CNC vs 3D Printing: Key Factors for Functional Prototypes

TL;DR

Choosing between CNC machining and 3D printing for functional prototypes involves a key trade-off: precision versus complexity. CNC machining is the superior choice for creating high-precision, strong parts with smooth surface finishes from production-grade materials. In contrast, 3D printing offers unmatched speed, design freedom for complex geometries, and lower costs for rapid, early-stage iterations.

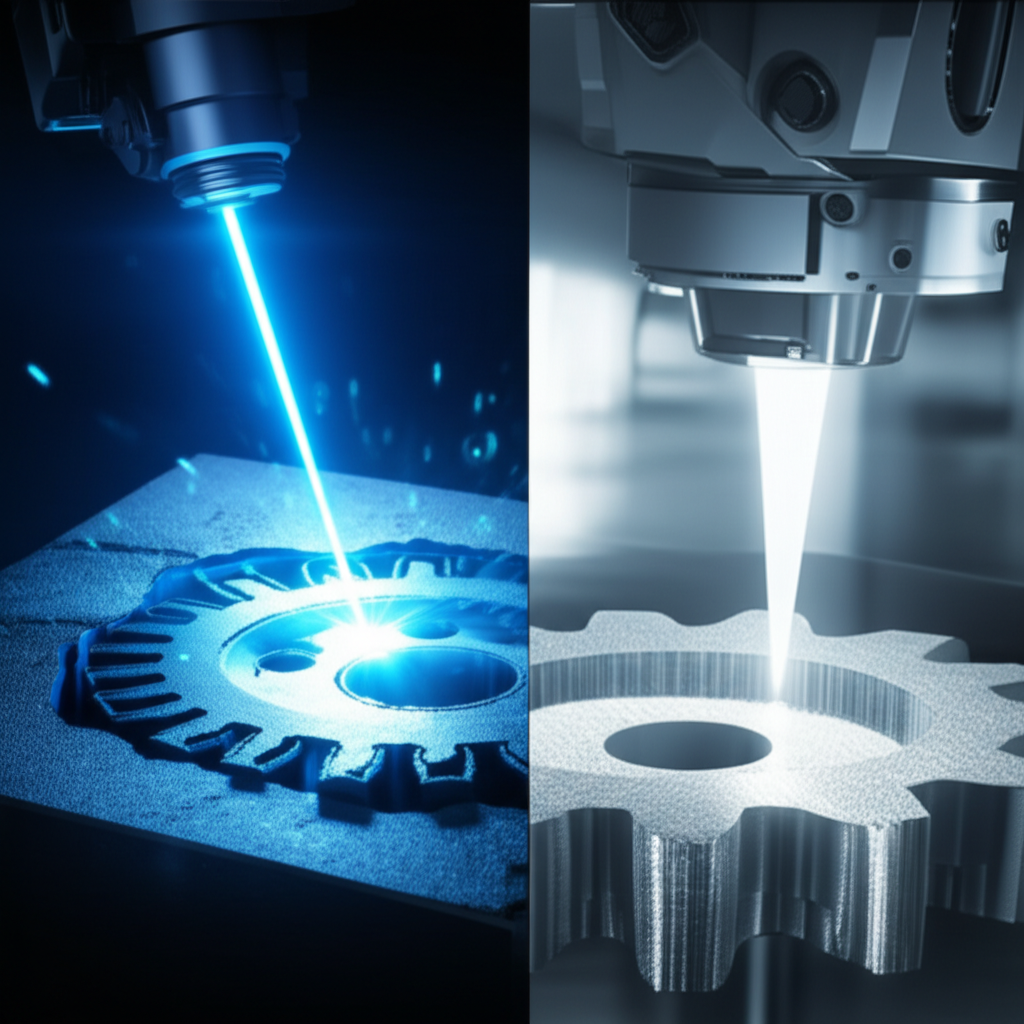

Understanding the Core Technologies: CNC Machining and 3D Printing

To make an informed decision, it's essential to understand the fundamental difference between these two manufacturing giants. CNC (Computer Numerical Control) machining is a subtractive process. It starts with a solid block of material, known as a blank, and uses high-speed rotating cutting tools to carve away material, sculpting the final part. Think of it as a highly precise, automated sculptor chipping away at a block of marble to reveal a statue within. This method is renowned for its ability to work with a wide range of robust materials, including metals and engineering-grade plastics.

