Aluminium Composite Panels (ACP/ACM): 8 Essential Points

Understanding Aluminium Composite Panels

What aluminium composite panels are made of

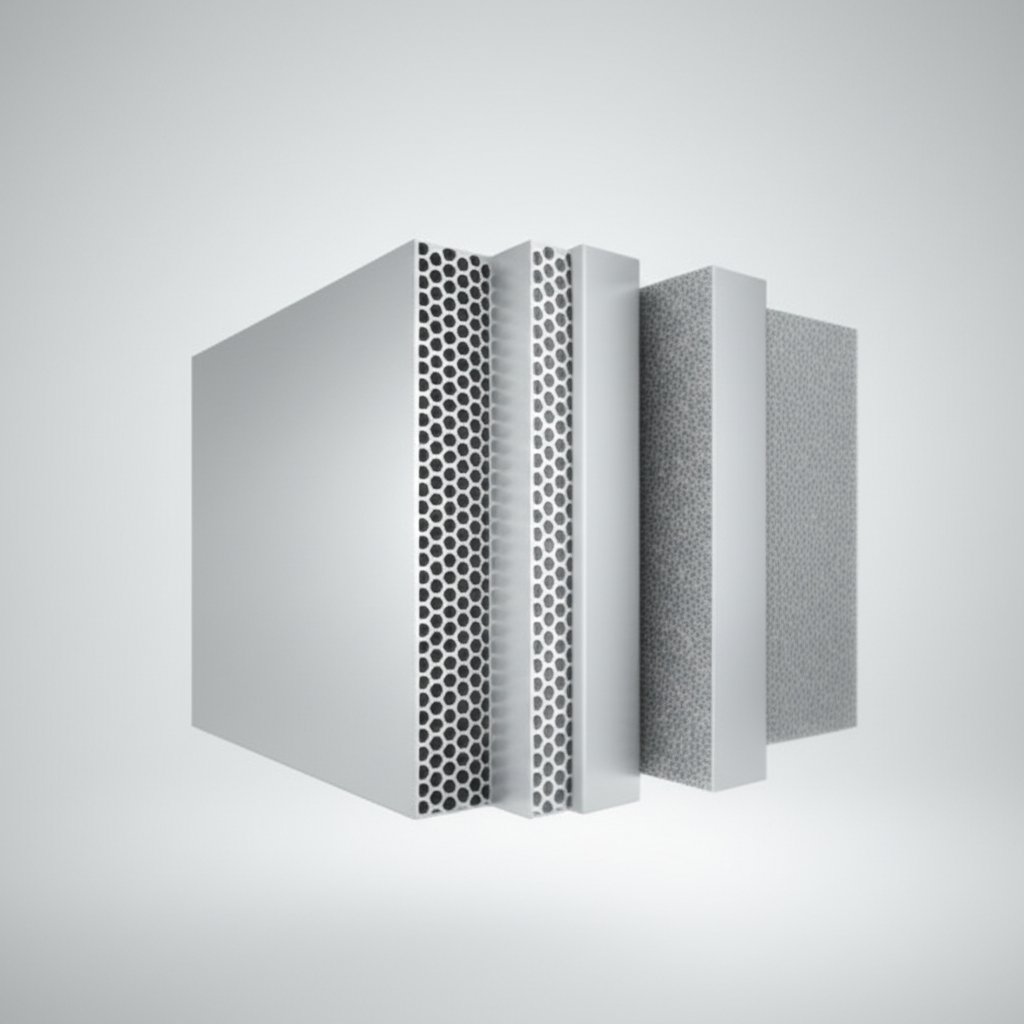

Ever wonder what makes aluminium composite panels such a popular choice in modern construction and signage? At their core, these panels—often called ACP or ACM panels—are engineered for versatility and performance. Picture a sandwich: two thin sheets of aluminum on the outside, bonded to a lightweight core made of mineral fillers and a thermoplastic binder. This unique structure delivers a material that's both strong and remarkably light, offering the best of both worlds for architects, builders, and designers.

Aluminium composite panels are two thin aluminum skins bonded to a lightweight core to deliver stiffness, flatness, and design flexibility at low weight.

