Master Your CNC Machine Power Requirements for a Safer Shop

TL;DR

Understanding your CNC machine's power requirements is critical for safety and performance. Power needs are typically rated in KVA (Kilo Volt Amps) and depend on the machine's spindle, motors, and accessories. Most hobbyist or small shop machines operate on a 220V single-phase circuit requiring 30-40 amps. However, larger industrial machines often demand a three-phase power supply, which can be achieved in a single-phase workshop by using a rotary phase converter.

Understanding Key Electrical Concepts for CNC

Before connecting your CNC machine, it's essential to grasp the fundamental electrical principles that govern its operation. Supplying your equipment with clean, stable electricity is just as important as using the right fuel in a high-performance engine. The primary terms you'll encounter are Voltage, Amperage, and KVA, each playing a distinct role in your machine's power profile.

Voltage (measured in Volts) is akin to water pressure in a pipe; it's the electrical potential or pressure that pushes the current through the circuit. Amperage (measured in Amps) is like the flow rate of the water; it represents the volume of electrical current moving through the wires. As noted by experts at machine manufacturer Okuma, power is the product of these two forces (Voltage x Amps). The overall power requirement for CNC equipment is expressed in KVA, or Kilo Volt Amps, which is a measure of apparent power. You must ensure your electrical supply can meet the machine's specified KVA rating without dropping below it.