On the other hand, 3D printing, also known as additive manufacturing, is an additive process. Instead of removing material, it builds a part layer by layer from a digital design file. This is more akin to building an object with LEGOs, where the final form is constructed from the ground up. This layered approach grants incredible design freedom, making it possible to create intricate internal structures and complex shapes that would be impossible to achieve with traditional subtractive methods.

Head-to-Head Comparison: Key Decision Factors for Prototypes

When evaluating CNC vs 3D printing for functional prototypes, the best choice depends entirely on your project's specific requirements. The decision hinges on a careful analysis of factors ranging from mechanical performance to geometric complexity. Below is a detailed breakdown of the critical criteria to consider.

Precision, Tolerances, and Surface Finish

For applications where accuracy is non-negotiable, CNC machining is the undisputed leader. It can achieve exceptionally tight tolerances, often as precise as ±0.025 mm (or ±0.001 inches), delivering parts with excellent dimensional accuracy and repeatability. This level of precision is critical for prototypes that need to fit perfectly with other components or undergo rigorous functional testing. The surface finish of CNC-machined parts is also typically much smoother than that of 3D-printed parts, though post-processing can improve the finish of both. For projects demanding the highest precision, providers like XTJ offer advanced 4 and 5-axis CNC machining that can hold tolerances down to +/- 0.005mm, ensuring components meet the most demanding specifications.

3D printing, while improving, generally offers lower precision, with typical tolerances ranging from ±0.1 mm to ±0.5 mm depending on the technology used. The layer-by-layer construction often results in visible layer lines on the surface, which may require post-processing like sanding or polishing to achieve a smooth finish. While sufficient for many form and fit prototypes, this level of accuracy may not be adequate for high-performance functional testing.

Material Selection and Strength

CNC machining excels in its ability to work with a vast array of production-grade materials, including various metals (aluminum, stainless steel, titanium) and engineering plastics (ABS, PEEK, Nylon). Because parts are carved from a solid block, they retain the material's full, isotropic mechanical properties, resulting in exceptional strength, durability, and thermal performance. This makes CNC ideal for functional prototypes that must withstand significant stress or harsh environmental conditions.

3D printing offers a diverse but different palette of materials, primarily polymers, resins, and some metal powders. While advanced materials like carbon-fiber-reinforced composites are available, 3D-printed parts often exhibit anisotropic properties, meaning they are weaker along the layer lines than in other directions. This can be a critical limitation for functional prototypes subjected to multi-directional loads. For prototypes that need to replicate the strength and feel of a final production part, CNC machining is almost always the better choice.

Speed and Lead Time

For one-off parts and rapid design iterations, 3D printing often has the edge in speed. With minimal setup required beyond preparing a digital file, a 3D printer can start building a part almost immediately and can often produce a prototype within 24 hours. This speed is invaluable during the early stages of product development, where quick feedback on form and fit is crucial.

CNC machining involves a more intensive setup process, including programming toolpaths, preparing the material blank, and setting up workholding fixtures. This can make it slower for a single prototype. However, once the setup is complete, CNC machines can cut material much faster than 3D printers can deposit it. For simpler geometries or small batches of parts, CNC machining can quickly become the more time-efficient option.

Geometric Complexity and Design Freedom

This is where 3D printing truly shines. Its additive nature allows for the creation of incredibly complex and organic shapes, including intricate internal lattices, hollow structures, and features with deep undercuts that are difficult or impossible for CNC tools to reach. This virtually unlimited design freedom enables engineers to create lightweight, topology-optimized parts that would be unfeasible to manufacture using subtractive methods.