ACP vs ACM Naming and Common Synonyms

If you’ve heard the terms "ACP," "ACM," or "composite aluminum panel" and wondered if they’re the same thing, you’re not alone. In industry practice, aluminium composite panel (ACP) and aluminum composite material (ACM) are used interchangeably. ACP typically refers to panels used for architectural cladding, while ACM is a broader term that also covers signage, canopies, and even vehicle skins. Other synonyms you might encounter include "bonded panels" or simply "composite panels." The table below helps clarify these terms and their typical uses:

| Term | Typical Uses |

|---|---|

| ACP (Aluminium Composite Panel) | Facade cladding, exterior/interior wall panels, architectural features |

| ACM (Aluminum Composite Material) | Signage, canopies, display panels, transportation |

| Bonded panels | General term for multi-layer panels in various industries |

| Composite aluminum panel | Synonym; used in both cladding and signage contexts |

Where aluminium composite panels are used

Imagine walking through a city center—you’ll notice sleek building facades, vibrant corporate signs, and even decorative interior partitions. Chances are, many of these surfaces are made from aluminium composite panels. Their main application areas include:

- Ventilated rainscreen facades (modern exterior cladding systems)

- Corporate signage and branding

- Interior wall features and ceilings

- Vehicle and trailer skins

- Decorative elements and room dividers

This adaptability is a big reason why the question "what is aluminum composite material" comes up so often—it's everywhere, serving both structural and decorative roles.

How ACP compares to solid aluminum sheets

When comparing an acp panel to a solid aluminum sheet, the difference is clear. ACPs are much lighter for the same thickness, yet still offer high resistance to impact and weather. Their composite structure also provides better insulation and allows for more creative shapes and finishes. Solid aluminum, while strong, is heavier and less flexible, making ACPs a smarter choice for many modern applications.

- Lightweight – Easier handling and installation

- Flatness – Smooth, modern appearance

- Formability – Can be curved or shaped for creative designs

- Wide range of finishes – From solid colors to metallics and wood effects

- Durability – Withstands weather, UV, and corrosion

- Thermal and acoustic insulation – Improves energy efficiency and comfort

In summary, aluminium composite panels are a modern solution that combines design freedom, technical performance, and sustainability. Whether you’re specifying a new facade, updating signage, or seeking energy-efficient materials, understanding the structure and terminology of ACP and ACM panels will help you make informed choices for your next project.

Fire Performance and Core Selection Guidance for Metal Composite Panels

Core Types and Fire Behavior Differences

When it comes to specifying aluminium composite panels, fire performance is a critical consideration—especially for exterior cladding and high-occupancy spaces. But what actually makes one aluminum composite metal panel safer than another? The answer lies in the panel's core material. Imagine three main types:

- PE (Polyethylene) Core: Lightweight and flexible, but highly combustible. Best for interior use, signage, and areas with minimal fire risk.

- FR (Fire-Retardant) Core: Modified polyethylene with halogen-free flame retardants. Offers improved fire resistance (often meeting B1 or similar classifications) and is suitable for many commercial interiors and low-rise façades.

- Mineral/A2 Core: Predominantly inorganic minerals—such as calcium or magnesium hydroxide—delivering non-combustible performance (A2 class) for high-rise curtain walls, hospitals, and critical infrastructure.

Each core type brings a different balance of flexibility, cost, and safety. Choosing the right composite metal panel core is essential for both code compliance and occupant protection.

| Core Type | Typical Uses | Common Test Standards | Cladding Suitability Notes | Documentation Needed |

|---|---|---|---|---|

| PE (Polyethylene) | Interiors, signage, low-risk areas | Basic combustibility tests | Not suitable for high-rise or critical fire zones | Material data sheet |

| FR (Fire-Retardant PE) | Malls, offices, schools, mid-rise facades | EN 13501-1 (B1), ASTM E84 | Improved fire resistance; check local code | Test/classification report |

| Mineral/A2 (Inorganic) | High-rise, hospitals, airports, public venues | EN 13501-1 (A2), NFPA 285, BS 8414 | Non-combustible, required for critical facades | Assembly test, project-specific approval |

How to Read Test Reports and Classifications

Sounds complex? Here’s how to make sense of the fire performance landscape for metal composite panels:

- Material Tests: Evaluate the combustibility of the panel core (e.g., EN 13501-1, ASTM E84). These are useful for comparing basic products.

