Why Precision CNC Machining Is Essential for Oil & Gas

TL;DR

CNC machining for the oil and gas industry is a highly specialized manufacturing process that uses computer-controlled tools to create exceptionally precise and durable components. It is essential for fabricating parts from high-performance metals and specialty alloys designed to withstand the sector's harsh and high-stress operational environments. This technology is critical for ensuring the safety, reliability, and efficiency of equipment used in drilling, extraction, transportation, and refining.

The Critical Role of Precision in a High-Stakes Industry

In the oil and gas sector, equipment failure is not just an inconvenience—it can be catastrophic. Operations frequently occur in extreme environments, from deep subsea wells to high-temperature refining facilities. This is why Computer Numerical Control (CNC) machining has become indispensable. It is a manufacturing process where pre-programmed computer software dictates the movement of machinery, enabling the creation of complex parts with a level of precision that manual processes cannot match. This accuracy is fundamental to operational safety and efficiency.

Components used in oil and gas applications face a constant barrage of demanding conditions that can compromise their integrity. Any imperfection, no matter how small, can lead to subpar performance or complete failure, endangering personnel and the environment. The ability of CNC machines to hold exceptionally tight tolerances, often measured in fractions of a millimeter, ensures that every part fits and functions perfectly, preventing leaks, breakages, and other critical failures. This precision directly mitigates the risks associated with the industry's inherent challenges.

The operational challenges in the oil and gas industry are multifaceted and severe. Equipment must reliably perform under a combination of stressors, including:

- Extreme Pressures: Components in drilling and extraction equipment, like blowout preventers and valve systems, must contain immense pressures to prevent uncontrolled releases.

- High Temperatures: From downhole drilling friction to refining processes, parts are often exposed to heat that can weaken or deform standard materials.

- Corrosive Environments: Exposure to saltwater, hydrogen sulfide (H2S), and various abrasive chemicals requires materials and finishes that resist degradation over time.

- Intense Mechanical Stress: The constant vibration and heavy loads involved in drilling and pumping operations demand components with superior strength and fatigue resistance.

Before the widespread adoption of advanced CNC machining, manufacturing processes were less precise, leading to a higher incidence of component variability and failure. Modern multi-axis CNC machines, by contrast, produce parts with unflinching accuracy and consistency, significantly enhancing the reliability and longevity of critical infrastructure. Investing in high-precision CNC-machined components is no longer just a technical choice; it is a crucial business decision for ensuring operational uptime, safety, and profitability.