CNC machining is limited by tool access. The cutting tool must be able to physically reach every surface it needs to machine, which restricts the creation of deep internal features or complex cavities. While advanced 5-axis CNC machines offer greater flexibility, they still cannot match the geometric freedom provided by 3D printing.

| Factor | CNC Machining | 3D Printing |

|---|---|---|

| Precision & Tolerance | Very High (±0.025 mm) | Moderate to Low (±0.1 mm or more) |

| Material Strength | Excellent (Isotropic properties) | Good to Moderate (Often anisotropic) |

| Geometric Complexity | Limited by tool access | Virtually unlimited |

| Speed (Single Part) | Slower due to setup | Faster due to minimal setup |

| Surface Finish | Excellent (Smooth) | Fair (Visible layer lines) |

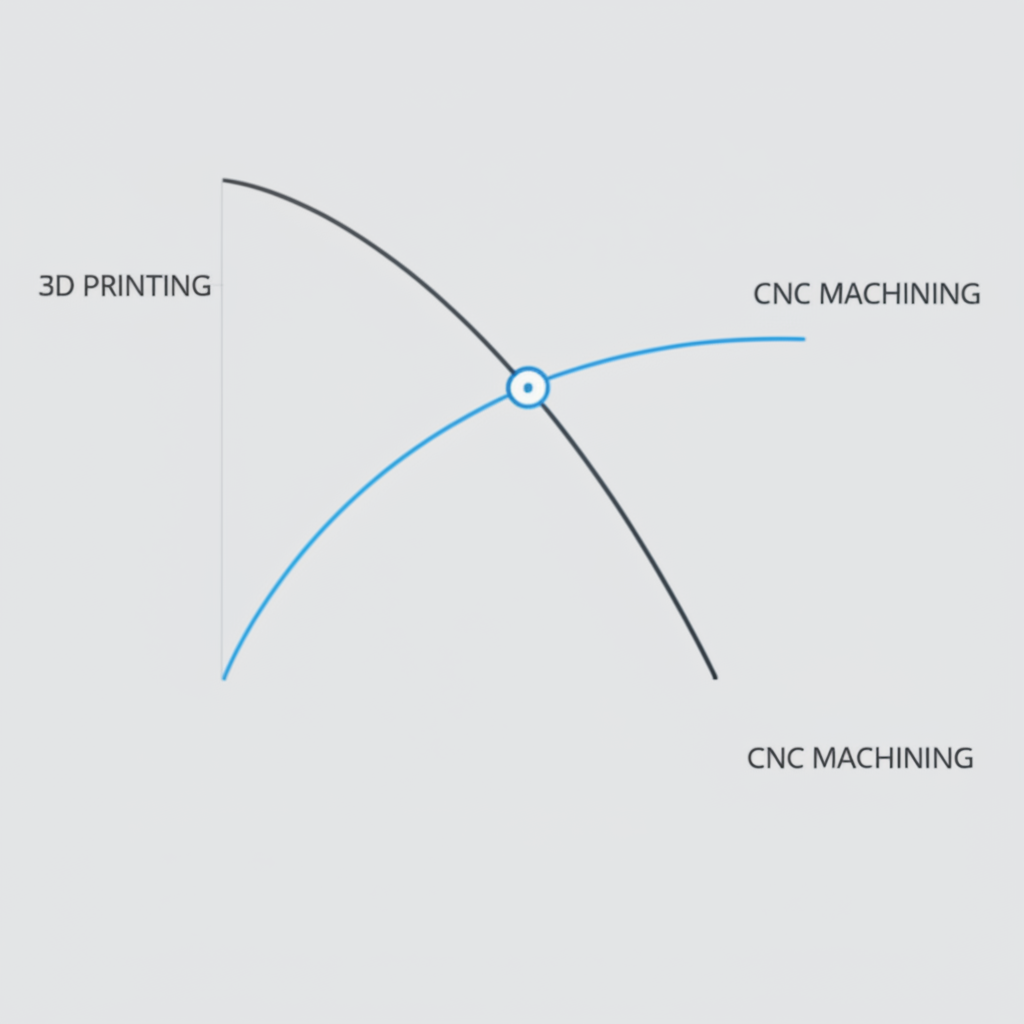

Cost Analysis: From Single Prototypes to Small Batches

The financial calculation for choosing between CNC and 3D printing is highly dependent on volume. For a single, one-off prototype, 3D printing is almost always the more cost-effective option. The process requires no custom tooling or fixtures, and the automated nature of the build process minimizes labor costs. Material usage is also highly efficient, as only the material needed for the part (and any necessary supports) is consumed.

CNC machining, conversely, has higher upfront costs associated with programming and setup time. Furthermore, its subtractive nature can lead to significant material waste, although this scrap is often recyclable. However, these initial costs are quickly amortized over larger quantities. As production volume increases to small batches (e.g., 10-100 units), CNC machining often becomes the more economical choice because the cost per part drops significantly once the machine is programmed and set up. For low-volume production, CNC's efficiency at scale typically outweighs the low initial cost of 3D printing, where the price per part remains relatively constant regardless of quantity.

Making the Right Choice: Which Method is Best for Your Project?

Ultimately, the decision between CNC machining and 3D printing is not about which technology is universally better, but which is the right tool for the specific job at hand. By aligning the strengths of each process with your project's priorities, you can optimize for performance, cost, and speed.

Choose 3D Printing When...

- Speed is critical: You need a physical model for a design review or form/fit test as quickly as possible, often within a day.