- Assembly Tests: Assess the fire propagation of the entire wall system (e.g., NFPA 285, BS 8414). Passing these is often required for exterior aluminium composite cladding on multi-story buildings.

- Certification: Always request up-to-date third-party reports, including summaries of test results and system details (like insulation, air gaps, and fasteners).

Remember, a panel's fire rating is only meaningful when installed as part of a tested wall assembly. Substituting any component—core, insulation, or even fasteners—can invalidate compliance.

Façade Compliance Pathways

When planning for aluminum cladding, you’ll need to navigate local building codes and approval processes. Here’s a quick roadmap:

- Interior linings and signage: Often allow PE or FR cores, but always confirm with local codes.

- Low-rise exteriors: FR cores may be acceptable, provided assembly tests are met.

- High-rise and critical-use buildings: Mineral/A2 cores are typically required, with full wall assembly testing and documentation.

- Documentation checklist: Third-party test reports, classification summaries, engineering judgements (if permitted), and system-level details (insulation, air gap, fasteners).

Façade compliance depends on the tested wall assembly, not just the panel.

Always consult your local authority having jurisdiction (AHJ) to verify requirements for your specific project. Siting, occupancy type, and project height all influence which metal composite panels are permitted for use. By understanding these distinctions and securing the right documentation, you can confidently specify safe and compliant aluminium cladding panels for any application.

Next, we’ll explore practical fabrication and installation techniques to ensure your chosen panel system delivers both safety and performance in the field.

Step-by-Step Fabrication and Installation Essentials for ACM Panels

Essential Tools and Safe Cutting Practices

When you’re ready to work with aluminium composite panels, the right tools and techniques make all the difference. Sounds complex? It doesn’t have to be. Whether you’re fabricating an acm sign or cladding a building, precision starts with preparation. Here’s a quick rundown of the tools you’ll need for smooth results:

- Protective film management tools (to keep the surface scratch-free until final installation)

- Scoring knives for light cuts and marking

- Carbide-tipped saws or fine-toothed circular saws (80–100 teeth recommended for clean edges)

- Straight-flute or single-flute router bits for grooving

- Step drills and HSS or carbide-tipped drill bits for accurate holes

- Deburring tools or files to smooth out rough cuts

- Clamps (bar clamps or C-clamps) for secure holding during cutting and drilling

- Personal protective equipment (PPE): gloves, safety glasses, and ear protection

For safe cutting, always leave the protective film on the aluminum composite sheet during fabrication. Support the panel to prevent vibration, set your blade or drill to the correct depth, and use slow, steady pressure—let the tool do the work. After cutting or drilling, remove burrs to ensure a neat finish.

Routing, Bending, and Return Edge Basics

Need to create crisp folds or complex shapes for your acp panels? Routing and bending are key. Use a router with a carbide-tipped bit and a straight edge guide for consistent grooves. For a clean fold, leave a thin layer of core material—test bends on offcuts to prevent cracking the aluminum skins. When forming returns, a press brake or folding jig will help achieve sharp, straight edges.

For curved elements, a three-roll bender or sheet metal bending tool is ideal. Always clamp panels firmly and make bends gradually to avoid surface damage. Clean away chips before folding to prevent imprinting or scratches.

Fastening, Joint Design, and Sealants

How you connect acm sheets to the subframe or each other affects both appearance and long-term durability. There are two main approaches: blind-fix cassette systems (where fasteners are hidden) and exposed face-fastened panels. For cassette systems, use slotted holes to accommodate thermal movement and prevent warping. If you’re using rivets or bolts, stainless steel or aluminum are preferred—and always isolate dissimilar metals to avoid corrosion.

