Anodizing vs. Powder Coating: Which Finish Is More Durable?

TL;DR

When comparing anodizing vs. powder coating durability, anodizing creates a harder finish that is integrated into the aluminum, making it exceptionally resistant to abrasion and impossible to peel or flake. Powder coating applies a protective polymer layer on top of the metal, offering superior flexibility, chip resistance, and a wider range of colors, which makes it better suited for applications where impact resistance is a primary concern, while anodizing offers superior UV stability.

Understanding the Basics: What Are Anodizing and Powder Coating?

Before diving into a head-to-head durability comparison, it's essential to understand the fundamental differences between these two popular metal finishing processes. Though they both protect and beautify metal parts, they achieve this through entirely different methods.

Anodizing is an electrochemical process exclusive to certain metals, most commonly aluminum. The aluminum part is submerged in an acid electrolyte bath, and an electric current is passed through it. This process doesn't add a layer on top of the metal; instead, it grows a controlled, porous, and extremely hard layer of aluminum oxide directly from the underlying aluminum. As detailed by experts at SAF, this makes the coating integral to the part itself, meaning it cannot peel or chip away. The resulting surface enhances wear resistance, corrosion protection, and provides a unique metallic sheen that can be dyed in various colors.

Powder coating, on the other hand, is a dry finishing process. It involves electrostatically spraying a fine powder, made of polymer resins and pigments, onto a grounded metal part. The static charge makes the powder adhere to the surface. The part is then cured in an oven, which melts the powder into a smooth, continuous, and tough coating that bonds to the surface. Unlike anodizing, this creates a distinct layer on top of the metal. As explained by Gabrian International, this method is highly versatile, environmentally friendly due to the lack of solvents, and can be applied to a wide range of metals.

