A Technical Guide to CNC Machining for Mold Making

TL;DR

CNC machining is the foremost manufacturing process for creating precise, durable molds used in high-volume production, particularly for plastic injection molding. This subtractive method uses computer-controlled cutters to shape materials like tool steel and aluminum with exceptional accuracy. Success depends on selecting a machine with high rigidity, thermal stability, and the correct axis configuration to meet the complex demands of modern mold making.

The Crucial Role of CNC Machining in Modern Mold Making

In manufacturing, the mold is the critical tool that defines the final product's shape, quality, and consistency. CNC (Computer Numerical Control) machining for mold making is a subtractive process where computer-guided machines precisely remove material from a solid block to create a mold cavity. This mold is then used in other processes, most commonly injection molding, to produce thousands or even millions of identical parts. Unlike the final molded part, the CNC-machined mold is the master tool, engineered for extreme durability and precision.

The process begins with a Computer-Aided Design (CAD) model of the mold. This digital blueprint is translated into machine-readable instructions, known as G-code, through CAM (Computer-Aided Manufacturing) software. A CNC machine then executes this code, directing cutting tools along precise paths to carve out the intricate features of the mold. According to an overview by DATRON, this integration of digital design and automated machining eliminates the human error inherent in manual methods, enabling the creation of complex geometries and tight tolerances that are otherwise unachievable.

CNC machining's dominance in the industry stems from its unparalleled accuracy. As explained by experts at Mastercam, molds for injection molding must withstand immense stress and high temperatures over countless cycles. Steel molds, in particular, need to maintain their exact dimensions to ensure every part produced is identical. CNC machining provides the necessary precision to create these robust tools, whether for a prototype run or mass production involving millions of units.

It's important to distinguish the role of CNC machining from the subsequent manufacturing process. As a comparison from Xometry clarifies, CNC machining creates the tool (the mold), while injection molding uses that tool to produce the final parts. This synergy is fundamental to modern manufacturing, allowing for the cost-effective mass production of everything from simple consumer goods to highly specialized automotive and medical components.