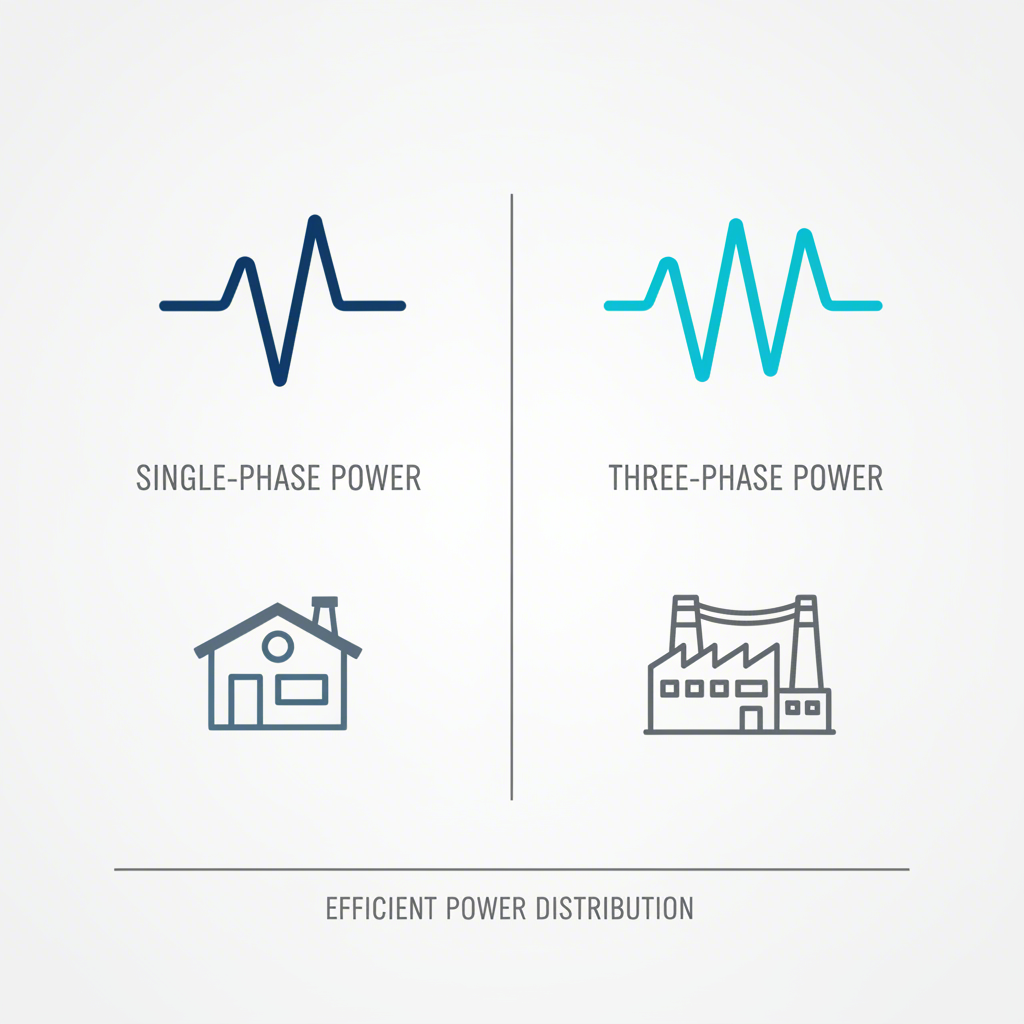

A crucial distinction in workshop power is between single-phase and three-phase electricity. Single-phase power is standard in residential homes and small shops, typically providing 120V or 240V. It's suitable for smaller equipment. Three-phase power, common in industrial and commercial settings, delivers more consistent and robust power, which is necessary for running large, high-demand motors found in industrial CNC machines. The power delivery is smoother, allowing motors to run more efficiently and last longer. Understanding which type of power your shop has is the first step in determining compatibility with a new CNC machine.

| Feature | Single-Phase Power | Three-Phase Power |

|---|---|---|

| Typical Voltage | 120V / 240V | 208V / 240V / 480V |

| Common Application | Homes, small workshops, hobbyist CNCs | Industrial facilities, large commercial shops, high-power CNCs |

| Power Delivery | Pulsating power delivery | Consistent, smooth power delivery |

| Motor Efficiency | Less efficient for large motors | Highly efficient for running large motors |

| Pros | Widely available in residential areas | Can power larger, more productive equipment |

| Cons | Not suitable for heavy industrial machinery | Rarely available in residential settings; requires special installation |

Determining the Power Requirements for Your Specific Machine

Every CNC machine has unique power needs, and guessing is not an option. The exact requirements are determined by a combination of factors, including the spindle horsepower, the size and number of axis motors, and the power draw of accessories like vacuum pumps and coolant systems. A machine designed for cutting aluminum will generally have a more powerful spindle and a more rigid frame, demanding significantly more power than a small hobbyist router used for wood engraving.

The most reliable source of information is the machine's data plate or specification tag. This label, typically located on the back or side of the machine, will list the required voltage, phase, and the KVA or full-load amperage rating. Always consult this plate first. If it's missing or illegible, the manufacturer's official documentation or manual is your next best source. For example, the technical manual for an Avid CNC controller clearly states the power draw for its different systems, such as ~6A @ 120VAC for a NEMA 23 controller and ~12A @ 120VAC for a NEMA 34 system. These precise figures are crucial for planning your circuit.

For those tackling highly demanding projects, particularly in metalworking where precision is paramount, managing these power requirements is a key part of the production process. When projects require tight tolerances and fast turnarounds that might exceed a small shop's capabilities, partnering with a specialized service can be a strategic advantage. For instance, for precision-engineered components with unparalleled accuracy and speed, XTJ offers advanced CNC milling services tailored to exact specifications. Utilizing a professional service can bypass the complexities of industrial power setups, providing access to high-end machinery without the need for significant infrastructure investment.

Follow these steps to accurately determine your machine's power needs:

- Locate the Specification Plate: Find the metal tag on your CNC machine's frame or control cabinet.

- Identify Key Ratings: Note the required Voltage (e.g., 220V), Phase (single-phase or three-phase), and power rating (in KVA or Amps).

- Check All Components: Remember to account for the power draw of accessories like vacuum pumps, dust collectors, and coolant systems, which often have their own separate power requirements.

- Consult the Manufacturer's Manual: If the plate is unclear, the manual is the definitive guide. It will provide detailed electrical schematics and installation instructions.

- Consult a Licensed Electrician: When in doubt, always have a qualified electrician review your machine's specifications and your workshop's electrical panel to ensure a safe and compliant installation.

