Aluminium Extrusion Design Rules Engineers Rely On Daily

Aluminium extrusion fundamentals made simple

What is aluminium extrusion?

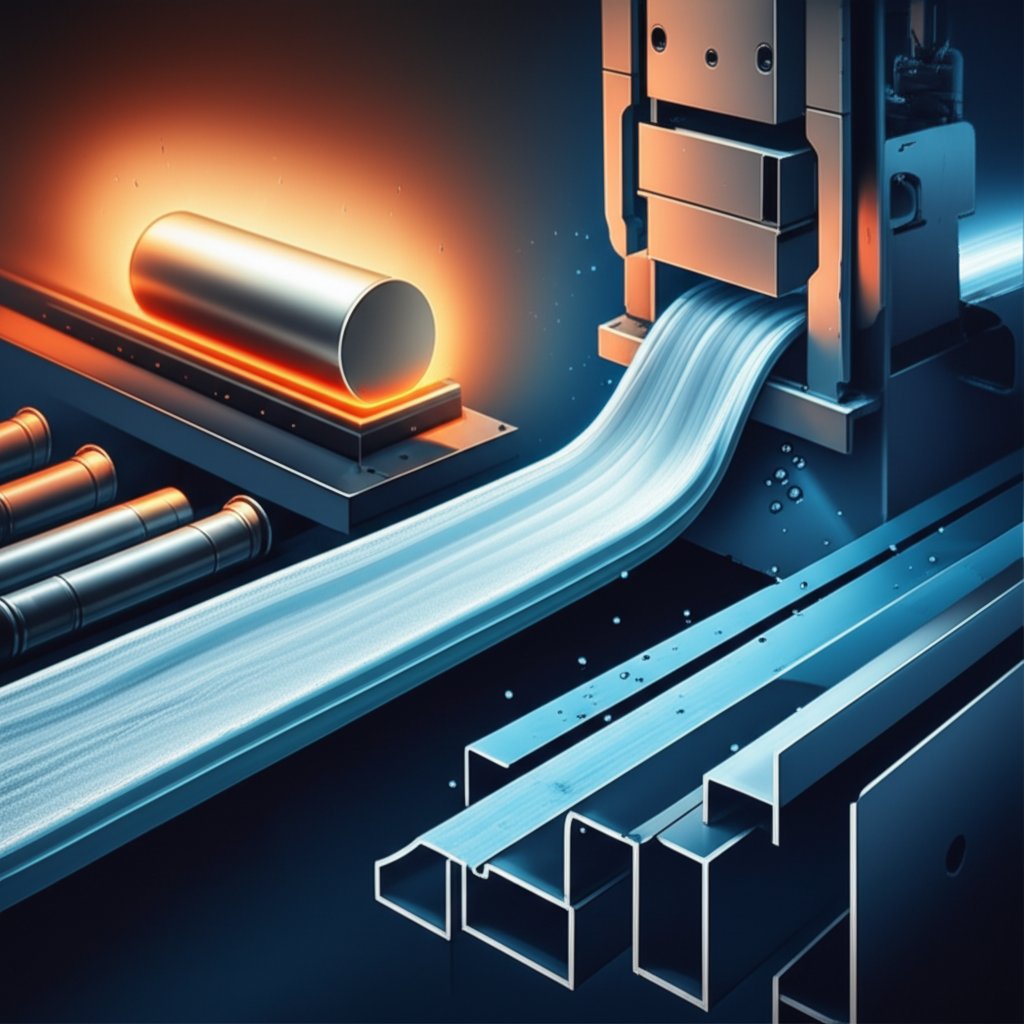

Ever wondered how those sleek, uniform metal channels and frames you see in everything from office partitions to solar panel mounts are made? That’s the work of aluminum extrusion. In simple terms, aluminium extrusion is a process where a heated aluminum billet is pushed through a shaped die, much like squeezing toothpaste out of a tube. The result? Long, continuous pieces with a consistent cross-section, known as extruded aluminum profiles. These can be solid, hollow, or semi-hollow, and take on a wide variety of forms—think tubes, T-slots, and channels—all tailored to specific applications.

Why extruded aluminum dominates lightweight structures

When you see lightweight structures—like modular furniture, machine guards, or even solar racking systems—they often rely on extruded aluminum channel or other aluminum profiles. Why? Aluminum’s unique combination of low weight, high strength, and corrosion resistance makes it the go-to material for engineers seeking efficiency and longevity. The extrusion process allows for the integration of multiple functions (such as slots for fasteners or cooling fins) into a single profile, reducing assembly steps and material waste. Imagine a heat sink with finely spaced fins or a frame with built-in cable management—these are only possible thanks to the flexibility of extrusion.

