Corrosion Of Aluminium Metal: 9 Essential Points For Engineers

Does Aluminum Rust or Corrode?

Corrosion vs Rust Definitions Made Simple

When you hear the words “aluminum rust” or “does aluminum rust,” it’s easy to assume that all metals degrade in the same way. But the truth is more nuanced—and critical for engineers to understand. Let’s break down the key definitions:

- Corrosion: The general process where metals deteriorate due to chemical reactions with their environment, often involving oxygen and moisture.

- Rust: A specific type of corrosion that only affects iron and its alloys (like steel). It results in reddish-brown iron oxides.

- Oxidation: The reaction of a metal with oxygen. For aluminum, this is not rust, but the formation of a protective oxide layer.

Key myth: Aluminum cannot form iron-oxide rust because it contains no iron. So, while “aluminum rust” is a common phrase, it’s technically incorrect.

Why Aluminum Does Not Rust Yet Still Corrodes

Imagine you install an aluminum extrusion or sheet in a humid environment. You’ll notice it doesn’t flake away in the same way as rusted steel. That’s because aluminum, when exposed to air or water, instantly reacts with oxygen to form a thin, hard film of aluminum oxide (Al2O3), also called a passive layer. This process is called aluminum oxidation and happens almost immediately—sometimes in fractions of a second after the surface is exposed.

- This oxide film is typically just a few nanometers thick but is continuous and tightly adherent to the metal surface.

- The passive film is chemically stable in most neutral environments, acting as a barrier against further attack.

- Unlike rust on steel, this layer does not flake off; instead, it protects the underlying metal.

However, under certain aggressive conditions—such as exposure to chlorides (like saltwater) or strong acids/bases—the protective oxide can break down. When that happens, the corrosion of aluminium metal can proceed, sometimes leading to pitting or localized attack.

Key Takeaway: Aluminum does not rust, but it does corrode. Its natural oxide film is both its greatest defense and, under harsh conditions, its potential weakness. When intact, this film makes oxidized aluminum highly resistant to further damage. But if the film is breached and cannot self-repair, corrosion can progress rapidly.

What Oxidized Aluminum Looks Like in Practice

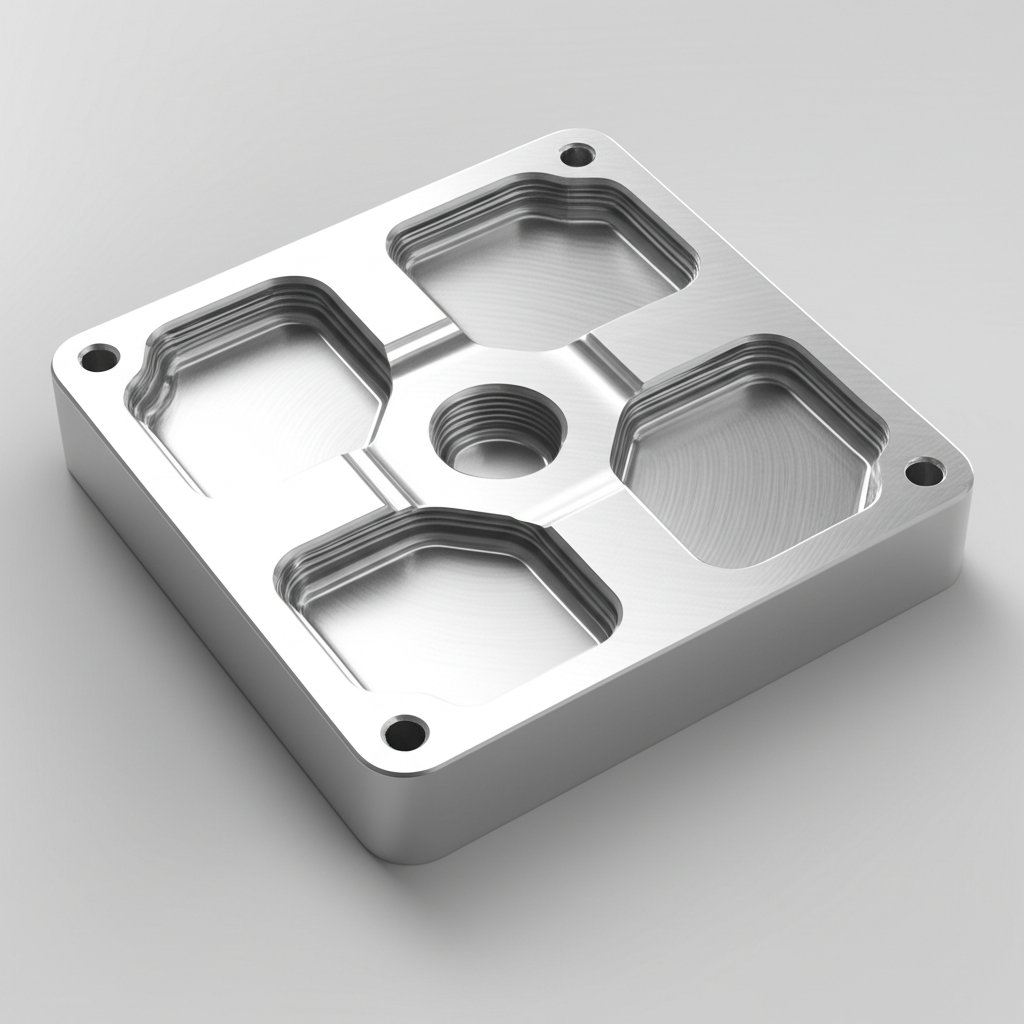

So, what should you expect to see on real-world aluminum surfaces? On architectural panels, machined parts, or castings, oxidized aluminum often appears as a dull, whitish or grayish surface—sometimes with a powdery residue. Unlike rust, which is reddish and flaky, this oxide film is thin, hard, and typically uniform unless attacked by aggressive agents.

