6061 vs 7075 Aluminum: The Essential Strength Trade-Offs

TL;DR

For applications demanding maximum strength, 7075 aluminum is the definitive choice, offering nearly double the tensile strength of 6061 aluminum. However, this superior strength involves significant trade-offs. 6061 aluminum provides far better weldability, formability, and corrosion resistance, making it a more versatile and often more practical alloy for a wider range of general-purpose and structural applications where extreme stress is not the primary concern.

Strength and Hardness: A Head-to-Head Comparison

When evaluating aluminum 6061 vs. 7075 for strength, the difference is substantial and primarily driven by their chemical compositions. Alloy 7075 is part of the 7xxx series, which uses zinc as its primary alloying element, along with magnesium and copper. This combination results in one of the highest-strength aluminum alloys commercially available. In contrast, 6061 is a 6xxx series alloy, relying on magnesium and silicon, which produces a more balanced, all-purpose material.

In a heat-treated T6 temper condition, 7075-T6's mechanical properties significantly outperform those of 6061-T6. The yield strength of 7075-T6—the point at which the material begins to deform permanently under stress—is nearly double that of 6061-T6. This makes 7075 ideal for components subjected to high stress and load, where preventing deformation is critical. Its superior hardness also means it can better withstand wear and abrasion.

The following table provides a clear, data-driven comparison of the key mechanical properties for both alloys in the common T6 temper, synthesized from multiple industry sources.

| Mechanical Property | 6061-T6 Aluminum | 7075-T6 Aluminum |

|---|---|---|

| Ultimate Tensile Strength | ~310 MPa (45,000 psi) | ~572 MPa (83,000 psi) |

| Yield Strength | ~276 MPa (40,000 psi) | ~503 MPa (73,000 psi) |

| Hardness (Brinell) | 95 | 150 |

| Shear Strength | ~207 MPa (30,000 psi) | ~331 MPa (48,000 psi) |

These figures clearly illustrate why 7075 is specified for high-performance applications. Its ability to withstand almost twice the stress before yielding makes it a non-negotiable choice for critical components in aerospace and defense. However, it's crucial to understand that these strength advantages do not exist in a vacuum; they are balanced by compromises in other essential fabrication properties.

Beyond Strength: Weldability, Formability, and Corrosion Resistance

While 7075 aluminum wins on pure strength, the decision between these two alloys is rarely that simple. Fabrication characteristics often dictate the more practical choice for a given project. 6061 aluminum's versatility in manufacturing processes makes it one of the most widely used alloys available.

