparing aluminum sheeting for a trailer or a batch of colored aluminum sheets 4x8 for signage. Here’s how to approach the job:

- Manual Shears or Snips: Best for thin aluminum sheet metal (up to 0.040"). Keep cuts straight and short to minimize distortion.

- Jigsaws and Circular Saws: Use fine-toothed, non-ferrous blades. Always clamp the sheet securely and use a sacrificial backer to prevent burring and vibration.

- CNC Routers: Ideal for repetitive, complex cuts—especially for perforated aluminum sheet 4x8 or intricate signage. Use sharp bits and moderate feed rates to avoid heat buildup.

- Laser Cutting: Delivers clean, precise edges, but can cause heat distortion on thick sheets. Minimize heat input by using short bursts and cooling techniques.

- Waterjet Cutting: Best for thick or heat-sensitive sheets. No heat means no warping—perfect for diamond plate aluminum sheets 4x8 or heavy-duty panels.

Always support large panels during cutting to prevent sagging or chatter, and trial your settings on offcuts before starting the main job.

Clean Drilling and Countersinking

Drilling holes in aluminum sheet metal is straightforward—if you use the right approach:

- Sharp HSS or Carbide Bits: Dull tools cause burrs and rough holes. Keep bits sharp and clean.

- Lubrication: Use light oil or cutting fluid to reduce friction and heat, especially on thicker sheets.

- Peck Drilling: For thicker or stacked sheets, drill in short bursts to clear chips and prevent binding.

- Step Bits: For thin sheet, step bits reduce burrs and make cleaner holes.

- Countersinking: Use a slow speed and light touch to avoid chatter and tearing.

Imagine prepping holes for trailer rivets or mounting brackets—taking the extra time here pays off with parts that fit and finish well.

Bending with Predictable Results

Bending 4 x 8 aluminium sheets can seem tricky, especially if you want a crisp fold without cracks or distortion. Here’s how to do it right:

- Check Alloy and Temper: Softer alloys (like 5052) and tempers (O, H14) are easier to bend. Harder alloys or tempers need a larger bend radius to avoid cracking.

- Use a Proper Bend Radius: For example, 0.080" thick 5052 aluminum needs at least a 0.16" inside radius to prevent cracking.

- Account for Springback: Aluminum wants to return to its original shape after bending. Slightly over-bend to achieve the desired angle.

- Grain Direction: Bend perpendicular to the grain when possible to reduce the risk of cracking.

- Precision Tools: Use press brakes or dedicated bending tools for consistent results, especially for repeated bends or thick sheets.

Always test your setup on scrap pieces, especially when working with painted aluminum sheets 4x8 or coated material, as finishes can affect bend quality.

Welding Notes by Alloy Family

Welding aluminum sheet metal is a skill that takes practice—and the right equipment. Here’s what you need to know:

- 5xxx Series (5052, etc.): Highly weldable. MIG and TIG welding both work well. Clean the oxide layer before welding for best results.

- 6xxx Series (6061, etc.): Weldable, but pay close attention to heat input. Excessive heat can reduce strength in the weld zone. Use compatible filler rods and reference AWS D1.2 for code compliance.

- 3xxx Series (3003, etc.): Generally weldable, but check alloy compatibility for your filler metal.

- Friction Stir Welding: Consider for thick or high-performance applications—produces less distortion and a stronger joint.

For many shop jobs, mechanical fasteners (rivets, bolts) may be faster and more forgiving than welding—especially for thin or perforated aluminum sheet 4x8.

Edge Finishing for Safety and Coatings

Sharp or rough edges can be a safety hazard and interfere with painting or powder coating. Here’s how to finish them right:

- Deburr: Use files, flap wheels, or deburring tools to smooth cut and drilled edges.

- Break Sharp Corners: Soften all edges to prevent cuts and improve coating adhesion.

- Clean Thoroughly: Remove dust, oil, and debris before painting, anodizing, or bonding.

- Inspect for Dings: Especially on finished or diamond plate aluminum sheets 4x8, check for dents or scratches before final installation.

Shop Safety and Handling Tips

- Wear proper PPE: gloves, safety glasses, and hearing protection.