Key Factors in Selecting a CNC Machine for Mold Making

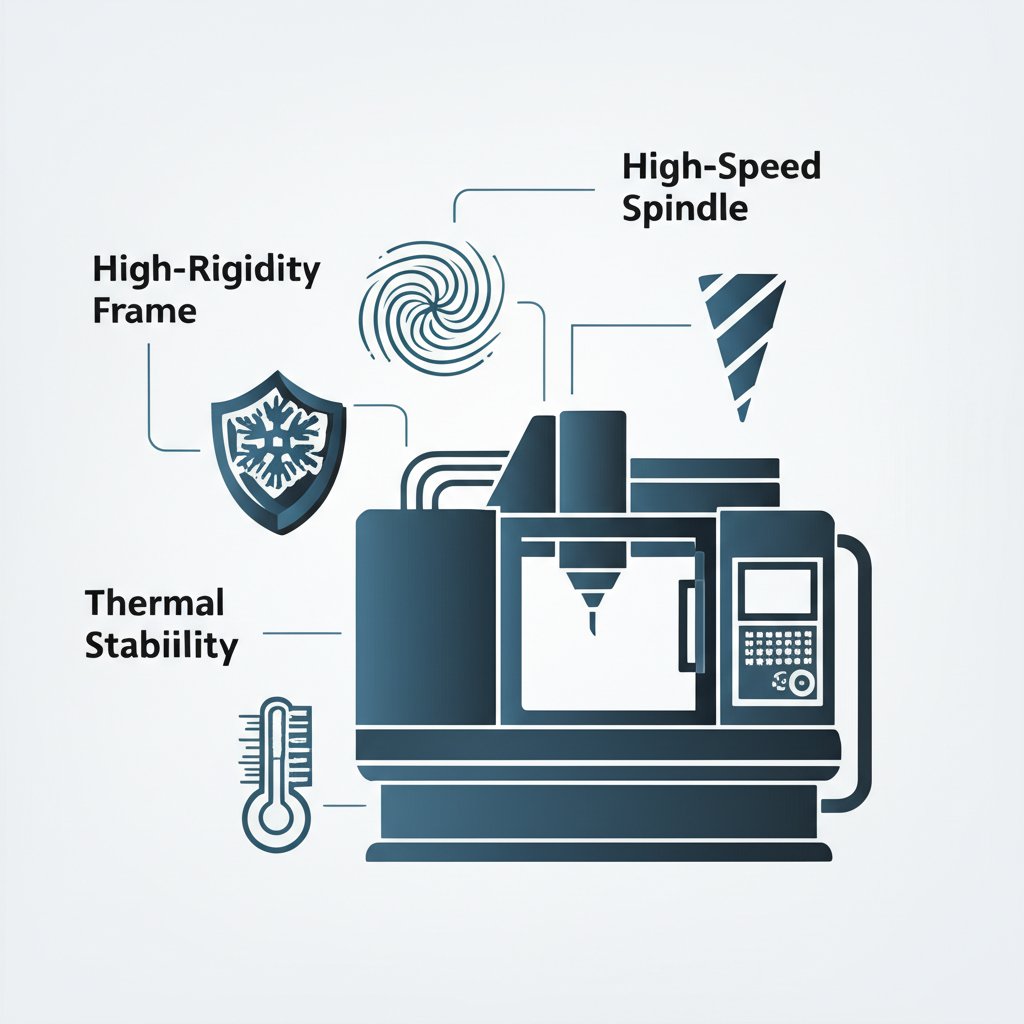

Choosing the right CNC machine is a critical decision that directly impacts mold quality, production speed, and overall profitability. The demands of mold making require machines that deliver uncompromising performance. Manufacturers must evaluate several key characteristics to ensure their equipment can handle the intricate and demanding nature of this work. The primary considerations are accuracy, rigidity, and thermal stability, as emphasized by industry leader Haas Automation.

A successful mold making operation is built on a foundation of several core machine attributes. These factors determine a machine's ability to consistently produce high-quality molds that meet stringent specifications. A thorough evaluation of these elements is essential before any investment.

- Precision and Accuracy: This is the most critical factor. The machine must be able to replicate the digital design with minimal deviation. High accuracy ensures that the mold's intricate details, such as complex contours and fine textures, are perfectly reproduced, leading to flawless final parts.

- Machine Rigidity: Rigidity refers to a machine's ability to resist deflection and vibration under the stress of cutting hard materials like tool steel. A rigid machine frame and components are essential for maintaining dimensional stability throughout the machining process, resulting in superior surface finishes and preventing tool chatter.

- Spindle Power and Speed: The spindle is the heart of the CNC machine. High spindle power is necessary for efficient material removal from tough metals, while high spindle speeds (RPM) are crucial for achieving fine surface finishes with smaller tools. The right balance allows for both aggressive roughing and precise finishing operations.

- Axis Configuration (3-Axis vs. 5-Axis): While 3-axis machines are suitable for simpler molds, 5-axis machines offer significantly greater versatility. A 5-axis configuration allows the cutting tool to approach the workpiece from multiple angles in a single setup, which is essential for machining complex geometries, undercuts, and deep cavities without repositioning the part. This reduces setup time, improves accuracy, and expands design possibilities.

- Control System and Software: An advanced control system with a user-friendly interface simplifies programming and operation. Compatibility with industry-standard CAD/CAM software ensures a seamless workflow from design to production, minimizing errors and setup times.

For example, the Haas VM-series machines are specifically configured for the mold industry, offering features tailored for high-precision work. Similarly, DATRON machines are noted for their high-speed spindles and rigid construction, which contribute to exceptional precision and surface quality. When evaluating options, buyers should ask critical questions: What level of tolerance do my molds require? What materials will I primarily be cutting? Answering these will guide the selection toward a machine that aligns with specific production needs, ensuring a valuable and productive investment.