Joint design matters, too. Sealed joints require compatible, neutral-cure sealants and primers. For open-joint rainscreen assemblies, ensure an air gap behind the panels for ventilation and install a weather barrier to keep moisture out. Here’s a quick comparison:

| Joint Type | Drainage/Ventilation | Sealant/Barrier | Typical Use |

|---|---|---|---|

| Rainscreen (Open Joint) | Rear-ventilated cavity, allows airflow | Weather barrier behind panels | Exterior facades, curtain walls |

| Sealed Joint | Minimal ventilation | Neutral-cure sealant at panel joints | Interior partitions, signage, some exterior trims |

| Route-and-Return Cassette | Can be ventilated or sealed | Caulking at perimeter if needed | High-end facades, modular panels |

| Face-Fastened Panel | Typically sealed | Sealant or gasket at fastener | Utility cladding, acm sign blanks |

Sequential Fabrication and Installation Workflow

Imagine you’re on-site, ready to start installing your composite aluminum panel system. Here’s a step-by-step workflow to keep things efficient and error-free:

- Receiving and inspection: Check all acm panel shipments for damage and verify quantities.

- Layout and marking: Use straight edges and accurate measurements to mark cuts and hole positions.

- Cutting and routing: Cut panels to size, route grooves for folding, and drill holes as needed.

- Dry fit: Assemble panels without fasteners to confirm fit and alignment.

- Edge finishing: Deburr, sand, and polish cut edges for a smooth look.

- Cleaning: Remove dust and chips before final assembly.

- Protection until install: Leave protective film on until the very end to prevent scratches.

During installation, ensure the subframe is perfectly aligned and shimmed for flatness. Tighten fasteners to the recommended torque if provided, and document as-built conditions for future reference.

By following these best practices, you’ll minimize on-site rework and ensure your aluminum paneling delivers both performance and aesthetics. Up next, we’ll discuss how panel assemblies handle sound and movement, so you can fine-tune your project for comfort and durability.

Acoustic Performance and Thermal Movement in Composite Wall Panels

Acoustic Principles for Lightweight Panels

When you step into a quiet office or a bustling lobby finished with aluminum composite wall panels, have you ever wondered how sound is managed in these spaces? Unlike heavy masonry, aluminium panels alone are lightweight and offer limited sound blocking. That means the acoustic comfort of a room is determined by the entire wall build-up, not just the outer skin. So, how do you get the best results?

| Wall Layer | Acoustic Strategy | Typical Effect |

|---|---|---|

| ACP/ACM Panel | Lightweight, rigid surface | Low sound attenuation by itself |

| Ventilated Cavity | Decoupling, rear air gap | Reduces direct transmission, helps dampen sound |

| Continuous Insulation (e.g., mineral wool) | Added mass, absorption | Improves overall sound blocking (higher STC/OITC) |

| Sheathing/Substrate | Structural support, seals air leaks | Controls flanking paths, stabilizes assembly |

To maximize acoustic performance, combine aluminium panels with mineral wool or rigid insulation behind the panel. This approach not only blocks more noise but also improves thermal efficiency—a win-win for both comfort and energy savings. For interiors, such as branding walls or ceilings, placing absorptive material in the cavity behind panels helps reduce echo and reverberation, making public spaces more pleasant.

Acoustic performance is assembly-driven; the panel is one layer within a larger system.

Designing Wall Build-Ups for Sound Control

Sounds complex? It doesn’t have to be. Imagine you’re designing composite wall panels for a hotel or office. Instead of relying on the panel alone, think about layering:

- Use acm wall panels as the outer finish for aesthetics and weather resistance.

- Add a ventilated cavity to decouple the panel from the structure, which dampens direct sound transmission.

- Install mineral wool or dense insulation in the cavity to absorb airborne noise.

- Seal perimeters and penetrations to prevent flanking noise paths.

This layered approach is especially effective for exterior composite panels on busy streets or in high-traffic zones. For interior partitions, you’ll notice a big difference in speech privacy and overall quietness by combining panels with acoustic insulation and careful detailing.

Thermal Movement and Oil-Canning Prevention

Ever noticed subtle waves or ripples on a metal facade? That’s called oil-canning, and it’s a visual concern—especially with aluminum wall panel systems. Aluminum naturally expands and contracts with temperature changes, so detailing for movement is critical to keep panels flat and looking sharp.

- Use slotted holes for fasteners to allow for thermal expansion and contraction.

