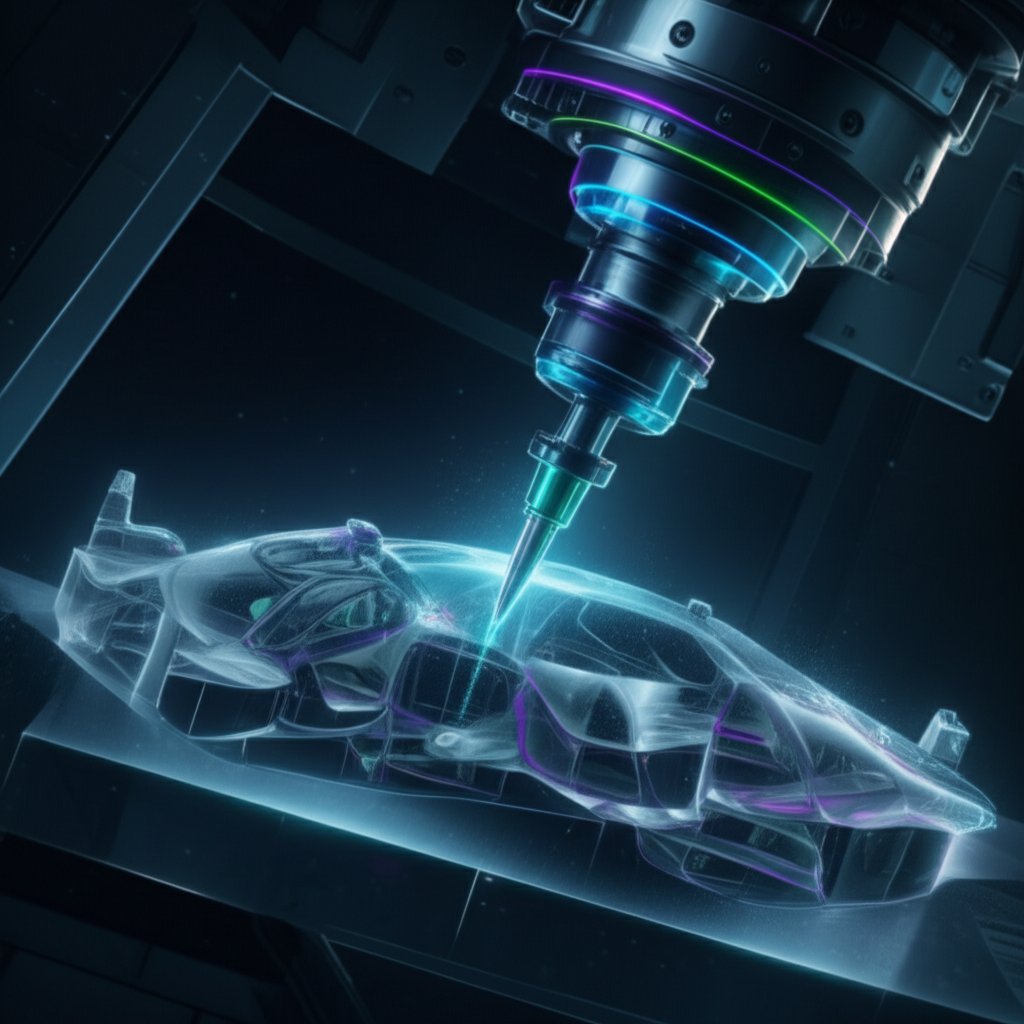

A Guide to CNC Machining for Complex Geometries

TL;DR

CNC machining for complex geometries leverages advanced multi-axis technology, particularly 5-axis machines, to produce highly intricate parts with exceptional precision. This process is essential for creating components with challenging features like free-form surfaces, deep cavities, thin walls, and undercuts. By enabling continuous cutting on multiple faces in a single setup, it achieves tight tolerances and superior surface finishes, making it indispensable for innovation in the aerospace, medical, and automotive industries.

What Defines a 'Complex Geometry' in CNC Machining?