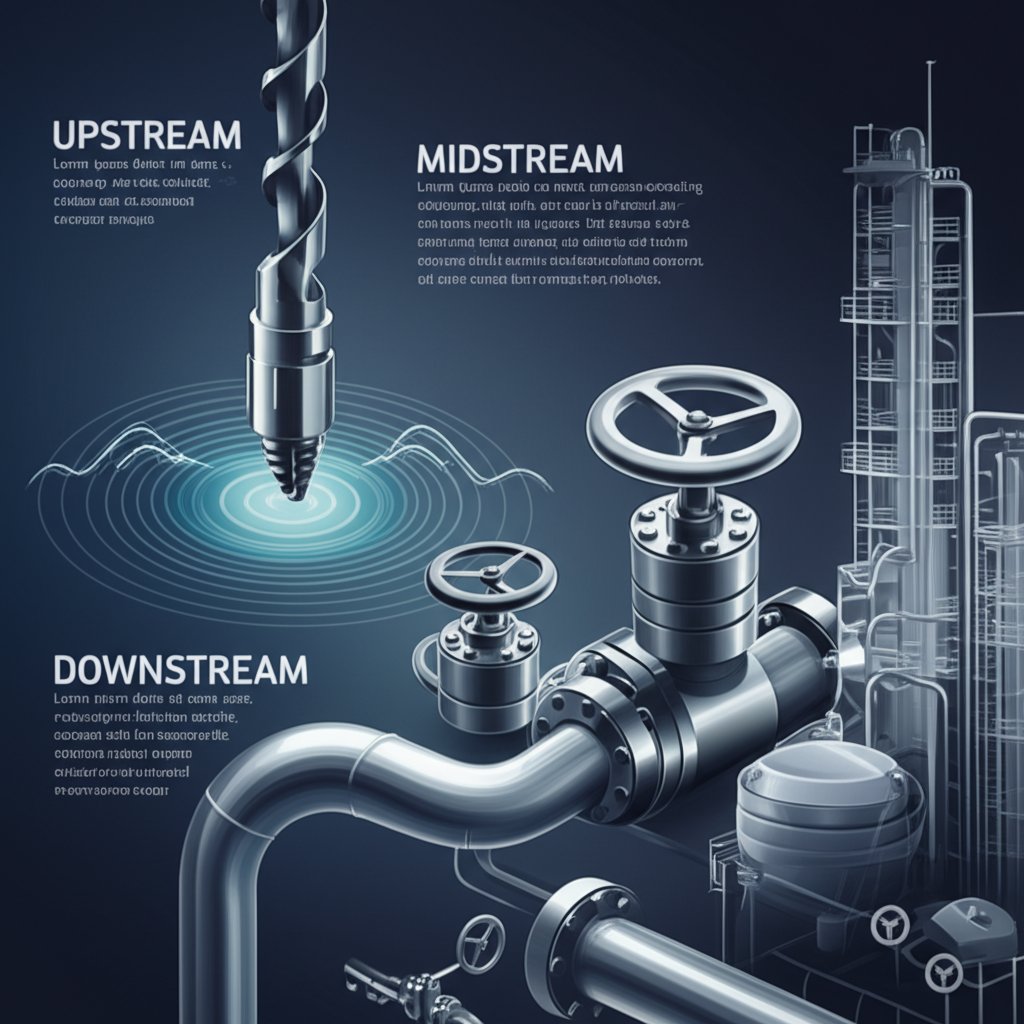

Key Applications: From Upstream Exploration to Downstream Refining

CNC machining's impact is felt across the entire lifecycle of oil and gas operations, which is typically divided into three main sectors: upstream, midstream, and downstream. Each stage has unique equipment and component requirements, but all share a common need for parts manufactured to the highest standards of precision and durability. The versatility of CNC technology allows for the creation of everything from massive valve bodies to intricate sensor housings.

In the upstream sector, which involves exploration and extraction, CNC machining is vital for producing the rugged equipment needed to find and recover resources. This includes components for downhole drilling tools, wellhead equipment, and subsea systems that must perform flawlessly thousands of feet below the surface. For the midstream sector, focused on transportation and storage, reliability is key to moving resources safely through pipelines and into storage facilities. CNC-machined parts ensure the integrity of pumps, valves, and connectors. Finally, the downstream sector, which covers refining and processing, relies on precision components to handle volatile substances at high temperatures and pressures.

The specific components produced through CNC machining are diverse and tailored to their function within these sectors. The ability to shape complex geometries and achieve superior surface finishes is critical for parts that regulate flow, withstand pressure, and transmit power. Below is a table highlighting some key examples of these applications.

| Component | Industry Sector | Critical CNC Contribution |

|---|---|---|

| Drill Bits & Downhole Tools | Upstream | Complex geometries for efficient cutting and high wear resistance. |

| Valve Bodies & Gates | Upstream, Midstream, Downstream | High-tolerance sealing surfaces to prevent leaks under extreme pressure. |

| Flanges & Connectors | Midstream | Precise dimensions for perfect fit and sealing integrity in pipelines. |

| Pump Housings & Impellers | Midstream, Downstream | Complex internal contours for optimized fluid dynamics and efficiency. |

| Blowout Preventers (BOPs) | Upstream | Extreme durability and reliability for critical safety functions. |

| Turbine Components | Downstream | Superior surface finishes to minimize friction and withstand high temperatures. |

Standard, off-the-shelf components are often inadequate for these specialized and high-stress applications. The oil and gas industry relies on custom-engineered parts designed for specific operational conditions. A project engineer specifying a subsea valve, for instance, requires a manufacturing partner capable of translating a complex CAD design into a physical component that meets exact material specifications and dimensional tolerances, a task for which CNC machining is perfectly suited.

Machining Advanced Materials for Extreme Environments

The material selection for oil and gas components is just as critical as the precision of their manufacturing. Standard metals like carbon steel or aluminum simply cannot withstand the corrosive chemicals, extreme temperatures, and high pressures common in the industry. Consequently, operations depend on parts fabricated from high-performance metals and specialty alloys, often referred to as "exotics." These materials offer superior strength, toughness, and corrosion resistance but are notoriously difficult to machine.