- Opt for oversized fastener holes with washers to reduce stress on the panel.

- Include expansion joints at logical breaks, such as floor lines or building corners.

- Check that subframing is plumb and flat before panel installation—uneven substrates can cause waviness.

- Select appropriate panel thickness and consider adding stiffening ribs or using textured/matte finishes to help mask minor ripples (source).

By following these movement detailing strategies, you can ensure your aluminium panels remain visually appealing for years to come. Early mockups are a smart way to confirm both acoustic and movement performance before committing to full installation.

With the right wall assembly and attention to movement, aluminium composite panels deliver both comfort and durability. Next, let’s explore how lifecycle cost and procurement strategies can help you achieve lasting value in your projects.

Lifecycle Cost and Procurement Playbook for Aluminium Composite Panels

Total Cost of Ownership Factors

When you’re comparing options for your next project, have you ever wondered why the lowest aluminum composite panel 4x8 price doesn’t always mean the best value? The real cost of aluminium composite panels goes far beyond the initial quote. Imagine you’re tasked with choosing between several aluminum composite panel suppliers—how do you know which will deliver true lifecycle value?

| Lifecycle Driver | Impact on Total Cost | Considerations |

|---|---|---|

| Finish Chemistry & Warranty | High | Longer warranties and premium coil coatings (like PVDF) offer better color retention and lower repaint frequency. Polyester finishes may cost less upfront but often fade faster. |

| Panel Core Type & Code Pathway | High | FR or mineral-filled cores may cost more but are often required for compliance in critical applications, reducing retrofit risk. |

| Subframing Complexity | Moderate | Curved, routed, or custom features increase installation time and labor costs—factor these into your bid scope. |

| Cleaning & Maintenance | Moderate | Panels with smooth, UV-resistant finishes require less frequent cleaning and resist graffiti or staining better. |

| Access Costs | Low to Moderate | High facades or complex geometries may require special lifts or scaffolding for both installation and future maintenance. |

| Replacement Logistics | Variable | Systems that allow single-panel replacement minimize disruption and cost if damage occurs. |

Finish Durability and Maintenance Planning

Imagine your building’s facade five or ten years from now—will it still look fresh, or will it need costly touch-ups? Finish selection is a key driver of long-term value. Most aluminum composite panel manufacturers offer coil-coated systems like PVDF (polyvinylidene fluoride) and polyester. PVDF finishes are recognized for superior gloss and color retention, making them the go-to for high-visibility or high-UV locations. Polyester coatings, while more budget-friendly, may require earlier repainting or replacement.

Maintenance is another area where you can save over time. Aluminium composite panels are inherently low-maintenance—routine cleaning is usually enough to keep them looking sharp. Their resistance to corrosion, weather, and UV means you won’t be scheduling frequent repairs or replacements. For graffiti-prone areas, opt for finishes that allow easy cleaning without damaging the surface.

Procurement Checklists and Submittals

Sounds overwhelming? It doesn’t have to be. Whether you’re working with established aluminium composite panel suppliers or new acm panel suppliers, following a structured procurement process helps you avoid surprises and ensures you get what you specified. Here’s a practical checklist to guide your procurement and submittal process:

- Verified test reports for panel fire performance and weather resistance

- Finish datasheets and warranty documentation

- Color consistency plan (sample panels from the same production batch)

- Accessory compatibility confirmation (sealants, tapes, fasteners)

- Mockup requirements (for visual and performance validation)

- Installation qualifications (certified crews, documented experience)

- Closeout O&M (Operation & Maintenance) manuals for future reference

When evaluating proposals, consider not just the aluminum composite panel 4x8 price but also the supplier’s track record, documentation transparency, and service responsiveness. A reputable aluminium composite supplier will provide thorough submittals and stand behind their product with clear warranty terms.

The lowest bid rarely reflects total lifecycle cost—documentation, finish durability, and installation quality drive long-term value.

By looking beyond the sticker price and focusing on lifecycle performance, you’ll select aluminium composite board systems that deliver lasting aesthetics, safety, and value. As you finalize your procurement, remember to align your documentation with project requirements—this will set you up for smooth regulatory approvals, which we’ll cover in the next section.