- Sheet aluminum: Usually displays a matte, silvery-gray patina from the oxide film.

- Castings: May show more pronounced white spots or patches if exposed to moisture or contaminants.

- Extrusions: Retain a consistent finish unless scratched or exposed to corrosive environments.

In summary, while “does aluminium rust” is a frequent question, the answer is a technical no. Instead, focus on understanding how aluminum oxidation provides both protection and, in rare cases, the starting point for deeper corrosion. This knowledge is foundational for all subsequent design, maintenance, and material selection decisions involving the corrosion of aluminium metal.

Understand the Mechanisms That Drive Material Loss in Aluminum

Passive Film Formation and Breakdown

When you think about oxidation in aluminum, imagine a shield that forms instantly as soon as bare metal meets air or water. This ultra-thin passive film of aluminum oxide is the main reason aluminum corrodes much more slowly than iron. But what happens when this film is damaged or exposed to aggressive environments?

- Film Formation: Aluminum naturally forms a continuous oxide layer (Al2O3) that’s only a few nanometers thick, but it’s dense and adherent.

- Film Breakdown: Chlorides (from saltwater or de-icing salts), acidic/alkaline environments, or mechanical damage can locally dissolve or disrupt this protective film.

- Result: Once the film is breached, the underlying aluminum is exposed to further attack, often leading to localized types of aluminum corrosion such as pitting or crevice corrosion.

Pitting and Crevice Corrosion in Chloride Media

Have you ever noticed tiny holes or dark spots on aluminum surfaces exposed to road salt or seawater? That’s pitting corrosion aluminum in action. It’s a localized attack where the passive film is penetrated, usually by chloride ions, resulting in small but deep pits. These pits can be hard to spot at first but may grow and compromise the integrity of the metal over time.

- Triggers: Chloride-rich environments (marine/coastal, road salts), stagnant water, or surface defects.

- Telltale Signs: Pinpoint holes, white or dark deposits, rough surface texture.

- Common Locations: Edges, under gaskets or washers, lap joints, and beneath deposits.

Crevice corrosion is similar but occurs in shielded areas—think under bolts, in lap joints, or where debris traps moisture. Low oxygen and high chloride concentrations inside crevices accelerate the attack, sometimes leading to rapid material loss in hidden spots.

Intergranular and Exfoliation Corrosion

Picture a cross-section of an aluminum part, and imagine corrosion spreading along the boundaries between grains rather than across the surface. That’s intergranular corrosion (sometimes called intercrystalline corrosion). It starts at the grain boundaries, often due to alloy composition or improper heat treatment, and can cause the metal to lose strength without much visible change on the surface.

- Triggers: Sensitization (precipitation of certain phases at grain boundaries), high-magnesium or high-copper alloys, improper processing.

- Telltale Signs: Loss of ductility, cracks, or delamination, especially in rolled or extruded products.

- Common Locations: Wrought products (sheet, plate, extrusions), especially in 2xxx, 5xxx, and 7xxx series alloys.

Exfoliation corrosion is a more severe form, where corrosion products build up between elongated grains, causing the surface to lift or flake off—much like layers peeling from an onion. It’s particularly aggressive in rolled or extruded sections and can quickly undermine structural integrity.

Stress Corrosion Cracking (SCC)

Imagine a high-strength aluminum part under constant tension—like a wing spar or pressure vessel—exposed to a humid or salty environment. Over time, cracks might appear and propagate, sometimes with little warning. This is stress corrosion cracking (SCC), a dangerous mode where the combination of tensile stress, a susceptible alloy, and a corrosive environment causes cracks to form and grow, often along grain boundaries (Total Materia).

- Triggers: High-strength alloys (notably 2xxx and 7xxx series), sustained tensile stress, humid or chloride-laden environments.

- Telltale Signs: Fine cracks, often branching or following grain boundaries, sometimes with little visible surface corrosion.

- Common Locations: Aerospace structures, pressure vessels, and any application with sustained loads and exposure to aggressive environments.

| Corrosion Mechanism | Typical Triggers | Telltale Signs | Common Locations |

|---|---|---|---|

| Passive Film Breakdown | Chlorides, acids, mechanical damage | Localized surface dulling, start of pits | Anywhere exposed to aggressive agents |

| Pitting Corrosion | Saltwater, road salts, surface defects | Tiny pits, white/dark spots | Edges, under deposits, splash zones |

| Crevice Corrosion | Low-oxygen gaps, trapped moisture | Hidden material loss, roughness | Lap joints, under gaskets/washers |

| Intergranular/Exfoliation Corrosion | Sensitized alloys, improper heat treatment | Loss of ductility, flaking, delamination | Wrought products, rolled/extruded sections |

| Stress Corrosion Cracking | High-strength alloys, sustained stress, humidity | Fine cracks, sudden failure | Loaded aerospace/structural parts |

Understanding these mechanisms helps you recognize why aluminum corrodes in different ways and how each type of attack relates to specific service conditions. This mental model is essential for diagnosing failures, planning inspections, and choosing the right alloy or protection strategy for your application. Next, we’ll map these mechanisms to real-world environments and explore how to mitigate them before they become costly problems.