Machining these advanced materials requires specialized equipment and deep expertise. CNC machine tools, including multi-axis turning centers and milling machines, are essential for shaping these tough alloys with the required precision. The process must be carefully controlled to manage heat generation, tool wear, and material stress, ensuring the final component retains its desired mechanical properties. This level of control is a hallmark of advanced CNC systems.

Engineers select materials based on the specific challenges of the application. Some of the most common high-performance alloys used in the oil and gas industry include:

- Inconel (625 & 718): A nickel-chromium-based superalloy known for its exceptional strength at high temperatures and outstanding corrosion resistance, making it ideal for subsea and downhole components.

- Stainless Steels (Duplex & Super Duplex): These alloys contain a mixed microstructure of austenite and ferrite, providing high strength and excellent resistance to chloride stress corrosion cracking, a common problem in marine environments.

- Titanium: Offers a high strength-to-weight ratio and remarkable corrosion resistance, particularly against saltwater. It is often used in risers, heat exchangers, and stress joints.

- Monel: A nickel-copper alloy that is highly resistant to corrosion from seawater and acids, frequently used for valve components, pumps, and propeller shafts.

- Hastelloy: Another high-performance nickel alloy that provides superior resistance to a wide range of corrosive chemicals at elevated temperatures, making it suitable for refining and processing equipment.

While CNC technology can shape an incredible range of materials, some are inherently unsuitable for this process. Materials that are too soft (like rubber), brittle (like ceramics and glass), or composite-based (like carbon fiber) require different manufacturing methods. Understanding these limitations is key to effective component design and material specification in the engineering phase.

Choosing a CNC Machining Partner for the Oil & Gas Industry

Selecting the right manufacturing partner is a critical decision that directly impacts project success, operational safety, and equipment reliability. Not all CNC machine shops are equipped to handle the rigorous demands of the oil and gas industry. A general-purpose shop may lack the specialized machinery, technical expertise, and quality control systems necessary to produce components that meet the sector's stringent standards. A true specialist will possess a deep understanding of the industry's challenges and a proven track record of success.

Key criteria for selecting a qualified vendor include their technical capabilities, such as having advanced multi-axis CNC machines that can produce complex parts in a single setup. Equally important is their experience machining the specialty alloys required for harsh environments. A prospective partner should also have robust quality control processes and industry-recognized certifications, such as ISO 9001, to demonstrate their commitment to quality and consistency.

When evaluating potential CNC machining vendors, it is crucial to ask detailed questions to verify their capabilities. For companies focused on the initial stages of product development, services like XTJ's formative manufacturing can be invaluable. They offer rapid prototyping with a wide range of materials and provide essential Design for Manufacturability (DFM) feedback, all under an ISO 9001:2015 certified quality system, helping to refine designs before full-scale production.

To ensure you partner with a capable supplier, consider asking the following questions:

- What is your specific experience manufacturing components for the oil and gas industry?

- Can you provide case studies or examples of projects similar to ours?

- What is your process for machining challenging materials like Inconel or Duplex stainless steel?

- What quality control measures and inspection technologies do you have in place?

- Are you ISO 9001 certified or do you hold other relevant industry certifications?

- What are your capabilities for holding tight tolerances (e.g., ±0.001 inches)?

- How do you ensure traceability of materials throughout the manufacturing process?

By conducting a thorough evaluation, you can identify a partner who not only has the right equipment but also the expertise to serve as a strategic asset. The ultimate goal is to find a supplier who can reliably deliver high-quality, mission-critical components that ensure the safety and efficiency of your operations.

Frequently Asked Questions

1. Which industries mostly use CNC machines?

While CNC machines are vital to the oil and gas sector, they are used across numerous industries where precision is paramount. The aerospace industry relies on them for critical components like turbine blades and structural parts. The automotive industry uses CNC machining for engine components and molds. Other major users include the medical field for surgical implants and instruments, electronics for intricate housings, and the military and defense sector for high-performance hardware.

2. What materials cannot be CNC machined?

Although CNC machining is versatile, it is not suitable for all materials. The process is subtractive, meaning it works by cutting material away, which poses challenges for certain substances. Materials that are generally not CNC machined include very soft or flexible materials like rubber and silicone, which deform under the cutting tool. Brittle materials such as ceramics and glass can fracture easily. Carbon fiber composites can delaminate, and very soft foams or sponges are difficult to hold and cut cleanly. These materials typically require other processes like molding, casting, or laser cutting.

-

Posted in

cnc machining, industrial components, oil and gas, precision manufacturing, specialty alloys