Aluminium Melting Point: What Makes It Different Across Alloys?

Aluminium Melting Point Essentials

What aluminium melting point really means

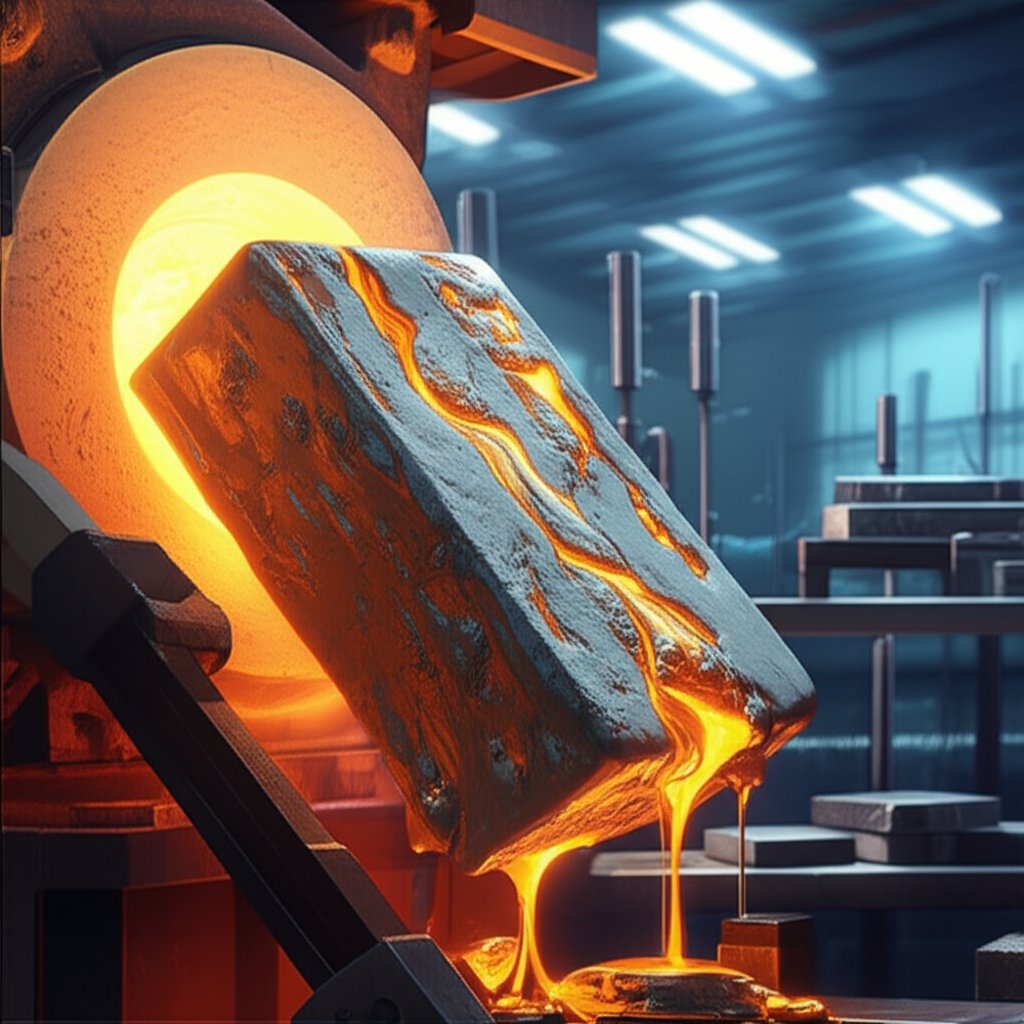

Ever wondered why the aluminium melting point is so crucial in engineering and manufacturing? Imagine you’re designing an aircraft wing or casting an automotive part—knowing exactly when aluminium transitions from solid to liquid can make or break your process. In simple terms, the melting point is the temperature at which a metal changes from a rigid solid to a flowing liquid. For pure aluminium, this temperature is precisely 660.36C (1220.56F), as confirmed by trusted sources like the Tilcon technical overview.

The melting point of aluminium is the specific temperature where it transitions from a solid to a liquid state, enabling casting, welding, and forming processes.