Relate Environments to Risk and Mitigation Tactics

Marine and Coastal Exposure Patterns

When you picture aluminum in harsh environments, the coast is often the first setting that comes to mind. But why is aluminum corrosion salt water such a concern—even though aluminum is known for its corrosion resistance? The answer lies in the unique chemistry of seawater and the way it interacts with aluminum's passive oxide film.

- Chloride ions—The main cause is the salt in seawater, whose total salinity is typically 30-35 g/L, with chloride ions being the most corrosive component. They aggressively attack the oxide layer, leading to pitting corrosion, especially where the film is thin or damaged (Alcan Marine).

- In tidal zones and splash areas, wet-dry cycles repeatedly break and reform the oxide film, making these areas more susceptible to localized attack.

- Stagnant pockets—like crevices, lap joints, or under deposits—trap water and exclude oxygen, promoting crevice corrosion.

Despite these risks, well-chosen aluminum alloys (notably the 5000 and 6000 series) can last for decades in marine service if proper design and protection measures are in place. Still, it’s crucial to avoid design traps that retain water and to use compatible coatings or sealants in high-risk areas.

Industrial Atmospheres and Acidic Byproducts

Now, imagine aluminum structures in a city or near an industrial plant. Here, airborne pollutants like sulfur oxides (SOx) and nitrogen oxides (NOx) mix with moisture to form acidic deposits. How does this change the equation?

- Acidic rain or dust can lower the pH at the metal’s surface, destabilizing the passive oxide layer and increasing the risk of uniform corrosion or pitting (ScienceDirect).

- Industrial particulates can act as deposits, creating micro-environments where water gets trapped, oxygen is depleted, and corrosion accelerates underneath.

- Sulfate ions, interestingly, may inhibit pitting to some extent, but this effect is often overshadowed by the presence of chlorides and fluctuating pH.

Frequent inspection and cleaning, along with the use of robust coatings or conversion treatments, are key mitigation strategies in these environments.

Freshwater Systems and Stagnant Water Risks

Does aluminum rust in water, or is it immune in freshwater service? The answer depends on water chemistry, flow, and maintenance. In pure, well-oxygenated water, aluminum is highly resistant. But in real-world systems, risks remain:

- Low pH (below ~4) or high pH (above ~8.5) can dissolve the oxide film, making the metal vulnerable to corrosion by water.

- Stagnant water (think dead legs in piping or closed tanks) quickly loses oxygen, favoring crevice and under-deposit corrosion.

- Even trace amounts of dissolved copper or other noble metal ions (as low as 20 ppb Cu2+) can trigger galvanic corrosion on aluminum surfaces.

To prevent these issues, ensure good circulation, avoid stagnant zones, and select water treatment chemistries that don’t destabilize the oxide film.

| Environment | Dominant Species/Trigger | Common Failure Modes | Mitigation Tactics |

|---|---|---|---|

| Marine/Coastal | Chloride (30–35 g/L), wet-dry cycles | Pitting, crevice, waterline corrosion | Drainage design, sealants, marine-grade coatings, alloy selection |

| Industrial | SOx/NOx, acidic particulates, dust | Uniform corrosion, pitting under deposits | Frequent cleaning, robust coatings, avoid dust traps |

| Freshwater/Service Water | Low/high pH, stagnant zones, dissolved metals | Crevice, under-deposit, galvanic corrosion | Good circulation, compatible water treatment, non-metallic isolation |

So, will aluminum rust in water? Not in the traditional sense, but it can corrode—sometimes rapidly—if the passive film is compromised by chemistry, contaminants, or poor design. That’s why it’s vital to match the alloy and protection system to the specific environment and to address known risks during design and maintenance.

Next, we’ll explore how galvanic coupling with other metals can further complicate the picture and what you can do to prevent those surprise failures.

Master Galvanic Corrosion Risks and Prevent Them

Common Metal Pairings That Accelerate Attack

Have you ever wondered why mixing aluminum and stainless steel in a damp environment sometimes leads to rapid, unexpected failure? The answer is galvanic corrosion—a process that can quietly attack the less noble metal (aluminum) when it’s paired with a more noble metal (like stainless steel or copper) in the presence of moisture. Sounds complex? Let’s break it down.

