Aluminium Al 6061 Data-Driven Properties, Tempers, And Uses

Aluminium Al 6061 Data-Driven Properties, Tempers, And Uses

What Aluminium Al 6061 Is And Why It Matters

When you’re searching for a material that balances strength, corrosion resistance, and versatility, aluminium al 6061 often tops the list. But what makes this alloy such a staple in engineering, manufacturing, and fabrication? Let’s break down what engineers, designers, and buyers need to know about 6061 aluminum, from its naming conventions to why it’s trusted for everything from aerospace parts to consumer products.

What Aluminium Al 6061 Means In Material Standards

Aluminium al 6061—also known as aluminum 6061, aluminium 6061, or by its UNS number A96061—is a precipitation-hardened alloy in the 6xxx series. Its main alloying elements are magnesium (Mg) and silicon (Si), which together create a material that’s both strong and easy to work with. You’ll see this alloy referenced in standards like the Aluminum Association’s AA 6061, ASTM designations (such as ASTM B209 for aluminum sheet and ASTM B221 for extrusions), and AMS specifications for aerospace applications. For a deeper dive into official alloy definitions or property ranges, sources like the ASM/MatWeb 6061-T6 data sheet and the Aluminum Association are considered best practice for engineers and specifiers.

Why 6061 Is A Go-To General-Purpose Alloy

Why do so many industries rely on aluminium al 6061? It’s simple: this alloy offers an exceptional blend of properties. You’ll notice it’s often selected when you need a material that is:

- Strong for its weight – Excellent strength-to-weight ratio for load-bearing designs

- Highly resistant to corrosion – Naturally forms a protective oxide layer, ideal for outdoor or marine applications

- Easy to machine and fabricate – Outstanding machinability, suitable for CNC, forming, and welding

- Widely weldable – Good weldability with common filler metals

- Available in many forms – Produced as aluminum sheet, aluminum bar, aluminum tubing, plate, and extrusions

Key takeaway: Choose 6061 when you need a balance of strength, workability, and corrosion resistance—especially for applications where neither pure formability nor maximum strength is the sole priority.

Common Product Forms And Typical Uses

Imagine building a bike frame, a structural bracket, or a precision-machined part—aluminium al 6061 is likely in the running. Its versatility means it’s available as:

- Aluminum sheet and plate for panels, covers, and structural components

- Aluminum bar and rod for shafts, fasteners, and connectors

- Aluminum tubing for frames, supports, and piping

- Extrusions for custom profiles in architecture, transportation, and consumer goods

Typical applications include aerospace fittings, automotive parts, marine hardware, and consumer electronics—thanks to its combination of mechanical properties and corrosion resistance.

Major Alloying Elements In 6061

| Element | Role in Alloy |

|---|---|

| Magnesium (Mg) | Increases strength and improves response to heat treatment |

| Silicon (Si) | Enhances strength and allows precipitation hardening |

| Iron (Fe), Copper (Cu), Chromium (Cr) | Present in smaller amounts; improve toughness, grain structure, and corrosion resistance |

Exact composition ranges should always be verified from trusted sources such as the Aluminum Association or Wikipedia for 6061 aluminum alloy.

In summary, aluminium al 6061 is a versatile, data-backed material trusted across industries for its unique combination of strength, corrosion resistance, and broad manufacturability. As we move forward, we’ll explore its properties by temper, machining guidance, and how to choose the right form for your project—whether you’re specifying an aluminum bar, sheet, or tubing.

Properties And Tempers Engineers Rely On

When you’re selecting a material for anything from a machined bracket to a lightweight structural panel, knowing how aluminum 6061 performs across different tempers is essential. But what do those temper designations really mean for strength, ductility, hardness, and even thermal behavior? Let’s break it down so you can make informed choices for your next project—without wading through guesswork or unsourced numbers.

