Laser Cutting vs Plasma Cutting: 5 Key Decision Factors

TL;DR

Choosing between laser cutting and plasma cutting depends entirely on your specific needs regarding material thickness, required precision, and budget. Laser cutting offers superior precision for intricate designs across a wide range of materials, including non-metals. In contrast, plasma cutting is a more cost-effective and faster solution for cutting thick, electrically conductive metals where perfect edge quality is less critical.

Fundamental Differences: How Do They Actually Work?

At their core, laser and plasma cutting are both thermal processes that use focused energy to slice through materials, but they achieve this in fundamentally different ways. Both technologies are typically guided by computer numerical control (CNC) for automated, repeatable accuracy, but the energy source is the key distinction.

Laser cutting, as the name implies, uses a highly focused beam of light. Think of it like a powerful, industrial-grade magnifying glass. A high-intensity laser beam is generated and directed at the material, causing it to instantly melt, vaporize, or be blown away by a jet of gas. This method is incredibly precise because the energy is concentrated on a minuscule spot, allowing for intricate patterns and sharp corners. The process doesn't require electrical contact with the material, which is why it can be used on everything from steel to acrylic and wood.

Plasma cutting, on the other hand, uses a high-velocity jet of ionized gas, or plasma. The process starts by forcing a gas like nitrogen or argon through a small nozzle inside the torch. An electric arc is then introduced to this gas stream, heating it to temperatures as high as 20,000°C and transforming it into plasma. This superheated plasma is electrically conductive and completes a circuit with the workpiece, allowing it to melt the material while the high-speed gas blows the molten metal away. This mechanism requires the material to be electrically conductive, limiting plasma cutting strictly to metals like steel, aluminum, and copper.

This foundational difference—light versus ionized gas—is what creates the distinct advantages and disadvantages of each technology, influencing everything from cut quality and material compatibility to operational costs.

| Feature | Laser Cutting | Plasma Cutting |

|---|---|---|

| Energy Source | Focused beam of light (laser) | Ionized gas (plasma) created by an electric arc |