- Framing for machinery, workstations, and modular structures

- Heat sinks for electronics and LED lighting

- Enclosures for electrical or mechanical assemblies

- Rails and tracks for sliding doors or conveyors

Extrusion vs other metal forming methods

So, how does extrusion stack up against other common metal forming processes? Let’s break it down:

| Method | Shape Complexity | Tooling Cost | Lead Time | Typical Applications |

|---|---|---|---|---|

| Extrusion | High (especially for long profiles) | Moderate | Short to moderate | Framing, channels, heat sinks, rails |

| Casting | Very high (complex shapes possible) | High | Moderate to long | Engine blocks, complex housings |

| Machining | High (but often for shorter runs) | Low (for simple parts), high (for CNC setups) | Short | Precision parts, prototypes |

While casting can achieve intricate internal geometries, it’s generally slower and more costly for long, continuous shapes. Machining offers precision but is less efficient for producing extended profiles. Extrusion strikes a balance, enabling the cost-effective production of long, uniform parts with integrated features.

Key terms every engineer should know

- Extruded aluminum channel: A U- or C-shaped profile used for framing, tracks, or supports.

- Aluminum profiles: General term for the shapes produced by extrusion, including tubes, angles, and custom designs.

- Die: The tool that shapes the aluminum as it’s forced through, defining the profile’s cross-section.

- Billet: The solid cylinder of aluminum that is heated and extruded.

- What is extruded aluminum: Refers to aluminum that has been shaped by the extrusion process, resulting in continuous lengths with a uniform cross-section.

Extrusion provides continuous profiles with consistent properties along the length, making it ideal for high-performance, repeatable applications.

From architectural frames to intricate heat sinks, the versatility of aluminium extrusion means you’ll find its profiles in nearly every industry. As you move through the rest of this guide, you’ll see how the process, design rules, and finishing options come together to unlock new possibilities for your next project.

Step by step aluminium extrusion process overview

From billet to profile: How the aluminium extrusion process works

Ever wondered what it takes for a simple aluminum log to transform into the complex profiles you see in framing systems, heat sinks, or enclosures? The aluminum extrusion process is a carefully controlled journey, blending heat, pressure, and precision engineering. Let’s break down how aluminum extrusion is made from start to finish, so you can better understand what happens at each stage—and what to ask your aluminum extruder or supplier.

- Die Preparation: The process begins by preheating the die (the tool that shapes the metal) to ensure smooth metal flow and maximize die life.

- Billet Cutting & Preheating: A billet (a solid aluminum cylinder) is cut from a longer log and heated in an oven until it’s malleable but not molten. This step is crucial for controlling flow and surface finish.

- Lubrication: Both the billet and the ram (the press component that pushes the billet) are lubricated to prevent sticking and ensure smooth movement inside the press.