In manufacturing, 'complexity' is not just about appearance; it's a technical classification based on features that challenge standard production methods. A part is considered to have complex geometry when it incorporates specific characteristics that demand advanced machinery, specialized tooling, and sophisticated programming. These features push the boundaries of traditional 3-axis machining and are often impossible to create without more advanced solutions. Understanding these drivers of complexity is the first step in designing for manufacturability and controlling costs.

Key characteristics that define a complex part include thin walls, deep pockets, and difficult-to-access features. For instance, walls with a thickness below 0.8 mm in metals or 1.5 mm in plastics are prone to vibration and deflection during machining, risking inaccuracies. Similarly, deep cavities with a depth-to-width ratio greater than 3:1 present significant challenges for tool access, heat buildup, and chip evacuation. Other common complex features are undercuts, free-form or curved surfaces, and micro-scale details smaller than 2.5 mm, which all require multi-axis toolpaths to execute correctly.

The stringency of tolerances also contributes significantly to a part's complexity. While standard tolerances are relatively easy to achieve, holding dimensions to extremely tight specifications across multiple features requires a highly controlled process. As noted by industry experts like FANUC America, some applications demand tolerances down to the nanometer level, which necessitates advanced machinery and meticulous quality control. This level of precision, combined with intricate geometric features, is what separates a simple component from a truly complex one.

| Feature | Simple Part | Complex Part |

|---|---|---|

| Surfaces | Flat, prismatic surfaces | Free-form, curved, or multi-faceted surfaces |

| Cavities | Shallow, easily accessible pockets | Deep cavities (ratio > 3:1), undercuts |

| Walls | Thick, self-supporting walls (>1.5mm) | Thin walls prone to vibration (<0.8mm for metal) |

| Tolerances | Standard or loose (e.g., +/- 0.1 mm) | Tight, high-precision tolerances (e.g., +/- 0.01 mm) |

| Access | Features accessible from one or two setups | Features on multiple faces requiring multi-axis access |

The Crucial Role of Multi-Axis Machining (3-Axis vs. 5-Axis)

