Machining Hardened Steel: Key Strategies to Prevent Failure

TL;DR

Machining hardened steel poses significant challenges primarily due to its extreme hardness, which leads to rapid tool wear, excessive heat generation, and work hardening during the cutting process. Overcoming these obstacles requires a strategic approach that combines specialized tooling like PCBN or coated carbides, optimized machine parameters with a focus on consistent feed rates, and a rigid, stable machine setup. Often, the most effective strategy involves machining the part to near-net shape before hardening, followed by a final finishing pass to ensure dimensional accuracy.

The Core Challenges: Why Machining Hardened Steel is Difficult

When a material's hardness exceeds 45 HRC, conventional machining rules no longer apply. The fundamental difficulty lies in the material's immense resistance to being cut, which creates a cascade of interrelated problems for machinists. These aren't minor inconveniences; they are process-defining obstacles that can lead to catastrophic tool failure, scrapped parts, and dramatically increased costs. Understanding these core challenges is the first step toward developing a successful hard machining strategy.

The primary concern is the presence of very high mechanical loads on the cutting edge. According to tooling experts at Seco Tools, these extreme forces lead directly to predictable failure modes, including rapid flank wear, crater wear, and even outright breakage of the cutting edge. Unlike in softer materials, the margin for error is razor-thin. A slight miscalculation in speed or feed doesn't just reduce tool life; it can destroy an expensive insert in seconds. This puts immense pressure on process stability and tool selection.

Another critical issue is excessive heat generation. In an ideal cutting scenario, the heat generated by friction is carried away with the chip. However, in hard machining, this heat often transfers directly into the workpiece and the cutting tool. This happens because the material resists shearing, causing the tool to rub more than cut, especially with incorrect parameters. This retained heat can cause thermal distortion in the part, compromise the integrity of the tool's coating and substrate, and exacerbate the next major problem: work hardening.

Work hardening is a phenomenon where the material being machined actually becomes harder due to the stress and heat of the cutting process. As explained by Harvey Performance, the heat generated by friction can alter the material's microstructure at the point of cut, making it as hard or even harder than the cutting tool itself. This creates a vicious cycle where each subsequent pass becomes more difficult, accelerating tool wear and making it nearly impossible to maintain consistent dimensions and surface finish. The primary challenges can be summarized as follows:

- Rapid Tool Wear: Extreme mechanical loads cause predictable and swift degradation of the cutting edge.

- Excessive Heat Generation: Friction transfers heat to the workpiece and tool instead of the chip, causing thermal damage.

- Work Hardening: The machining process itself increases the material's surface hardness, making subsequent cuts more difficult.

- Dimensional Instability: High cutting forces and thermal stress can lead to part distortion and difficulty holding tight tolerances.

Strategic Planning: Pre-Machining Decisions for Success

Success in machining hardened steel begins long before a toolpath is programmed. The most critical decisions are strategic, focusing on the entire manufacturing process from material selection to heat treatment. A reactive approach that only addresses problems as they occur at the machine is destined for failure. Instead, a proactive, well-planned strategy can mitigate the majority of challenges and significantly reduce costs and lead times.