The galvanic series is a ranking of metals by their tendency to corrode in an electrolyte, such as water or saltwater. Aluminum sits toward the anodic (less noble) end, while stainless steel, copper, and brass are more cathodic (noble). When two dissimilar metals are electrically connected and exposed to an electrolyte, the less noble metal (the anode) corrodes faster—this is the essence of galvanic corrosion of aluminum.

| Metal Pairing | Galvanic Risk (Humid) |

Galvanic Risk (Splash/Marine) |

Galvanic Risk (Immersed) |

Preferred Mitigations |

|---|---|---|---|---|

| Aluminum + Stainless Steel | Moderate | High | Very High | Isolate with coatings, washers; minimize electrolyte exposure |

| Aluminum + Carbon Steel | Moderate | High | High | Insulate, coat both surfaces, use inhibitors |

| Aluminum + Copper/Brass | High | Very High | Very High | Strict isolation, avoid direct contact, use sacrificial anodes if needed |

For example, stainless steel and aluminum corrosion is especially aggressive in marine or splash-prone environments. The risk increases when the aluminum surface area is small compared to the stainless steel (such as aluminum rivets in a large steel plate)—the smaller the anode, the faster it will corrode. On the other hand, using stainless steel bolts in a large aluminum structure is less risky, provided the environment is not highly corrosive.

Area Ratio, Water Traps, and Runoff Paths

Imagine you’re assembling a structure: you use a few aluminum fasteners on a large stainless steel panel. In a salty or humid environment, those fasteners will deteriorate quickly due to the area ratio effect. Why? Because the corrosion current is concentrated on the small anodic (aluminum) area, accelerating material loss. The opposite setup—a few stainless fasteners in a large aluminum surface—poses less risk, but vigilance is still needed if water is present.

Water traps, such as crevices or poorly drained joints, also increase the risk of galvanic corrosion on aluminum. These traps retain electrolytes, keeping the metals in electrical and ionic contact. Good drainage and design that avoids stagnant water are essential to minimizing steel aluminium corrosion.

Isolation, Fasteners, and Barrier Materials

So, how do you prevent galvanic corrosion without giving up the benefits of mixed-metal construction? Here are proven tactics you can use during design, assembly, or maintenance:

- Non-conductive washers and sleeves: Use nylon, rubber, or plastic washers and sleeves to separate fasteners from the base metal.

- Sealants and coatings: Apply insulating paints, primers, or corrosion-inhibiting pastes to both mating surfaces before assembly.

- Tapes and gaskets: Polypropylene or other non-absorbent tapes/gaskets break electrical contact and block moisture ingress.

- Continuous protective coatings: Make sure paint or anodizing is unbroken at joints—any gap becomes a corrosion hotspot.

- Good drainage: Design joints and assemblies to shed water, avoiding crevices and stagnant zones wherever possible.

When you’re forced to pair aluminum with more noble metals, always check for the presence of electrolytes (water, condensation, salt spray) and use multiple barriers if the environment is harsh. Regular inspection and maintenance of these barriers are just as important as their initial application.

Key Takeaway: Galvanic corrosion of aluminum is preventable. Understand the metals you’re joining, control the area ratio, isolate them electrically, and keep water out. These simple steps can add years to the life of your aluminum assemblies and avoid costly, surprise failures.

Next, we’ll shift focus to alloy selection—because not all aluminum grades offer the same resistance to corrosion, especially when dissimilar metal contact is unavoidable.

Choose the Right Aluminum Alloy for Durability in Corrosive Environments

How Alloy Chemistry Drives Corrosion Behavior

Ever wondered why some aluminum alloys last for decades in marine or industrial environments, while others fail quickly? The answer comes down to the chemistry behind each aluminum alloy. Different types of aluminum are created by adding elements like magnesium, manganese, copper, silicon, or zinc. These additions tune mechanical properties, but they also have a dramatic effect on how resistant each alloy is to corrosion.

- 1xxx Series (Commercially Pure Aluminum): Contains 99% or more aluminum. These alloys are highly resistant to corrosion but have lower strength. They’re ideal where electrical conductivity and formability matter more than toughness—think enclosures or conductors.

- 3xxx Series (Al-Mn): Adding manganese improves strength while maintaining good corrosion resistance. Common in cookware, automotive trim, and heat exchangers.

- 5xxx Series (Al-Mg): Magnesium boosts both strength and corrosion resistance, especially in marine and industrial settings. These aluminium alloys are widely used in shipbuilding and storage tanks.

- 6xxx Series (Al-Mg-Si): Silicon and magnesium make these alloys heat-treatable and versatile. Their corrosion resistance is moderate—better than copper-rich alloys but not as robust as 1xxx or 5xxx. 6061 is a workhorse for structural and automotive parts.

- 2xxx Series (Al-Cu): Copper greatly increases strength, making these popular in aerospace. However, copper also makes the alloy more prone to corrosion, especially in marine or industrial atmospheres. Protective coatings are often required.

- 7xxx Series (Al-Zn): Zinc (often with magnesium and copper) delivers the highest strength, but these alloys are the most susceptible to localized corrosion and stress corrosion cracking (SCC) unless carefully protected. Used heavily in aerospace applications.

So, is aluminium corrosion resistant? The answer depends on the alloy—some are exceptionally durable, while others need extra care or coatings to survive harsh environments.

