Automotive CNC Prototyping Services: A Buyer's Guide

TL;DR

Automotive CNC prototyping services utilize computer-controlled machines to rapidly fabricate high-precision physical models of vehicle parts. This process is essential for testing, validation, and innovation, allowing engineers to create functional components from a wide range of production-grade metals and plastics. Key benefits include exceptional accuracy, material versatility, and the speed required to accelerate development cycles in the competitive automotive industry.

What is CNC Prototyping and Why is it Critical for the Automotive Industry?

Computer Numerical Control (CNC) prototyping is a subtractive manufacturing process where computer-controlled machines cut, drill, and shape a solid block of material to create a finished part based on a digital design file. Unlike additive processes like 3D printing that build objects layer by layer, CNC machining carves away material, resulting in components with superior mechanical properties and surface finishes. This precision is not just a benefit but a necessity in the automotive sector, where every part must meet exact specifications for performance, safety, and reliability.

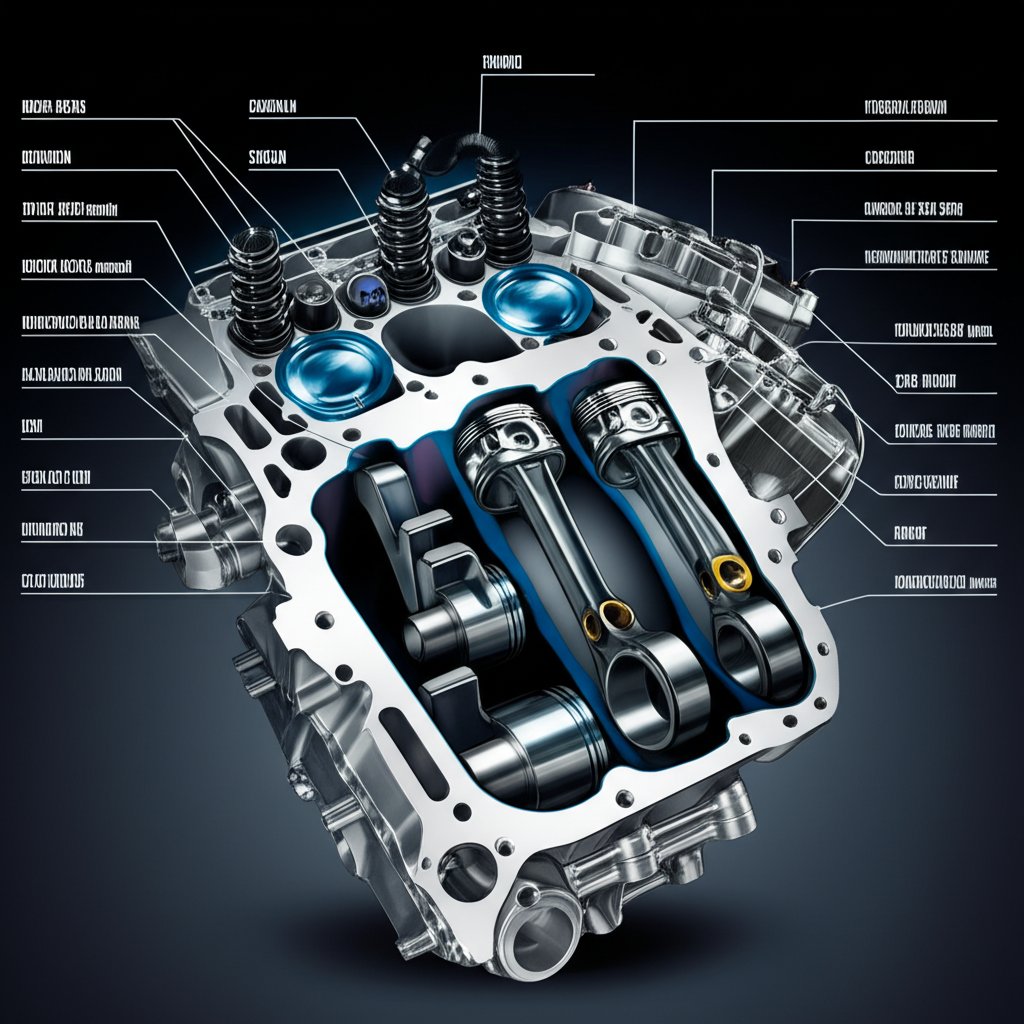

The role of CNC machining is fundamental to modern vehicle production, from traditional combustion engines to advanced electric vehicle (EV) systems. The process ensures that complex components fit perfectly within intricate assemblies, maintaining the tight tolerances required for optimal fuel efficiency and driver safety. For example, engine blocks, transmission gears, and brake calipers all depend on the accuracy that only CNC machining can consistently deliver. This level of precision minimizes wear and tear, boosts performance, and upholds the stringent quality standards of the automotive world.