Why does this matter? The melting point directly impacts how aluminium behaves under heat, which influences everything from casting and welding to heat treatment and recycling. If you’re asking, what is the melting point of aluminum?—it’s not just trivia. It’s the foundation for selecting the right materials and processes across industries.

Aluminium vs aluminum spelling for searchers

Confused about whether to type "aluminium" or "aluminum" when searching for information? You’re not alone. Both spellings are correct and refer to the same element, but the choice depends on where you are. "Aluminum" is the preferred spelling in the United States, while "aluminium" is used in the UK and most other English-speaking countries. This difference dates back to early scientific history and was shaped by dictionary choices and official standards, as explained in Gabrian International’s guide. So, whether you search for aluminum melting point or aluminium melting point, you’ll find the right answers.

Purity and the exact melt temperature

Here’s where things get interesting: the melting temperature of aluminum isn’t always a fixed number. The textbook value—660.36C—applies to pure, high-grade aluminium. But in real-world settings, impurities and alloying elements can shift this value slightly. Even trace amounts of elements like iron, silicon, or copper can lower the melting point and change how the metal behaves during heating. This is why the melting temp of aluminum you observe in a lab or factory may vary by a few degrees depending on the sample’s purity and the measurement method used.

- Purity: Higher purity gives a more precise, consistent melting point.

- Oxide skin: The thin, protective oxide layer on aluminium can affect how the surface melts and appears during heating.

- Measurement method: Techniques like Differential Scanning Calorimetry (DSC) or standard furnace tests can yield slightly different results.

So, if you’re comparing the aluminum melting temperature for industrial processes or materials selection, always check the alloy’s composition and the test method used. This ensures your data matches the real-world conditions you’ll face.

In summary, understanding the aluminium melting point is more than just memorizing a number. It’s about knowing how purity, spelling, and measurement all play a role in the science and application of this versatile metal. Whether you call it aluminum or aluminium, the principles remain the same—and mastering them is key to successful engineering and manufacturing.

Alloys and the Realities of Melting Ranges

Solidus vs Liquidus Explained

Sounds complex? Let’s break it down. When you heat up pure aluminum, it melts at a single, precise temperature—660.3°C (1220.5°F)—but most real-world applications use alloys instead of pure metal. That’s where the concepts of solidus and liquidus come in. The solidus is the highest temperature at which an alloy is still completely solid. The liquidus is the lowest temperature at which it’s fully liquid. Between these two points, the alloy exists in a partially melted, mushy state—neither solid nor fully liquid. This range is known as the freezing range or melting temperature range (Lucas Milhaupt).

Unlike pure aluminum, most alloys do not melt at a single point but over a temperature range defined by their solidus and liquidus values.

Why Aluminum Alloys Melt Over a Range

Imagine you’re working with cast aluminum or a high-strength aircraft alloy. You’ll notice that as you heat the material, it doesn’t suddenly liquefy—it softens and partially melts before becoming fully fluid. This is because alloying elements like silicon, magnesium, copper, and zinc disrupt the orderly atomic structure of pure aluminum, causing different parts of the alloy to melt at slightly different temperatures. The result? The melting temperature of aluminum alloys can range anywhere from about 500°C to 650°C, depending on the specific composition and processing history.

- Alloy composition: More alloying elements usually mean a wider melting range and a lower solidus temperature.

- Impurities: Even small amounts of contaminants can shift the melting range downward.

- Heat treatment: Processes like annealing, quenching, and aging change the internal structure, which can subtly affect the melting behavior.

This is why the melting point aluminium you see for a specific alloy is often given as a range, not a single number. For instance, A356 (a popular cast aluminum alloy) melts at a lower temperature than pure aluminum, making it easier to cast but requiring careful temperature control for quality results.