Pitting, Intergranular, Exfoliation, and SCC Trends

Not all corrosion is created equal. Some alloys are more vulnerable to specific attack modes. Here’s how the most common families stack up for key corrosion risks:

| Alloy Series | Pitting | Crevice | Intergranular/Exfoliation | Stress Corrosion Cracking (SCC) | Notes |

|---|---|---|---|---|---|

| 1xxx | Low | Low | Low | Low | Excellent corrosion resistance; low strength |

| 3xxx | Low | Low | Low | Low | Good general resistance; common in cookware and heat exchangers |

| 5xxx | Low | Low-Moderate | Moderate (if sensitized) | Low (can be high if sensitized) | Excellent in marine settings; beware of sensitization in high-Mg grades |

| 6xxx | Moderate | Moderate | Moderate | Low-Moderate | Versatile; 6061 widely used; moderate aluminum corrosion resistance |

| 2xxx | High | High | High | High | High strength, but needs coating; sensitive to SCC and pitting |

| 7xxx | High | High | High | High | Highest strength; most vulnerable to localized attack and SCC |

- Pitting & Crevice Corrosion: Most severe in 2xxx and 7xxx series, especially in chloride-rich (marine) environments. 5xxx and 6xxx perform better, but even they can pit if exposed to aggressive ions or stagnant water.

- Intergranular/Exfoliation: A risk for high-strength alloys (2xxx/7xxx) and for 5xxx if sensitized by improper processing.

- SCC: Stress corrosion cracking is a special concern for aerospace-grade 2xxx and 7xxx, especially under sustained loads and humidity.

Understanding these trends helps you select the right alloy and protection strategy for your application, whether you’re building a marine structure, a pressure vessel, or a lightweight frame.

Cast vs Wrought Considerations

Imagine you’re choosing between a cast aluminum pump housing and a wrought (rolled or extruded) beam. Does the manufacturing method matter for corrosion? Absolutely. Cast alloys, often rich in silicon, generally offer good resistance to uniform corrosion but may contain microstructural features (like porosity or intermetallics) that can act as corrosion initiation sites. Wrought alloys, especially those in the 5xxx and 6xxx series, are engineered for a balance of strength and corrosion resistance, but their performance can be compromised if not processed or heat-treated correctly.

In summary, the corrosion resistance of aluminum alloys is a direct result of both their chemical composition and their processing. Always consult corrosion data and, when in doubt, request corrosion testing for your specific application environment.

Key Takeaway: Not all aluminum alloys are created equal. For optimal aluminum alloy corrosion resistance, match the alloy series to your environment and loading conditions, and always consider both composition and processing history. In the next section, we’ll explore how to spot corrosion early and implement effective inspection routines to keep your assets safe and reliable.

Adopt a Repeatable Inspection and Monitoring Workflow for Aluminum Corrosion

Visual Cues and Early Warning Signs

When you walk up to an aluminum structure—be it a marine hull, architectural panel, or aircraft skin—what should you look for first? Recognizing early symptoms of the corrosion of aluminium metal is essential for timely intervention and long-term durability. Unlike the red flakes of rust on steel, aluminum corrosion usually presents as subtle surface changes. But don’t let these faint cues fool you; hidden damage can escalate quickly if left unchecked.

- White or grayish surface deposits: These are classic signs of oxidized aluminum. Sometimes called white rust aluminum, these powdery or chalky residues signal the breakdown of the protective oxide layer.

- Dullness or loss of luster: Fresh aluminum is bright and reflective, but oxidation on aluminium causes a matte or frosted appearance. This is especially visible on extrusions and sheet products.

- Aluminum stain or discoloration: Look for darker streaks, water marks, or blotchy patches. These can indicate water retention, chemical attack, or the presence of contaminants.

- Blisters or underfilm bubbles: Swelling under paint or coating may mean corrosion products are accumulating beneath, lifting the finish.

- Pitting or pinhole clusters: Tiny holes or rough spots, especially in splash zones or near fasteners, are often the first visible evidence of pitting corrosion.

- Dissimilar metal staining: Blue-green or dark stains near steel, copper, or brass fittings suggest galvanic activity and should be investigated.

Measuring Pits, Crevices, and Coating Condition

Once you spot a potential issue, how do you quantify it? Sounds complex, but with a systematic approach, you can turn subjective impressions into actionable data. Here’s a practical, field-ready checklist for inspecting aluminum surfaces:

- Prepare the area: Clean the surface gently with a non-metallic brush or mild detergent to remove loose debris, stains, or oxidation on metal. Avoid harsh abrasives that could damage the oxide film.

- Lighting and access: Use bright, angled lighting to highlight surface irregularities. Move around the structure to catch reflections and shadows that reveal pits or blisters.

- Visual examination: Scan for the red flags listed above. Pay special attention to lap joints, fastener heads, drain holes, and areas under gaskets or sealant beads.

- Pit and crevice measurement: Use a magnifier (4–10x) and a depth gauge or needle probe to size pits. According to industry standards, pits deeper than 10% of the sheet thickness or wider than 3 mm may require engineering review.

- Coating adhesion check: Lightly tap or press on painted areas. If the coating lifts, blisters, or peels, note the extent and location.

- Photographic documentation: Take clear, close-up photos of affected areas, including a scale or ruler for reference. This helps with trending and communication.

- Record findings: Log all symptoms, measurements, and locations in an inspection report. Note environmental conditions (humidity, temperature, recent exposure) for context.