Essential Materials for High-Performance Molds

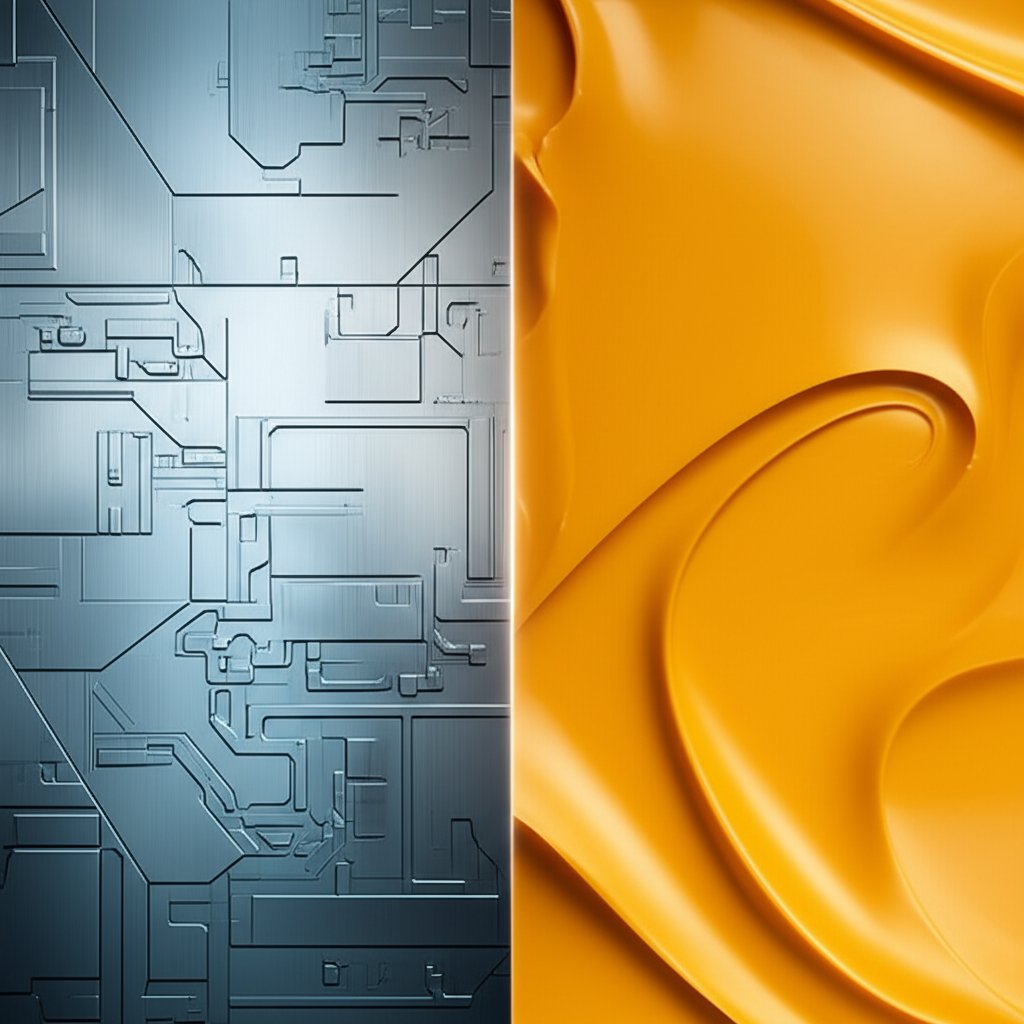

The material chosen for a mold is just as critical as the machine used to create it. The selection depends heavily on the intended application, including the number of parts to be produced, the type of plastic being molded, and the required level of detail. Materials range from durable metals for high-volume production to specialized boards for rapid prototyping.

For mass production, metals are the standard due to their durability and resistance to the high pressures and temperatures of injection molding. Tool steel and stainless steel are the most common choices because they can withstand millions of injection cycles without degradation. Aluminum is a less durable but more cost-effective option for smaller production runs or prototypes. While it machines faster, it wears more quickly than steel.

For prototyping and short-run tooling, a different class of materials known as tooling boards is often preferred. As detailed in a handbook by Omni CNC, these boards are made from materials like polyurethane, epoxy, or urethane. They are significantly easier and faster to machine than metal, allowing for rapid iteration of designs. While not suitable for high-volume production, they are ideal for creating master models, fixtures, and prototype molds. For companies focused on rapid development, services that offer a wide range of material options for prototypes can be invaluable. For instance, XTJ's comprehensive formative manufacturing services provide access to over 50 materials for creating high-quality rapid prototypes, backed by expert DFM feedback to accelerate product development cycles.