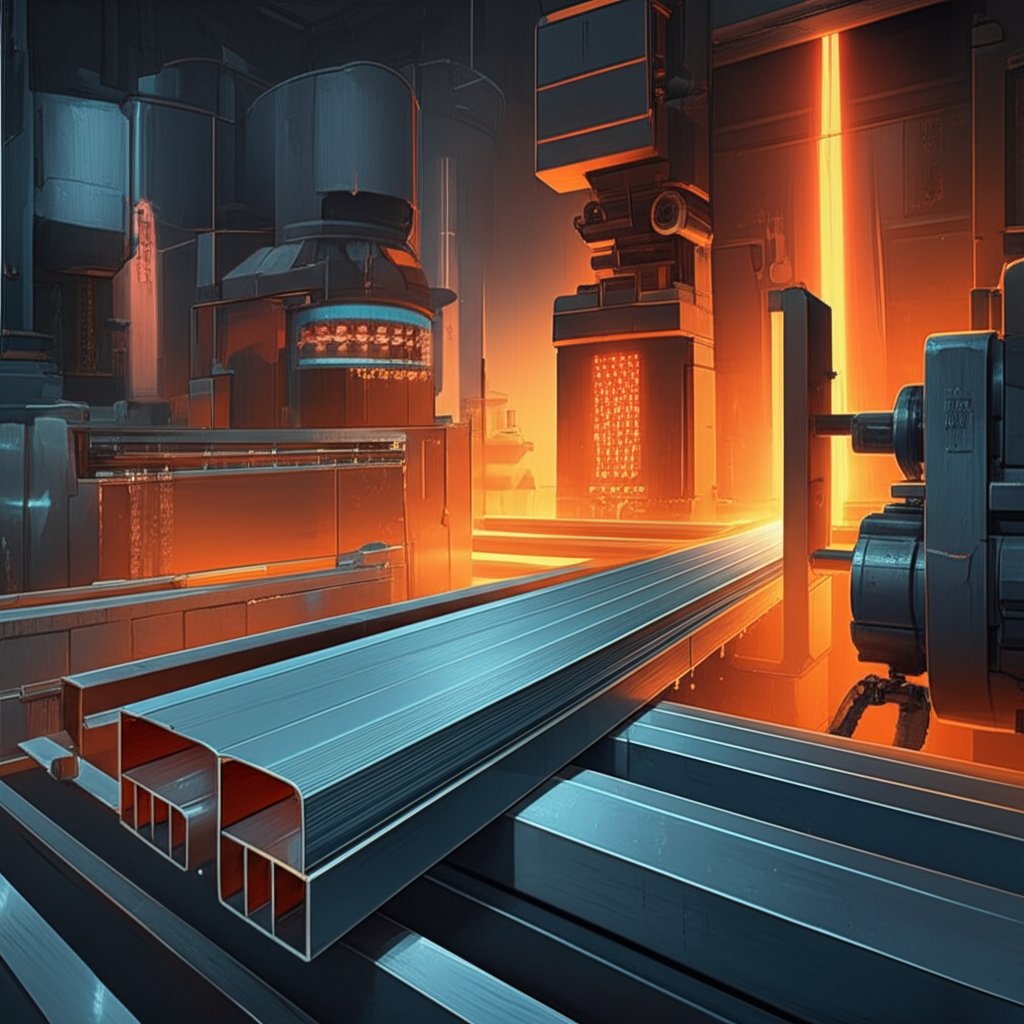

- Extrusion: The billet is loaded into the press. A hydraulic ram applies immense pressure, forcing the softened billet through the die. As it emerges, it takes on the die’s shape—this is the heart of the extrusion aluminium process.

- Quenching: The newly formed profile is rapidly cooled, often with fans or a water bath, to lock in mechanical properties and maintain straightness.

- Shearing: Once the profile reaches the desired length, it is cut from the rest of the extrusion using a saw while still hot.

- Cooling: The cut profiles are transferred to a cooling table, where they reach room temperature before further processing.

- Stretching: To correct any twists or bows, the profiles are mechanically stretched, ensuring dimensional accuracy and improved strength.

- Sawing: Profiles are cut to their final lengths, ready for aging or further fabrication.

- Aging: The last step is heat treatment (artificial aging) in an oven, which brings the material to its final temper and mechanical properties.

Direct vs indirect extrusion: Understanding the process variants

While the sequence above describes the general aluminium extrusion process, there are two main variants: direct and indirect extrusion. Each has unique advantages, especially when considering surface finish, die wear, and speed.

| Process | Die Wear | Surface Finish | Speed | Best For |

|---|---|---|---|---|

| Direct Extrusion | Higher (more friction) | Good | Faster | General profiles, high volume |

| Indirect Extrusion | Lower (less friction) | Excellent (more uniform) | Slower | Thin-walled or hollow sections, improved consistency |

In direct extrusion, the die is stationary and the ram pushes the billet through it. This is the most common approach, especially for straightforward shapes. Indirect extrusion keeps the billet stationary while the die assembly moves against it. This reduces friction, resulting in better temperature control, more consistent properties, and smoother surfaces—but at the cost of speed.

Die design, cooling, and handling: The keys to quality

Die preparation and design are critical for the extrusion of aluminium. Preheating the die ensures even material flow and extends die life. After extrusion, rapid cooling—called quenching—locks in desirable mechanical properties. Profiles are then stretched to remove minor twists and ensure straightness. Each of these steps is monitored for temperature and speed, as these parameters greatly affect the final surface finish and dimensional accuracy.

Stable temperature control and ram speed are crucial for maintaining dimensional stability and achieving a high-quality surface finish throughout the extrusion process.

Understanding the full lifecycle of the extrusion process helps you communicate more effectively with your aluminum extruder, specify the right parameters, and anticipate how design choices will influence cost and quality. Next, we’ll explore the specific design rules engineers use to turn these process insights into reliable, manufacturable aluminium extrusion profiles.

Design for extrusion rules engineers rely on

Wall thickness and uniformity: The foundation of robust profiles

When you start designing aluminum extrusion profiles, it’s tempting to push the boundaries of complexity. But what separates a profile that runs smoothly on the press from one that twists, bows, or cracks? It all starts with wall thickness and uniformity. Profiles with consistent wall thicknesses not only extrude more predictably but also cool evenly, reducing internal stresses and surface marks. According to industry best practices, avoid sudden jumps between thick and thin walls—streamlined transitions with generous radii are your best friend.

- Keep adjacent wall thickness ratios below 2:1 for best dimensional control.

- Use streamlined, curved transitions between thick and thin areas to aid material flow.

- Specify the minimum wall thickness that meets your structural needs, but avoid ultra-thin walls unless absolutely necessary.

- For exposed surfaces, minimize thickness changes to reduce visible marks.

Corner radii, ribs, and webs: Enhancing flow and stability

Ever notice how aluminum extruded shapes rarely have sharp corners? That’s by design. Generous inside and outside radii help the metal flow smoothly through the die, reducing die stress and the risk of cracking. Ribs and webs are more than just decorative—they add stiffness, help control twist, and allow for thinner wall sections in hollow or semi-hollow profiles. For profiles like t-slot extrusion or complex channels, these features can be the difference between a part that’s easy to assemble and one that’s prone to distortion [AEC].

- Use inside corner radii of at least 0.015" and outside radii of at least 0.020" where possible.

- Integrate ribs to prevent twisting and improve flatness, especially in wide, thin sections.

- Design webs to support hollow areas, enabling thinner walls without sacrificing strength.

- Round all voids and interior corners to reduce die breakage risk.

Tolerancing and functional zones: Balancing precision and cost

Not every feature on your aluminium extrusion profiles needs to be held to the tightest possible tolerance. It’s easier to control dimensions measured across solid metal than across open spaces, such as slots or holes. When specifying tolerances, target critical fit areas (like mating faces or assembly slots) and relax requirements elsewhere to keep costs in check. For example, aluminum extrusion t slot profiles often hold tighter tolerances in the slot area for reliable fastening, while less critical faces can be looser.