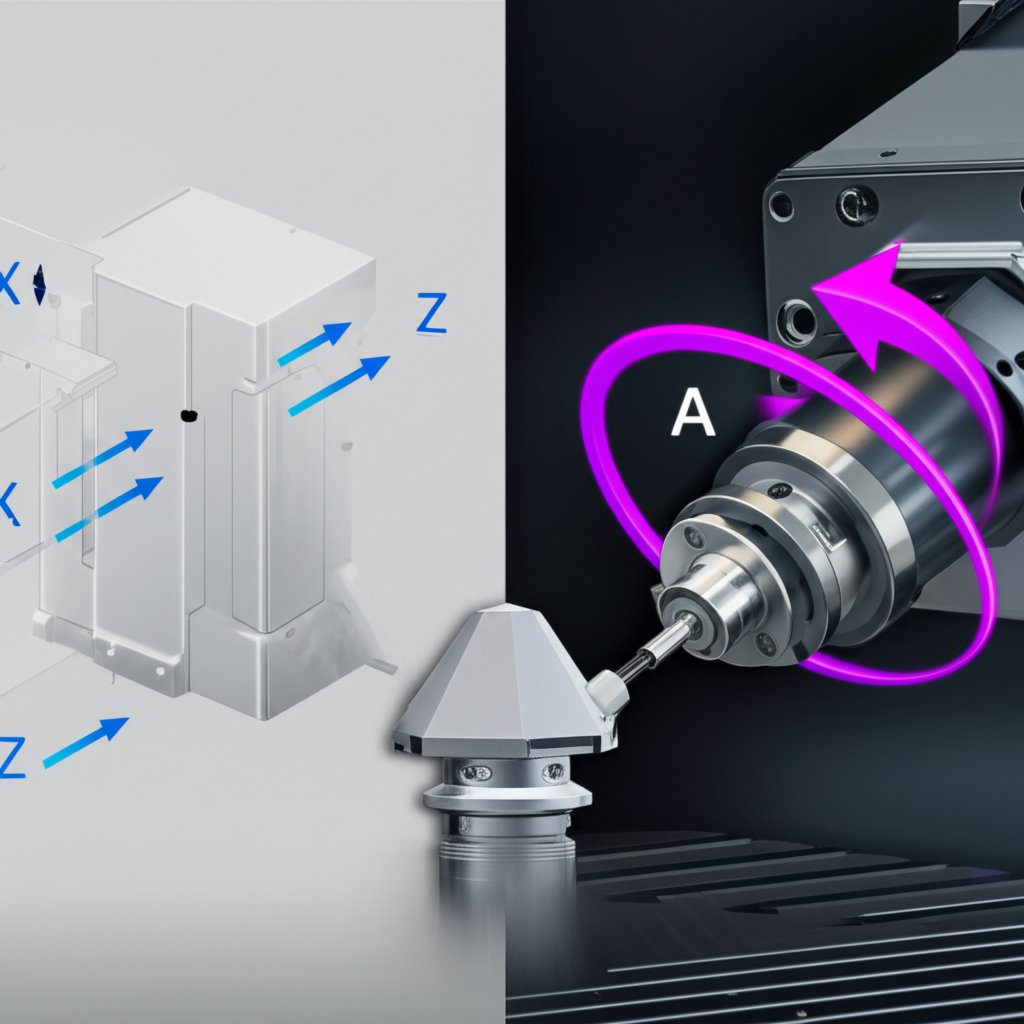

The solution to manufacturing complex geometries lies in the technology used. While traditional 3-axis CNC machines are workhorses for simpler parts, they face significant limitations when confronted with intricate designs. A 3-axis machine moves the cutting tool along the X, Y, and Z linear axes, which is perfect for drilling holes and cutting profiles on a single plane. However, to machine features on a different face of the workpiece, the part must be manually unclamped, rotated, and re-fixtured—a process that introduces opportunities for error and dramatically increases labor and production time.

This is where multi-axis machining, particularly 5-axis technology, becomes essential. A 5-axis CNC machine adds two rotational axes (typically the A and B axes) to the three linear axes. This allows the cutting tool to approach the workpiece from a virtually infinite number of angles. As explained in a detailed overview by Baker Industries, this capability eliminates the need for multiple setups. The entire part, with all its compound curves and angled features, can often be completed in a single clamping. This not only speeds up the cycle time but also drastically improves accuracy by removing the cumulative tolerance stack-up that occurs with each manual repositioning.

The difference in capability is stark. For components like turbine blades, medical implants, or aerospace impellers, 5-axis machining is not just an advantage; it's often the only practical method. It allows for continuous tool contact with complex surfaces, resulting in a superior surface finish and enabling geometries that would be physically impossible to create on a 3-axis machine. The choice between these technologies directly impacts a project's feasibility, cost, and final quality.

| Factor | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Part Complexity | Best for simple, prismatic parts with features on one plane. | Ideal for complex geometries, compound curves, and undercuts. |

| Number of Setups | Requires multiple setups for features on different faces. | Often completes a part in a single setup. |

| Cycle Time | Longer due to manual repositioning and multiple operations. | Shorter due to continuous machining and no setup changes. |

| Accuracy | Lower potential accuracy due to tolerance stack-up from re-fixturing. | Higher accuracy and repeatability by eliminating repositioning errors. |

| Cost | Lower initial machine cost, but can be higher for complex parts due to labor. | Higher machine and programming cost, but more cost-effective for complex parts. |

| Ideal Applications | Brackets, plates, simple molds, drilling, tapping. | Aerospace components, medical implants, impellers, complex tooling. |

Key Advantages of Advanced CNC for Complex Projects

Opting for advanced CNC machining, especially 5-axis systems, provides a range of tangible benefits that are critical for high-stakes industries. These advantages go beyond simply making a difficult part; they enhance performance, reduce costs, and accelerate innovation.

The foremost advantage is the achievement of High Precision and Accuracy. By minimizing human intervention and eliminating the need for multiple setups, 5-axis machining drastically reduces the risk of error. Every movement is computer-controlled, ensuring that each part in a production run is identical to the first. This process can achieve incredibly tight tolerances, which is critical for components in aerospace, defense, and medical devices where even microscopic deviations can lead to failure.