The table below compares common mold materials based on their properties and ideal applications.

| Material | Key Properties | Best Use Case |

|---|---|---|

| Tool Steel (e.g., P20, H13) | High durability, excellent wear resistance, high temperature tolerance. | High-volume injection molding (100,000+ parts). |

| Aluminum | Good thermal conductivity, fast machining, lower cost. | Prototyping and low- to mid-volume production (up to 10,000 parts). |

| Epoxy Tooling Board | High temperature resistance, excellent surface finish, dimensionally stable. | Master patterns, prepreg composite molds, high-accuracy models. |

| Polyurethane Tooling Board | Lightweight, easy to machine, good for creating large models. | Concept models, mock-ups, prototype tools, styling models. |

Choosing the right material involves a trade-off between cost, durability, and speed. For a final production run expected to yield a million parts, hardened tool steel is the only viable option. However, for a short run of 50 prototypes to test form and fit, a high-density urethane board offers the fastest and most economical path.

The Step-by-Step CNC Mold Making Process

Creating a high-quality mold with CNC machining is a systematic process that transforms a digital design into a precise, physical tool. Each stage requires careful planning and execution to ensure the final mold meets all specifications. The workflow is a blend of digital design, software programming, and hands-on machine operation.

The journey from concept to finished mold can be broken down into five primary stages:

- CAD Design: The process begins in CAD software, where engineers create a detailed 3D model of the mold. This digital file serves as the blueprint for the entire project. The design must account for not only the final part geometry but also factors like material shrinkage, draft angles for part ejection, and cooling channels.

- CAM Programming and Toolpath Generation: Once the CAD model is finalized, it is imported into CAM software. Here, a programmer generates the toolpaths—the specific routes the cutting tools will follow to shape the material. This stage is critical for efficiency and precision, involving the selection of appropriate tools, cutting speeds, and machining strategies for both roughing (rapid material removal) and finishing (creating a smooth surface).

- Machine Setup and Workholding: Before machining begins, the raw block of material (e.g., steel or aluminum) must be securely fastened to the CNC machine's worktable. This is known as workholding. A rigid workholding setup is crucial to prevent any movement or vibration during machining, which could compromise accuracy. The operator also loads the necessary cutting tools into the machine's tool changer.

- Machining Operation: With the program loaded and the workpiece secured, the CNC machine executes the G-code. It automatically performs a series of operations, such as milling, drilling, and tapping, to carve the mold cavity. This process is often monitored by an operator to ensure everything proceeds smoothly and to make adjustments if needed. For complex molds, this stage can take many hours or even days.

- Finishing and Quality Control: After the primary machining is complete, the mold often requires finishing touches. This can include manual deburring to remove sharp edges, polishing to achieve a specific surface texture, and assembly of different mold components. Finally, the mold undergoes rigorous quality control checks using precision measurement tools to verify that all dimensions are within the specified tolerances.

Throughout this process, success hinges on attention to detail. Practical tips from experienced machinists often emphasize the importance of rigid workholding and careful tool selection to achieve the best results. The complexity of the process can also vary significantly between a simple 3-axis mold and a multi-part 5-axis mold with intricate undercuts and lifters, but the fundamental steps remain the same.

Frequently Asked Questions

1. What is a CNC mold?

A CNC mold is a tool, typically made of metal or a durable tooling board, created using a Computer Numerical Control (CNC) machine. It is not the final product itself but rather the master tool used in manufacturing processes like plastic injection molding. The CNC machine follows a digital design to precisely carve a cavity into a block of material, and this cavity is then used to shape molten material into identical parts.

2. What materials cannot be CNC machined?

While CNC machining is versatile, certain materials are not suitable due to their properties. These generally include very soft or flexible materials like rubber, silicone, and soft polymers that can't be held rigidly or cut cleanly. Other challenging materials include carbon fiber composites (which can delaminate and create hazardous dust), hard ceramics, and tempered glass (which can shatter). Super-soft metals and foam-like materials also pose significant challenges for conventional CNC cutting methods.

3. Do CNC machinists make a lot of money?

Compensation for CNC machinists can be quite competitive, reflecting the skill and precision required for the job. Salaries vary based on experience, skill level (e.g., operating 3-axis vs. 5-axis machines), geographic location, and the specific industry. Highly skilled machinists with expertise in programming and operating complex machinery for high-value industries like aerospace or medical devices often command higher salaries.

-

Posted in

cnc machining, injection molding, manufacturing process, mold making, tooling