- Call out tight tolerances only where necessary for assembly or function.

- Use index marks or shallow grooves to aid in drilling, punching, or distinguishing surfaces.

- Communicate finish requirements early—surface protection during extrusion and handling starts at the design stage.

Combining functions: The real power of extrusion

One of the greatest advantages of aluminum extrusion shapes is the ability to combine multiple functions into a single profile. Imagine a frame with integrated cable channels, mounting slots, or even snap-fit features—these can all be built into the initial die, streamlining downstream fabrication. Common aluminum extrusion types include channels, tubes, and t-slot extrusions, each tailored for specific uses.

| Aluminum Extrusion Type | Typical Use Case |

|---|---|

| T-slot extrusion | Modular framing, machine guards, workstations |

| Channel | Tracks for sliding doors, supports, cable management |

| Tube (round/square/rectangular) | Structural frames, enclosures, transport rails |

| Custom hollow shapes | Heat sinks, architectural mullions, specialized enclosures |

Consistent section thickness and smooth transitions are key to achieving high-quality surfaces and efficient press speeds in aluminum extrusion profiles.

With these design principles in mind, you’ll create extruded aluminum profiles that are robust, reliable, and cost-effective to produce. Next, we’ll look at how to choose the right alloy and temper to match your performance and finishing requirements.

Choosing alloys and tempers for performance and finish in aluminum profile extrusion

Most-used alloys for extrusion and why they matter

When you’re planning a new aluminum profile extrusion, have you ever wondered why some profiles hold up better outdoors, or why certain frames are easier to machine? The answer often comes down to alloy selection. Aluminum alloy extrusion offers a range of choices, each with its own strengths and trade-offs. Imagine you’re designing a structural frame for a marine environment, or a sleek enclosure that needs a flawless finish—your choice of alloy will shape everything from strength to corrosion resistance and even how well your profile accepts surface treatments.

| Alloy Series | Main Alloying Element(s) | Key Properties | Finishing & Typical Use |

|---|---|---|---|

| 1xxx | 99%+ Aluminum | Excellent corrosion resistance, high conductivity, very formable, low strength | Good for electrical applications; not typical for structural aluminium extrusion profile |

| 3xxx | Manganese | Good corrosion resistance, moderate strength, good workability | Heat exchangers, architectural trim, general sheet applications |

| 5xxx | Magnesium | Excellent corrosion resistance (marine), moderate strength, weldable | Marine, transportation, architectural panels |

| 6xxx | Magnesium & Silicon | Balanced strength, good corrosion resistance, good machinability, heat treatable | Most extruded aluminum profiles: frames, enclosures, automotive parts, architectural finishes |

| 7xxx | Zinc | Very high strength, lower corrosion resistance, heat treatable | Aerospace, high-strength structural components |

You’ll notice that 6xxx series alloys (like 6061 and 6063) dominate the world of aluminum extrusion profile because they strike a unique balance—strong enough for structural use, yet formable and easy to finish. For extreme strength, 2xxx and 7xxx are options, but may require special handling and post-processing.

Temper options and aging: Tuning properties for your needs

Once you’ve picked your alloy, the next decision is temper. Sounds complex? It’s simply a code that tells you how the profile was heat-treated or work-hardened. For example, a 6063-T5 aluminium extrusion profile has been cooled from an elevated temperature and artificially aged, while a T6 temper goes through solution heat treatment and artificial aging for higher strength. These treatments influence not only strength and hardness but also machinability and how well the surface will accept anodizing or coating [AEC].

- O (annealed): Maximum ductility, lowest strength

- T1/T4: Naturally aged, moderate strength

- T5/T6: Artificially aged, higher strength, common for structural extruded aluminum profiles

The right temper ensures your aluminum extrusion profile meets both mechanical and finishing requirements.

Finish compatibility: Anodizing, coating, and machining

Planning for a premium finish or tight-tolerance machining? Your choice of aluminum alloy extrusion and temper can make or break the result. 6xxx series alloys, especially 6063 and 6061, are prized for their excellent anodizing response—yielding a clean, consistent surface for architectural or decorative use. If your application demands powder coating or painting, these alloys also provide a receptive base. For marine or chemical exposure, 5xxx series alloys offer superior corrosion resistance but may require extra care for cosmetic finishes.

- Will the profile be exposed to harsh weather or saltwater?

- Is high strength or light weight more important?

- Do you need tight bends or complex shapes?

- Will the surface be visible or require a decorative finish?

- Are there welding or machining steps after extrusion?

Balancing strength, formability, and cost

Choosing between aluminium alloy extrusion options is always a balancing act. High-strength alloys like 7xxx may be tempting for demanding applications, but they increase cost and can be harder to extrude. On the other hand, 6xxx alloys offer a sweet spot for most aluminum profile extrusion needs, giving you good strength, reasonable cost, and wide compatibility with surface treatments. For projects where corrosion is the top concern, the 5xxx series is a strong candidate, even if it means compromising some strength or finish options.