Strength And Ductility Across 6061 Tempers

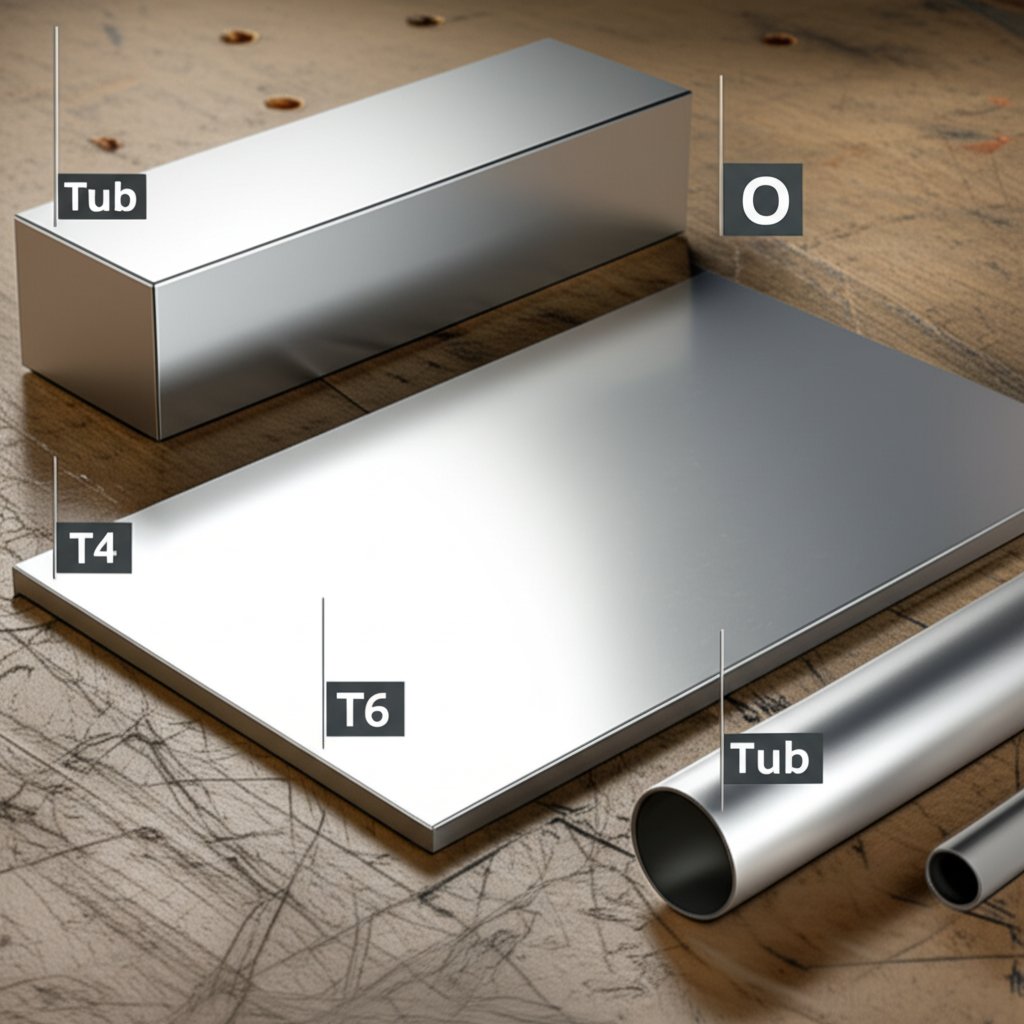

Imagine you’re comparing options for a high-strength frame versus a part that needs to be bent or formed. The temper of aluminium al 6061—such as O (annealed), T4 (solution heat-treated), T6 (solution heat-treated and artificially aged), or T651 (T6 plus stress relief)—directly affects its mechanical properties. For example, the T6 temper is widely recognized for its excellent strength, while O temper offers maximum ductility for forming.

Here’s how typical properties compare, based on authoritative sources like ASM/MatWeb and AZoM:

| Temper | Yield Strength (MPa) | Ultimate Strength (MPa) | Elongation (%) | Brinell Hardness | Key Notes |

|---|---|---|---|---|---|

| O (Annealed) | Lowest | Lowest | Highest | Lowest | Best formability, lowest strength |

| T4 | Moderate | Moderate | Moderate-High | Moderate | Good balance for forming and moderate strength |

| T6 | ~276 | ~310 | 12–17 | 95 | Highest strength, reduced elongation |

| T651 | Similar to T6 | Similar to T6 | Similar to T6 | Similar to T6 | T6 with stress relief—better dimensional stability for machining |

Note: Values for T6 are typical and sourced from ASM/MatWeb. Other tempers are shown for relative comparison; always confirm exact values for your specification.

- 6061 t6 yield strength is typically around 276 MPa (40,000 psi).

- Ultimate tensile strength for 6061 t6 is about 310 MPa (45,000 psi).

- Elongation (ductility) varies by form and thickness but is generally 12–17% in T6.

These differences matter when you’re deciding between maximizing strength (T6), formability (O), or minimizing distortion in machining (T651).

Hardness Scales And Practical Correlations

How hard is 6061 aluminum? In the T6 temper, its Brinell hardness is typically 95. If you’re more familiar with Rockwell scales, that translates to approximately 60 on the Rockwell B scale. This level of hardness makes 6061 t6 suitable for applications where moderate wear resistance is needed, but not so hard that it becomes brittle or difficult to machine.