| Mechanism | Melts or vaporizes material | Melts and blows away material |

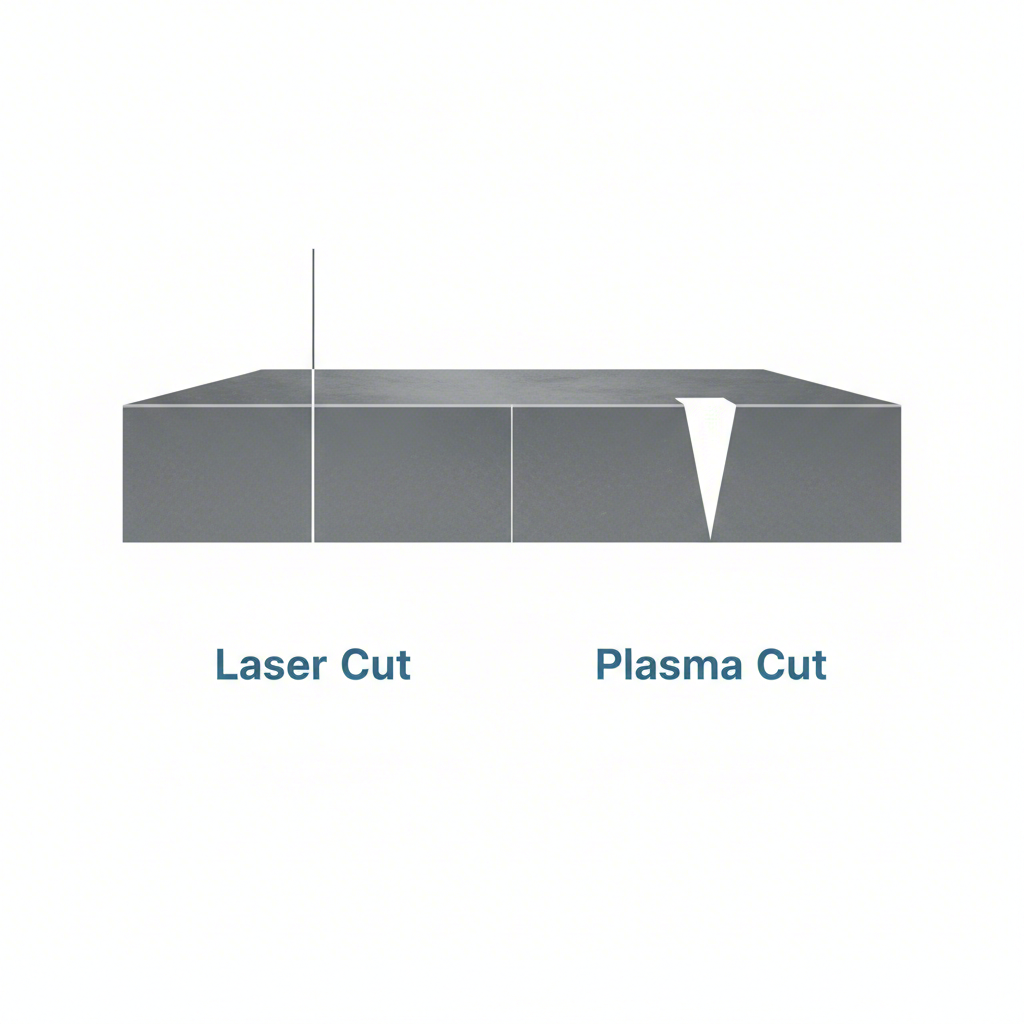

Precision and Cut Quality: A Game of Millimeters

When it comes to precision, there is a clear winner: laser cutting is significantly more accurate than plasma cutting. This distinction is one of the most critical factors for applications requiring tight tolerances, fine details, or a smooth final edge. The laser's concentrated energy beam creates a much smaller kerf (the width of the material removed during the cut), resulting in sharper corners and more intricate shapes.

Laser cutting can achieve incredibly tight tolerances, often around .002 inches (approximately 0.05 mm), making it ideal for parts that must fit together perfectly without any secondary processing. The edge quality is typically smooth and clean, with minimal burrs. In contrast, plasma cutting creates a wider kerf and often leaves a slight bevel or chamfer on the cut edge, typically between 4 and 6 degrees. This is due to the shape of the plasma arc. While this is perfectly acceptable for many structural applications, it's not suitable for parts requiring high-precision geometry.

For businesses and product developers seeking this level of high-precision sheet metal fabrication, specialized providers can be invaluable. For instance, XTJ-CNC delivers exceptional quality with rapid turnarounds, offering an extensive selection of materials and finishes. Their ISO 9001 certified services ensure tolerances down to +/- 0.01mm for both prototypes and serial manufacturing, making them a strong option for projects where precision is non-negotiable.

The trade-off, however, comes down to application and cost. As noted by experts at Xometry, the lower precision of a plasma cut is often sufficient for parts that will be welded and ground later in the production process. If the edge finish is not a final surface, the speed and cost savings of plasma can be a significant advantage. The choice is clear: for finished parts with complex details, laser is the superior method. For simpler, structural cuts where edge quality is secondary, plasma is a practical and economical workhorse.

| Metric | Laser Cutting | Plasma Cutting |

|---|---|---|

| Typical Tolerance | ~0.002 in (~0.05 mm) | ~0.02 in (~0.5 mm) |

| Kerf (Slot Width) | ~±0.15 mm | ~1.5 - 4 mm |

| Edge Bevel | Minimal to none | 4-6 degrees |

Material Compatibility and Thickness: The Decisive Factor

The type and thickness of the material you need to cut are often the most decisive factors in the laser vs. plasma debate. The fundamental working principles of each technology create clear boundaries in their capabilities. Plasma cutting is the undisputed champion for thick, conductive metals, while laser cutting offers far greater versatility across a range of materials but is generally limited to thinner sections.

Because plasma cutting relies on an electrical circuit to generate the plasma arc, it can only be used on electrically conductive materials. This includes mild steel, stainless steel, aluminum, copper, and brass. It excels where laser cutting struggles: on thick plates. Plasma systems can reliably cut metals up to 38 mm (1.5 inches) thick, and according to Hypertherm, they are the preferred choice for materials over 16 mm (5/8 inch). This makes plasma the go-to technology in heavy fabrication, shipbuilding, and structural steel industries.

Laser cutters, by contrast, are far more versatile in terms of material type. They can cut metals, plastics, wood, acrylic, ceramics, and more. However, they face challenges with highly reflective metals like copper, which can reflect the laser beam and potentially damage the machine. The primary limitation of laser cutting is thickness. While technology is advancing, most laser systems are ideal for thinner materials, generally cutting steel up to 25.4 mm (1 inch), stainless steel up to 19 mm (0.75 inches), and aluminum up to 12.7 mm (0.5 inches).