Durability Deep Dive: A Head-to-Head Comparison

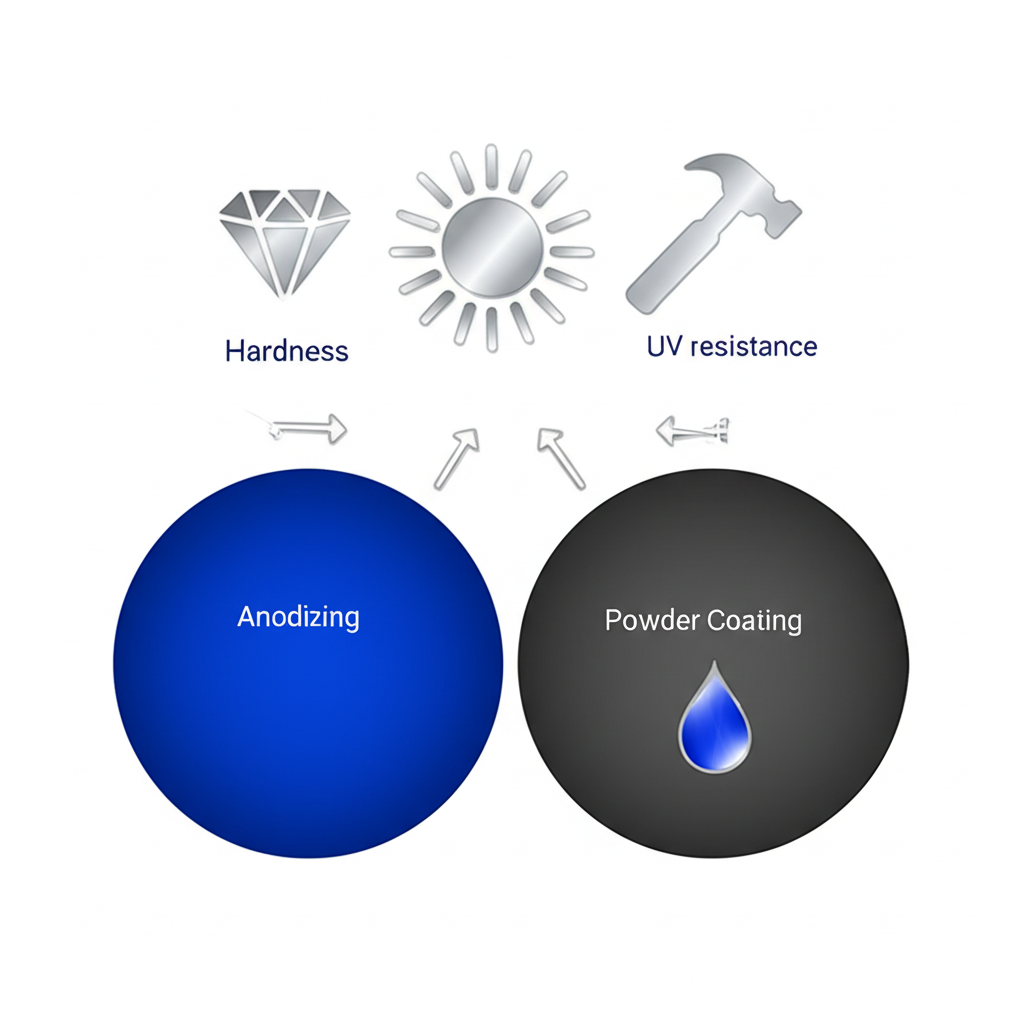

Durability isn't a single metric; it's a combination of factors including hardness, resistance to impact, and performance in various environments. Both anodizing and powder coating offer excellent protection, but their strengths lie in different areas. Choosing the right one depends entirely on the specific demands of your application.

Here is a breakdown of how they compare across key durability characteristics:

| Durability Factor | Anodizing | Powder Coating |

|---|---|---|

| Hardness & Abrasion Resistance | Superior. The aluminum oxide layer is harder than the base aluminum and most powder coats, offering excellent scratch resistance. | Good. Provides a tough finish but is generally softer than an anodized layer and can be scratched under heavy wear. |

| Chipping & Peeling Resistance | Excellent. Because the finish is integral to the metal, it cannot peel or flake off. | Good to Excellent. The cured polymer is flexible and impact-resistant, but a severe impact can cause it to chip. |

| UV & Weather Resistance | Excellent. Anodized finishes are highly resistant to UV degradation, making them superior for outdoor applications. | Good to Excellent. High-performance powders offer strong UV resistance, but are generally not as long-lasting as anodizing. |

| Corrosion Resistance | Excellent. The dense oxide layer provides a robust barrier against moisture and oxidation. However, it can be vulnerable to harsh acids and alkalis. | Excellent. The continuous, non-porous polymer layer effectively seals the metal from corrosive elements. As noted by Keystone Koating, it can offer superior chemical resistance in certain environments. |

The key takeaway is that anodizing's durability comes from its incredible hardness and integration with the metal. This makes it the preferred choice for high-wear applications where components rub against each other or are subject to frequent handling. In contrast, powder coating's strength is its flexibility and thickness. It can absorb impacts that might cause a more brittle anodized surface to fracture, and its chemical formulation can be tailored for specific environmental challenges like constant sun exposure.

Beyond Durability: Other Critical Factors to Consider

While durability is a primary concern, other factors like cost, aesthetics, and environmental impact play a crucial role in the final decision. A holistic view ensures the chosen finish meets all project requirements.

Cost

The cost comparison isn't always straightforward. According to Industrial Metal Service, anodizing can sometimes be more expensive due to the complex electrochemical process. However, for large production runs, powder coating can be more cost-effective. The price also varies based on color complexity, required coating thickness, and part geometry. It's always best to get quotes for your specific project to make an accurate financial comparison.