Curious about how this compares to other alloys? 6061 T6 is harder than many pure aluminum alloys, but softer than high-strength 7000-series grades. Its balance of hardness and workability is a key reason it’s so popular for 6061 aluminum properties in both structural and precision parts.

Thermal And Electrical Behavior That Affects Design

Thermal and electrical properties are often overlooked but can be crucial. The density of 6061 aluminum is approximately 2.7 g/cm³ (0.0975 lb/in³), which is standard for aluminum alloys and enables lightweight designs. If you’re building parts that need to dissipate heat, you’ll appreciate its thermal conductivity—typically around 152-167 W/m-K for the T6 temper—making it suitable for heat sinks and electronic housings (ASM/MatWeb).

- The modulus of elasticity of aluminum 6061 is about 68.9 GPa (10,000 ksi), meaning it’s stiff enough for many load-bearing applications but still offers some flex under load.

- Electrical resistivity is 3.99×10-6 ohm-cm, making it a decent conductor for non-critical electrical components.

- The aluminum melting point for 6061 alloy ranges from 582°C to 652°C (1080°F to 1205°F), which is important for welding and high-temperature service.

Practical Takeaways for Engineers

- Higher strength in 6061 T6 may reduce formability—choose O or T4 tempers for bending or complex forming.

- T651 temper is preferred for thick plate or precision machining since it minimizes residual stress and warping.

- Thermal conductivity and moderate density make 6061 ideal for lightweight, heat-dissipating parts.

Tip: Always verify mechanical and physical property values using authoritative datasheets for your specific product form (bar, sheet, plate, or extrusion) and desired temper.

Understanding these core 6061 aluminum properties helps you confidently select the right temper for your application—whether you’re optimizing for strength, machinability, or thermal performance. Next, we’ll walk through the heat-treatment pathways that enable these property differences, so you can see how processing shapes performance.

Heat Treatment Pathways For 6061

Ever wondered why two parts made from the same aluminum alloy 6061 can feel so different in strength or machinability? The answer lies in the heat treatment process—specifically, how 6061 tempers like T4, T6, and T651 are created. If you’re specifying, machining, or fabricating, understanding these pathways is key to getting the performance you need and avoiding surprises down the line.

From Solution Heat Treatment To Aging

Sounds complex? Here’s a step-by-step look at how 6061 aluminum transforms from a soft, formable material into a high-strength, stable engineering alloy. This process is governed by standards such as AMS-QQ-A-250/11 and is referenced in most material certifications.

- Solution Heat Treatment (Solutionizing): The alloy is heated to a high temperature, allowing magnesium and silicon to dissolve into a solid solution. This step prepares the metal for hardening.

- Quenching: Rapid cooling (usually in water) locks the alloying elements in place, creating a supersaturated structure that’s relatively soft and ductile.

-

Aging: Depending on the target temper, aging can be

- Natural (T4): The material is left at room temperature to age naturally, increasing strength moderately.

- Artificial (T6, T651): The alloy is heated again at a lower temperature to accelerate precipitation, resulting in the high strength typical of t6 aluminum.

- Stress Relief (T651): For thick plate or precision applications, the metal is stretched after aging to relieve internal stresses—this is what distinguishes 6061-t651 from 6061-t6 and helps prevent warping during machining.

Understanding T4 Versus T6 Versus T651

Imagine you’re choosing between easy forming, maximum strength, or dimensional stability. Here’s how the main 6061 tempers stack up, using insights from Xometry and Smiths Metal Centres:

| Temper | Machinability | Dimensional Stability | Formability | Typical Product Form |

|---|---|---|---|---|

| T4 | Good | Moderate | Best (easy to bend/form) | Sheet, extrusions |

| T6 | Very Good | Good | Moderate (less ductile) | Sheet, thin plate |

| T651 | Excellent (preferred for CNC machining) | Best (low residual stress) | Fair (least ductile) | Plate (≥0.25" thick), bar |

For many engineering projects, 6061-t6 is the default for aluminum sheet or thin plate when you need a balance of strength and workability. When machining thick plate or precision parts, 6061-t651 is often specified for its excellent stability and reduced risk of warpage.

Post-Weld And Post-Machining Considerations

After welding or heavy machining, you might notice unexpected movement or distortion—especially in thick sections. That’s because quenching and machining can introduce residual stresses. The T651 temper (sometimes called out as ams 4027 or ams-qq-a-250/11) is specifically designed to address this by stretching the plate after heat treatment, minimizing these effects.