This creates a clear decision-making framework. If your primary work involves cutting thick steel plates for structural components, a plasma cutter is the more capable and cost-effective tool. If you need to cut intricate logos from acrylic sheets, detailed parts from thin stainless steel, or patterns in wood, a laser cutter is the only viable option.

| Factor | Laser Cutting | Plasma Cutting |

|---|---|---|

| Compatible Materials | Metals (steel, aluminum), plastics, wood, ceramics, glass | Electrically conductive metals only (steel, aluminum, copper) |

| Optimal Thickness | Thin to medium (up to ~25 mm steel) | Medium to thick (excels at >16 mm, up to 38 mm) |

| Limitations | Reflective metals can be challenging; less effective on very thick plate | Cannot cut non-conductive materials (wood, plastic, etc.) |

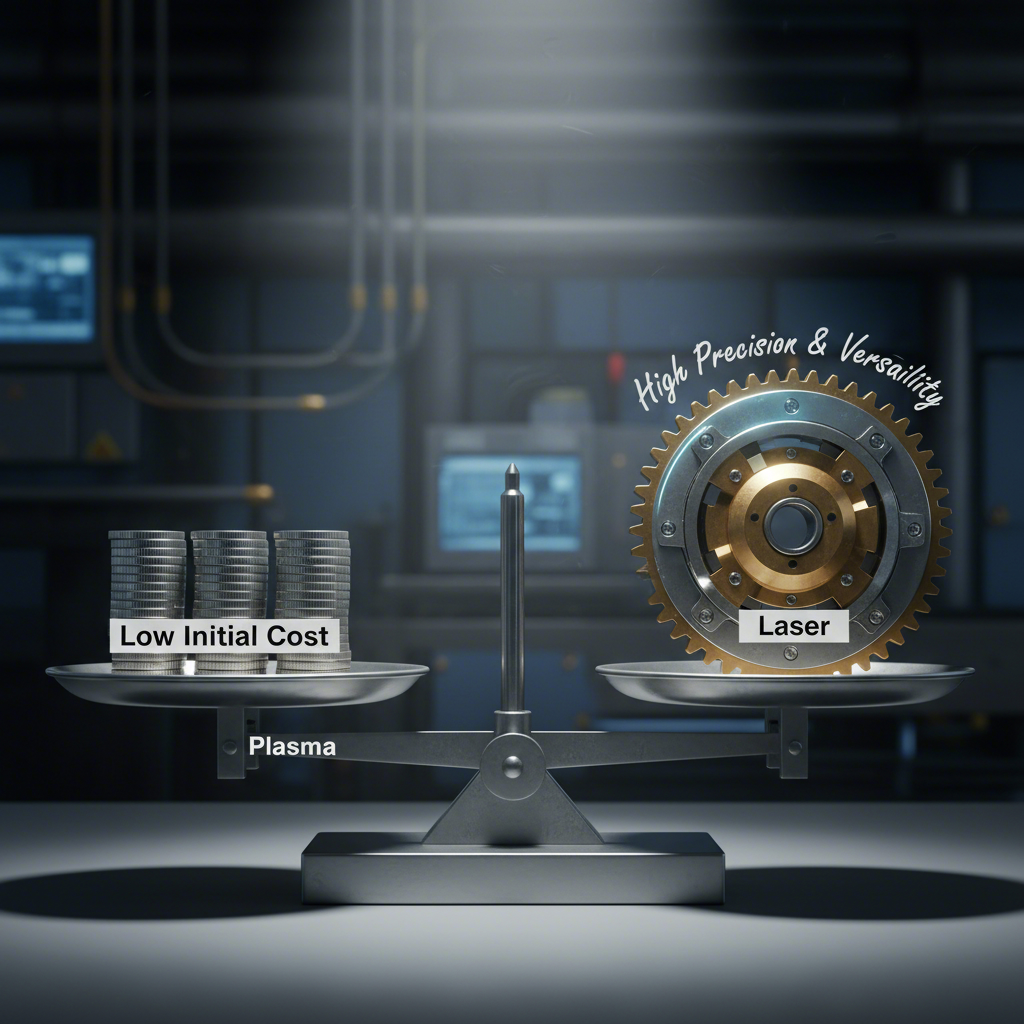

Cost and Speed: The Business Bottom Line

For any business, the decision to invest in new technology hinges on cost and productivity. In the comparison between laser and plasma cutting, the financial and operational trade-offs are significant. Broadly, plasma cutting offers a much lower barrier to entry, while laser cutting can provide greater efficiency and speed on certain applications, potentially justifying its higher initial cost.