Alloy and temper selection not only determine the strength of your extruded aluminum profiles, but also how cleanly the surface will anodize and how well the part will machine or weld.

By weighing your project’s environment, load requirements, finishing needs, and budget, you can zero in on the ideal alloy and temper. Up next, we’ll see how process parameters—like temperature and press speed—further influence the quality and cost of your aluminium extrusion profile.

Process parameters that control quality and cost in extrusion manufacturing

Billet preheat and thermal consistency: The foundation of quality

Ever wonder why some extrusion lines deliver flawless profiles while others struggle with surface marks or inconsistent tolerances? It often starts with the billet—the aluminum log that feeds the process. Uniform preheating of the billet is essential; uneven temperatures can cause the metal to flow unpredictably through the die, leading to warping, rough surfaces, or unwanted internal stresses. In a well-run extrusion manufacturing setup, the aluminum extrusion machine uses precise temperature controls to ensure every billet reaches the ideal plasticity before pressing begins. This attention to detail is the first step in producing high-quality extrusion aluminum profiles.

Press selection, die design, and alignment: Matching machine to profile

Choosing the right aluminum extrusion machine and die setup is more than a matter of size or power. The extruder must be matched to the complexity and dimensions of the profile being produced. For example, a profile with thin walls or intricate hollows may require a press with tighter alignment and a die designed for smooth material flow. Misalignment or poorly designed dies can cause uneven pressure, resulting in defects like surface swirl, die lines, or dimensional instability. Advanced extrusion lines often use computer-controlled systems to monitor alignment and make real-time adjustments, reducing downtime and scrap rates.

Ram speed, lubrication, and flow balance: The art of control

Imagine pushing dough through a cookie press—too fast, and it tears; too slow, and it sticks. The same principle applies to the ram speed in an extrusion line. Ram speed directly affects both productivity and surface finish. If set too high, it can raise the exit temperature, risking surface defects or excessive die wear. Too slow, and you lose efficiency. Lubrication—applied both to the billet and the die—reduces friction, helping maintain a consistent flow and preventing sticking or tearing of the profile. Flow balance is achieved by carefully adjusting these parameters based on profile geometry, alloy, and die design.

| Process Variable | Main Effect | Potential Issues if Uncontrolled |

|---|---|---|

| Billet Preheat Temperature | Enables smooth flow; sets initial plasticity | Surface marks, warping, inconsistent properties |

| Container/Die Alignment | Ensures profile accuracy, reduces wear | Twist, bow, die lines, premature die failure |

| Ram Speed | Controls productivity, surface finish, and exit temperature | Surface swirl, overheating, dimensional instability |

| Lubrication | Reduces friction, ensures even flow | Sticking, tearing, rough surfaces |

| Die Design | Optimizes flow, balances pressure | Flow marks, uneven thickness, poor fill |

Quenching, stretching, and cooling: Locking in properties

Once the profile leaves the die, rapid and uniform cooling—known as quenching—is critical. This step locks in the mechanical properties and helps prevent distortion. If cooling is uneven or too slow, it can lead to residual stresses, warping, or inconsistent hardness. After quenching, profiles are stretched to remove minor twists or bows and to improve straightness, a step especially important for extruded aluminum framing and long structural parts. Proper cooling and stretching ensure the final product meets both dimensional and performance specifications.

- Check billet and die preheat before each run

- Inspect container and bearing surfaces for wear or misalignment

- Monitor ram speed and adjust based on profile complexity

- Confirm lubrication is evenly applied to billet and die

- Verify quench system coverage and cooling rates

- Perform stretch-straightening and inspect for residual bow or twist

In extrusion manufacturing, temperature uniformity and balanced flow often matter more than absolute speed. Prioritizing these parameters helps achieve consistent surface quality and reliable tolerances.

By understanding and controlling these process variables, you’ll be better equipped to troubleshoot issues, communicate effectively with your extrusion line operators, and specify parameters that result in cost-effective, high-quality extrusion aluminum parts. As we transition to post-extrusion steps, you’ll see how machining and finishing further refine the performance and appearance of your aluminium profiles.

Post extrusion heat treatment, machining, and finishing

Heat treatment and aging: Setting strength and machinability

Once your aluminium extrusion leaves the press, the journey is far from over. Have you ever wondered why some extruded aluminum parts are stronger or easier to machine than others? The answer lies in heat treatment and aging. After extrusion, profiles are often subjected to controlled heat treatment—also known as aging—to fine-tune their mechanical properties. For instance, a T5 temper is achieved by cooling the profile from the extrusion temperature and then artificially aging it, while T6 involves solution heat treatment followed by artificial aging for greater strength. The right temper selection impacts not only the final strength but also how well the material responds to downstream processes like aluminium extrusion machining or finishing.