Key insight: Quench-induced distortion and residual stress can be significant in thick or complex 6061 parts. Choosing t651 over t6 aluminum plate helps maintain tight tolerances and flatness, especially in CNC-machined components.

In summary, the right choice of 6061 tempers—whether T4 for forming, T6 for strength, or T651 for machining—comes down to your project’s priorities. Always confirm your specification with the latest standards and material certifications, and consult with your supplier if you’re unsure which temper is best for your application.

Next, we’ll dive into hands-on machining strategies that help you get the most out of 6061, from tool selection to managing residual stresses in real-world parts.

Machining 6061 For Precision And Finish

When you’re working with 6061 aluminum plate, 6061 t6 aluminum bar, or even intricate 6061 aluminum sheet metal, achieving a flawless finish and tight tolerances isn’t just about running a CNC program—it’s about understanding the alloy’s quirks and using the right techniques. So, how do you turn bar stock aluminum or a 6061 aluminum round bar into a precision part without fighting chatter, burrs, or dimensional drift? Let’s break down the shop-floor know-how that gets you there.

Tooling Choices And Cut Strategy For 6061

Imagine you’re setting up to machine a batch of 6061 t6 aluminum rod. Your tool selection makes all the difference. For most operations, carbide tooling with a sharp, high positive rake angle is the gold standard—these tools cut cleanly, reduce cutting forces, and help evacuate chips efficiently. High-speed steel (HSS) tools, while economical, generally don’t hold up as well in 6061, especially for high-volume runs or when you need a pristine finish.

- Use carbide end mills and face mills with a high helix angle for superior chip evacuation.

- For drilling and tapping, sharp carbide or HSS tools with high helix angles work best—just ensure frequent chip clearing.

- For turning, opt for carbide inserts with a positive rake and keep cutting depths light to minimize vibration.

Climb milling is recommended for finishing passes, as it provides a smoother surface and reduces tool deflection. Always secure your workpiece firmly, especially when machining thin sections or long parts, to avoid vibration and chatter.

Coolant, Chip Control, And Burr Reduction

Ever notice a haze or roughness on your finished 6061 aluminum bar? That’s often a sign of inadequate cooling or poor chip control. 6061’s relatively low modulus and high thermal conductivity mean heat can quickly build up at the tool edge, leading to built-up edge and poor finishes. The solution? Generous use of coolant and sharp tools.

- Flood coolant (water-soluble, 5–10% concentration) keeps temperatures down and flushes chips away.

- For drilling and tapping, peck cycles help break chips and prevent clogging.

- Use deburring tools or light passes to remove burrs—especially on small or intricate features.

Regular maintenance—checking tool sharpness, coolant levels, and workholding—ensures you maintain surface quality and dimensional accuracy, whether you’re machining a 6061 t6 aluminum plate or a custom 6061 aluminum bar.

Troubleshooting Common Machining Defects

Even with the best setup, you might encounter symptoms like chatter, warping, or burrs. Here’s a quick-reference table to help you diagnose and fix the most frequent issues:

| Symptom | Likely Cause | Corrective Action |

|---|---|---|

| Chatter or Vibration | Long tool overhang, insufficient workholding, dull tool | Shorten tool extension, improve clamping, use sharper carbide tools |

| Poor Surface Finish | Dull tool, inadequate coolant, too high feed/speed | Replace or resharpen tool, increase coolant flow, adjust parameters |

| Burr Formation | Tool wear, improper feed, insufficient deburring | Use fresh tool, optimize feed, add dedicated deburring step |

| Dimensional Drift/Distortion | Residual stress in material, excessive heat, poor fixturing | Use T651 stress-relieved plate, reduce heat input, improve fixturing |

| Chip Packing/Clogging | Low chip evacuation, dull tool, inadequate coolant | Increase coolant, use peck cycles, sharpen tool |

Best Practices for Machining 6061 Aluminum

- Choose sharp, positive-rake carbide tools for high material removal rates and clean finishes.

- Apply flood coolant to control heat and extend tool life.

- Use climb milling for improved surface finish and reduced tool deflection.

- Select stress-relieved 6061 t6 aluminum plate (T651 temper) for critical parts to minimize movement after machining.

- Incorporate deburring steps, especially for small holes and edges, to ensure safety and assembly fit.

Keep in mind: The relatively low modulus of elasticity in 6061 means long, thin parts are prone to flexing and chatter. Optimize your toolpaths, minimize unsupported lengths, and consider finishing passes with reduced depth of cut for best results.