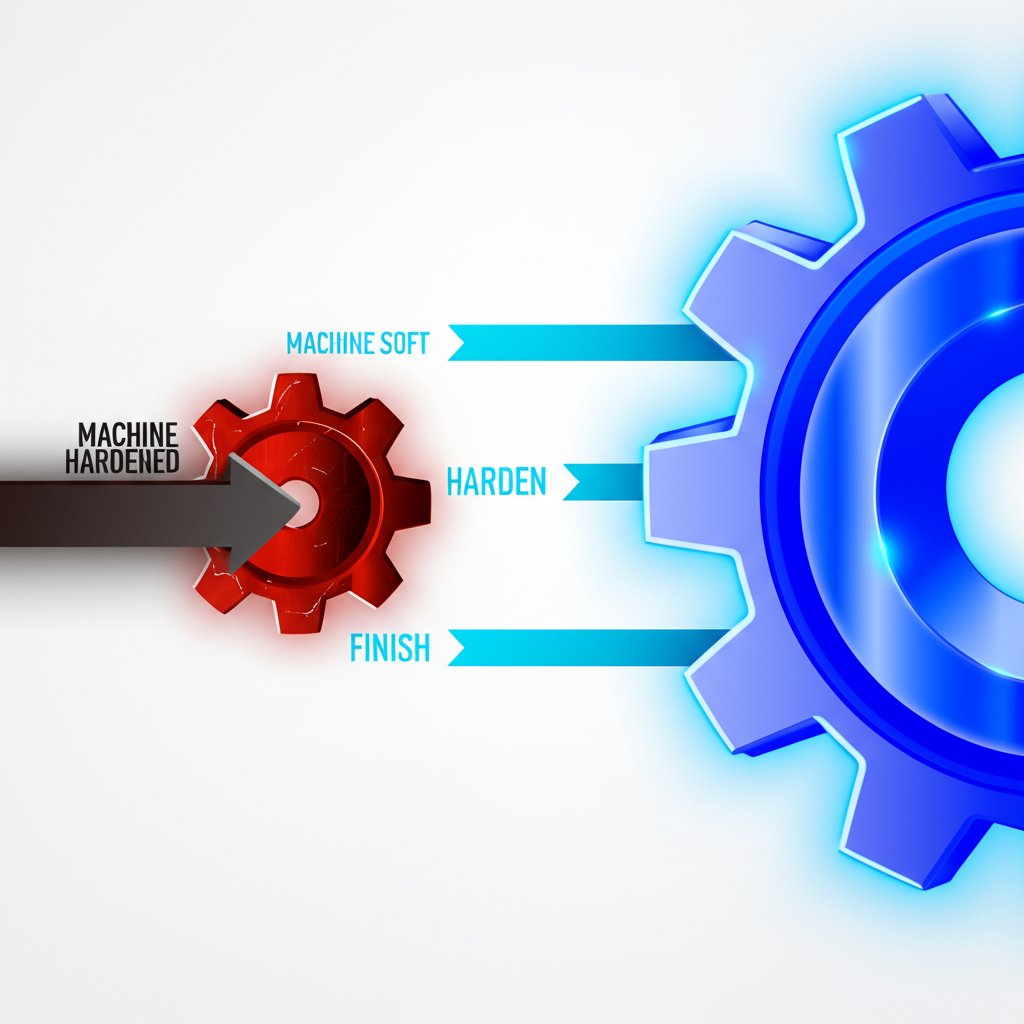

One of the most effective strategies is a hybrid approach: machine the part in its softer, annealed state, then harden it, and finally perform a finish machining operation. This 'machine-harden-finish' workflow dramatically reduces tool wear and stress on the machine during the roughing phase. A typical stock allowance of 0.010" to 0.015" is left for the final finishing pass, which is just enough to correct any distortion from the heat treatment process and bring the part into final tolerance. While this adds a process step, it is often more cost-effective than attempting to remove large amounts of hardened material.

Managing tolerance expectations is also crucial. As material hardness increases, the ability to hold extremely tight tolerances diminishes due to increased cutting forces and thermal instability. For instance, while tolerances of ±0.01 mm might be achievable on materials up to 45 HRC, this may open up to ±0.02-0.05 mm on materials in the 55-65 HRC range. Communicating these realities during the design and quoting phase prevents costly rework and unrealistic expectations. This is where early-stage collaboration and prototyping become invaluable. To accelerate product development and validate these manufacturing choices, many engineering teams partner with formative manufacturing specialists. For example, services like those offered by XTJ can provide rapid prototypes and vital Design for Manufacturability (DFM) feedback, helping to refine designs and process plans before committing to full-scale production of hardened components.

The table below illustrates the relationship between hardness, achievable tolerances, and the significant cost impact of hard machining.

| Hardness Range (HRC) | Achievable Tolerance (Typical) | Relative Cost Increase |

|---|---|---|

| < 45 HRC | ±0.01 mm | Base |

| 45-55 HRC | ±0.02 mm | +150% |

| 55-65 HRC | ±0.05 mm | +250-300% |

In-Process Techniques to Combat Heat and Wear

Once a solid strategic plan is in place, success shifts to the tactical execution at the machine. The right in-process techniques are essential to manage the immense forces and heat generated during the cut. Simply using a tougher tool is not enough; the toolpath, cutting parameters, and coolant strategy must all be optimized to prevent rubbing, evacuate heat, and maintain a stable cutting action.