Common Wrought and Cast Alloy Ranges

To make this practical, here’s a summary table showing typical solidus–liquidus ranges for representative wrought and cast aluminum alloys. Always verify with the latest datasheet for your exact alloy and heat treatment state.

| Alloy Series/Grade | Solidus (°C) | Liquidus (°C) | Typical Melting Range (°C) | Notes |

|---|---|---|---|---|

| 1xxx (Pure Al, e.g., 1050) | 643 | 657 | 14 | High purity; narrow range. |

| 2xxx (e.g., 2024) | 502 | 638 | 136 | Cu-rich; wide range. Heat treatable. |

| 5xxx (e.g., 5083) | 570 | 638 | 68 | Mg-rich; good marine resistance. |

| 6xxx (e.g., 6061) | 582 | 652 | 70 | Mg+Si; popular for machining, weldable. |

| 7xxx (e.g., 7075) | 477 | 635 | 158 | Zn-rich; high strength, wide range. |

| Cast A356 | 555 | 615 | 60 | 7% Si; excellent castability. |

| Cast 319 | 515 | 635 | 120 | Si+Cu; auto parts, wide range. |

| Cast 356 | 557 | 613 | 56 | Si-rich; good for precision castings. |

Melting ranges vary with exact alloy chemistry and heat treatment. Always consult your alloy’s datasheet for critical applications.

As you can see, the aluminum melting temp for wrought and cast grades can differ by over 100°C. This affects everything from the choice of furnace temperature to the risk of partial melting during heat treatment. For example, if you’re melting a cast aluminum like A356, you’ll typically target a pouring temperature just above the liquidus—often 680°C to 720°C for best quality.

Understanding these melting temperature ranges is key for anyone working with aluminum alloys, whether you’re casting, welding, or heat treating. It’s the difference between a flawless part and a costly defect. Next, let’s see how phase diagrams and eutectics provide even deeper insight into why these melting behaviors occur.

Why Alloys Melt the Way They Do

Reading Binary Phase Diagrams for Aluminum

When you start working with aluminum alloys, you’ll notice that the melting behavior isn’t as simple as pure aluminum’s sharp transition. Why does this happen? The answer lies in binary phase diagrams. These diagrams map out how two elements—like aluminum and silicon—interact as you heat or cool them. They show where mixtures will start to melt (the solidus) and when they’re fully liquid (the liquidus), revealing the freezing range for each composition. If you’re wondering how metal melting points can vary so much, phase diagrams are your roadmap.

Al–Si Eutectic and Fluidity in Casting

Let’s zoom in on the aluminum–silicon (Al–Si) system, the foundation of many cast aluminum alloys. Here’s where things get interesting: at a silicon content of about 12–13% by weight, the alloy reaches a special composition called the eutectic point—a sweet spot where the mixture melts and solidifies at a single, lower temperature compared to either pure element. According to research compiled in the Al-Si phase diagram, this eutectic temperature is approximately 577°C (Murray & McAlister, 1984).

-

Al–Si system:

- Eutectic at ~12.6% Si, ~577°C

- Narrow freezing range at eutectic; broader range for other compositions

- High silicon improves casting fluidity and reduces shrinkage

Key takeaway: The Al–Si eutectic allows foundries to produce complex castings with excellent flow and minimal hot cracking, making it the go-to choice for engine blocks and transmission cases.

Effects of Cu, Mg, and Zn on Melting Behavior

But aluminum’s story doesn’t end with silicon. Add copper, magnesium, or zinc, and you’ll see even more changes in melting temperature aluminum alloys display. Here’s how each system behaves:

-

Al–Cu system:

- Eutectic at ~33% Cu, ~548°C (Smallman & Ngan, 2014)

- Common alloys (like 2024) melt over a wide range, with solidus as low as 502°C

- Cu increases strength but broadens the melting range and can form brittle intermetallics

-

Al–Mg system:

- Eutectic at ~34% Mg, ~450°C

- Most commercial alloys use much less Mg, so melting points are higher

- Mg enhances corrosion resistance and weldability

-

Al–Zn system:

- Eutectic at ~82% Zn, ~381°C

- High-strength alloys (like 7075) melt over a broad range, with solidus as low as 477°C

- Zn boosts strength but can increase susceptibility to hot cracking

Key takeaway: Alloying with Cu, Mg, or Zn can dramatically lower the onset of melting and expand the freezing range, which means more careful temperature control is needed in processes like welding, forging, and heat treatment.

Why the Oxide Skin Matters: Aluminum Oxide Melting Point

Ever notice that aluminum doesn’t seem to wet or flow easily, even when it’s clearly melted? That’s because of its persistent oxide skin—a thin layer of aluminum oxide (Al2O3). This skin forms instantly in air and has a much higher melting point than the metal underneath. While the melting temperature of alumina (aluminum oxide) is over 2,000°C, the base aluminum is already liquid at 660°C. This difference explains why the surface can appear solid or resist joining, even as the bulk metal melts. The aluminum oxide melting point is a big factor in casting, welding, and even recycling, as it can trap gases or act as a barrier to full fusion (SpecialChem).