- Set follow-up intervals: If minor corrosion is found, schedule re-inspection in 3–6 months. For significant or advancing damage, plan immediate remediation or engineering review.

-

Red Flags to Watch For:

- White or gray powder (white rust aluminum)

- Underfilm blisters or bubbles

- Pinhole clusters or deep pits

- Staining near dissimilar metal contacts

- Loss of coating adhesion or flaking

- Cracking or delamination, especially near fasteners

If localized pitting clusters are found in splash zones, schedule coating repair and galvanic isolation measures. For any area where pits exceed 10% of the material thickness or where cracking is present, consult engineering standards or a qualified DER before returning the part to service.

Recording, Trending, and Deciding Next Steps

Consistent documentation is your best defense against unexpected failures. By recording each finding—no matter how minor—you can spot trends, identify recurring problem areas, and justify preventative maintenance before costly repairs are needed. Many organizations use digital inspection forms or asset management software to streamline this process.

- Trend analysis: Compare current findings with previous inspections. Are pits growing? Is aluminum stain spreading? Are new areas of oxidation on aluminium appearing?

- Action thresholds: Use accepted industry standards (such as ASTM G46 for pitting or G69 for corrosion potential) to set criteria for repair, recoating, or replacement (ASTM).

- Consult standards and experts: When in doubt, reference the manufacturer’s maintenance manual, AC 43.13-1B, or relevant ASTM/ISO standards for acceptance limits and remediation protocols.

By following this repeatable workflow, you’ll turn what could be a guessing game into a reliable process—catching corrosion early, extending service life, and keeping your aluminum assets safe. Next, we’ll look at how to prevent these issues in the first place through smart design and protective finishes.

Prevent Corrosion with Smart Design and Proven Finishes

Design Out the Problem with Drainage and Geometry

Ever noticed how water tends to collect in corners or crevices, and then—over time—those are the first places you see signs of corrosion? That’s no coincidence. When you’re thinking about how to prevent aluminum corrosion, smart design is your first line of defense. By minimizing features that trap water or debris, you can dramatically reduce the risk of corrosion of aluminium metal.

- Ensure proper drainage: Slope surfaces and add drain holes to prevent standing water.

- Avoid crevices: Use continuous welds or sealant in lap joints, and design assemblies to minimize tight gaps where moisture can linger.

- Isolate dissimilar metals: Preventing electrolytic corrosion starts with breaking the electrical path between aluminum and more noble metals—think plastic washers, gaskets, or sealant beads between fasteners and base material.

Conversion Coatings and Anodizing Selection

When environmental exposure is unavoidable, surface treatments add a critical layer of aluminum corrosion protection. But which finish is best for your application? Here’s a quick overview of the most effective options, each with its own strengths and ideal uses.

| Treatment Type | Best for Environment Severity | Repairability | Typical Applications | Notes / Common Failure Modes |

|---|---|---|---|---|

| Anodizing (Type II/III) | Moderate to severe (outdoor, marine) | Low (must be reapplied professionally) | Architectural panels, marine parts, electronics | Excellent wear/corrosion resistance; edge creep if film is breached |

| Conversion Coating (Chromate/Non-chromate) | Mild to moderate (indoor, prep for painting) | Moderate (can spot repair) | Aerospace, automotive, as primer for paint | Good paint adhesion; underfilm corrosion if damaged |

| Powder Coating | Moderate to severe (industrial, outdoor) | Moderate (can touch up chips) | Appliances, outdoor furniture, machinery | Thick, durable; risk of edge chipping or underfilm attack |

| Organic Coatings (Paint, Lacquer) | Mild to moderate | High (easy to recoat) | Household goods, interior panels | Lower durability; frequent maintenance needed |

| Nano-Ceramic Coating | Severe (abrasion, marine, high-performance) | Low (specialized repair) | Aerospace, automotive, digital displays | Exceptional hardness; advanced option, higher cost |

Surface prep essentials: For any aluminium protective coating to perform, start with a clean surface. Degrease, deoxidize, and activate the aluminum to ensure strong adhesion—skipping these steps can lead to premature failure.

Anodizing is an electrochemical process that builds up the natural oxide layer, making it much thicker and more protective. This layer is durable, non-conductive, and can even be dyed for aesthetics. For marine or outdoor uses, sealed anodizing is best, as it resists both corrosion and wear.

Conversion coatings (such as chromate or newer non-chromate formulas) are often used as a primer for paint or powder coatings. They enhance paint adhesion and add a sacrificial barrier, but must be applied carefully to avoid gaps or thin spots.

Organic Primers, Topcoats, and Sealants

Sometimes, a layered approach is the most effective aluminum corrosion treatment. Organic coatings—like epoxy or polyurethane paints—provide a flexible, colorful barrier that can be easily touched up. Powder coatings take this a step further, offering a thick, chip-resistant finish for high-wear environments. For long-term aluminium corrosion prevention, consider using corrosion-inhibiting primers under your topcoats, especially in marine or industrial applications.

Sealants and gaskets are essential wherever aluminum meets other metals or where water might intrude. Look for compatible products that maintain flexibility and adhesion over time, even after repeated wet/dry cycles or thermal expansion.