Navigating Compliance for ACM Cladding and Beyond

Facade Cladding Compliance Essentials

When specifying aluminium wall cladding or any aluminum composite panel system, the regulatory landscape can feel overwhelming. Imagine you’re tasked with a new facade—what steps ensure your design meets building codes and passes inspection? It all starts with understanding how regulations apply to each use case, from high-rise exteriors to interior partitions and signage.

- Determine occupancy and building height: Is your project a high-rise office, a mid-rise school, or a storefront? Occupancy and height drive which codes and test standards apply.

- Identify codes and standards: In the U.S., the International Building Code (IBC) and NFPA standards govern most projects. Section 1407 of the IBC specifically addresses metal composite material wall panels and their use in exterior walls (reference). Local amendments may add further requirements.

- Select core type and assembly: For exterior walls, fire-retardant or mineral-filled cores are often mandatory—especially on buildings above two stories or in critical use categories.

- Gather test reports: Always collect third-party fire, weather, and structural test data for the entire wall assembly, not just the panel.

- Prepare detailed drawings: Include panel layout, attachment details, insulation, vapor barriers, and cavity barriers where required.

- Submit for approval: Provide all documentation to the authority having jurisdiction (AHJ), including stamped drawings and engineering calculations as needed.

- Field inspections and special tests: Be ready for on-site reviews and, in some cases, additional testing before occupancy is granted.

In many jurisdictions, wall performance is judged at the assembly level, not at the material level.

| Application | Key Compliance Factors | Typical Standards |

|---|---|---|

| Exterior Walls (Façades) | Assembly fire testing, WRB continuity, cavity barriers, compatible insulation | NFPA 285, ASTM E84, IBC 1407, AAMA 508 |

| Interior Partitions/Linings | Surface burning (flame/smoke), finish class, smoke development, sprinkler status | ASTM E84, local fire code, IBC Ch. 8/10 |

| Signage & Freestanding Elements | Sign code, electrical code (if illuminated), material allowances for smaller faces | Local sign/electrical code, UL listings |

Signage and Interior Use Considerations

Not every aluminum composite panel ends up on a facade. For signage and interior applications, the rules shift. Have you ever wondered, what is acm in construction when used for branding or displays? In these cases, codes may be less stringent—especially for small, non-loadbearing signs or temporary interior features. However, illuminated signs must comply with electrical codes, and interior panels still need to meet surface burning and smoke criteria, particularly in assembly spaces or unsprinklered buildings.

- Signage: Smaller signs or freestanding pylons may allow more flexibility in core type, but always check local sign ordinances and electrical requirements.

- Interiors: Confirm whether your project is sprinklered—this can affect the finish class and smoke development limits for aluminium composite panel cladding inside the building.

- Partitions vs. finishes: Wall partitions may be subject to stricter fire standards than decorative wall panels or ceiling clouds.

Documentation for AHJs and Plan Reviewers

Imagine you’re preparing your submission package. What will help your acm cladding approval go smoothly? Early and thorough documentation is key. Here’s a checklist to keep you on track:

- Stamped architectural and engineering drawings (showing all aluminum wall panels exterior details)

- Full assembly fire and weather test reports (NFPA 285, ASTM E84, AAMA 508)

- Manufacturer’s installation guidelines and maintenance instructions

- Installer qualifications and experience records

- Mockup and inspection plans, if required by the project or AHJ

It’s smart to schedule early meetings with code officials and plan reviewers. This helps clarify expectations, address unique design features, and streamline the approval process. Remember, each jurisdiction may interpret codes differently, so proactive communication saves time and reduces rework.

By understanding the regulatory landscape for aluminium composite panels—from exterior wall assemblies to signage and interior finishes—you’ll be equipped to navigate approvals with confidence. Up next, we’ll examine how to build robust specifications and submittal packages that align with these requirements and set your project up for success.

Specification Templates and Submittal Checklists for ACM Paneling

Outline Specification Structure

When it comes to specifying aluminium composite material panels, clarity and structure are your best friends. Ever opened a spec document and felt lost in the details? A well-organized specification not only smooths coordination between teams but also helps avoid costly miscommunication. Here’s a practical outline for your next aluminum composite paneling project:

- Summary – Briefly describe the scope and intent of the composite paneling work.