Optimizing speeds and feeds is paramount. The goal is to maintain a constant, aggressive feed rate that ensures the tool is always cutting, not rubbing. Rubbing generates excessive heat and is a primary cause of work hardening. Therefore, a consistent chip load must be maintained. This often means using a smaller depth of cut but a higher feed rate to ensure the cutting edge is properly engaged. It's a delicate balance; the feed must be aggressive enough to cut cleanly but not so high that it overloads and breaks the cutting edge.

For milling operations, the choice between conventional and climb milling is critical. Climb milling is strongly recommended for hardened materials. In climb milling, the tool enters the cut at maximum chip thickness and exits at zero. This action efficiently transfers heat into the chip and away from the workpiece. Conversely, conventional milling starts at zero chip thickness and builds, which causes the tool to rub against the surface before it begins to cut, generating significant heat and inducing work hardening. This single choice can make the difference between a successful part and a broken tool.

Effective coolant management also plays a vital role. While some materials like ceramics are designed to run dry at very high speeds, most hard machining operations benefit from high-pressure flood coolant. The coolant serves two purposes: it controls the temperature of the workpiece to prevent thermal distortion, and it helps flush chips away from the cutting zone. Preventing chips from being recut is especially important, as a hardened chip can easily damage or break a cutting edge.

The Right Tools for the Job: Tooling and Machine Rigidity

Even with the best strategy and techniques, machining hardened steel is impossible without the right equipment. The immense forces involved demand specialized cutting tools and an exceptionally rigid machine tool. Using standard carbide tooling or a lightweight machine will result in immediate failure. Investment in the proper hardware is a non-negotiable prerequisite for success in this demanding application.

The choice of cutting tool material is the most critical decision. The primary options each have specific strengths and weaknesses. Polycrystalline Cubic Boron Nitride (PCBN) is often the top choice for high-volume production of hardened steels, offering excellent wear resistance and thermal stability at high cutting speeds. Ceramics are another option, particularly for continuous finishing operations, as they retain their hardness at very high temperatures and are often run without coolant. Advanced, coated carbide grades represent a more economical option and can be effective in situations with interrupted cuts or lower cutting speeds where PCBN might be too brittle.

Beyond the material, tool geometry must be selected for maximum strength. Negative rake angles and strong edge preparations (hones or T-lands) provide the support needed to withstand high cutting pressures. Thin, sharp, positive-rake inserts designed for soft materials will chip and fail instantly. The goal is to prioritize strength and stability over achieving the absolute lowest cutting forces. A detailed comparison of these tooling options is essential for making a cost-effective choice, as detailed in publications like Cutting Tool Engineering magazine.

Finally, none of these advanced tools can perform without a solid foundation. Machine rigidity is paramount. Any vibration or chatter in the setup will be amplified by the high cutting forces, leading to poor surface finish, dimensional inaccuracy, and catastrophic tool failure. A heavy, rigid, and well-maintained machine with a robust spindle and minimal overhang in the tool setup is essential. This intrinsic stability is what allows the cutting edge to remain consistently engaged with the material, which is the key to predictable and successful hard machining.

| Tool Material | Hardness Range (HRC) | Typical Cutting Speed | Cost | Pros | Cons |

|---|---|---|---|---|---|

| PCBN | 50-70 HRC | High | Very High | Excellent wear resistance, long tool life in continuous cuts | Brittle, not ideal for heavy interruptions, high initial cost |

| Ceramic | 50-65 HRC | Very High | High | Maintains hardness at high temps, good for finishing | Brittle, sensitive to thermal shock, requires rigid setup |

| Coated Carbide | 45-55 HRC | Low to Medium | Medium | Tougher than PCBN/Ceramic, good for interrupted cuts | Lower wear resistance, cannot match speeds of PCBN |

Frequently Asked Questions

1. What is the major drawback of hardened steel?

The primary drawback of hardened steel is its reduced ductility, which makes it brittle. While it is extremely hard and resistant to wear, it is more susceptible to fracturing under sharp impacts or in very low-temperature environments. This brittleness, combined with its hardness, also makes it significantly more difficult to machine, weld, or otherwise work with after the hardening process is complete.

2. How to soften hardened steel for machining?

Hardened steel can be softened for machining through a process called annealing. This involves heating the steel to a specific temperature (which varies depending on the alloy) and holding it there for a period of time. Afterward, it is cooled very slowly, often over many hours inside the furnace. This controlled slow cooling process reverses the hardening, resulting in a softer, more ductile microstructure that is much easier to machine.

-

Posted in

CNC milling, hardened steel, Machining, manufacturing, tool wear