A Guide to CMM Inspection for Precision CNC Parts

TL;DR

Coordinate Measuring Machine (CMM) inspection is a high-precision quality control process essential for verifying the dimensional accuracy of CNC machined parts. It uses a sophisticated probe to capture geometric data from a component's surface, comparing it against the original CAD model to ensure features and tolerances meet exact design specifications. This method is crucial for reducing waste, ensuring compliance, and maintaining the highest standards of quality in modern manufacturing.

What Is CMM Inspection and Why Is It Crucial for CNC Machining?

In the world of precision manufacturing, adherence to design specifications is not just a goal—it is a fundamental requirement. A Coordinate Measuring Machine (CMM) is a device that measures the geometry of physical objects by collecting discrete points on the surface with a probe. For CNC machined parts, where tolerances can be incredibly tight, CMM inspection serves as the definitive method for quality assurance. It moves beyond the limitations of traditional measurement tools like calipers and micrometers, offering a comprehensive, three-dimensional assessment of a part's geometric characteristics.

The importance of CMM inspection for CNC machining lies in its ability to provide unparalleled accuracy and repeatability. A CMM operates on a three-axis Cartesian coordinate system (X, Y, Z) to map a part's features with micrometer-level precision. This process is critical for verifying complex geometries, tight tolerances, and intricate features that manual inspection methods cannot reliably assess. The output is a detailed inspection report that provides a pass/fail analysis against the design's geometric dimensioning and tolerancing (GD&T) specifications, forming the backbone of a robust quality control system.

By integrating CMM inspection into the workflow, manufacturers can catch deviations early, preventing costly rework and material waste. This verification is vital for industries like aerospace, automotive, and medical, where component failure is not an option. Ultimately, CMM inspection validates the entire CNC machining process, from tool setup to final production, ensuring that every part conforms perfectly to its digital blueprint. The key benefits of this process are numerous and impactful.

- Exceptional Accuracy: CMMs deliver precise measurements far beyond the capability of manual tools, often measuring tolerances as tight as a few microns.

- High Repeatability: The automated nature of CMM inspection eliminates human error and ensures that measurements are consistent across multiple parts and inspection cycles.

- Speed and Efficiency: An inspection that could take hours with manual tools can often be completed in minutes with a CMM, significantly reducing production bottlenecks.

- Complex Geometry Verification: CMMs excel at measuring complex shapes, contours, and angles that are difficult or impossible to assess with conventional instruments.

- Comprehensive Data Reporting: The process generates detailed reports that are crucial for quality assurance documentation, process improvement, and compliance with industry standards like ISO 9001.

The CMM Inspection Process: A Step-by-Step Breakdown

The CMM inspection process is a systematic procedure designed to ensure accuracy and repeatability. While the specifics can vary based on the part and machine, the fundamental stages remain consistent, transforming a physical component into a set of verifiable data points compared against a digital model. Each step is critical to achieving a reliable outcome and validating the quality of CNC machined parts.

Understanding this workflow demystifies how CMMs achieve such high precision. It is a blend of careful preparation, precise programming, and sophisticated data analysis. According to an article from 3ERP, the process can be broken down into three primary stages: preparation, conducting the inspection, and post-inspection activities. This structured approach ensures that every variable, from environmental conditions to part fixturing, is controlled for maximum accuracy.

Here is a detailed breakdown of the typical CMM inspection process:

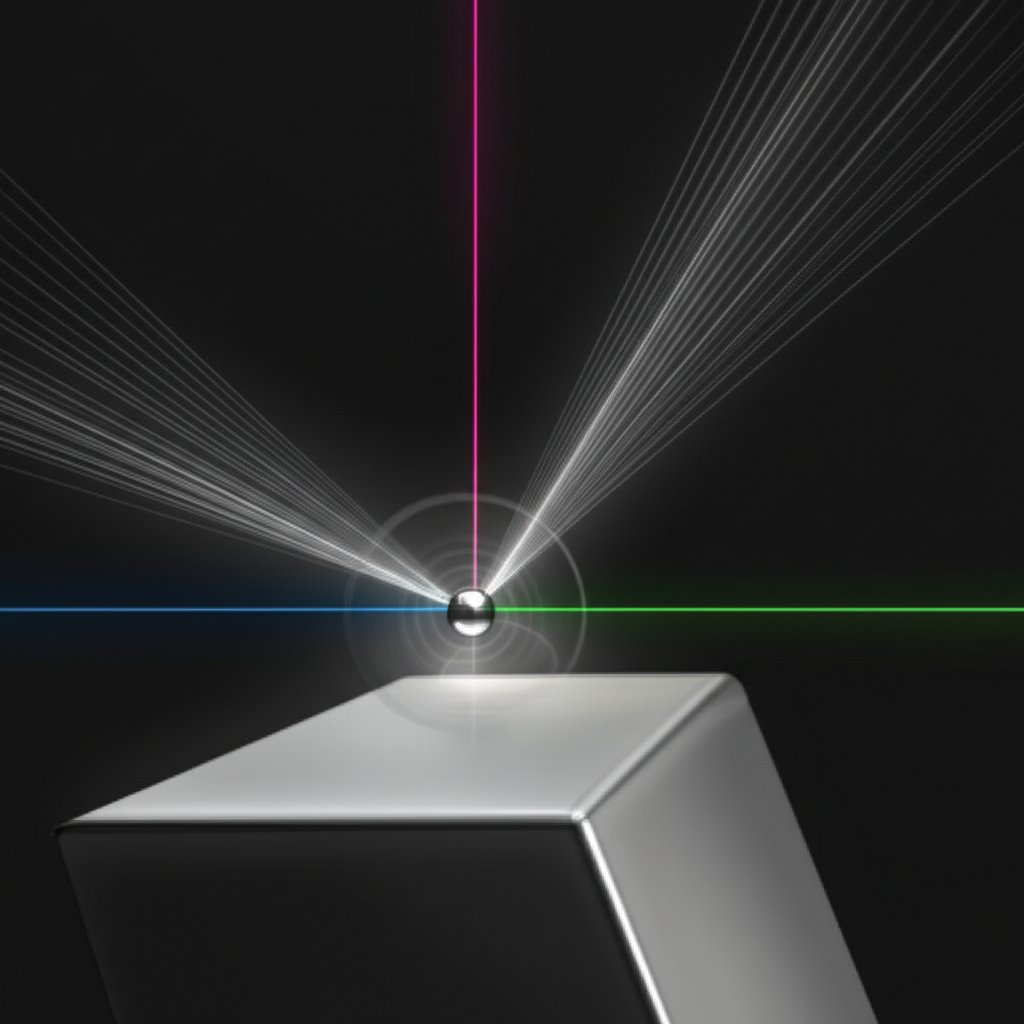

- Preparation and Setup: The first step involves securing the CNC part on the CMM's granite table using fixtures. The part must be held rigidly to prevent any movement during measurement. It's also crucial for the part to acclimate to the temperature of the inspection room, as thermal expansion or contraction can affect dimensional accuracy. The appropriate probe (e.g., touch-trigger, scanning, laser) is selected and calibrated to a known standard, such as a precision sphere.

- Programming the Measurement Routine: A CMM program is created, often directly from the part's CAD model. The programmer defines the coordinate system, the features to be measured (holes, planes, slots), the probing path, and the required tolerances. This program dictates every movement the CMM will make, ensuring the process is automated and repeatable.

- Execution and Data Collection: Once the program is launched, the CMM's probe automatically moves to the specified locations on the part. For a touch-trigger probe, it makes contact with the surface at discrete points, recording the X, Y, and Z coordinates for each touch. Scanning probes move across surfaces to collect a dense cloud of data points. This raw coordinate data is captured by the machine's software.

- Data Analysis and Reporting: The CMM software processes the collected data points. It constructs geometric features from the points (e.g., calculating a circle's diameter from three points) and compares these measurements to the nominal dimensions and tolerances defined in the CAD model. The software then generates a detailed inspection report, which typically includes a pass/fail summary for each feature, color-coded deviation maps, and a full analysis of GD&T callouts. This report serves as the official record of the part's quality.