Key takeaway: The stubborn oxide layer means that even though aluminum’s metal melting points are relatively low, surface treatments and fluxes are often needed for clean, defect-free joins in real-world processes.

Understanding these phase diagrams and eutectic points is more than academic—it’s the foundation for predicting how alloys will behave in the foundry or on the shop floor. Next, we’ll translate this knowledge into actionable steps for safely melting and handling aluminum in practical settings.

Safe and Practical Aluminum Melting Workflow

Pre-melt Checklist for Aluminum

When you’re ready to melt aluminum—whether for a small prototype or a full foundry batch—safety and preparation are non-negotiable. Wondering what temp does aluminum melt or how to ensure a smooth process? Start with a systematic checklist to avoid common pitfalls and maximize metal quality:

- Verify your alloy: Confirm the exact aluminum grade and check for contaminants or coatings. Even small traces of moisture or oil can cause dangerous reactions once you reach the temperature to melt aluminum.

- Inspect equipment: Ensure the furnace, crucible (ideally made of high-grade steel or graphite), and handling tools are clean, dry, and free of cracks or residues.

- Calibrate thermocouples: Accurate temperature readings are crucial. Double-check that your sensors are working, as the temp to melt aluminum must be precisely controlled for quality results.

- Dry all charges: Preheat scrap, ingots, or any additions to remove surface moisture. Water and molten aluminum are a hazardous mix.

- Prepare fluxes and degassers: Select the right type and quantity for your alloy and process. Have safety data sheets (SDS) on hand for all chemicals.

Safety, PPE, and Ventilation

Melting aluminum is not just about hitting what temperature will aluminum melt—it’s about protecting yourself, your team, and your workspace. Here’s what you need to know:

- PPE: Always wear heat-resistant gloves, a face shield, goggles, and flame-retardant clothing. Closed-toe boots are a must.

- Ventilation: Work in a well-ventilated area or use local exhaust systems to capture fumes. Aluminum melting can release gases and fine particulates, so follow OSHA and local guidelines for air quality (Aluminum Association).

- Moisture control: Keep all tools, molds, and additions bone dry. Even a drop of water can cause a violent steam explosion when it contacts molten aluminum.

- Emergency readiness: Have a Class D fire extinguisher nearby and train all personnel in its use. Never use water on aluminum fires.

Safety warning: Never allow water, wet tools, or damp materials near molten aluminum. Water instantly vaporizes, expanding over 1,000 times in volume, and can cause explosive eruptions of molten metal—posing severe burn and injury risks.

Fluxes, Dross, and Environmental Handling

To melt aluminum efficiently and achieve clean castings or ingots, fluxes play a key role. But not all fluxes are created equal, and each type comes with tradeoffs:

Pros and Cons of Common Flux Types

-

NaCl-KCl-based fluxes:

Pros: Cost-effective, reduce oxidation, widely used.

Cons: Can entrap some metal in slag, require careful handling to avoid environmental contamination. -

Fluoride-containing fluxes:

Pros: Excellent inclusion removal, improve coalescence.

Cons: Environmental and health hazards due to toxic fumes—use the minimum necessary and ensure proper ventilation (MDPI review). -

Granulated or tablet fluxes:

Pros: Easier handling, less dust, more uniform composition.

Cons: Higher cost, may require different dosing.

As you handle dross (the oxidized layer that forms on the melt), skim it promptly and collect it in designated containers. Dross may contain recoverable aluminum but is also a regulated waste in many regions. Dispose of dross and spent fluxes according to local environmental guidelines—never dump them in regular trash or drains.

- Consider recycling options for dross where available—modern processes can reclaim significant aluminum content and reduce waste.

- Always store fluxes in dry, labeled containers away from acids and moisture to prevent hazardous reactions.

By following these best practices, you’ll not only hit the right what temperature does aluminum melt at for your process, but you’ll also protect your team, equipment, and the environment. The next step? Troubleshooting—learn how to diagnose and fix issues if your melting results aren’t what you expect.