Another key benefit is a Superior Surface Finish. Because the cutting tool can be continuously oriented at the optimal angle to the material's surface, multi-axis machining produces smoother finishes with fewer tool marks. According to an analysis by Fictiv, modern CNC lathes can achieve finishes up to 32 micro-inches, often eliminating the need for secondary polishing or grinding operations. This not only saves time and cost but also improves the functional properties of the part, such as fatigue life and corrosion resistance.

Finally, advanced CNC brings Reduced Production Time and Increased Efficiency. Consolidating what might take four or five separate operations on a 3-axis machine into a single setup on a 5-axis machine generates massive time savings. This efficiency is compounded by optimized tool paths and the potential for automated, 'lights-out' manufacturing. The result is shorter lead times, more predictable production schedules, and a lower cost-per-part for complex components, enabling faster product development cycles.

Design for Manufacturability (DFM): Optimizing Complex Parts for Production

While advanced CNC technology is incredibly capable, it is not magic. The most successful projects are born from designs that are optimized for the manufacturing process. Design for Manufacturability (DFM) is a critical practice where engineers anticipate and mitigate potential production challenges during the design phase. Applying DFM principles to complex parts can dramatically reduce machining time, lower costs, and improve the final quality without compromising functionality.

One of the most important DFM considerations is managing internal corners and wall thickness. Sharp internal corners are difficult and time-consuming to machine, requiring very small tools that are prone to breaking. A best practice is to design corners with a radius that is at least 130% of the milling tool's radius. For wall thickness, a guide from Xometry recommends a minimum of 0.8 mm for metals and 1.5 mm for plastics to prevent chatter and deflection. Adhering to these simple rules ensures a more stable and efficient machining process.

Tolerances should also be applied with careful consideration. Specifying tight tolerances on every feature significantly increases cost due to slower machining speeds and more intensive inspection requirements. Instead, engineers should apply tight tolerances selectively only to critical features, such as mating surfaces or alignment pins, while using standard tolerances for non-critical areas. For expert guidance, services like XTJ's formative manufacturing offer crucial Design for Manufacturability (DFM) feedback to optimize parts before production. By collaborating with manufacturing experts and using DFM checklists, designers can ensure their complex ideas translate into high-quality, cost-effective physical parts.

Actionable DFM Checklist for Complex Parts:

- Wall Thickness: Maintain a minimum of 0.8 mm for metals and 1.5 mm for plastics.

- Corner Radii: Use the largest possible internal corner radii. Avoid sharp corners where possible.

- Deep Pockets: Keep cavity depths within a 3:1 depth-to-width ratio to ensure tool access and chip removal.

- Hole Design: Use standard hole sizes and keep thread lengths to a maximum of 1.5 times the hole diameter.

- Tolerances: Apply tight tolerances only where functionally necessary. Use standard tolerances (e.g., ISO 2768) for other features.

- Feature Simplification: Wherever possible, replace complex curves with simpler arcs or straight lines if it does not affect function.

Navigating Complexity for Manufacturing Success

Successfully producing complex geometries is a blend of smart design, advanced technology, and strategic planning. It begins with a clear understanding of what makes a part technically complex—from thin walls and deep pockets to free-form surfaces and stringent tolerances. Recognizing these challenges early allows for proactive design choices that enhance manufacturability. The cornerstone of execution is leveraging the right technology, where 5-axis CNC machining offers unparalleled advantages in accuracy, efficiency, and surface quality by tackling intricate features in a single setup. Ultimately, applying Design for Manufacturability (DFM) principles is the crucial final step, ensuring that even the most ambitious designs are optimized for a cost-effective and reliable production process.

Frequently Asked Questions

1. Which CNC configuration is best for machining undercuts and complex surfaces?

For parts that require machining undercuts, compound curves, or other complex surfaces, a 5-axis CNC machine is unequivocally the best configuration. Its two additional rotational axes allow the cutting tool to approach the workpiece from multiple angles in a single setup, enabling it to reach areas that are inaccessible to a standard 3-axis machine. This capability is essential for creating the smooth, continuous toolpaths needed for free-form surfaces and for accurately cutting features like undercuts without needing to reposition the part.

-

Posted in

5-axis machining, cnc machining, complex geometries, design for manufacturability, precision engineering