Aesthetics & Color Variety

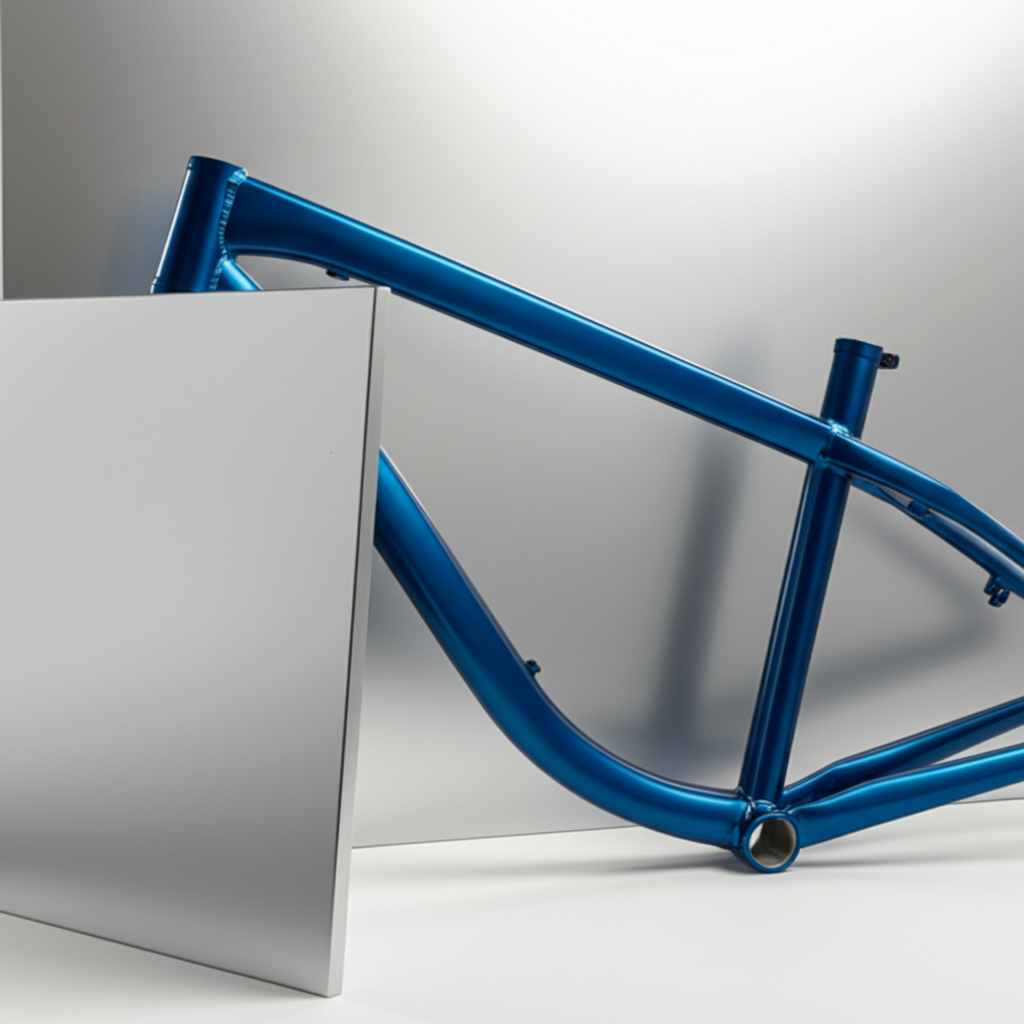

This is where powder coating has a distinct advantage. It is available in a virtually limitless spectrum of colors, textures, and gloss levels, from high-gloss and matte finishes to wrinkled and metallic effects. Anodizing, while offering a unique and deep metallic luster, has a more limited color palette. The color in anodizing is achieved by infusing dye into the porous oxide layer, which results in a translucent finish that highlights the metal's natural texture.

Environmental Considerations

Both processes are considered more environmentally friendly than traditional liquid painting. Powder coating excels here because it emits nearly zero volatile organic compounds (VOCs), and any oversprayed powder can be collected and reused, minimizing waste. Anodizing is also a water-based process without VOCs, and the chemicals used are recyclable. However, the process does involve acidic baths that require careful waste treatment.

The Verdict: Which Finish Is Right for Your Project?

The best choice between anodizing and powder coating durability depends entirely on the product's intended use and environment. There is no single "better" option, only the most appropriate one for the application.

Choose Anodizing if:

- Your part is made of aluminum and requires extreme hardness and abrasion resistance.

- The component will be in a high-wear, high-traffic environment (e.g., machine parts, door hardware).

- A premium, translucent metallic appearance is desired.

- The finish must be integral to the part and cannot peel or flake under any circumstances.

Choose Powder Coating if:

- The underlying metal has surface imperfections that need to be covered.

- A wide range of colors, textures, or special effects is needed for branding or aesthetics.

- The part needs good impact and chip resistance (e.g., automotive wheels, playground equipment).

- You are coating metals other than aluminum, such as steel.

For projects requiring high-precision components before finishing, such as in the aerospace or medical fields, partnering with a capable manufacturer is key. The quality of the underlying part is just as important as the finish. Services like XTJ's CNC machining can produce parts with tight tolerances, ensuring the foundation for a perfect and durable finish, whether you choose anodizing or powder coating.

Frequently Asked Questions

1. Is anodising more expensive than powder coating?

Generally, anodizing can have a higher initial cost than powder coating, especially for custom colors or smaller batches. However, powder coating can become more economical for large-scale projects. The final cost depends on factors like the size of the project, the complexity of the parts, and the specific finish requirements.

2. What are the disadvantages of anodising?

The main disadvantages of anodizing include a more limited color selection compared to powder coating, its applicability is mostly restricted to aluminum alloys, and while very hard, the finish can be brittle and may crack under severe stress or impact. It can also have lower resistance to highly acidic or alkaline chemicals compared to certain specialized powder coats.

3. What is the 720 rule for anodizing?

The 720 rule is a formula used in the anodizing industry to calculate the time needed to achieve a specific coating thickness. It states that the current density (in amps per square foot) multiplied by the time (in minutes) equals 720 for a 1 mil (0.001 inch) thick coating. It's a guideline that helps anodizers control the process for consistent results.

-

Posted in

aluminum coating, Anodizing, metal finishing, powder coating, surface treatment