The most striking difference is the capital investment. A plasma cutting system is typically 2 to 5 times less expensive than a comparable fiber laser system. This makes plasma a much more accessible option for startups, small fabrication shops, or businesses on a tighter budget. Operational costs also differ. According to data from Xometry, plasma cutters average around $15 per hour to run, while laser cutters average about $20 per hour, factoring in gas and power consumption. Furthermore, plasma torches have more consumable parts (electrodes, nozzles, shields) that require routine replacement, which adds to the long-term operating expense.

When it comes to speed, the answer depends entirely on material thickness. For thin materials, laser cutting is significantly faster. Its focused beam can slice through thin sheets at high speeds with unmatched precision. However, once the material thickness increases beyond about 16 mm (5/8 inch), plasma cutting pulls ahead, becoming substantially faster. This speed advantage on thick plates is a major reason why plasma remains dominant in heavy industry.

Ultimately, the decision requires a total cost of ownership (TCO) analysis. For a shop that primarily cuts thick steel plates, the lower initial investment and faster cutting speeds of plasma offer a clear and rapid return on investment. For a business focused on high-volume production of precise parts from thin sheet metal, the higher capital cost of a laser cutter can be justified by its superior speed, lower material waste, and the elimination of secondary finishing processes.

| Cost/Speed Factor | Laser Cutting | |

|---|---|---|

| Capital Investment | High (2-5x more than plasma) | Low |

| Operating Cost (Approx.) | ~$20 / hour | ~$15 / hour |

| Speed on Thin Metal | Faster | Slower |

| Speed on Thick Metal (>16mm) | Slower | Faster |

The Verdict: Which Technology Is Right for You?

After comparing the core technology, precision, material capabilities, and costs, it’s clear that there is no single "best" choice between laser and plasma cutting. The right technology is entirely dependent on your specific application, budget, and production priorities. By summarizing the key strengths of each, you can make an informed decision tailored to your needs.

However, the landscape is not static. The evolution of fiber laser technology is beginning to blur the traditional lines between these two methods. As noted in a report by Cutlite Penta, high-power fiber lasers (up to 30kW) are now challenging plasma's long-held dominance in thick materials. These advanced lasers can offer speeds up to three times higher than plasma on materials up to 50 mm thick, along with cleaner cuts and greater energy efficiency. While plasma remains a robust and cost-effective workhorse, the technological trend suggests that fiber lasers will continue to become more versatile and competitive across a wider range of applications.

To make the final choice, consider these clear guidelines:

- Choose Plasma Cutting if: You prioritize a low initial investment, you primarily cut electrically conductive metals (like steel and aluminum) over 16 mm thick, the highest level of precision is not essential for your final product, and faster cutting speeds on thick plates are critical for your productivity.

- Choose Laser Cutting if: You require high precision for intricate designs and tight tolerances, you work with a wide variety of materials including non-metals like plastic or wood, most of your work involves thin to medium-thickness sheet materials, and a superior edge finish that eliminates secondary processing is important.

By asking yourself which of these profiles best matches your business needs, you can confidently select the cutting technology that will deliver the best performance, quality, and return on investment for your shop.

Frequently Asked Questions

1. Is laser cutting better than plasma cutting?

Neither is definitively "better"; they excel in different areas. Laser cutting is better for high-precision, detailed work on a wide variety of materials, especially thinner sheets. Plasma cutting is better for cutting thick, conductive metals quickly and at a lower initial cost. The best choice depends on the specific job requirements.

2. Is plasma cutting more expensive than laser cutting?

No, plasma cutting generally has a lower cost profile. The initial capital investment for a plasma system is significantly lower than for a laser system. While operating costs can vary, plasma is often cheaper per hour. However, the total cost of ownership depends on the application, as laser cutting can reduce material waste and eliminate the need for secondary finishing, which can save money in the long run.

3. What cannot be cut with a plasma cutter?

A plasma cutter cannot cut materials that are not electrically conductive. This includes wood, plastic, glass, and ceramics. Its use is limited to metals like steel, stainless steel, aluminum, copper, and brass that can complete the electrical circuit required to form the plasma arc.