- Contain chips and dust—especially when cutting or drilling.

- Keep protective film or masking on as long as possible to prevent scratches.

- Clamp and support large panels to avoid movement and chatter.

- Trial all settings on offcuts before processing your main sheet.

Whether you’re fabricating aluminum sheet metal for trailer builds, architectural panels, or custom enclosures, these best practices will help you achieve professional, repeatable results every time. Up next, you’ll learn how to estimate costs and source your materials smartly—so your next order of colored aluminum sheets 4x8 or diamond plate aluminum sheets 4x8 arrives on time and on budget.

Pricing and Procurement Strategy That Works

What Drives Price Up or Down?

Ever found yourself wondering why 4x8 sheet aluminum prices seem to swing from one quote to another? The cost of 4x8 sheet of aluminum is shaped by a handful of key factors—some you can control, and some you can’t. Here’s what you need to know before you request your next quote:

- Alloy and Temper: Higher-grade alloys (like 6061-T6) and special tempers cost more due to their performance and production complexity. For example, a 4x8 sheet of 6061-T6 can run $150–$200, while a 3003 alloy of the same size might be $100–$150.

- Thickness: Thicker sheets mean more material, driving up the price. A 4x8 sheet of 1/4 inch aluminum price is typically on the higher end of the spectrum.

- Finish: Mill finish is standard and most affordable. Brushed, painted, or anodized finishes add cost—anodized sheets can reach $200–$300 for a 4x8 panel.

- Quantity: Buying in bulk usually lowers your per-sheet cost. Small orders may carry a premium.

- Cutting and Fabrication: Custom sizes, edge conditioning, or cut-to-size services add to the base price.

- Certifications: Requests for MTRs, special traceability, or compliance documentation can increase costs.

- Freight and Packaging: Shipping, palletizing, and protective packaging are often additional.

- Market Conditions: Global aluminum prices fluctuate with demand, supply chain issues, and geopolitical events. Always check recent trends if you’re planning a large purchase.

RFQ Essentials That Prevent Costly Surprises

Sounds complex? It doesn’t have to be. The best way to avoid confusion and get accurate 4x8 aluminum sheet price quotes is to submit a clear, detailed RFQ (Request for Quote). Here’s what to include:

Product: 4 × 8 aluminum sheet; Alloy-Temper: [e.g., 5052-H32]; Thickness: [decimal]; Finish: [mill/anodized/painted]; Standards: ASTM B209; Quantity: [units]; Tolerance: [thickness/flatness]; Certifications: MTR with heat number; Services: [cut-to-size, deburr]; Delivery: [date/incoterms]. Provide unit price, lead time, and freight.

Imagine you’re building a batch of enclosures and need a consistent look and fit. By listing every requirement up front, you’ll get quotes that reflect the true 4 x 8 aluminum sheet cost—and avoid last-minute adders.

- Palletizing and special packaging

- Protective film or masking

- Edge conditioning (deburred, rounded)

- Tight tolerances (thickness, flatness, squareness)

- Special certifications or traceability

Don’t forget to specify if you need a 4 x 8 aluminum sheet metal with custom fabrication or finishing—these details can add significant costs if not clarified early.

Negotiation and Quantity Breaks

When you’re sourcing for a large project, don’t leave money on the table. Ask suppliers to provide tiered pricing (for example, 1–10, 11–50, 51+ sheets) so you can see where the best value lies. Confirm whether cutting scrap or remnant policies affect your bottom line, especially if you’re ordering non-standard sizes.

Bulk orders almost always reduce the cost of 4x8 sheet of aluminum per unit, and some suppliers may offer additional discounts for full pallet or truckload quantities. If you’re working on a tight budget, consider adjusting your order size to hit a better price break.

Keep in mind, regional surcharges and freight rates can impact your total landed cost. If your supplier doesn’t provide up-to-date surcharge information, monitor trusted market bulletins or industry news for trends in raw aluminum pricing.

“A clear, detailed RFQ—listing alloy, temper, thickness, finish, quantity, and all services—gets you the most accurate 4x8 sheet aluminum prices and prevents costly surprises.”