-

Isolation tactics for joints and fasteners:

- Plastic or rubber washers and bushings

- Non-conductive gaskets

- Sealant beads under bolt heads and washers

- Dielectric pastes or anti-corrosion greases

Cathodic Protection for Immersed Aluminum

For structures submerged in water—think marine hulls or buried piping—cathodic protection offers another layer of defense. By attaching a more reactive “sacrificial” metal (like zinc or magnesium), you can ensure that the anode corrodes instead of your aluminum structure. This is a proven method for how to protect aluminum from corrosion in the harshest environments, but it requires regular inspection and replacement of the sacrificial anodes.

Key Takeaway: Effective aluminum corrosion protection is never one-size-fits-all. Start with smart design—eliminate water traps and isolate dissimilar metals. Then, select a robust protection stack: anodizing for marine or outdoor use, conversion coatings plus paint for industrial service, or powder/nano-ceramic coatings for extreme durability. Layered defenses, routine maintenance, and proactive inspection are your best strategies for aluminium corrosion treatment that stands the test of time.

Up next, we’ll walk through a controlled, step-by-step process for repairing corroded aluminum—ensuring safety, longevity, and restored performance.

Repair Corroded Aluminum with a Controlled Process

Stabilize the Environment and Prepare the Surface

When you spot aluminum corroded or showing signs of chalky, white, or dull patches, it’s tempting to jump straight into aggressive cleaning. But a rushed approach can make things worse, especially with sensitive alloys or critical components. The key to successful aluminum corrosion removal is a stepwise, conservative process that preserves both safety and long-term performance.

- Isolate and dry the area: If the item is in service, disconnect it from sources of moisture or chemicals. Allow the surface to dry thoroughly; moisture can accelerate further corrosion and make cleaning less effective (DST Chemicals).

- Degrease gently: Use a mild detergent or commercial aluminum cleaner with warm water to remove oils, dirt, and surface contaminants. Avoid harsh chemicals that might attack the aluminum or its oxide film.

Remove Corrosion Products Without Embedding Iron

- Mechanical removal: For light oxidation or surface corrosion, use non-abrasive pads, soft nylon brushes, or fine-grade non-ferrous abrasives. For more stubborn cases, a paste of baking soda and water or a solution of vinegar/lemon juice and water can help lift oxidation. Gently scrub in the direction of the grain to minimize scratching.

- Chemical deoxidizing (if needed): For severe cases—such as heavy, chalky buildup or water-stain corrosion—a commercial aluminum brightener or a mild acid solution (like diluted vinegar or lemon juice) may be used. Always rinse thoroughly to remove any chemical residue.

- Rinse and dry: After each cleaning or chemical step, rinse the surface with clean water and dry with a soft, lint-free cloth to prevent water spots and further oxidation.

-

Do not:

- Use steel wire brushes or steel wool, which can embed iron and trigger further corrosion (leading to a rusted aluminum appearance).

- Trap moisture under sealants or coatings—ensure surfaces are completely dry before recoating.

- Skip steps or mix cleaning agents without verifying compatibility.

- Allow recontamination between steps—use clean tools and gloves throughout.

Restore Protection and Verify Results

- Apply protective coatings: Once clean and dry, restore protection by applying an appropriate finish. For industrial or marine parts, consider conversion coatings (chromate or non-chromate), anodizing, or a high-quality primer and topcoat. For cookware or food-contact items, use only food-safe polishes and, if needed, a clear sealant.

- Inspect and document: Carefully inspect the repaired area for uniformity, coating adhesion, and absence of moisture. Take photos and log the repair details for future reference.

- Schedule follow-up: Plan a re-inspection at regular intervals—especially if the environment is harsh or if the original corrosion was extensive. Early detection of recurring issues can save significant time and cost later.

Key Decision: If pits coalesce, crack indications appear, or corrosion removal on aluminum reveals thinning beyond 10% of material thickness, stop-work and consult engineering or relevant standards before reuse. Safety and structural integrity must always come first.

By following this controlled process, you’ll not only remove corrosion from aluminum but also minimize the risk of recurrence. Whether you’re cleaning corroded aluminum in a food facility, restoring a marine component, or maintaining architectural panels, these steps help ensure that even aluminium rusty from years of neglect can be safely returned to service—without introducing new problems. Next, we’ll look at how design and manufacturing practices can further reduce the risk of aluminum corrosion from the very start.

Design and Machining Choices That Curb Corrosion Risk

DFM Moves That Improve Corrosion Performance

Ever wondered why some aluminum parts last for decades, while others succumb to corrosion in just a few years? The answer often lies in the earliest stages—design for manufacturing (DFM) and machining. By making thoughtful design and process choices, you can dramatically improve the corrosion resistance of aluminium, even in tough environments where stainless and aluminium corrosion or aluminium steel corrosion are common concerns.

- Specify fillets and drain paths: Rounded internal corners (fillets) and sloped surfaces help water flow away, reducing moisture traps that can accelerate corrosion.

- Avoid moisture traps: Design out undercuts, deep pockets, and tight crevices where water or contaminants could linger.

- Call out surface roughness targets: Smoother surfaces allow coatings to adhere better and reduce the initiation sites for corrosion, especially in aluminum and copper corrosion-prone assemblies.