Troubleshooting Low or Anomalous Melting Behavior

Confirm the Alloy and Composition First

Ever tried to melt aluminum foil and wondered why the melting point of aluminum foil sometimes seems lower or less predictable than expected? If your observed melting temp of aluminum foil doesn’t match the textbook value, you’re not alone. Inconsistent melting can stem from several factors—most often, a mismatch between the actual material and what you think you have. Start by verifying the alloy and its composition:

- Check documentation: Review Mill Test Certificates (MTCs) or supplier records for alloy grade and batch details.

- Conduct chemical analysis: Use a Positive Material Identification (PMI) gun or spectrometric analysis to confirm alloying elements and detect contaminants. This is vital for distinguishing between common grades like 6061, 5052, or 7075, which have different solidus and liquidus points.

- Visual inspection: Look for coatings, laminates, or surface treatments—these can affect the observed melting behavior, especially in thin products like aluminum foil.

If you’re still not sure what is the melting point for aluminium in your sample, consult the alloy’s datasheet. For example, 6061 aluminum has a solidus around 582°C and a liquidus near 652°C, while 7075 can start melting as low as 477°C.

Validate the Measurement System

When the aluminum foil melting point you observe is off, your measurement setup could be the culprit. Instrumentation errors are surprisingly common. Here’s how to check:

- Thermocouple calibration: Regularly calibrate your temperature sensors using certified reference standards. Even small errors can lead to significant discrepancies, especially at the aluminium foil melting temperature range.

- Thermocouple placement: Ensure the sensor is in direct contact with the sample or as close as possible for accurate readings. Poor placement can cause lag or underestimation.

- Heating rate consistency: Use a controlled, steady heating rate. According to METTLER TOLEDO, higher heating rates can artificially raise the observed melting point, while slower rates yield more accurate results.

- Cross-check with a secondary thermometer: Use an independent thermometer or infrared sensor to validate readings, especially if you suspect instrument drift.

Assess Oxide, Flux, and Contamination Effects

Even if your alloy and equipment are correct, surface and environmental factors can skew melting results. Thin materials like aluminum foil are especially sensitive to these variables:

- Oxide layer: Aluminum forms a thin, tough oxide skin instantly in air. This layer remains solid at much higher temperatures than the underlying metal, sometimes making it seem like the foil isn’t melting when it actually is. Disrupting the oxide (mechanically or with flux) can clarify observations (Encon Thermal Engineers).

- Contaminants: Traces of zinc, magnesium, oil, or moisture can lower the apparent melting point and cause erratic results. Clean and dry all samples thoroughly before testing.

- Flux residues: Leftover flux or dross from previous melts can contaminate the sample and shift the melting temperature. Always use clean crucibles and tools.

- Verify alloy designation and review lot certificates for correct grade.

- Recalibrate thermocouples and confirm optimal sensor placement.

- Reduce sample size and use a consistent, moderate heating rate.

- Inspect for contamination: check for zinc, magnesium, oil, or moisture.

- Cross-check readings with a secondary thermometer.

- Compare your observed freezing range to the alloy’s published datasheet values. If discrepancies persist, consult the manufacturer’s technical support or a metallurgical lab for further analysis.

Tip: Distinguishing between softening, partial melting, and full liquidity is key—aluminum foil may sag or lose shape before it fully liquefies. True melting is confirmed when the entire sample becomes a uniform, flowing liquid.

In summary, troubleshooting unusual melting behavior—whether it’s with bulk ingots or thin foil—means systematically checking composition, equipment, and environmental factors. If you’re unsure what is the melting temp of aluminum for your specific alloy or product, always refer to the certified datasheet or consult a specialist. By following this approach, you’ll resolve most melting anomalies and ensure reliable, safe processing every time.

Now that you know how to diagnose melting inconsistencies, let’s compare how aluminum’s melting characteristics stack up against other common metals and what that means for your manufacturing choices.

