Live Tooling in CNC Turning: Boost Efficiency and Precision

TL;DR

Live tooling in CNC turning equips a lathe's turret with powered, rotating cutting tools. This technology allows the machine to perform secondary operations like milling, drilling, and tapping all in a single setup. By combining the functions of a lathe and a mill, live tooling dramatically increases efficiency, enhances accuracy by maintaining a single point of reference (datum), and reduces overall production time by eliminating the need to move a workpiece between different machines.

What Is Live Tooling in CNC Turning?

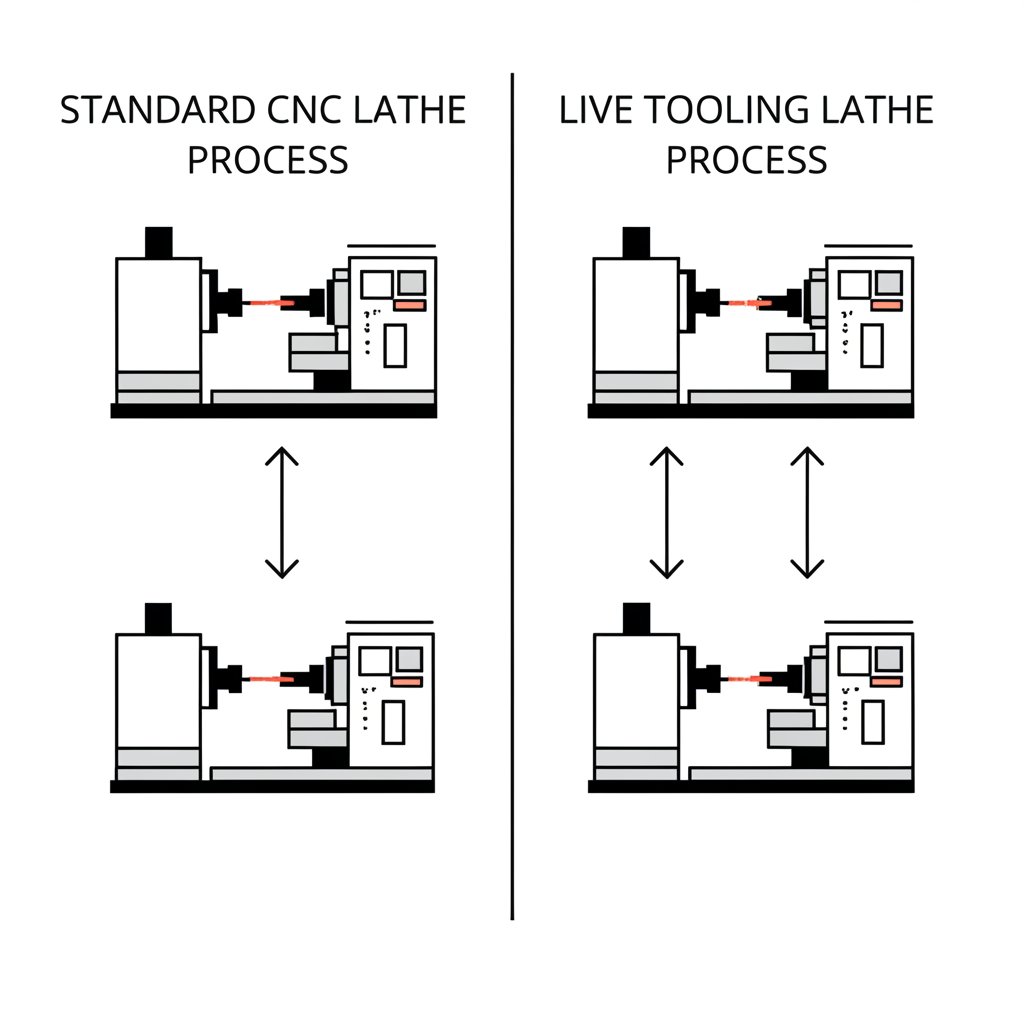

In traditional CNC turning, a workpiece spins rapidly in a spindle while a static, non-rotating cutting tool carves material from its face or diameter. Live tooling fundamentally changes this process. The term "live" refers to tooling on the CNC turning center's turret that is powered to rotate independently, driven by its own motor. This capability transforms a standard lathe into a multi-functional mill-turn center, enabling it to perform a range of secondary operations without removing the part from the machine. Essentially, it allows a machine that primarily creates cylindrical parts to also create features typically made on a milling machine.

This integration allows for a variety of complex machining operations to be completed in one clamping. Instead of only turning, a live tooling lathe can execute tasks such as milling flats onto a shaft, drilling off-center holes, cutting keyways or slots, and tapping threads perpendicular to the part's centerline. As explained by Southern Fabricating Machinery Sales, this versatility means a single machine can produce a finished part that would otherwise require both a lathe and a milling machine, along with the associated setup and transfer time.