Finally, before finalizing your design, always validate material availability. Stock constraints or supply chain delays can force last-minute redesigns, so confirm your chosen alloy, thickness, and finish are available in the quantities and lead times you need. This simple step can save you time, money, and frustration on your next aluminum sheet order.

Next up: Learn how to plan for shipping, handling, and storage to keep your aluminum sheets safe and project timelines on track.

Shipping, Handling, and Storage Without Surprises

Ever received a shipment of aluminum sheets only to find bent corners, scratches, or moisture stains? When you’re investing in materials—whether it’s for a custom build, a batch of diamond plate sheets 4x8 near me, or a simple restock—it’s critical to plan ahead for safe shipping, careful handling, and smart storage. Here’s how to keep your materials in top shape from the supplier’s dock to your fabrication shop.

Packing and Palletizing for Safe Transit

Sounds complex? It’s actually a matter of following a reliable checklist to prevent the most common shipping damage. Whether you’re sourcing from a specialty supplier or picking up aluminum sheets home depot style, these best practices apply:

- Corner protectors on all stacks to prevent dents and dings.

- Interleaving paper or plastic between sheets to minimize scratching.

- PE film applied to cosmetic faces for extra surface protection.

- Banding with edge guards to hold the stack tight without crushing edges.

- Moisture control—use desiccant packs or wrap to keep humidity at bay, especially for long hauls.

- Clear labeling for alloy, temper, thickness, and heat number so every sheet is traceable.

For shipping, stack sheets on a flat, sturdy pallet or in a weather-resistant crate. Avoid over-compressing the stack—tight is good, but too much pressure can cause bending or surface distortion. According to best practices, aluminum sheets should be tightly packed but not compressed, and always placed in a weather-resistant crate for transport (source).

Receiving Inspection and Handling

Imagine you’re unloading a shipment of aluminum sheet 4x8 near me—how do you prevent accidental damage? Here’s what to do:

- Use forklifts or vacuum lifts with spreader bars to lift large sheets—never drag them, as this can cause surface scratches or warping.

- Inspect every stack for flatness, edge damage, and the integrity of protective films before signing the delivery paperwork.

- If you’re working with heavier or thicker sheets, ensure you have enough people or the right equipment to handle the load safely. Vacuum lifters can allow a single operator to move sheets up to 1,100 lbs horizontally, making handling both safer and more efficient.

| Sheet Thickness Range | Recommended Handling Method | Minimum Team/Equipment |

|---|---|---|

| Up to 0.050" | Manual lift with gloves; two people for 4x8 | 2 people |

| 0.050"–0.125" | Forklift or vacuum lifter with spreader bar | 1 operator with equipment |

| Above 0.125" | Vacuum lifter or forklift only | 1 operator, supervisor recommended |

For larger orders or when sourcing aluminum sheets for sale in bulk, always confirm that your team and equipment match the weight and handling requirements before delivery day.

Storage That Preserves Surface Quality

Once your sheets are in the shop, storage becomes the next critical step. Even premium home depot aluminum sheet can lose its luster if stored incorrectly. Here’s how to keep your inventory in prime condition:

- Store sheets on flat racks with separators or spacers to prevent pressure points and bending.

- Keep sheets in a dry, well-ventilated area—moisture is the enemy of clean aluminum surfaces. Avoid stacking near exterior walls or in direct sunlight, which can cause fading or surface aging.

- Leave protective film on until just before fabrication to minimize the risk of scratches or contamination. Check with your supplier if there are any recommended time limits for film removal.

- Isolate aluminum sheets from chemicals or other reactive materials to prevent surface reactions.

- Perform regular inspections for any signs of oxidation, rust, or surface damage, especially if sheets are stored for more than a few weeks.

Proper storage and handling not only protect your investment but also ensure that your finished parts look professional and perform as intended—especially when you’re working with high-visibility applications or custom orders like diamond plate sheets 4x8 near me.

Remember, shipping costs are influenced by total weight, pallet dimensions, and destination—always verify with your carrier using the calculated weights from your planning stage. By following these steps, you’ll minimize the risk of damage and delay, keeping your project on schedule and your materials ready for action. Up next, we’ll explore when it makes sense to move from hand fabrication to CNC machining for your 4 x 8 aluminium sheets—so you’re ready for projects that demand the next level of precision.