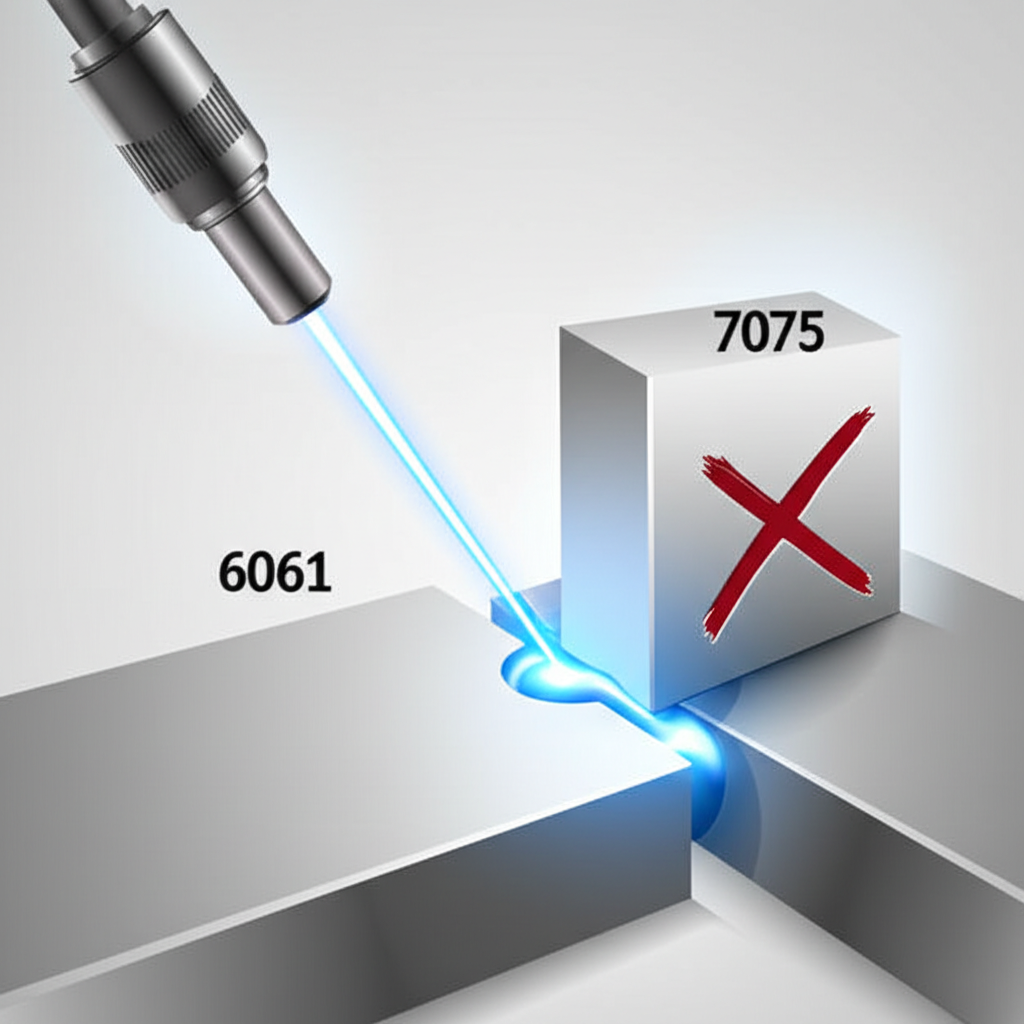

Weldability and Machinability

Here, the difference is stark. 6061 aluminum offers excellent weldability due to its silicon content, making it suitable for complex structural assemblies that require strong, reliable joints. In contrast, 7075 is generally considered unweldable for structural applications because its composition makes it highly susceptible to cracking during and after welding. While both alloys are machinable, 6061 is easier to work with due to its lower hardness, resulting in less tool wear and faster machining times. However, for projects requiring complex, high-tolerance components from either material, leveraging advanced manufacturing is key. For example, specialized providers like XTJ CNC machining services handle a wide range of materials, including high-strength alloys, to produce precise parts for demanding industries like aerospace and medical.

Formability

Formability, or the ability to be bent and shaped without fracturing, is another area where 6061 has a distinct advantage. Its lower strength and hardness give it greater ductility, allowing it to be cold-worked and formed into complex shapes more easily. 7075 aluminum is significantly more brittle. Attempting to bend or form it, especially in the T6 temper, often results in cracking, requiring specialized techniques or annealing to perform any shaping.

Corrosion Resistance

6061 aluminum demonstrates good corrosion resistance in most environments, including marine settings, thanks to the protective oxide layer that forms on its surface. The higher copper content in 7075, a key contributor to its strength, unfortunately makes it more susceptible to corrosion, particularly stress corrosion cracking. Because of this, 7075 parts often require a protective finish, such as anodizing or painting, to ensure long-term durability, especially in harsh environments.

Common Applications: Where Each Alloy Shines

The distinct properties of 6061 and 7075 aluminum dictate their use in very different applications. Understanding these real-world examples helps clarify the practical implications of their respective strengths and weaknesses.

6061 Aluminum, often called "structural aluminum," is a versatile workhorse prized for its balance of strength, corrosion resistance, and fabricability. Its applications are widespread and varied:

- Structural Components: Used in building construction, bridges, and general machine framing.

- Automotive and Transportation: Found in truck and bus bodies, automotive parts, and railway cars.

- Marine Applications: Excellent for boat hulls, marine fittings, and hardware due to its good corrosion resistance.

- Consumer Products: Commonly used for bicycle frames, furniture, and scuba tanks.

7075 Aluminum is the go-to choice when the highest possible strength-to-weight ratio is the most critical factor, and cost or ease of fabrication are secondary. Its use is concentrated in high-performance fields:

- Aerospace and Defense: Known as an "aircraft grade" alloy, it is essential for aircraft fuselages, wings, and other structural components that endure high stress.

- Military Equipment: Used in military-grade vehicles, weaponry, and other high-stress components.

- High-Performance Sporting Goods: Found in rock climbing equipment, high-end bicycle components, and competition-grade frames where minimal weight and maximum strength are paramount.

- Industrial Tooling: Used for creating molds for plastics and other materials due to its high hardness and wear resistance.

Cost and Availability: The Financial Bottom Line

For any project, budget is a critical constraint, and there is a noticeable cost difference between these two alloys. 6061 aluminum is generally less expensive and more widely available than 7075. Its popularity and ease of manufacturing contribute to its cost-effectiveness, making it an economical choice for a vast array of applications.

7075 aluminum, on the other hand, is more expensive. The higher cost is a result of its more complex chemical composition, particularly the inclusion of zinc, and the more rigorous heat treatment processes required to achieve its superior strength properties. When making a selection, it is essential to perform a cost-benefit analysis. The premium price of 7075 is only justified when the application's performance requirements demand its exceptional strength and cannot be met by 6061 or other alloys.

Making the Right Choice: A Summary

Choosing between aluminum 6061 and 7075 is a matter of identifying the primary requirement of your application. The decision hinges on a clear understanding of the trade-offs between elite strength and practical versatility. If your project's success depends on the highest possible strength-to-weight ratio and can accommodate higher costs and more complex fabrication, 7075 is the correct and often necessary choice. This is typically the case in mission-critical aerospace, defense, and high-performance sporting applications.

Conversely, if your project requires good all-around strength combined with excellent weldability, formability, and corrosion resistance, 6061 is the superior and more economical option. Its versatility has made it one of the most popular aluminum alloys in the world, suitable for everything from structural frames and marine hardware to automotive parts and consumer goods. Ultimately, a careful evaluation of performance needs against fabrication and budget constraints will lead to the optimal material selection.

Frequently Asked Questions

1. What is the best aluminum for strength?

Grade 7075 is widely considered one of the strongest commercially available aluminum alloys. Its high zinc content allows it to achieve a tensile strength comparable to many types of steel, making it the premier choice for applications where maximum strength and hardness are the most critical factors.

2. Is 7075 aluminum as strong as steel?

While 7075 aluminum is exceptionally strong for a lightweight metal, its strength relative to steel depends on the specific alloys being compared. 7075 is stronger than many mild and low-carbon steels. However, it is not as strong as high-strength steel alloys like 4130 chromoly or various hardened tool steels. Its key advantage is its excellent strength-to-weight ratio, providing steel-like strength at about one-third of the weight.