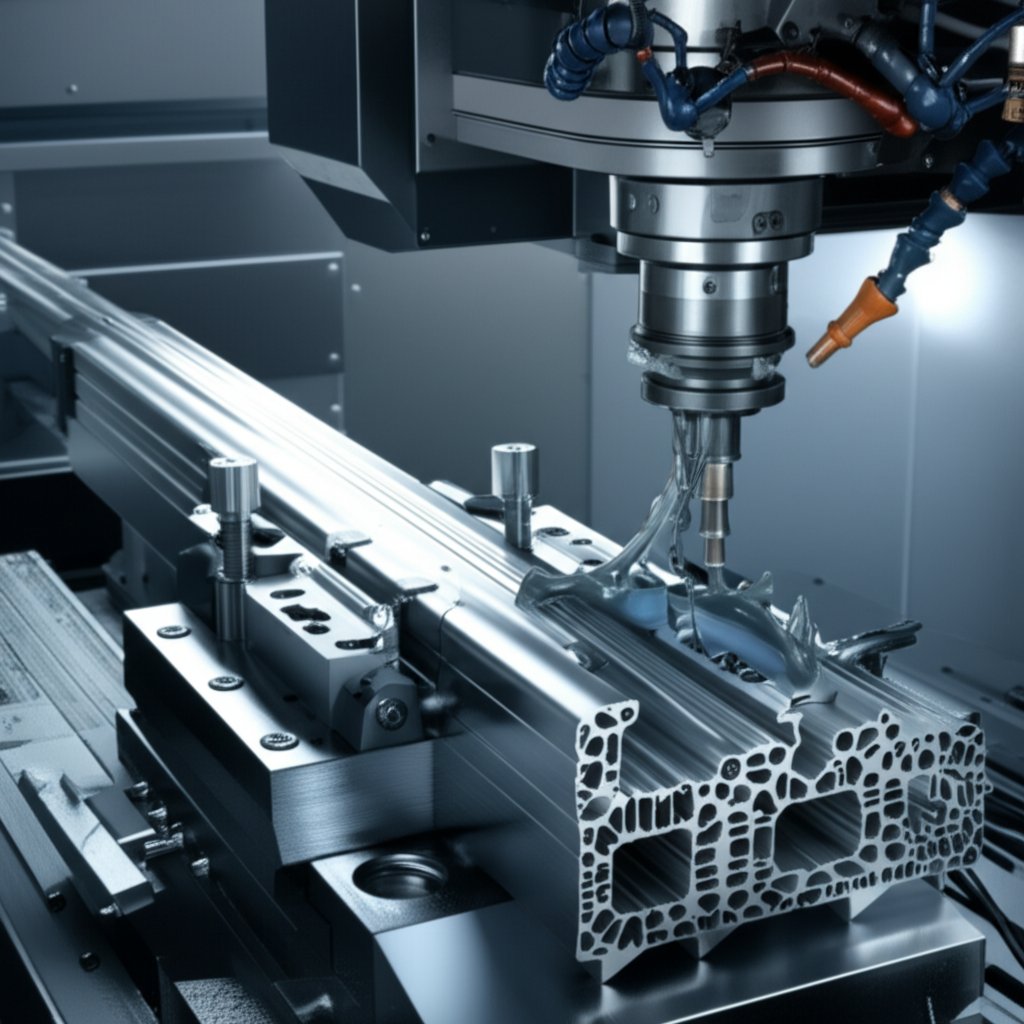

Machining, drilling, and tapping: Best practices for extruded profiles

Now imagine you need to add holes, slots, or threads to an extruded aluminum tube or frame. Sounds straightforward? Not always. Thin walls, long lengths, and intricate shapes can pose challenges for cutting aluminum extrusion and secondary operations. Here are some essential tips to get the best results:

- Support long parts: Use proper fixturing to prevent vibration and chatter, especially with extruded aluminum square tubing or track profiles.

- Pre-drill pilot holes: For thin-walled sections, pilot holes help avoid distortion and ensure cleaner threads.

- Use sharp tools and moderate speeds: Aluminum is soft but can gum up tools—sharp bits and the right speed reduce burrs and improve finish.

- Deburr after machining: Always remove burrs, especially near slots and ports, to ensure safe handling and proper assembly.

- Plan for tolerances: Account for the extrusion’s natural tolerances before specifying tight fits in aluminum extrusion parts.

Finishing options: Anodizing, powder coat, and mechanical treatments

Ever picked up an aluminum part and marveled at its smooth, colored surface? That’s the result of post-extrusion finishing. While mill finish (the as-extruded state) is suitable for hidden or low-cost applications, most visible or high-performance aluminum extrusion parts receive additional finishing. Here’s a look at the most common options:

| Finish Type | Durability | Appearance | Preparation Needed |

|---|---|---|---|

| Anodized aluminum extrusions | Excellent corrosion and wear resistance | Matte or satin, limited color range | Thorough cleaning and surface prep |

| Powder coating | Very good (if coating remains intact) | Wide color options, smooth or textured | Cleaning, masking, sometimes pre-anodizing |

| Mechanical finishes (brushing, polishing) | Moderate (mainly aesthetic) | Bright, brushed, or mirror-like | Abrasive blasting, grinding, or buffing |

| Mill finish | Low (prone to oxidation) | Dull, may show die/tooling marks | None |

Anodized aluminum extrusions are especially popular for architectural, electronic, and consumer products due to their enhanced corrosion resistance and stable appearance. Powder coating offers broader color choices and a thicker protective barrier, while mechanical finishes like brushing or polishing are ideal for decorative applications. Always ensure surfaces are properly prepped to maximize finish adhesion and durability.

