From Code to Creation: 5-Axis CNC for Artistic Projects

TL;DR

A 5-axis CNC router is a powerful machine equipped with five axes of motion, providing exceptional maneuverability for creating complex shapes. For artists, this technology is revolutionary; it translates intricate digital designs into physical reality with unparalleled precision. This capability empowers sculptors to produce highly detailed 3D geometries and fluid forms in materials like wood, stone, and foam that would be incredibly difficult or impossible to achieve by hand.

The Artistic Revolution: What is 5-Axis CNC and Why Does it Matter for Sculpture?

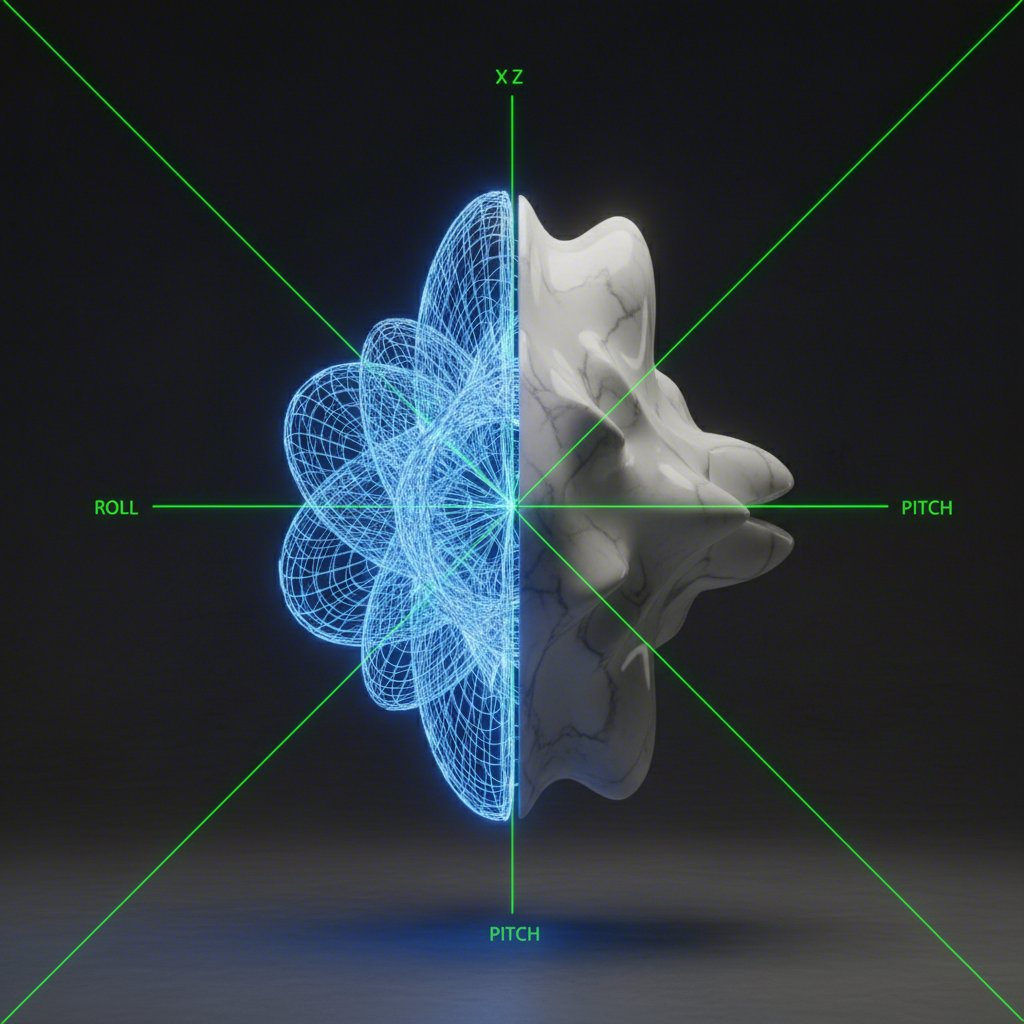

At its core, 5-axis CNC (Computer Numerical Control) technology represents a significant leap forward from traditional machining methods. Unlike a standard 3-axis machine that moves a tool along the X, Y, and Z linear axes (left-right, forward-back, up-down), a 5-axis machine adds two rotational axes. This allows the cutting tool to approach the workpiece from a much wider range of angles, often by tilting the tool head or rotating the worktable itself. This multidirectional capability is the key to its power, enabling the machine to carve deep undercuts and complex curves in a single setup, drastically reducing the need to manually re-fixture the material.