By following these strategies, you’ll unlock the full machinability potential of 6061 aluminum—whether you’re starting with bar stock aluminum, a 6061 aluminum round bar, or a complex 6061 aluminum sheet metal profile. Next, we’ll explore how forming and welding practices can further expand your design options with this versatile alloy.

Forming And Welding 6061 Without Surprises

When you’re working with 6061 aluminium—especially in the popular T6 temper—you’ll quickly discover that its strength is both a blessing and a challenge. Want to bend, weld, or finish aluminum sheet 6061 t6 without cracks, distortion, or unexpected corrosion? Let’s walk through the real-world strategies that professionals rely on to get flawless results, whether you’re making a 1/4 aluminum sheet bracket or fabricating intricate aluminum sheet metal enclosures.

Bending And Springback Considerations By Temper

Ever tried to form 6061 t6 aluminium and ended up with cracks along the bend? That’s because the T6 temper, while strong, has limited ductility. The solution: match your bend strategy to the temper and thickness, and don’t be afraid to use some creative techniques when needed.

- Use larger inside bend radii for harder tempers. For 6061-T6, aim for an inside radius at least 1.5 to 3 times the material thickness for thin sheets (for example, a 1/4 aluminum sheet might need a bend radius of 3/8 inch or more). Tighter bends increase the risk of cracking. Always check with your material supplier for minimum recommended radii (The Fabricator).

- Consider annealing for tight bends. For complex shapes or small radii, torch annealing (using an oxyacetylene torch) can locally soften the bend area, making 6061 t6 aluminium as formable as possible without major strength loss. This is especially useful for custom or prototype work.

- Align bends with the grain direction. Bending perpendicular to the grain direction in aluminum sheet metal reduces the risk of cracking.

- Trial bends are your friend. If you’re unsure how thick is 16 gauge aluminum or how it will behave, make a test bend on a scrap piece first.

Keep in mind: The harder the temper, the more pronounced the springback. Factor this into your bend angles, and don’t expect the part to hold sharp corners as easily as softer alloys.

Welding 6061 While Controlling Distortion

Need to weld aluminum for a structural frame or enclosure? 6061 aluminium is weldable, but you’ll want to plan ahead to avoid distortion, softening, and alignment issues—especially with thicker sections or precision assemblies.

- Clean the surface thoroughly. Remove the oxide layer and any contaminants using a stainless steel brush or approved cleaner before welding. This ensures strong, defect-free welds.

- Choose the right filler material. Filler alloys like 4043 or 5356 are common for 6061-T6, with 4043 offering less shrinkage and 5356 providing better corrosion resistance. Select based on strength and service environment—always check the latest datasheets for compatibility.

- Control heat input. Use TIG for thin sections and MIG for thicker parts. Minimize heat to reduce warping and preserve strength in the heat-affected zone (HAZ). Pulse welding techniques help here.

- Use fixturing and sequence control. Secure your parts with jigs or clamps and weld in balanced sequences to minimize residual stress and distortion.

- Consider post-weld heat treatment. For critical parts, artificial aging or stress relief can help restore strength lost during welding.

| Fabrication Step | Risk | Mitigation |

|---|---|---|

| Bending T6 sheet | Cracking at bend | Anneal locally, use large radius, trial bends |

| Welding | Softening in HAZ, distortion | Control heat, use proper filler, fixturing, post-weld heat treatment |

| Assembly/Finishing | Misalignment from residual stress | Sequence welds, stress-relieve if needed, check alignment after cooling |

Key insight: Differential thermal expansion and concentrated heat input during welding or forming can introduce significant residual stresses in 6061 structures. Always plan for post-process inspection and, where possible, use tempers or techniques that minimize distortion—especially for precision assemblies.

Corrosion And Post-Fabrication Protection

6061 t6 aluminium is naturally resistant to aluminum corrosion, but welds and bare edges can be more vulnerable—especially in harsh environments. Protecting your finished parts isn’t just about aesthetics; it’s about long-term durability.

- Anodizing (Type II or III) offers excellent corrosion resistance for most applications. However, it’s not always suitable for welded joints, as the process can attack the weld area.

- Chemical conversion coatings (such as MIL-C-5541C) are a good alternative for protecting welds and complex assemblies where anodizing isn’t feasible.

- Solid film lubricants can add extra corrosion protection, especially in assemblies with moving parts or where disassembly is required.

- Always seal or finish exposed surfaces after fabrication to maximize corrosion resistance—especially on cut edges and weld seams.

Wondering how thick is 16 gauge aluminum? While gauge-to-thickness varies by standard, 16 gauge aluminum sheet is typically around 0.0508 inches (1.29 mm) thick—always confirm with your supplier for precise values.