Fabrication, welding, and assembly: From stick to system

Turning raw extrusions into finished assemblies is where the design comes to life. Whether you’re fabricating frames from extruded aluminum tube, building enclosures, or installing aluminum track extrusion systems, follow these do’s and don’ts for efficient assembly:

- Do use compatible alloys and tempers when welding to avoid weak joints.

- Do specify surface finish and temper together—some finishes require certain tempers for best results.

- Do use proper jigs and fixtures for cutting aluminum extrusion to length, especially for batch consistency.

- Don’t overlook the impact of heat from welding or machining on temper and finish—plan the sequence to minimize rework.

- Don’t skip post-fabrication cleaning before applying any finish.

Specifying both the temper and finish at the outset ensures your aluminium extrusion parts are ready for assembly and minimizes costly rework down the line.

By following these post-extrusion best practices, you’ll transform raw profiles—whether it’s extruded aluminum square tubing for a frame or an aluminum extrusion tube for a custom enclosure—into reliable, high-quality components. Up next, we’ll explore how to set and verify tolerances and quality standards so your finished parts meet every expectation.

Tolerances, Inspection, and Standards That Matter for Aluminium Extrusions

Dimensional Tolerances by Feature Type

When specifying aluminium extrusions, one of the first questions engineers ask is: how close can I hold my dimensions? The answer depends on the feature, the alloy, and the profile's size and shape. For example, tolerances for solid sections are generally tighter than for hollow or complex shapes. Features like wall thickness, width, depth, and length each have their own standard tolerance ranges. Industry guidelines—such as those from the Aluminum Association and ASTM—divide tolerances into 'standard' and 'precision' classes, with the latter requiring closer collaboration and often higher costs.

| Feature | Standard Tolerance (in.) | Precision Tolerance (in.) | Reference Table | Notes |

|---|---|---|---|---|

| Wall Thickness (solid) | Up to ±0.009 | Up to ±0.006 | Table 11.2 | Varies by size; see aluminum extrusion catalog for exacts |

| Width/Depth (profiles) | ±0.012 to ±0.044 | ±0.008 to ±0.029 | Table 11.2 | Depends on circumscribing circle size |

| Length | ±0.25 to ±1.0 | — | Table 11.5 | Longer lengths allow wider tolerances |

| Straightness | 0.0125 × length (ft) | — | Table 11.6 | Measured over total or per foot |

| Twist | 1° per ft, up to 7° total | — | Table 11.7 | Critical for long extrusion profiles |

Note: Always cite the specific standard or aluminum extrusion profiles catalog when referencing numeric tolerances for your application.

Straightness, Twist, and Bow Control

Ever received an extrusion that just wouldn’t sit flat or align during assembly? That’s where straightness and twist come in. For most aluminium extrusions, straightness is checked by measuring the maximum deviation from a straight line along the length—typically using a straightedge or laser. Twist is measured in degrees per foot, and excessive twist can complicate installation or reduce structural integrity. Bow, or overall curvature, is also checked, especially for long or slender extrusion profiles. These checks are especially important for products like rails, frames, or tracks, where fit and function are critical.

Surface Finish Checks and Defect Diagnosis

Surface quality is more than just aesthetics—it can signal underlying process issues. Common surface imperfections include:

- Die lines: Fine lines running along the length, often from die wear or uneven flow.

- Surface scratches: Usually from handling or worn tooling; impact appearance and coating quality.

- Pickup: Localized roughness or buildup, typically from material sticking to the die.

- Warping/twist: Often due to uneven cooling or mishandling after extrusion.

Standard inspection methods for aluminium extrusions include visual checks, dimensional measurement with calipers or micrometers, and surface roughness gauges. For critical applications, additional tests like hardness, tensile strength, or salt spray corrosion resistance may be specified—especially if your project references an aluminum extrusion profile catalog with mechanical property requirements.

Relevant ASTM, ISO, and EN Standards

Want to ensure your extrusion profiles meet industry benchmarks? Referencing recognized standards is key. Here are some of the most relevant:

- ASTM B221: Standard for extruded aluminum bars, rods, wire, profiles, and tubes

- ASTM B241/B241M: Seamless pipe and tube

- EN 755-9: European standard for extrusion tolerances

- ISO 2768: General tolerances for linear and angular dimensions

Many suppliers publish an aluminum extrusion catalog or aluminum extrusion profiles catalog that cross-references these standards and details the available aluminum extrusion sizes, finishes, and mechanical properties. For the most up-to-date tolerances and requirements, always consult the relevant section of the catalog or the original standard [Aluminum Association].

- Review lot samples for dimensional and surface compliance

- Check straightness and twist over full length and per foot

- Verify mechanical properties (tensile, hardness) as specified

- Conduct surface finish and coating adhesion tests if required

- Use non-destructive tests (eddy current, salt spray) for critical applications

Before committing to tooling, align your drawing tolerances with what’s achievable for your extrusion class and size—this avoids costly surprises and ensures a smoother production run.