- Geometric complexity is high: Your design includes intricate internal channels, organic shapes, or complex lattice structures that cannot be machined.

- Cost for a single part is a key concern: You are in the early stages of prototyping and need to produce a one-off model affordably to validate a concept.

- Material properties are less critical: The prototype is for visual assessment or basic functional testing and does not need to withstand high mechanical stress.

Choose CNC Machining When...

- High precision and tight tolerances are required: The prototype must mate perfectly with other components or meet strict dimensional specifications for functional testing.

- Superior material strength is necessary: The functional prototype will be subjected to significant mechanical loads, high temperatures, or harsh conditions that require the properties of production-grade metals or plastics.

- A smooth surface finish is essential: The part's aesthetic appearance is important, or it requires a smooth surface for functional reasons, such as sealing or sliding against another part.

- You are producing a small batch: For quantities beyond a few units, CNC machining often becomes more cost-effective per part than 3D printing.

Frequently Asked Questions

1. What are the advantages of CNC over 3D printing?

The primary advantages of CNC machining are its superior precision, ability to achieve much tighter tolerances, and smoother surface finishes. It also uses production-grade materials, resulting in parts with excellent, isotropic mechanical properties that are significantly stronger and more durable than most 3D-printed equivalents. This makes CNC ideal for high-performance functional prototypes and end-use parts.

2. Is CNC harder than 3D printing?

Generally, yes. CNC machining requires more technical expertise. It involves programming complex toolpaths (G-code), selecting appropriate cutting tools and speeds, and setting up workholding fixtures. 3D printing is more automated; software called a 'slicer' handles most of the preparation, and the machines often run with minimal supervision once a print starts.

3. Is 3D printing good for prototyping?

Yes, 3D printing is an excellent tool for prototyping, particularly in the early stages of design. Its speed and low cost for single parts allow engineers and designers to quickly and affordably create physical models to test form, fit, and ergonomics. This ability to rapidly iterate helps identify design flaws early, saving significant time and money before committing to more expensive manufacturing processes.

-

Posted in

3d printing, cnc machining, engineering design, manufacturing, rapid prototyping