By tailoring your fabrication approach to the unique properties of 6061 aluminium, you can confidently bend, weld, and finish everything from 1/4 aluminum sheet to complex aluminum sheet metal parts. Next, we’ll explore the fatigue and fracture considerations that matter most when your parts face repeated loading or critical service environments.

Fatigue And Fracture Considerations For 6061

When you design with aluminium al 6061, it’s easy to focus on headline numbers like 6061 tensile strength or yield stress of aluminum 6061. But what happens when your part faces millions of cycles, vibrations, or repeated impacts? Fatigue and fracture performance often determine real-world reliability—especially in aerospace, vehicles, or structural frames. Let’s break down what you need to know so your 6061 parts stand the test of time, not just the first load.

Designing With 6061 Under Cyclic Loads

Imagine a bike frame, a bridge deck, or a robotic arm. These parts endure countless cycles of stress and shear stress, often well below their ultimate strength. Yet, over time, even modest loads can initiate microscopic cracks that grow with each cycle—a phenomenon known as metal fatigue. For 6061-T6, authoritative fatigue data shows it does not have a true endurance limit like some steels. Instead, allowable stress drops as cycles increase.

According to design fatigue curves compiled from sources such as the Structural Alloys Handbook and Alcoa Structural Handbook, the fatigue strength for 6061-T6 after 500 million completely reversed cycles is about 96.5 MPa (14,000 psi). If you’re converting between units, remember that mpa to psi conversion (1 MPa ≈ 145 psi) and ksi to psi (1 ksi = 1,000 psi) are handy for comparing specs.

Fatigue strength is further reduced when mean stress is present or after welding. For instance, welds in 6061-T6 can halve the fatigue allowable, so always apply a conservative reduction factor for critical joints (Engineers Edge).

Surface Finish, Stress Concentrations, And Fatigue Life

Sounds complex? It’s often the details—like a sharp corner or a rough surface—that dictate whether a part will last. Cracks typically start at “stress concentrators” such as notches, holes, or weld toes. The smoother and more rounded your design, the lower the risk of premature fatigue failure. Here’s a checklist of proven fatigue design tips:

- Minimize sharp corners—use generous fillets and radii to reduce stress concentrations.

- Polish or smooth critical surfaces to eliminate micro-crack initiation sites.

- Apply compressive surface treatments (like shot peening) where possible.

- Control residual stresses through proper heat treatment and stress-relief processes.

- Avoid galvanic couples—dissimilar metals can accelerate pitting at stress risers.

The right surface finish and geometry can dramatically extend the fatigue life of 6061 aluminum, especially in applications exposed to vibration or cyclic loads.

| Load Case | Risk Factor | Mitigation |

|---|---|---|

| Reversed bending (e.g., cycling, vibration) | High stress at notches | Increase fillet radii, polish surface, use FEA for hotspot detection |

| Welded joints | Soft heat-affected zone (HAZ), residual stress | Apply weld reduction factor, post-weld heat treatment, inspect for cracks |

| Bolted/fastened connections | Hole edge cracking | Use washers, optimize hole geometry, avoid sharp transitions |

Inspection Intervals And Damage Tolerance Thinking

Imagine catching a crack before it grows—routine inspection is your best defense. Non-destructive testing (NDT) methods like dye penetrant, ultrasonic, or eddy current inspection can spot early signs of fatigue before catastrophic failure. For mission-critical parts, set inspection intervals based on expected load cycles and environmental exposure.

Designing for damage tolerance means assuming flaws will exist and planning for them. Use finite element analysis (FEA) to predict stress and shear stress hotspots, and specify larger radii or surface treatments in those areas. If your application is sensitive to fatigue (think: aircraft, bridges, or safety-critical robots), invest extra effort in both design and inspection planning.

Takeaway: Fatigue and fracture in 6061 are driven by design details, loading history, and surface quality—not just the tensile strength of 6061 aluminum. By addressing stress concentrators, improving finishes, and planning for inspection, you’ll extend service life and boost safety.

Next, we’ll compare 6061 with other aluminum alloys, helping you choose the right grade for your project’s unique demands.

Choosing 6061 Versus Other Aluminum Alloys

When you’re faced with a shelf full of aluminum grades—6061, 5052, 6063, 7075, 2024—how do you know which to pick for your next project? Do you need strength, formability, a flawless finish, or resistance to corrosion? Let’s break down how aluminium al 6061 stacks up against its most common competitors, so you can select with confidence.