By understanding how tolerances, inspection methods, and standards intersect, you’ll be able to specify aluminium extrusions that are realistic, cost-effective, and verifiable at every stage. Next, we’ll explore when it makes sense to combine extrusion with CNC machining for the most demanding applications.

When to pair extrusion with precision CNC machining for aluminum frames and custom parts

Make vs. outsource: Deciding on complex features

When you’re designing an aluminum extrusion frame or a custom enclosure, you’ll quickly realize not every feature can be achieved by extrusion alone. Need pockets, threaded holes, ultra-flat mating surfaces, or intricate cutouts? That’s where secondary CNC machining comes in. But the big question is: should you handle this work in-house, or rely on experienced extruded aluminum suppliers with advanced machining capabilities?

| Provider | Machining Capability | Lead Time | Tolerance Reliability | Certification |

|---|---|---|---|---|

| XTJ Precision CNC Machining Services | 4 & 5-axis, high-complexity, wide material range | Rapid (from 3 days) | Ultra-tight (±0.005mm) | ISO 9001 & IATF 16949 |

| In-House Machining | Dependent on equipment and staff | Variable (often longer for complex jobs) | Depends on expertise/tools | May lack formal certifications |

| Other Outsourced Partners | Varies (often 3-axis or limited 4-axis) | Moderate to long | Variable | Check for relevant standards |

Holding tight tolerances on long and complex profiles

Imagine needing a custom extruded aluminum frame with precisely located threaded inserts or a long track with consistent slot widths over several feet. CNC machining is often the only way to achieve the flatness and positional accuracy required for these demanding features. Dedicated fixturing, especially for extruded aluminum frame assemblies, is crucial—specialized jigs prevent vibration and distortion during cutting, drilling, or tapping, ensuring each part stays within tolerance. Advanced providers leverage 4 and 5-axis machining to reach multiple faces and complex geometries without repeated setups, reducing the risk of misalignment.

Fixturing strategies for frames, enclosures, and tracks

Securing long or intricate profiles during machining is an art in itself. For example, when working with an aluminum extrusion frame or a track profile, using custom fixtures and supports minimizes deflection and ensures repeatability. If you’re planning to scale up production, consider whether your in-house setup can handle the volume—or if it’s time to partner with specialized extruded aluminum suppliers who already have the right tooling and process controls in place.

Prototype to production: Scaling with confidence

Launching a new product? Prototyping a custom extruded aluminum part often starts with small runs and rapid design changes. Outsourcing to a provider with flexible capacity and rapid turnarounds lets you iterate quickly. As you transition to full production, a partner with robust quality systems and certification can help you maintain consistency across thousands of parts. If you’re searching for precision CNC machining services that can handle everything from one-off prototypes to high-volume runs, be sure to match your supplier’s capabilities to your tolerance, volume, and certification needs.

Pros and Cons: In-House vs. Outsourced CNC Machining

In-House Machining

|

Outsourced/Vetted Partners

|

Early design-for-manufacturability (DFM) collaboration with your machining provider can reduce total project cost, minimize design changes, and streamline production for even the most complex aluminum extrusion frames.

Whether you’re weighing in-house resources or searching where to buy extruded aluminum machining services, the best path depends on your project’s complexity, tolerance requirements, and production goals. By understanding when to combine extrusion with advanced CNC machining, you unlock new possibilities for innovation and quality in every aluminum extrusion frame or custom component you design.

Frequently Asked Questions About Aluminium Extrusion

1. What are the main steps in the aluminium extrusion process?

The aluminium extrusion process involves preheating the billet, lubricating components, forcing the billet through a die, quenching, stretching to correct straightness, cutting to length, and aging for final properties. Each step is carefully controlled to ensure dimensional accuracy and surface quality.

2. What types of aluminium extrusion profiles are most common?

Common aluminium extrusion profiles include T-slot extrusions for modular framing, channels for tracks and supports, tubes (round, square, rectangular) for structural frames, and custom hollow shapes for specialized applications like heat sinks or architectural elements.

3. How do I choose the right alloy and temper for my aluminium extrusion?

Selecting the right alloy and temper depends on your project's strength, corrosion resistance, machinability, and finishing needs. 6xxx series alloys are widely used for their balanced properties and anodizing response, while 5xxx series suit marine environments and 7xxx for high-strength applications. Temper codes indicate heat treatment and affect final performance.

4. What are the benefits of combining aluminium extrusion with CNC machining?

Pairing aluminium extrusion with CNC machining enables complex features like precise holes, pockets, and threads that cannot be formed by extrusion alone. This approach is ideal for custom frames, enclosures, or parts requiring tight tolerances, and can be handled in-house or by specialized machining providers.

5. How are tolerances and quality standards managed for aluminium extrusions?

Tolerances for aluminium extrusions vary by profile type and feature, with industry standards like ASTM and EN providing guidance. Quality is ensured through dimensional checks, surface inspections, and referencing supplier catalogs for specific tolerance classes, helping ensure parts meet design and functional requirements.

-

Posted in

aluminium extrusion, aluminum profiles, cnc machining, extruded aluminum design, extrusion process