The core advantage is the consolidation of processes. By completing all operations in a single setup, the part's indexed position is never lost. This not only saves significant time but also drastically improves the accuracy and repeatability of the finished components. For beginners, a helpful analogy is turning a specialized workshop into an all-in-one manufacturing cell, where one machine handles multiple, distinct jobs sequentially with high precision.

| Feature | Standard CNC Lathe | Live Tooling Lathe |

|---|---|---|

| Primary Function | Turning, facing, drilling on-center | All standard lathe functions |

| Tooling Type | Static (non-rotating) tools | Static and powered (rotating) tools |

| Secondary Operations | Requires moving part to another machine (e.g., mill) | Milling, cross-drilling, tapping, slotting in a single setup |

| Setup Time | Multiple setups across different machines | Single setup for multiple operations |

| Part Accuracy | Potential for error when re-clamping on a new machine | Higher accuracy due to preserved datum |

| Part Complexity | Limited to concentric features | Can produce complex parts with both turned and milled features |

Key Advantages of Live Tooling vs. Secondary Operations

The decision to invest in live tooling often comes down to a direct comparison with the traditional method: performing secondary operations. Secondary ops involve completing the initial turning on a lathe, then physically moving the workpiece to a separate machine, like a milling center, for additional features. While this method is flexible, live tooling offers compelling benefits in efficiency, accuracy, and cost-effectiveness that are hard to ignore.

The most significant advantage is the consolidation of processes. As detailed by manufacturing experts at Zintilon, completing a part in a "single-machine environment" eliminates the substantial time lost to machine setup, part handling, and queuing for the next operation. This leads to faster fabrication and shorter overall lead times. Furthermore, accuracy is greatly enhanced through what is known as "datum preservation." Every time a part is unclamped and moved to a new machine, there is a risk of introducing small alignment errors. By keeping the workpiece in the same chuck for all operations, live tooling maintains a single, consistent point of reference, ensuring higher precision and part-to-part repeatability.

The financial impact can be substantial. A case study highlighted by SME illustrates this point perfectly: a company saved $45,000 annually on a single part by switching to an improved live tool. The new process reduced the cycle time from 262 seconds to just 172 seconds by completing the operation in a single pass instead of three, all while achieving a better surface finish. This demonstrates how the initial investment in live tooling can yield a significant return through reduced cycle times and improved quality.

For businesses looking to optimize their production, especially in areas like rapid prototyping and low-volume manufacturing, these efficiencies are critical. Streamlining the path from design to a functional part is key. Services specializing in formative manufacturing, such as those offered by XTJ, leverage such advanced technologies to provide rapid turnarounds and expert feedback, which is essential for accelerating product development cycles.

However, it's important to weigh the pros and cons of each approach. While live tooling offers numerous benefits, it also comes with higher initial equipment costs and increased programming complexity compared to simpler, separate operations.

Pros and Cons of Live Tooling

-

Pros:

- Reduced Setup and Cycle Time: Combines multiple operations, eliminating transfers.

- Increased Accuracy: Maintains a single datum, reducing clamping errors.

- Lower Labor Costs: Less part handling and operator intervention required.

- Smaller Footprint: One machine does the work of two or more, saving floor space.

-

Cons:

- Higher Initial Investment: Live tooling lathes are more expensive than standard lathes.

- Increased Complexity: Programming and setup can be more intricate.

- Maintenance: Driven tools have more moving parts (gears, bearings) that require regular maintenance.

Pros and Cons of Secondary Operations

-

Pros:

- Lower Initial Cost: Standard lathes and mills are less expensive individually.

- Simplicity: Each machine is dedicated to a specific task, simplifying programming.

- Flexibility: Can be a cost-effective solution for simple parts or low-volume jobs.

-

Cons:

- Longer Lead Times: Involves multiple setups, part handling, and potential delays.

- Reduced Accuracy: Higher risk of error from re-clamping the workpiece on different machines.

- Higher Labor Costs: Requires more operator time for setups and transfers.

How Live Tooling Works: Orientations, Axes, and Components

Understanding the mechanics of live tooling involves three key concepts: tool orientation (axial and radial), the machine axes that enable positioning (C-axis and Y-axis), and the systems used to mount the tools to the turret (VDI and BMT).

Tool orientation is defined by the direction the cutting tool points. As explained in a Hurco blog post, the distinction is straightforward: Axial tools point along the Z-axis, parallel to the main spindle. They are used for operations on the face of the workpiece, such as drilling holes or milling features. Radial tools point along the X-axis, perpendicular to the spindle centerline. These are used for operations on the diameter of the workpiece, like cross-drilling holes or milling flats.

These operations are made possible by additional machine axes. The C-axis is the crucial component that allows for positioning. It controls the rotational position of the main spindle, allowing it to be precisely indexed and held stationary while the live tool performs its milling or drilling operation. For more advanced machining, an optional Y-axis can be added. The Y-axis allows the entire turret to move up and down, perpendicular to the X-axis, enabling the machining of features that are off the part's centerline. This is essential for creating complex geometries that are not radially or axially symmetric.