Where 6061 Outperforms And Where It Does Not

Imagine you’re building a structural bracket, an architectural extrusion, or a lightweight aerospace part. Each alloy brings a unique blend of properties to the table. For example, 6061 aluminum alloy is celebrated for its balance of strength, weldability, and machinability, making it a go-to choice for general-purpose engineering. But if you’re after extreme formability or maximum corrosion resistance, you might look to 5052. For pristine surface finishes in extrusions, 6063 shines, while 7075 and 2024 are reserved for high-strength, less weldable applications.

| Alloy | Strength Class | Weldability | Formability | Corrosion Resistance | Anodizing/Finish Quality | Typical Applications |

|---|---|---|---|---|---|---|

| 6061 | High (structural) | Good | Moderate (best in T4/O) | Good | Good | Machined parts, frames, 6061 plate, aerospace, marine, general engineering |

| 5052 | Moderate | Excellent | Excellent | Excellent | Fair | Aluminum sheeting, marine panels, tanks, enclosures, formed parts |

| 6063 | Moderate | Excellent | Excellent (extrusions) | Very Good | Excellent (anodized finish) | Architectural extrusions, window frames, tubing, decorative trim |

| 7075 | Very High | Poor | Poor | Moderate | Good | Aerospace fasteners, high-stress components |

| 2024 | High | Poor | Fair | Poor | Fair | Aerospace structures, military, riveted assemblies |

Note: Property classes are qualitative and based on typical industry usage. For precise values, always consult datasheets or standards for the specific alloy and temper you plan to use.

Choosing By Process: Extrusion, Plate, Or Sheet

Sounds complex? Let’s simplify. If your project calls for aluminum sheeting that will be bent or deep drawn, 5052 is often preferred for its formability and corrosion resistance. For extruded profiles where surface finish is paramount, 6063 usually wins—think window frames or architectural trim. When you need a 6061 plate or 6061 aluminum alloy plate for CNC machining or structural use, 6061 is the workhorse, balancing strength, machinability, and weldability. For high-strength needs, such as aerospace bolts or critical fasteners, 7075 or 2024 are considered, but with trade-offs in weldability and corrosion resistance.

- Extruded architectural profiles → Choose 6063 for finish and formability

- Formed or marine sheet → 5052 for corrosion and deep drawing

- General-purpose machined parts → 6061 alloy for versatility

- High-strength aerospace → 7075 or 2024 for maximum mechanical performance

Cost, Availability, And Finish Considerations

You’ll notice that aluminium alloy 6061 is widely available in almost every product form—sheet, plate, bar, tube, and extrusions. Its popularity means competitive pricing and easy sourcing, whether you need a single prototype or a production run. 5052 and 6063 are also broadly stocked, but 7075 and 2024 can be more expensive and harder to find outside of specialty suppliers.

Finish matters, too. If you need a visually appealing, anodized surface, 6063 is the preferred choice for extrusions, offering a smoother, more consistent finish. 6061 can be anodized but may show more variation in color and texture. For marine or outdoor applications, both 5052 and 6061 offer good corrosion resistance, but 5052 is often favored for its superior performance in saltwater environments.

Key takeaway: There’s no one-size-fits-all “best” aluminum alloy—choose based on your project’s priorities: strength, finish, formability, or corrosion resistance. Always confirm with up-to-date datasheets and supplier recommendations for your specific use case.

By understanding the strengths and trade-offs of 6061 versus other common alloys, you can confidently select the right material—whether you’re machining a 6061 alloy plate, forming marine-grade aluminum sheeting, or specifying architectural extrusions. Next, we’ll connect these choices to manufacturability, showing how CNC machining can unlock the full potential of your selected alloy.

From Design To Production With CNC Machined 6061

When you’re ready to transform a CAD model into a physical part, aluminium al 6061 stands out for its machinability, stability, and broad availability in forms like 1/2 aluminum plate, bar, and extrusion. But how do you get the most out of this alloy in real-world CNC projects—especially when precision, surface finish, and lead time are on the line? Let’s walk through actionable design-for-manufacturing (DFM) strategies and see how modern CNC capabilities unlock the full potential of 6061.

Design For CNC With 6061 Features That Machine Well

Imagine you’re designing a complex bracket or housing from 6061-T651 plate. The choices you make at the design stage directly impact cost, quality, and speed. Here’s a checklist to help you avoid common pitfalls and deliver parts that meet both functional and aesthetic goals:

- Specify consistent wall thickness to minimize distortion and ensure even cooling during machining.

- Use generous fillets (inside radii) on pockets and corners—this reduces tool deflection and improves machinability, especially in deep cavities.