How Aluminum Compares to Other Metal Melting Points

Where Aluminum Sits Among Common Metals

When you compare the aluminium melting point to other metals, you’ll notice some striking differences. Why does this matter? Imagine selecting a metal for casting, forging, or high-temperature service—the melting point directly impacts your process, tooling, and even the risk of defects. Let’s look at how aluminum stacks up against copper, steel, magnesium, zinc, and tungsten, referencing only trusted data sources.

| Metal | Typical Melting Point (°C) | Notes on Process Implications | Common Applications |

|---|---|---|---|

| Aluminum (Aluminium) | 660 | Low melting point; enables energy-efficient casting, rapid recycling, but requires careful oxide and hydrogen control. | Automotive parts, aerospace, packaging, structural components |

| Copper | 1084 | Higher melting point; needs robust furnace linings and higher energy input. Excellent for electrical and thermal applications. | Electrical wiring, plumbing, heat exchangers |

| Steel (Carbon/Alloy) | 1371–1540 | Very high melting point; suitable for structural and load-bearing uses, but requires specialized high-temperature tooling and furnaces. | Construction, machinery, automotive frames |

| Magnesium | 650 | Low melting point, similar to aluminum; highly ignitable in molten form, demanding strict safety precautions. | Lightweight castings, aerospace, electronics |

| Zinc | 420 | Very low melting point; ideal for die casting, but limited to lower-temperature applications. | Galvanizing, die-cast parts, batteries |

| Tungsten | 3422 | Highest melting point among metals; used where extreme heat resistance is essential (e.g., lamp filaments, aerospace). | Light bulb filaments, rocket nozzles, electrodes |

Process Implications of Higher and Lower Melting Points

So, what does all this mean for your manufacturing process? Metals with a lower melting point, like aluminum and magnesium, are easier and less energy-intensive to melt. This makes them ideal for casting and recycling operations. For example, the aluminium melting point is low enough to allow for rapid mold filling and shorter cycle times, but not so low as to limit its use in most ambient environments. In contrast, metals like steel or tungsten require much higher temperatures—meaning more robust furnaces, higher energy costs, and specialized refractories.

On the flip side, working with metals like copper or steel, which have higher melting points, typically means greater strength and durability at elevated temperatures. That’s why you’ll see iron melting temperature and steel melting point referenced in industries where heat resistance and mechanical strength are critical, such as construction or heavy machinery.

And for precious metals? The gold melting point (1064°C) and silver melting temperature (961°C) are also important in jewelry, electronics, and specialized industrial uses, where precise thermal control is required for refining and forming.

Energy, Tooling, and Defect Considerations

Imagine the energy savings when melting aluminum compared to steel or tungsten. Lower melting temperatures mean less fuel or electricity is needed, and equipment can be lighter and less expensive. However, there’s a trade-off: aluminum’s low melting point brings challenges like rapid oxidation and hydrogen absorption, which can cause porosity and defects if not carefully managed.

- Tooling: Aluminum molds and dies can be less expensive, but must be designed to prevent sticking and manage rapid heat transfer.

- Defect risk: Lower melting metals are more sensitive to surface contamination and gas pickup, while higher-melting metals may be prone to thermal cracking or require more complex solidification control.

- Recycling: Aluminum’s relatively low melting point makes it highly recyclable, with less energy required per cycle compared to most metals.

Key insight: Aluminum’s low melting point is a double-edged sword—it enables efficient casting and recycling, but demands vigilant control of oxide formation and hydrogen pickup to ensure quality results.

In summary, understanding where aluminum sits in the spectrum of metal melting temperatures helps you make smarter choices about process selection, energy use, and product design. Next, we’ll connect these insights to practical decisions—should you cast, or is precision CNC machining from wrought aluminum sheets and plate the better path for your project?

Choosing Casting or CNC for Aluminum Parts

When Alloy Melting Ranges Favor Casting

Imagine you’re launching a new product and need hundreds—or thousands—of identical aluminum housings. Should you pour molten metal into molds or carve each part from a solid block? The answer often starts with the aluminium melting point and how it varies across alloys. For many high-volume parts, especially those with moderate tolerances and complex shapes, casting remains the go-to. Why? Because the melting temperature of aluminum alloys is low enough to allow efficient, energy-saving casting, and the broad freezing range of many alloys (like A356 or 319) supports intricate mold filling—even for challenging geometries.

- High production volume: Casting is cost-effective when you need many identical parts.

- Complex, organic shapes: Molds can capture undercuts, curves, and features that would be difficult or expensive to machine.