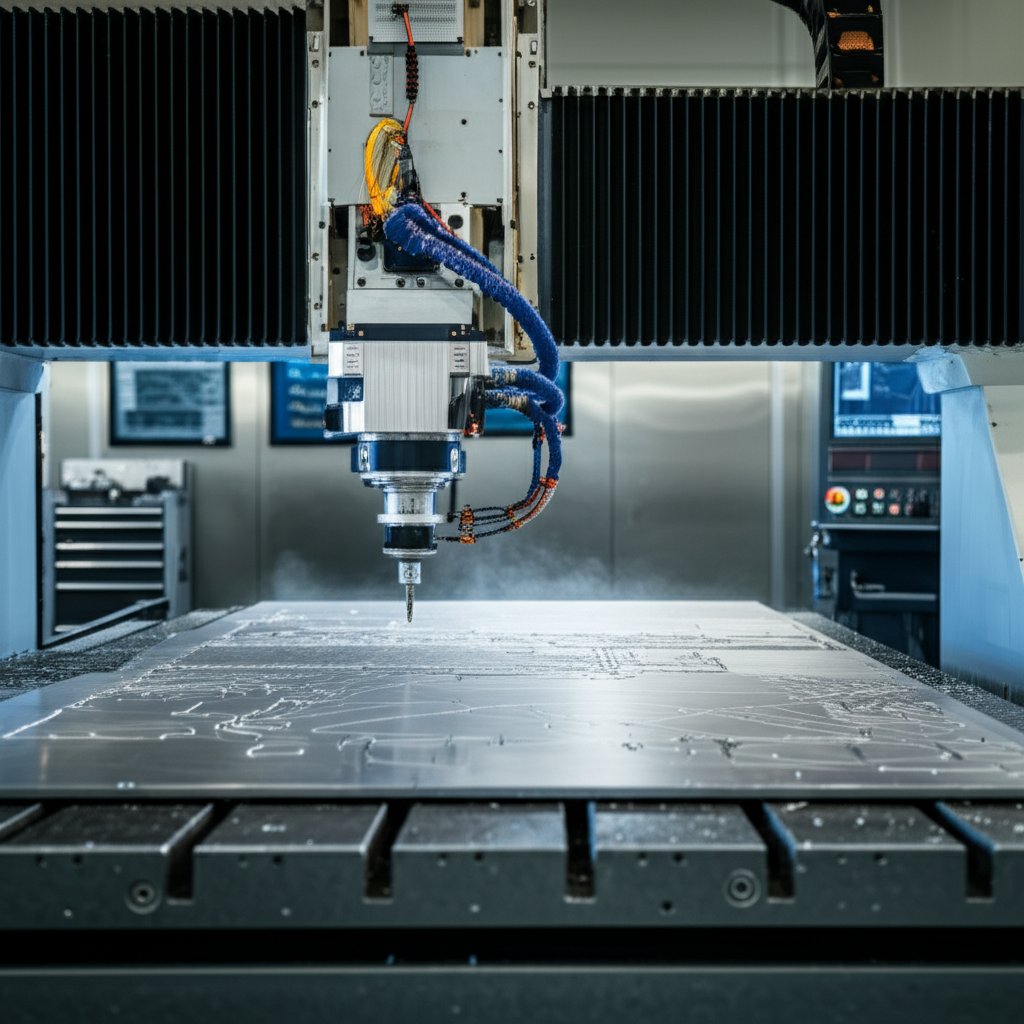

When to Leverage CNC Machining from Flat Sheet

Ever wondered when it’s time to move beyond hand tools and simple shop setups for your 4x8 aluminum sheet metal projects? Maybe you’re cutting dozens of identical parts, need perfectly aligned holes, or want flawless contours on a batch of aluminum panels. Let’s break down when—and why—CNC machining becomes the smart choice for transforming flat sheets into finished components.