Solutions for Powering CNC Machines in a Home or Small Shop

One of the most common challenges for hobbyists and small businesses is discovering that their newly acquired CNC machine requires three-phase power, while their workshop is only equipped with a standard single-phase supply. Fortunately, this is a solvable problem. The most reliable and widely recommended solution is to use a phase converter, a device that transforms single-phase electricity into the balanced three-phase power that industrial motors need to run efficiently.

The two primary types of phase converters are rotary converters and digital converters, often integrated into a Variable Frequency Drive (VFD). For most CNC applications, especially those with large spindle motors, a rotary phase converter is the preferred choice. As detailed by experts at Phoenix Phase Converters, rotary converters use an idler motor/generator to produce a true three-phase output with well-balanced voltage across all three lines. This stability is critical for the health and accuracy of sensitive CNC electronics and motors. VFDs can also work, but they are typically better suited for controlling a single motor rather than powering an entire machine with multiple components.

Sizing a rotary phase converter is crucial. A common rule of thumb is to select a converter with a horsepower rating that is at least double that of your largest motor, which is usually the spindle. For example, a CNC machine with a 15 HP spindle motor would require a 30 HP rotary phase converter. This oversizing ensures the converter can handle the high inrush current when the motor starts without causing a voltage drop that could damage the machine. Proper installation also requires a dedicated circuit from your electrical panel, sized with an appropriate breaker to handle the converter's load—for instance, a 30 HP converter might need an 80-amp breaker.

| Feature | Rotary Phase Converter | Digital Converter / VFD |

|---|---|---|

| Best Use Case | Powering an entire CNC machine with multiple motors (spindle, axes, pumps) | Controlling the speed of a single three-phase motor |

| Voltage Balance | Excellent; provides balanced voltage across all three legs for stable operation | Can be less balanced, potentially causing issues for sensitive electronics |

| Scalability | Can run multiple machines simultaneously (if sized correctly) | Typically dedicated to one motor/machine |

| Cost | Higher initial investment (e.g., a 30 HP unit can cost over $3,000) | Generally less expensive for smaller motor applications |

| Noise | Modern units are quiet, but older models can be noisy | Very quiet operation |

To successfully set up your CNC machine in a home shop, follow this checklist:

- Confirm Machine Requirements: First, verify if your machine needs single-phase or three-phase power by checking its data plate.

- Assess Your Shop's Power: Identify if your workshop has a 220V single-phase circuit available with sufficient amperage.

- Select the Right Phase Converter: If three-phase power is required, choose a rotary phase converter sized at least twice the horsepower of your machine's spindle motor.

- Plan the Installation: Work with a licensed electrician to install a dedicated circuit and breaker appropriately sized for the phase converter.

- Ensure Proper Grounding: A solid earth ground is essential for safety and to protect the machine's sensitive electronics from electrical noise.

Frequently Asked Questions

1. What are the electrical requirements for a CNC machine?

The electrical requirements for a CNC machine vary widely depending on its size and purpose. Smaller, hobbyist machines might run on a standard 120V outlet, but most professional-grade machines require a 220V single-phase circuit with 30-40 amps. Larger industrial machines typically need a 208V or higher three-phase power supply. Always check the manufacturer's specification plate for the exact KVA or amperage rating.

2. How are CNC machines powered?

CNC machines are powered by electricity that runs a computer controller and multiple motors. A digital design is converted into G-code, which the controller reads to send precise electrical signals to servo or stepper motors. These motors drive the machine's axes and spindle, executing the programmed movements. The entire system relies on a clean, stable power supply that matches the machine's voltage and phase requirements to function correctly.

3. How much electricity does a CNC machine use per hour?

Electricity consumption depends heavily on the machine's size, the material being cut, and the intensity of the operation. On average, a CNC machine's power consumption is between 7.5 and 25 kW. A small router cutting wood will use significantly less power than a large vertical machining center milling steel. To estimate costs, find your machine's power consumption in kW and multiply it by your local electricity rate per kilowatt-hour (kWh).

-

Posted in

cnc machine, CNC Power, Electrical Requirements, Phase Converter, Workshop Setup