Types and Capabilities of Coordinate Measuring Machines

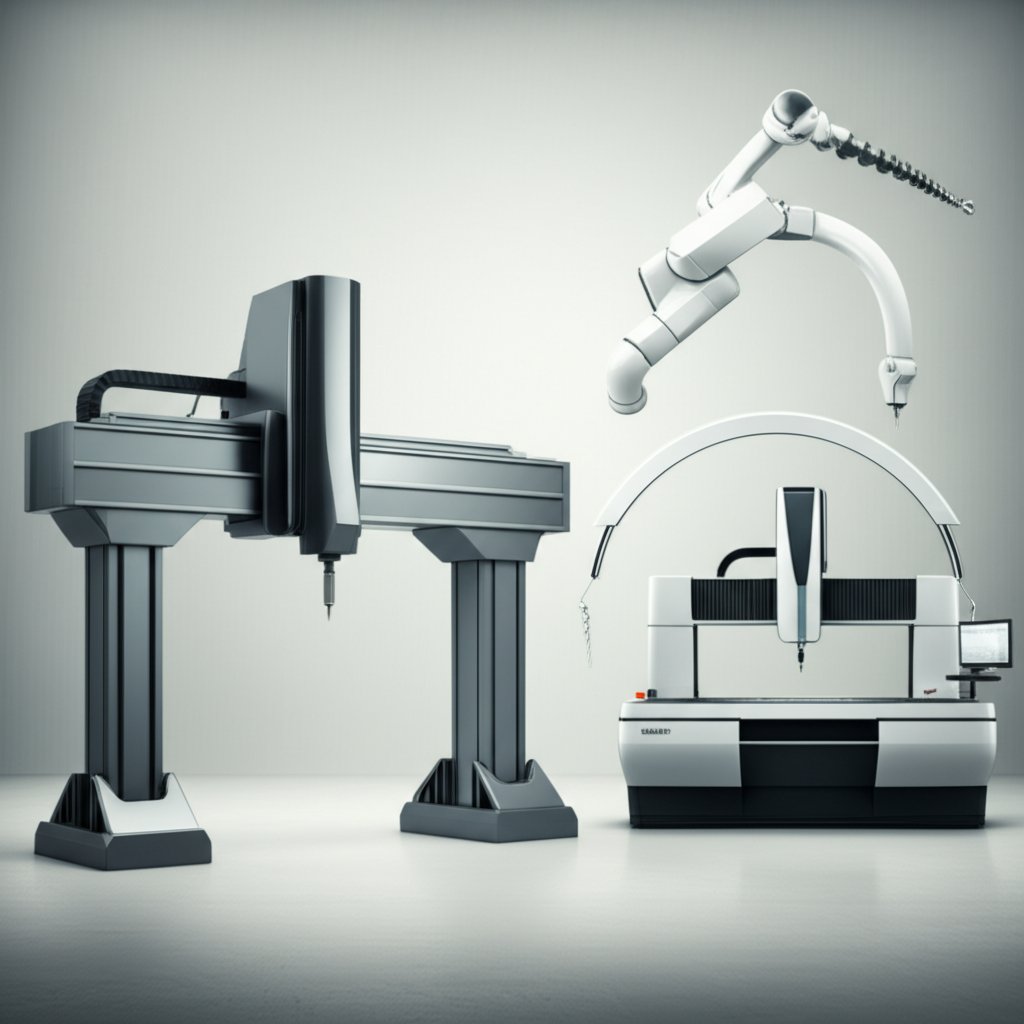

Not all Coordinate Measuring Machines are created equal. They are designed in various configurations to accommodate different part sizes, accuracy requirements, and manufacturing environments. The main types include Bridge, Gantry, Cantilever, and Horizontal Arm CMMs, each with a distinct structural design that dictates its primary applications. Choosing the right machine is critical for balancing precision, throughput, and cost-effectiveness in a CNC machining operation.

Bridge CMMs are the most common type found in quality labs, known for their high accuracy and versatility with small to medium-sized parts. For inspecting very large and heavy components, such as automotive frames or aerospace structures, Gantry CMMs are the preferred solution. Cantilever CMMs offer excellent accessibility for small parts, while Horizontal Arm CMMs are often used for inspecting thin-walled components like sheet metal panels. Portable CMMs, or articulating arms, bring measurement flexibility directly to the shop floor, though often with a slight trade-off in absolute accuracy compared to their stationary counterparts.