Finally, the live tools themselves must be securely mounted and powered. The two most common mounting systems are VDI and BMT. A detailed comparison from MSC Direct outlines their differences:

| System | Description | Pros | Cons |

|---|---|---|---|

| VDI (Verein Deutscher Ingenieure) | Uses a serrated shaft that slides into a hole on the turret and is locked by a cam mechanism. Power is transmitted via a spline gear. | Flexible (can often be mounted on face or periphery), easily aligned for high accuracy. | Considered less rigid due to its adjustability, potentially longer setup time. |

| BMT (Base-Mounted Turret) | Uses four bolts and keyways to secure the toolholder directly to the face of the turret. Power is transmitted via a tang or spline coupling. | Highly rigid, quick setup with no alignment needed (bolt-and-go). | Less flexible in terms of mounting positions, frustratingly nonstandard bolt patterns between machine builders. |

Introduction to Live Tooling Programming and Maintenance

While powerful, live tooling requires specific programming commands and diligent maintenance to ensure longevity and performance. Programming involves synchronizing the C-axis (spindle rotation) with the live tool's rotation and movement. This is primarily handled through M-codes (Miscellaneous functions) and G-codes (Preparatory functions).

Specific M-codes are used to control the live tool's spindle, such as commands to start it spinning in a clockwise or counter-clockwise direction, and to stop it. For example, on some Haas machines, M135 is the M-code used to stop the live tool. Once the C-axis has positioned the workpiece to the desired angle, G-code commands for milling or drilling (like G01 for linear feed or G81 for a drilling cycle) are used to control the path of the live tool. The programming style can vary from conversational controls, which use graphical interfaces to simplify the process, to pure G-code for more complex toolpaths.

Here is a simplified, illustrative code snippet for a cross-drilling operation:

G54; (Select work coordinate system)

T0101; (Select live tool and offset)

M154; (Engage C-axis)

G00 C90.; (Rapid C-axis to 90 degrees)

M133; (Start live tool forward at programmed speed)

G98 G81 Z-0.5 R0.1 F10.; (Drilling cycle to a depth of 0.5 inches)

G80; (Cancel drilling cycle)

M135; (Stop live tool)

M155; (Disengage C-axis)

G00 Z1.0; (Retract tool)

Proper maintenance is just as critical as correct programming. Live toolholders contain intricate systems of gears, bearings, and seals that operate at high speeds. Neglecting their care can lead to premature failure and costly repairs. It's essential to treat them with care and not push them beyond their limits, as they are not as robust as the spindle on a dedicated machining center.

To maximize the life and return on your live tooling investment, follow these essential maintenance best practices:

- Run a Warm-Up Cycle: Before starting a job, run the live tool at a gradually increasing RPM for a few minutes. This allows the bearings and grease to reach optimal operating temperature.

- Keep Toolholders Clean: Regularly clean the toolholder body, mating surfaces, and collets to prevent debris from causing runout or damage.

- Inspect Between Jobs: Check for signs of wear, damage, or overheating between setups. Listen for unusual noises, which can indicate bearing failure.

- Track Usage Hours: Keep a log of how many hours each live tool has been in operation to schedule preventative maintenance before a failure occurs.

- Follow Manufacturer Recommendations: Adhere to the specific lubrication and maintenance procedures outlined by the toolholder manufacturer.

Is Live Tooling the Right Choice for Your Shop?

Live tooling represents a significant leap in CNC turning technology, effectively merging the capabilities of a lathe and a mill into a single, highly efficient platform. By enabling secondary operations like milling, drilling, and tapping within a single setup, it offers dramatic improvements in cycle time, part accuracy, and labor efficiency. The ability to produce complex components without transferring them between machines minimizes setup errors and streamlines the entire manufacturing workflow.

While the initial investment is higher and the programming more complex than traditional methods, the long-term returns can be substantial. For shops that frequently move turned parts to a mill for completion, the business case is compelling. The reduction in scrap, faster turnaround, and ability to take on more complex, higher-value work often justify the cost. Ultimately, the decision depends on a shop's specific needs, part complexity, and production volume, but for those looking to boost productivity and precision, live tooling is an essential technology to consider.

Frequently Asked Questions

1. Which axis allows positioning for live tooling on a lathe?

The C-axis is the primary axis that allows for positioning with live tooling. It controls the rotational angle of the main spindle, enabling it to be precisely indexed and held stationary. This allows the live tool to perform operations like cross-drilling and milling at specific angular locations on the workpiece.

2. What M-code is used to stop live tooling?

The specific M-code to stop a live tool can vary depending on the machine tool builder and control system. However, a common example is M135, which is used on Haas CNC lathes to stop the live tool spindle from rotating. Always consult your machine's specific programming manual to verify the correct M-codes for live tool functions.

-

Posted in

cnc machining, CNC turning, live tooling, manufacturing efficiency, mill-turn