- References – List relevant standards (e.g., ASTM B209 for aluminum sheet, AAMA 2605 for finishes, ASTM E84 for fire performance).

- Submittals – Define all required documentation (see checklist below).

- Quality Assurance – State installer and manufacturer qualification requirements.

- Delivery, Storage, and Handling – Outline protocols to prevent damage (store panels vertically, covered, and off the ground).

- Materials – Specify acceptable panel types, thicknesses, core materials, and finishes (e.g., PVDF, polyester, anodized).

- Accessories – Include trims, flashings, fasteners, gaskets, and subframing details.

- Fabrication – Reference tolerances, edge treatments, and factory-applied protective films.

- Installation – Require alignment, plumbness, and movement accommodation (expansion joints, slotted holes).

- Field Quality Control – Call for mockups, periodic inspections, and on-site testing as needed.

- Cleaning and Protection – Instruct on post-installation cleaning and protection from construction damage.

Performance and Submittal Language

Sounds complex? It doesn’t have to be. Imagine you’re reviewing aluminum composite panel details for a new facade. What should you require from your suppliers and installers?

- Product Data: Manufacturer’s technical literature for aluminium composite material panels

- Samples: Finish cards or physical panel samples for color and texture approval

- Test Reports: Current fire, air, water, and structural test results (material and assembly level)

- Shop Drawings: Panel layout, attachment, and acm panel details showing all trims and accessories

- Mockup Plan: Requirements for on-site or off-site mockup, including visual and performance criteria

- Installer Qualifications: Documentation of prior experience with acm paneling systems

- Operation & Maintenance (O&M) Manuals: Cleaning, inspection, and repair instructions

This checklist streamlines submittals and helps plan reviewers focus on what matters most. For example, requiring shop drawings that detail aluminum panel details ensures that all transitions, corners, and penetrations are coordinated before fabrication begins (reference).

Provide complete wall assemblies that meet applicable fire and weather-resistive performance requirements as demonstrated by accredited third-party testing.

Warranty and Quality Assurance Clauses

Imagine a project five years down the road—will your composite paneling still perform and look as intended? That’s where robust warranty and quality assurance language comes in. Here are some essentials to include:

- Finish Warranty: Minimum 20 years against fading, chalking, peeling, or delamination for coil-coated finishes (PVDF or equivalent).

- Panel Bond Warranty: Minimum 10 years against separation of skins and core.

- Quality Assurance: Require manufacturers with a proven track record (often 5–10 years in the industry) and installers with documented experience in ACM paneling systems.

- Substitutions: Define documentation standards for alternate products—require equivalent test data, samples, and review time prior to approval.

- Field Quality Control: Call for mockups, on-site adhesion checks, and inspection hold points to catch issues early.

By including these requirements, you’ll help ensure the long-term durability and appearance of your aluminum plate panels. Remember, warranty effectiveness often depends on following O&M guidelines—document maintenance responsibilities clearly in your specs.

With a solid specification and submittal process, your aluminium composite panels project will move forward smoothly and meet both performance and regulatory expectations. Next, let’s explore how leveraging precision fabrication partners can further streamline your project and deliver superior results for complex geometries and tight tolerances.

Precision Fabrication Partners and Next Steps for ACM Manufacturing

When to Outsource Precision Routing and Parts

Ever found yourself facing a project with complex curves, ultra-tight tolerances, or a fast turnaround? In the world of aluminium composite panels, these challenges are more common than you might think. While many fabricators and installers handle basic panel sizing or straight cuts in-house, certain scenarios call for professional precision machining partners. Outsourcing can be the key to unlocking higher quality, efficiency, and design freedom—especially when you need to keep up with demanding schedules or intricate designs.

- XTJ Precision CNC machining services – Ideal for fabricating subframes, custom brackets, routing templates, and intricate trims for ACP/ACM systems. Look for providers with ISO 9001 & IATF 16949 certifications, proven multi-axis capabilities, and the ability to deliver ultra-tight tolerances for both prototypes and production runs.