- Relaxed tolerances: If your part can handle slight dimensional variation due to the alloy’s melting range, casting is ideal.

- Material savings: Minimal waste, as most molten metal fills the mold.

- Surface finish: As-cast surfaces may need post-processing for critical fits or aesthetics.

However, casting isn’t a one-size-fits-all solution. The same melting range that makes casting possible can also introduce variability—think shrinkage, porosity, or microstructural differences—that may be unacceptable for precision applications.

When Precision CNC Outperforms Molten Processes

Ever needed a prototype or a part where every micron counts? That’s where CNC machining from aluminum plate or sheet shines. Instead of relying on the precise control of what temperature aluminum melts at—and the inherent variability of solidification—CNC machining starts with wrought material that’s already been carefully processed for uniformity and strength. The result? Predictable, repeatable properties and ultra-tight tolerances.

- Tight tolerances: CNC machining routinely achieves precise fits that casting cannot match.

- Superior surface finish: Machined surfaces are smoother and often require little or no further finishing.

- Consistent mechanical properties: Wrought aluminum sheets and plate have fewer internal defects and more predictable strength than cast parts.

- Material flexibility: Choose from a wide range of alloys, including those difficult to cast.

- Low- to mid-volume runs: CNC is cost-effective for prototypes and custom parts, avoiding the upfront expense of mold tooling.

- Rapid iteration: Design changes are easy—just update the CAD file and re-machine.

For components where melting range variability might impact dimensional accuracy or microstructure—especially in aerospace, medical devices, or high-performance machinery—precision 4/5-axis CNC machining from wrought aluminum plate or aluminum sheets can bypass melt-process risks. If you’re seeking a partner for these demanding projects, consider XTJ’s CNC machining services, which specialize in high-complexity, tight-tolerance aluminum parts using advanced equipment and rapid turnaround.

Picking the Right Path for Prototypes and Production

So, how do you decide between casting and CNC machining? Start by weighing your priorities. Here’s a quick checklist to guide your decision:

- Tolerance requirements: Need ultra-tight fits? CNC machining wins.

- Feature complexity: Deep cavities, thin walls, or intricate details may be easier to cast—but with less precision.

- Surface finish: Cosmetic or functional surfaces often benefit from machining.

- Mechanical properties: If uniformity and high strength are critical, machined aluminum sheet metal or plate is preferred.

- Lot size: Large runs favor casting; small batches or one-offs are ideal for CNC.

- Lead time: CNC machining can deliver parts in days, while casting may require weeks for tooling and setup.

- Cost: Casting is often cheaper per part at scale, but CNC avoids tooling costs for prototypes and short runs.

Key takeaway: For prototypes, tight tolerances, or when alloy melting behavior could introduce risk, machining from aluminum sheets or plate is often the safest route. For high-volume, less critical parts, casting leverages the advantages of aluminum’s low melting point and moldability.

By understanding the interplay between the aluminium melting point, process variability, and your project’s requirements, you’ll make smarter manufacturing choices—balancing speed, cost, and performance. Ready to move from theory to practice? Next, let’s wrap up with a glossary and references for all the key melting terms and data sources you’ll need.

Glossary, References, and Source Validation

Glossary of Melting Terms

When you’re navigating the world of aluminum alloys, unfamiliar terms can quickly become stumbling blocks. Here’s a concise glossary to help you define melting range concepts and master the language found in any metal melt temperature chart:

- Melting Point: The temperature at which a pure substance transitions from solid to liquid under standard pressure. For pure aluminum, this is a single, well-defined value.

- Solidus: The highest temperature at which an alloy remains completely solid. Below this, no melting occurs.

- Liquidus: The lowest temperature at which an alloy is fully liquid. Above this, the entire sample is molten.

- Freezing Range (Melting Range): The temperature interval between solidus and liquidus where both solid and liquid phases coexist. Most alloys, including aluminum grades, have a melting range rather than a single melting point.

- Eutectic: A unique alloy composition that melts and solidifies at a single temperature, lower than any of its components. Eutectics are important for understanding metals with low melting points and for precision casting.

- Superheat: The practice of heating a molten metal above its liquidus temperature to improve fluidity or compensate for heat losses before casting.