For sculptors and artists, this technical advantage translates directly into creative freedom. The primary benefit is the ability to transform a digital model—often created in software like ZBrush or Rhino—into a tangible object with incredible fidelity. Where traditional methods might require compromises due to the physical limitations of tools, 5-axis machining removes many of those barriers. As detailed in a case study by MecSoft Corporation, the process involves sophisticated CAM software that generates complex toolpaths, distinguishing between indexed (3+2) machining, where the tool is locked into a tilted position, and continuous 5-axis machining, where all five axes move simultaneously for truly fluid carving. This precision empowers artists to realize intricate visions that were once confined to the digital realm.

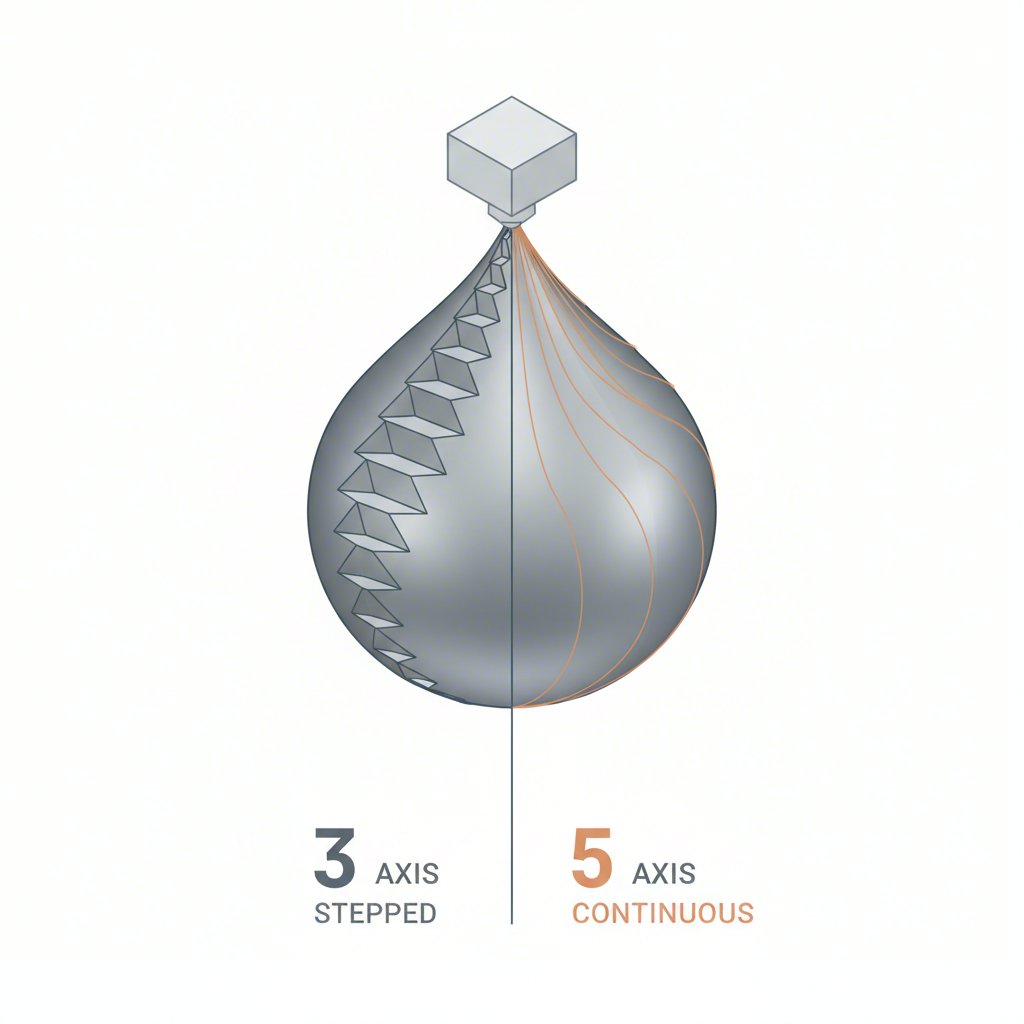

The difference between 3-axis and 5-axis machining becomes most apparent when creating organic, non-geometric forms. A 3-axis machine, limited to vertical tool movements, often leaves behind a stepped or terraced finish on curved surfaces, requiring extensive manual sanding and finishing. A 5-axis machine, however, can keep its tool perpendicular to the surface at all times, resulting in a much smoother finish and finer detail straight off the machine. This not only saves significant time but also preserves the subtle nuances of the artist's original design.

3-Axis vs. 5-Axis CNC for Sculptural Projects

| Feature | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Complexity | Best for relatively flat objects, engravings, and simple geometric shapes. | Excels at complex 3D forms, organic curves, and deep undercuts. |

| Tool Access | Limited to approaching the workpiece from directly above. | Can approach the workpiece from multiple angles in a single setup. |

| Setup Time | Often requires multiple setups and re-fixturing for complex parts. | Reduces or eliminates the need for multiple setups, saving time. |

| Surface Finish | Can produce a rough, terraced finish on curved surfaces. | Achieves a superior, smoother surface finish that requires less manual work. |

| Project Types | Relief carvings, signage, basic furniture parts. | Detailed busts, life-sized sculptures, intricate architectural models. |

From Digital Vision to Physical Form: Inspiring 5-Axis Sculptural Projects

The true potential of 5-axis technology is best understood through the incredible projects it enables. Artists and fabrication studios are leveraging these machines to push the boundaries of what's possible in various materials, turning ambitious digital concepts into breathtaking physical sculptures. From monumental stone carvings to intricate wooden art pieces, 5-axis CNC is the bridge between imagination and reality. This technology is not limited to a single medium; its versatility allows creators to work with a diverse palette of materials, each bringing a unique character to the final form.