When Tolerances Outgrow Manual Methods

Picture this: you’re fabricating a set of aluminum plates for an enclosure. At first, a drill press and shear seem fine. But as soon as you need bolt holes to line up precisely across multiple sheets, or you require pockets milled for weight reduction, manual methods start to fall short. CNC machining, with its computer-controlled accuracy, delivers repeatable results down to tight tolerances—often ±0.005mm with advanced setups. This is especially valuable for 5000 and 6000 series aluminum sheets, where consistent fit is critical for structural or mechanical assemblies.

- Critical bolt patterns with tight spacing

- Consistent countersinks or tapped holes

- Precise cutouts and radiused corners

- Matched features across dozens or hundreds of sheets of aluminum 4x8

When your parts must fit together perfectly every time—or when a small error means a costly rework—CNC is the clear winner.

Complex Geometries and Repeatability

Imagine you’re tasked with producing an intricate aluminum panel featuring internal pockets, decorative slots, or multi-level contours. Manual fabrication can’t match the speed or complexity of a 4- or 5-axis CNC machine. These systems excel at:

- Pocketing for weight reduction without sacrificing strength

- Complex cutouts and edge profiles for custom aluminum panels

- Repeatable, high-volume production runs with minimal scrap

- Surface finishing, such as engraving or chamfering, integrated into a single setup

For projects demanding both complexity and consistency—think aerospace brackets, robotics mounts, or architectural feature panels—CNC machining is not just faster, but often more economical in the long run.

From Sheet to Finished Components: Comparing Your Options

So, should you keep fabrication in-house, invest in new equipment, or outsource to a specialized provider? Here’s a practical comparison for typical 4x8 aluminum sheet metal projects:

| Provider/Method | Strengths | Limitations | Best Use Cases | Relative Cost |

|---|---|---|---|---|

| XTJ CNC Machining Services | Ultra-tight tolerances (±0.005mm), multi-axis (4 & 5-axis) capability, rapid lead times (3 days+), ISO 9001 & IATF 16949 certified, supports complex aluminum plates and panels | Requires finalized CAD files; best suited for medium to high complexity or production runs | Precision bolt patterns, pocketed panels, 3D contouring, rapid prototyping, and production | Premium for high precision; cost effective at scale or for complex jobs |

| Local Laser/Waterjet Shop | Fast profiling of 2D shapes, good for simple cutouts, quick turnaround for basic sheets of aluminum 4x8 | Limited to 2D; minimal machining (no pockets, threads, or deep features) | Flat panels, signage, basic brackets, quick prototypes | Moderate; economical for simple, flat parts |

| In-House Manual Fabrication | Maximum flexibility for one-offs or custom work; no lead times for setup | Variable precision, labor-intensive, slow for repeatable or complex work | Prototypes, repair parts, artistic or one-off aluminum plates | Low for simple jobs, high for volume or tight tolerances |

In summary, if your project involves tight tolerances, multi-axis features, or high repeatability, outsourcing to a specialist like XTJ CNC Machining Services is often the most efficient route. For straightforward 2D profiles, a local laser or waterjet shop may suffice, while in-house manual fabrication is best reserved for simple, low-volume, or artistic work.

For 4x8 aluminum panels that demand precision, consistency, and complex geometry, CNC machining transforms raw sheet into finished components with unmatched accuracy and repeatability.

As you plan your next batch of aluminum panels or plates, consider the complexity, volume, and tolerance requirements. Making the right call on fabrication methods upfront will save time, reduce waste, and ensure your finished parts meet every expectation. Next, we’ll walk through a step-by-step workflow that takes your concept from drawing to finished part—ensuring a smooth transition from specification to production.

Design to Fabrication Workflow and Final Recommendations

From Concept to Fabrication-Ready Drawing

Ever wondered how a simple idea becomes a finished 4 x 8 sheet metal part? It starts with a clear roadmap. Imagine you’re launching a new enclosure or a run of 4 x 8 checker plate panels. The process is less daunting when you break it down into focused steps:

- Define functional requirements and environment. Will your part see marine exposure, high loads, or need a decorative finish? This shapes every downstream decision.

- Select alloy-temper and finish referencing standards. Use ASTM B209 and Aluminum Association designations to avoid confusion. For example, 5052-H32 for marine panels or 6061-T6 for structural 8x4 sheet aluminium applications.