Authoritative Data Sources

Reliable engineering and manufacturing decisions depend on accurate melting point of metals data. For aluminum and its alloys, always consult trusted references. Here are the primary sources—these are the backbone of any robust metal melting point chart:

- ASM Handbook – Comprehensive physical and mechanical property data for metals and alloys, including melting points, solidus/liquidus, and alloy-specific details. Refer to the volume on Properties and Selection: Nonferrous Alloys and Special-Purpose Materials for aluminum data.

- NIST Chemistry WebBook – Authoritative source for fundamental melting points and thermochemical data for pure substances, including aluminum.

- MatWeb – Extensive database of wrought and cast aluminum alloy properties, including melting points, solidus, liquidus, and thermal characteristics. Search by alloy number or property.

- Producer and supplier datasheets – For the most current and precise melting range values, always review the technical datasheet provided by your alloy’s manufacturer. These documents often specify the exact solidus/liquidus for the supplied batch.

For a broader view, consult a metal melt temperature chart that includes a range of metals, from those with low melting points (like zinc or tin) to those with high melting points (such as tungsten). This helps contextualize where aluminum sits among metals and why it’s chosen for specific applications.

Editorial Review and Update Policy

Accurate data is essential, but even the best sources can contain errors or become outdated. How can you trust the melting point of metal values you find? Here’s what goes on behind the scenes:

- All melting points, freezing ranges, and alloy data presented here are cross-checked against at least two authoritative sources or direct producer datasheets.

- When discrepancies exist, preference is given to the most recent peer-reviewed or standards-based publication. Where uncertainty remains, ranges are presented, and notes are added for user verification.

- We encourage users to confirm values for safety-critical or high-precision applications, and to consult a specialist if the melting points or alloy ranges are mission-critical. The field of thermophysical property measurement is continually evolving, and even small impurities or measurement differences can affect results (see discussion on data validation and uncertainty).

For critical projects, always cross-reference the melting point of metals and freezing ranges with primary datasheets and consult experts for safety or compliance requirements. Even small differences can impact process control or product quality.

Last reviewed and source-validated on [update date]. For downloadable tables or charts, versioning and embedded source citations are included in the file metadata to ensure traceability.

By relying on these definitions and sources, you can confidently interpret melting points, compare metals with low melting points to those with extreme heat resistance, and answer questions like what metal has the highest melting point or where aluminum fits on the metal melting point chart. This clarity supports better material selection and safer, more efficient manufacturing choices every time.

Frequently Asked Questions about Aluminium Melting Point

1. Why is aluminium difficult to melt?

Aluminium forms a tough oxide layer when exposed to air, which melts at a much higher temperature than the metal itself. This oxide skin can hinder melting efficiency and requires proper fluxes or mechanical disruption to achieve a uniform melt. Ensuring dry materials and clean surfaces helps overcome this challenge in casting or recycling processes.

2. What happens if you melt aluminum and steel together?

Melting aluminum and steel together is problematic because their melting points differ greatly—steel melts at much higher temperatures than aluminum. They are largely insoluble in each other and can form brittle intermetallic compounds when mixed, leading to weak, unusable material. Specialized joining techniques, not melting, are required for combining these metals.

3. How does alloying affect the melting point of aluminum?

Adding elements like silicon, copper, magnesium, or zinc to aluminum creates alloys that melt over a range of temperatures instead of a single point. These alloying elements can lower the solidus temperature and broaden the melting range, impacting casting, welding, and heat treatment processes. Always consult alloy datasheets for specific melting ranges.

4. What role does the oxide layer play during aluminum melting?

The aluminum oxide layer acts as a barrier, remaining solid well above the metal’s melting point. This can prevent proper flow and joining during melting or welding, making fluxes or mechanical removal necessary for clean, defect-free results. The oxide layer also impacts recycling and casting efficiency.

5. When should you choose CNC machining over casting for aluminum parts?

CNC machining is preferred when tight tolerances, superior surface finish, or consistent mechanical properties are required—especially for prototypes or complex parts where the variability of casting due to melting range could impact quality. Machining from wrought aluminum plate or sheet avoids melt-process risks and delivers precise, reliable results.

-

Posted in

aluminium melting point, aluminum alloys, aluminum casting, cnc machining, metal melting temperatures