A compelling example of this process is detailed in a project by RustFab LLC, which utilized RhinoCAM software to create a complex sculpture from high-density foam. The project involved machining a faceted mesh model standing 36 inches tall, requiring nine indexed 5-axis setups for roughing and finishing, followed by a continuous 5-axis operation for the final details. This case study highlights how the machine meticulously carves away material from multiple angles to achieve a finished piece that would be exceptionally challenging to produce otherwise. The ability to work with foam is particularly valuable for creating large-scale prototypes, molds for casting, or lightweight art installations.

Beyond foam and wood, 5-axis technology is making a profound impact on one of the most traditional art forms: stone carving. Companies like Chiarini Marble now offer services that can take an artist's small maquette model, 3D scan it, and reproduce it as a magnificent, life-sized stone masterpiece. This fusion of cutting-edge scanning and robotic carving allows for a level of detail and scale that was previously the domain of history's most renowned masters, democratizing the ability to create monumental works in marble and other stones. The precision of the machine ensures that the artist's original intent and subtle details are perfectly preserved in the final, enduring piece.

Applications Across Materials

- Wood Arts & Crafts: 5-axis routers are perfect for creating detailed 3D wood carvings, intricate furniture components, and decorative panels. The machine can handle hardwoods like mahogany with ease, producing sculptures with complex, flowing lines.

- Stone Masterpieces: As seen with specialized services, 5-axis mills can carve marble, granite, and other stones into life-sized statues and architectural elements, faithfully reproducing an artist's vision with robotic precision.

- Foam Prototypes & Molds: High-density foam is frequently used for creating large, lightweight sculptures, architectural models, and master patterns for mold-making in industries like automotive and aerospace, as detailed by manufacturers like China 5 Axis CNC Router.

- Composite Structures: The technology is also adept at machining modern materials like carbon fiber and fiberglass, enabling the creation of strong, lightweight components for everything from marine applications to bespoke industrial art.

Getting Started: Your Guide to 5-Axis CNC for Art Projects

For an artist inspired by the potential of 5-axis CNC, the question quickly becomes: how can I access this technology? The path from concept to creation involves practical considerations around machinery, software, and cost. Fortunately, there are several pathways available, each with its own set of advantages and challenges, making the technology more accessible than ever before. Whether you're a hobbyist looking to experiment or a professional artist planning a major commission, understanding your options is the first step toward bringing your vision to life.