- Require non-ferrous tooling/brushes: Always specify the use of non-steel tools during finishing to prevent iron embedding, which can trigger aluminum and brass reaction or unwanted galvanic cells.

- Include post-machining cleaning and finishing: Clearly note on drawings that parts must be cleaned of cutting fluids, chips, and residues before any coating or assembly process.

By integrating these steps into your process plans, you lay the foundation for corrosion resistant aluminium, regardless of the alloy or environment.

Machining Practices That Reduce Post-Process Risk

Machining isn’t just about shaping metal—it’s about controlling every variable that might affect the long-term durability of your part. Surface finish, residual stresses, and contamination all play a role in how well your aluminum resists corrosion. For example, rough or scored surfaces can hold onto moisture, making the answer to "is aluminum waterproof" less straightforward in real-world service (ScienceDirect).

- Minimize surface roughness: Specify a fine finish (Ra ≤ 1.6 µm) on exposed or coated surfaces to help coatings wet uniformly and seal the metal from corrosive agents.

- Control residual stresses: Use proper cutting parameters and consider stress-relief treatments to reduce microcracking or warping, which can open up new corrosion pathways.

- Prevent cross-contamination: Segregate aluminum machining from ferrous metals to avoid accidental transfer of iron particles, which may trigger aluminium steel reaction or accelerate local corrosion.

- Thorough cleaning: Mandate post-machine washing with deionized water or approved cleaners to remove all traces of machining fluids and chips before finishing or assembly.

These steps are especially vital when your design includes joints with other metals, such as aluminum and copper corrosion or stainless and aluminium corrosion interfaces. Precision and cleanliness are your best allies for aluminum corrosion prevention.

Choosing a Partner for Tight Tolerances and Finishes

Not all machining shops are created equal—especially when it comes to complex, high-precision aluminum components that require both corrosion resistance and tight tolerances. Below is a comparison of common manufacturing options to help you make an informed choice:

| Provider | Achievable Tolerances | Surface Finish Control | Material Range | Certification | Finishing Support |

|---|---|---|---|---|---|

| XTJ CNC | Ultra-tight (+/- 0.005mm) | Excellent (Ra ≤ 1.6 µm standard) | 30+ metals and plastics (aluminum, steel, copper, etc.) | ISO 9001:2015, IATF16949 | Full: cleaning, deburring, anodizing, coating, engineering support |

| Generic Job Shop | Standard (+/- 0.05mm) | Variable (often coarser, may require rework) | Limited (common alloys only) | May lack formal certifications | Partial: basic cleaning, limited finishing |

| In-House Machining | Depends on equipment/operator | Highly variable | Depends on stock and tooling | Internal QA only | Often requires external finishing partners |

For projects where corrosion resistant aluminium is a must—especially in assemblies with potential for aluminum and brass reaction or aluminium steel corrosion—partnering with a vendor that offers both precision machining and coordinated finishing is essential. The XTJ CNC team can provide engineering support on alloy selection, post-processing, and finishing strategies to help you achieve robust aluminum corrosion prevention from prototype to production.

Key Takeaway: Effective corrosion control starts with design and continues through machining and finishing. By specifying DFM features, controlling machining variables, and choosing a partner with proven expertise in both precision and protection, you can reduce the risk of galvanic attack, moisture ingress, and premature failure—even in challenging mixed-metal assemblies. Imagine the confidence of knowing your parts are built to last, not just to spec.

Frequently Asked Questions About Corrosion of Aluminium Metal

1. How long does it take for aluminum to start corroding?

Aluminum forms a protective oxide layer almost instantly when exposed to air or water, which significantly slows down corrosion. However, in aggressive environments—such as those containing chlorides or strong acids—corrosion can begin more rapidly if the oxide film is damaged. The visible effects may take years to develop in benign settings, but pitting or localized attack can occur much sooner in harsh conditions.

2. Does aluminum rust like iron or steel?

No, aluminum does not rust because rust refers specifically to iron oxide formation on iron or steel. Instead, aluminum undergoes oxidation, forming a thin, hard aluminum oxide layer that protects it from further attack. In certain environments, this protection can fail, leading to other forms of corrosion such as pitting or crevice corrosion.

3. What environments increase the risk of aluminum corrosion?

Marine and coastal areas with high chloride content, industrial zones with acidic pollutants, and freshwater systems with low pH or stagnant water all increase aluminum corrosion risk. Design features that trap moisture or pair aluminum with dissimilar metals can further accelerate corrosion in these environments.

4. How can aluminum corrosion be prevented in engineering applications?

Prevention involves a combination of smart design—such as ensuring drainage and isolating dissimilar metals—and protective finishes like anodizing, conversion coatings, or robust paints. Regular inspections, proper alloy selection, and the use of sealants or non-conductive fasteners further reduce corrosion risks in demanding environments.

5. What is the best way to repair corroded aluminum components?

Start by isolating and cleaning the affected area with non-ferrous tools, then remove corrosion products using gentle mechanical or chemical methods. Restore protection with suitable coatings or anodizing, and document the repair for future monitoring. For critical parts or severe damage, consult engineering standards to ensure safety and structural integrity before reuse.

-

Posted in

aluminum alloys, aluminum corrosion, corrosion prevention, corrosion repair, galvanic corrosion