- Set realistic tolerances—don’t over-specify unless function demands it. Tighter tolerances increase cost and lead time.

- Choose 6061-T651 plate for critical parts—stress-relieved material resists warping after heavy machining, making it ideal for precision work.

- Plan for fixturing—add flat surfaces or features that enable secure workholding during multi-axis machining.

- Consider anodizing or surface finishing needs early to avoid design changes late in the process.

Tolerance, Finish, And Inspection Planning

With 6061, you’ll notice it’s possible to achieve very tight tolerances—down to ±0.005 mm on advanced equipment—making it a favorite for high-precision components. However, tolerances and surface finish must be matched to the application. For example, a 1/4 inch aluminum plate used as a mounting base may not need the same finish as a cosmetic enclosure panel.

| Feature Type | Typical Achievable Tolerance | Surface Finish (Ra, µm) |

|---|---|---|

| Precision bores (reamed) | ±0.01 mm | 0.4 – 0.8 |

| General milled surfaces | ±0.05 mm | 1.6 – 3.2 |

| Flatness on T651 plate (<300 mm) | 0.1 mm | 1.6 – 3.2 |

Values are typical industry standards for CNC-machined 6061, but always validate requirements against the end use and reference up-to-date sources or supplier data.

Advanced metrology, such as in-process laser interferometry or coordinate measuring machines (CMM), is often used to inspect tight-tolerance features—especially for thin walls or complex 5-axis geometries. This is crucial if you’re sourcing from providers specializing in ultra-precision work.

From Prototype To Production With Reliable Lead Times

Ready to move from design to build? Modern CNC shops with 4- and 5-axis capabilities can machine intricate 6061 parts with speed and repeatability, whether you need a single prototype or a production batch. For complex geometries, multi-axis machining reduces setups and improves accuracy, making it easier to hit aggressive deadlines.

Looking for where to buy aluminum sheets or custom 1/2 aluminum plate components? Partnering with a reputable CNC service provider can streamline the entire process. For example, XTJ’s CNC machining services offer ISO 9001 & IATF 16949 certified production, rapid lead times, and the ability to handle demanding 6061 projects with ultra-tight tolerances. Their 4- and 5-axis machining centers are ideal for precision bores, thin walls, and complex features—especially when machining from stable T651 plate.

Pro tip: Always review your drawings and functional requirements with your CNC partner. Confirm that tolerances, surface finishes, and material specs are realistic for your application—whether you’re ordering an aluminum 1/2 plate for a fixture or a 1/4 inch aluminum plate for a lightweight cover.

By combining thoughtful DFM, material selection, and the right CNC capabilities, you’ll unlock the true value of aluminium al 6061—from rapid prototyping to production-scale manufacturing. This approach ensures your final parts deliver on both performance and reliability, no matter how complex the design.

Frequently Asked Questions About Aluminium Al 6061

1. What is 6061 aluminium alloy commonly used for?

6061 aluminium alloy is widely used for structural components, machined parts, frames, and extrusions in industries like aerospace, automotive, marine, and consumer electronics. Its balanced strength, corrosion resistance, and excellent machinability make it ideal for applications such as brackets, bike frames, and panels.

2. How does 6061 compare to other aluminum alloys like 5052, 6063, or 7075?

6061 stands out for its balance of strength, weldability, and machinability. While 5052 offers better formability and corrosion resistance, 6063 is preferred for superior surface finish in extrusions. 7075 and 2024 provide higher strength but are less weldable and more prone to corrosion. Choose 6061 for general-purpose engineering and CNC machining.

3. What are the main tempers of 6061 aluminum and how do they differ?

The most common tempers are O (annealed, maximized ductility), T4 (solution heat-treated, naturally aged), T6 (solution heat-treated, artificially aged for maximum strength), and T651 (T6 plus stress relief for dimensional stability). T6 is popular for strength, while T651 is preferred for precision machining.

4. Is 6061 aluminum easy to machine and weld?

Yes, 6061 is known for its excellent machinability, especially in the T651 temper, which minimizes warping. It is also weldable with appropriate filler materials, but care must be taken to control heat input and post-weld treatments to maintain strength and alignment.

5. What should I consider when selecting aluminum 6061 for CNC machining projects?

When designing for CNC with 6061, use consistent wall thickness, generous fillets, and realistic tolerances. T651 plate is ideal for stability. Partnering with a CNC service provider experienced in aluminum machining, such as those offering 4- and 5-axis capabilities, ensures precision and quality for both prototypes and production.

-

Posted in

6061 aluminum properties, aluminium al 6061, aluminum alloy comparison, CNC aluminum, machining aluminum