One of the most direct routes is to commission a specialized fabrication service. For industries and artists demanding ultimate precision on complex parts, providers like XTJ-CNC offer advanced 5-axis machining services. They can handle a broad spectrum of materials, including aluminum, steel, titanium, and plastics, with tight tolerances and rapid turnarounds. Working with a professional service gives you access to industrial-grade machinery and expertise without the immense upfront investment and learning curve of owning a machine. Other services, such as AARNE and Chiarini Marble and Stone, focus specifically on creating bespoke sculptures and art pieces.

For those with a more hands-on approach and a dedicated workshop space, purchasing a machine is a viable option. The market has expanded to include more "affordable" or "hobbyist" 5-axis machines. While these smaller units, sometimes available for around $5,000, don't have the scale or power of their industrial counterparts, they are excellent for creating smaller 3D wood arts, crafts, and models. Owning a machine provides complete creative control and is ideal for iterative design processes. However, this path requires a significant investment in both time and money to learn the necessary CAD/CAM software and machine operation.

Comparing Your Options

| Option | Pros | Cons |

|---|---|---|

| Buy a Hobbyist Machine |

|

|

| Commission a Service |

|

|

| Collaborate with a Fab Lab |

|

|

When vetting a 5-axis CNC service provider, it's crucial to ask the right questions to ensure they can meet the specific needs of your artistic project. Prepare a checklist to guide your conversation:

- What materials are you experienced in machining?

- What is the maximum size (work envelope) of a piece you can create?

- Which 3D file formats can you work with (e.g., STL, STEP, IGES)?

- Can you provide examples of similar artistic projects you have completed?

- What is your typical turnaround time and pricing structure?

- What level of surface finish can I expect directly from the machine?

The Future of Form Is in Your Hands

The convergence of digital design and advanced manufacturing has unlocked a new frontier for artistic expression. 5-axis CNC technology is no longer just an industrial tool for creating precise components; it has become a powerful medium for artists and sculptors. By removing many of the physical constraints of traditional methods, it empowers creators to produce forms of unprecedented complexity and detail. The ability to flawlessly translate a vision from a screen into a tangible object made of wood, stone, or foam represents a fundamental shift in the creative process.

Whether through commissioning a specialized service, investing in a personal machine, or collaborating with a local fabrication lab, the pathways to accessing this technology are becoming increasingly diverse. This accessibility invites a new generation of artists to experiment, innovate, and redefine the boundaries of sculpture. As the bridge between the digital and the physical grows stronger, 5-axis CNC stands ready to carve out the future of art, one intricate layer at a time.

Frequently Asked Questions

1. What software is needed for 5-axis artistic projects?

Artists typically use a combination of 3D modeling (CAD) software and manufacturing (CAM) software. Popular choices for creating the initial sculpture design include ZBrush, for its organic sculpting capabilities, and Rhinoceros (Rhino) for more geometric and surface-based modeling. This design is then imported into a CAM program, like RhinoCAM, which is used to generate the specific toolpaths and G-code that instruct the 5-axis CNC machine how to move and cut the material.

2. Can a 5-axis CNC be used for woodworking?

Absolutely. Wood is one of the most common materials used in 5-axis CNC for artistic projects. The technology is ideal for creating complex 3D wood carvings, custom furniture with curved joinery, and detailed architectural models. The machine's ability to approach the wood from multiple angles allows for smooth, continuous curves and intricate details that are difficult to achieve with traditional woodworking tools or 3-axis routers.

3. How much does a hobbyist 5-axis CNC machine cost?

The cost for hobbyist or small-scale 5-axis CNC machines has become more accessible in recent years, though it is still a significant investment. Entry-level desktop models can start around $5,000, but prices can increase substantially based on size, rigidity, precision, and features. Industrial machines used by professional fabrication services cost hundreds of thousands of dollars, which is why many artists choose to commission work rather than purchase a machine outright.

-

Posted in

5-axis CNC, CNC art, digital fabrication, sculpture, woodworking