The capabilities of these machines extend beyond simple dimensional checks. Modern CMMs can be equipped with advanced probing systems, including non-contact laser scanners that capture millions of data points in seconds, making them ideal for reverse engineering and profiling complex surfaces. This versatility allows manufacturers to perform a wide range of inspection tasks with a single machine. The table below outlines the key characteristics and applications of the most common CMM types.

| CMM Type | Typical Size/Volume | Accuracy Level | Common CNC Application |

|---|---|---|---|

| Bridge | Small to Medium | Very High | Precision-machined engine components, medical implants, molds and dies. |

| Gantry | Large to Very Large | High | Automotive body-in-white, large aerospace structural components, heavy machinery parts. |

| Cantilever | Small | High | Small, high-precision parts where open access from three sides is beneficial. |

| Horizontal Arm | Medium to Large | Moderate to High | Sheet metal panels, thin-walled castings, and hard-to-reach features on large parts. |

| Portable Arm | Small to Medium (within arm's reach) | Moderate | In-process checks on the factory floor, large part inspection in situ, fixture verification. |

Integrating CMM Inspection for Enhanced Quality Control

Simply having a CMM is not enough; its true value is unlocked when it is strategically integrated into a broader quality control ecosystem. Effective integration transforms CMM inspection from a simple pass/fail gate into a powerful tool for process improvement. The data generated by a CMM provides deep insights into the stability and capability of CNC machining processes. By analyzing measurement trends, manufacturers can identify issues like tool wear, machine misalignment, or thermal variations before they result in out-of-tolerance parts.

This proactive approach is the foundation of Statistical Process Control (SPC). CMM data can be fed directly into SPC software to monitor production in real-time, allowing engineers to make data-driven decisions that enhance consistency and reduce scrap rates. Furthermore, CMMs are indispensable for conducting First Article Inspections (FAI), which are required to validate that a new or revised production process is capable of producing parts that meet all engineering specifications. A comprehensive FAI report from a CMM provides the objective evidence needed to approve a process for full-scale production.

For businesses looking to leverage this technology, the decision often comes down to investing in in-house equipment or partnering with a specialized service provider. Companies offering comprehensive manufacturing solutions often provide rigorous quality control as part of their services. For instance, some partners in formative manufacturing, such as XTJ, emphasize their ISO 9001:2015 certified quality control to ensure that every prototype and part meets high standards. When choosing a service, it is critical to evaluate their capabilities and certifications to ensure they align with your project's quality requirements.

When selecting a CMM inspection service provider, consider the following checklist:

- Certifications and Accreditations: Look for providers with certifications like ISO 9001, AS9100 (for aerospace), or ISO 13485 (for medical), which demonstrate a commitment to recognized quality standards.

- Machine Capabilities and Technology: Ensure their CMMs have the required size, accuracy, and probing technology (e.g., contact vs. non-contact) for your specific parts.

- Reporting Standards: Inquire about their reporting format. A good provider will offer clear, comprehensive reports that include GD&T analysis and color maps for easy interpretation.

- Technical Expertise: The skill of the CMM programmers and operators is just as important as the machine itself. Experienced technicians can develop more efficient and reliable inspection routines.

- Turnaround Time: Confirm that their lead times for inspection align with your production schedule to avoid becoming a bottleneck.

Frequently Asked Questions About CMM Inspection

1. What is the process of CMM inspection?

The CMM inspection process typically involves three main stages. First is the setup, where the part is securely fixed to the machine's table. The second is probing or scanning, where a tactile or optical probe automatically captures data points on the part's surface according to a pre-written program. Finally, in the data analysis stage, the CMM software compares the measured coordinates to the part's original CAD design file and generates a report detailing any deviations from the specified tolerances.

2. What is CMM in CNC?

In the context of CNC (Computer Numerical Control) machining, a CMM (Coordinate Measuring Machine) is a quality control device used to verify the geometric accuracy of the machined parts. While a CNC machine creates the part by removing material, the CMM measures the finished part to ensure it was made correctly and conforms to all dimensions and tolerances specified in the engineering drawings and CAD models.

3. What is a CMM quality inspector?

A CMM quality inspector, often called a CMM operator or programmer, is a skilled technician responsible for using a Coordinate Measuring Machine to perform inspections. Their duties include creating inspection programs (often from CAD models), setting up parts on the machine, running the inspection cycles, and interpreting the measurement data and reports to determine if a part passes or fails quality standards.

4. What is the full form of CMM inspection?

The full form of CMM is Coordinate Measuring Machine. Therefore, CMM inspection stands for Coordinate Measuring Machine inspection. It is a process of using this specialized equipment to perform highly accurate and precise measurements of an object's physical geometric characteristics.