- Tight-tolerance cassettes or panels requiring complex edge folding

- Custom brackets, standoffs, or mounting hardware not available off-the-shelf

- Curved or 3D features that demand roller bending, stamping, or multi-axis machining

- Prototype mockups for design validation before full-scale production

- Rapid design iterations where speed and repeatability are critical for project delivery

When evaluating partners for acm manufacturing, compare not just the price, but also certifications, lead times, and their track record with similar architectural aluminum panels. This ensures your project benefits from both quality and reliability.

Optimizing Complex Features with Multi-Axis Machining

Imagine you’re tasked with a facade that calls for organic curves, intricate perforations, or deep relief patterns. Standard fabrication tools can only take you so far. Multi-axis CNC machining—using 4 or 5-axis equipment—enables you to achieve shapes and details that would be nearly impossible by hand or with basic machinery. This is especially valuable for high-end projects featuring alucobond acm panels, custom signage, or decorative elements with unique geometry.

According to industry best practices, advanced machining supports:

- Consistent, repeatable accuracy across large batches of panels

- Clean, burr-free edges for visible surfaces and tight-fitting joints

- Complex cutouts, perforations, or reliefs for ventilation, sun-shading, or branding

- Reduced material waste through optimized nesting and cutting paths

- Integration of detailed CAD/CAM data, ensuring the final product matches the designer’s vision

By leveraging professional fabrication partners with advanced technology, you not only streamline the process but also minimize the risk of costly mistakes or rework. This is particularly important for acm panel manufacturers supplying large or technically demanding projects.

Professional machining partners bring both quality and schedule certainty to high-complexity aluminium composite panel projects.

Action Plan and Next Steps

Ready to take your aluminum composite panel project from concept to flawless installation? Here’s a practical action plan to help you stay ahead:

- Finalize performance requirements: Define structural, fire, and aesthetic goals for your panels.

- Confirm code pathway: Ensure your panel assembly meets all relevant codes and standards for your application.

- Select core and finish: Choose the right combination for durability, appearance, and compliance.

- Produce prototype mockups: Validate design intent and fabrication tolerances before mass production.

- Validate fabrication tolerances: Specify critical dimensions and allowable deviations for all parts—especially for complex or curved features.

- Schedule maintenance planning: Establish cleaning and inspection routines for long-term performance.

- Engage precision partners as complexity increases: For multi-axis machining, intricate details, or tight deadlines, collaborate with experienced precision fabrication shops to keep your project on track.

Wondering where to start your search for acm panels near me or a reliable acm panel manufacturer? Look for partners who combine technical expertise, responsive support, and a proven track record with aluminum composite panel systems. By following this action plan and leveraging the right resources, you’ll be well-equipped to deliver architectural aluminum panels that stand out for both precision and performance.

Frequently Asked Questions About Aluminium Composite Panels

1. What is an aluminium composite panel?

An aluminium composite panel is a layered material featuring two thin aluminum sheets bonded to a lightweight core, commonly used in building facades, signage, and interior features for its combination of strength, lightness, and design flexibility.

2. What are the disadvantages of aluminium composite panels?

While aluminium composite panels offer many benefits, they can be vulnerable to damage from sharp impacts and may require full panel replacement if compromised. Additionally, certain core types may not meet fire safety codes for high-rise or critical buildings, so proper selection and compliance checks are essential.

3. Are ACM panels expensive?

The cost of ACM panels varies based on core type, finish, and project requirements. While initial prices can range widely, total value depends on factors like fire performance, finish durability, and ease of maintenance. Investing in higher-quality panels often reduces long-term costs by minimizing repairs and replacements.

4. What is the cost of aluminum composite panel per square foot?

Aluminum composite panel pricing per square foot depends on core type, finish, and installation complexity. While there are budget options, panels with advanced fire-resistant cores or premium finishes may cost more upfront but provide better lifecycle value and code compliance.

5. Where are aluminium composite panels most commonly used?

Aluminium composite panels are widely used in ventilated building facades, corporate signage, interior branding walls, ceilings, and even vehicle or trailer skins due to their adaptability and attractive appearance.

-

Posted in

acm panels, aluminium composite panels, architectural cladding, fire safety, panel installation