- Lock decimal thickness and tolerances. Instead of just saying “1/8 inch,” specify 0.125" ± tolerance, and confirm with your supplier.

- Plan fabrication steps. Factor in bend allowances, weld notes, and any special requirements for finishes or cutouts. For tight bends or complex features, check minimum bend radii and grain direction for your chosen alloy.

- Calculate weights for handling and freight. Use density values for your alloy-temper combination to estimate shipping and installation needs.

- Issue an RFQ with complete spec and certification asks. Include everything: alloy-temper, thickness, finish, standards, quantity, tolerances, MTR requirements, and services like deburring or custom packaging.

- Prototype, test, and refine. Before committing to a full run, build a prototype to validate fit, function, and manufacturability. For advanced features—like deep pockets or 3D contours on a 4 x 8 checker plate aluminum—partnering with a precision CNC shop can streamline this step.

- Release for production with packing and inspection criteria. Specify how you want your aluminum sheets 4x8 packed, labeled, and inspected before shipment to avoid surprises at delivery.

Specify decimal thickness, standards, and MTR requirements in every RFQ.

Supplier Alignment and Prototyping

Sounds complex? It’s all about collaboration. Work closely with your supplier or fabrication partner to clarify design intent, review drawings, and confirm every detail—especially when you’re sourcing custom 4 x 8 sheet metal or specialty items like 4 x 8 checker plate. For advanced requirements, consider involving a CNC machining specialist early in the design for manufacturability (DFM) phase. Services like XTJ CNC Machining Services can help optimize tolerances, workholding strategies for large panels, and toolpaths for intricate features, ensuring your 8x4 sheet aluminium is both manufacturable and cost-effective.

Quality Checks and Iteration

Once you have a prototype in hand, test it under real conditions. Is the fit correct? Do bends and welds hold up? Are finishes consistent? Use this feedback to refine your design, update drawings, and adjust specs as needed. Before full production, confirm all packing, labeling, and inspection criteria with your supplier—this prevents costly errors and ensures your aluminum sheet for sale arrives as expected.

Prioritizing clear communication and step-by-step validation—from first sketch to finished batch—will help you avoid costly redesigns and delays, whether you’re sourcing standard panels or custom 4 x 8 checker plate aluminum.

Ready to move from concept to completion? By following this workflow, you’ll streamline every stage—making it easier to answer questions like “where can I buy 4x8 sheets of aluminum?” and ensuring your aluminum sheets 4x8 meet every project goal, from prototype to final installation.

Frequently Asked Questions About 4 x 8 Aluminium Sheets

1. What is the price of an 8x4 aluminium sheet?

The price of an 8x4 aluminium sheet varies based on alloy, thickness, finish, and supplier. Factors like certification, cutting services, and market demand also affect the cost. For the most accurate pricing, provide precise specifications in your RFQ and request tiered quotes from suppliers.

2. How heavy is a 4x8 sheet of aluminum?

A 4x8 sheet of aluminum's weight depends on its thickness and alloy. For example, a 1/8 inch (0.125") thick sheet typically weighs around 56 lbs, but always confirm with your supplier’s datasheet for the specific alloy and temper, as density can vary.

3. What is the typical lifespan of a 4x8 aluminum sheet?

With proper handling and installation, a 4x8 aluminum sheet can last up to 50 years or more. Factors like environment, finish, and maintenance play key roles in maximizing lifespan, especially for exterior or marine applications.

4. What thicknesses are available for 4 x 8 aluminium sheets?

Standard 4 x 8 aluminium sheets are available in a range of thicknesses, typically from 0.2 mm up to 6 mm (0.25 in) for sheet, with thicker options classified as plate. Always specify decimal thickness and tolerance to ensure you receive the correct material.

5. When should I consider CNC machining for 4x8 aluminium sheets?

CNC machining is ideal when you need tight tolerances, repeatable features, or complex geometries that are difficult to achieve manually. For high-precision panels or parts, partnering with a CNC specialist ensures accuracy and efficiency.

-

Posted in

4x8 aluminum sheet, aluminum fabrication, aluminum panels, aluminum sheet metal, aluminum sheet price