Automotive engineers and designers choose CNC prototyping when functional testing in real-world conditions is required. While 3D printing is excellent for early-stage conceptual models, CNC-machined prototypes are made from production-grade materials, allowing for rigorous testing of mechanical stress, heat resistance, and durability. This capability is vital for validating new designs before committing to the high costs of mass production tooling. The ability to create a functional, high-fidelity prototype quickly makes CNC machining an indispensable tool for innovation and quality assurance.

A wide array of critical automotive parts are developed using CNC prototyping. The process is versatile enough to handle everything from powertrain components to suspension and braking systems. Some common examples include:

- Engine Components: Cylinder heads, pistons, crankshafts, and engine blocks.

- Transmission Parts: Gears, shafts, and housings.

- Braking System Components: Calipers, rotors, and mounting brackets.

- Suspension Parts: Control arms, linkages, and knuckles.

- Fuel System Components: High-pressure fuel rails, injectors, and pumps.

- Drivetrain Components: Axles, driveshafts, and universal joints.

Choosing the Right Materials for Automotive Prototypes

Selecting the appropriate material is a critical decision in automotive CNC prototyping, as it directly impacts the part's performance, durability, and cost. The choice depends entirely on the prototype's intended application—whether it's for visual confirmation, fit testing, or full functional testing under stress. CNC machining services offer a broad spectrum of metals and plastics, each with unique properties suited for different automotive systems. The main categories include lightweight metals like aluminum, high-strength steels, and various engineering-grade plastics.

Metals are the go-to choice for functional prototypes that require high strength, thermal resistance, and durability. Aluminum alloys, such as 6061 and 7075, are popular for their excellent strength-to-weight ratio, making them ideal for lightweighting components in body panels, chassis parts, and some engine components. Stainless steel offers superior corrosion resistance and strength, which is essential for exhaust components and parts exposed to harsh environments. For extreme performance applications, titanium provides an exceptional balance of strength, low weight, and heat resistance, though at a higher cost.

Engineering plastics offer a versatile and cost-effective alternative for many automotive prototypes, especially for interior components, housings, and non-load-bearing parts. Materials like ABS (Acrylonitrile Butadiene Styrene) are valued for their impact resistance and are often used for interior trim and dashboards. Polycarbonate provides excellent optical clarity and strength for lighting components, while PEEK (Polyether Ether Ketone) offers exceptional thermal and chemical resistance for under-the-hood applications. These materials allow for rapid iteration and testing of form and fit before finalizing a design for production.

To aid in the selection process, here is a comparison of common materials used in automotive CNC prototyping:

| Material | Key Properties | Common Automotive Uses |

|---|---|---|

| Aluminum (6061) | Good strength-to-weight ratio, corrosion resistance, highly machinable. | Engine blocks, suspension parts, chassis components. |

| Stainless Steel (304) | High strength, excellent corrosion resistance, good temperature resistance. | Exhaust systems, fuel system components, brackets. |

| ABS Plastic | High impact strength, good toughness, easily machined. | Interior trim, dashboards, electronic enclosures. |

| Polycarbonate (PC) | High impact resistance, optical clarity, temperature resistant. | Headlight and taillight lenses, instrument panels. |

| Titanium | Very high strength-to-weight ratio, excellent corrosion and heat resistance. | High-performance engine parts (valves, connecting rods), exhaust components. |

How to Select the Best Automotive CNC Prototyping Service

Choosing the right CNC prototyping partner is crucial for ensuring your project's success. The ideal service provider goes beyond simply manufacturing a part; they act as a strategic partner who can provide valuable feedback and ensure quality from start to finish. When evaluating potential suppliers, it is essential to look at a combination of technical capabilities, quality control processes, industry experience, and project management.

For a comprehensive approach, consider a provider like XTJ's formative manufacturing services, which exemplify many key selection criteria. A strong partner offers a wide range of material options (over 50 in their case), rapid turnaround times, and critical Design for Manufacturability (DFM) feedback from an expert engineering team. This kind of analysis can identify potential design flaws before machining begins, saving significant time and money. Furthermore, certifications like ISO 9001:2015 are a clear indicator of a company's commitment to quality control and process consistency, a non-negotiable for the automotive industry.

When vetting potential services, use the following criteria to make an informed decision:

- Technical Capabilities: Assess their machinery. Do they offer both 3-axis and 5-axis CNC machining? 5-axis capabilities are essential for producing parts with complex geometries in a single setup, which improves accuracy and reduces lead times.

- Material Selection and Expertise: A good partner will have a wide variety of metals and plastics available and possess the expertise to help you select the best one for your specific application.

- Quoting Process: Look for a streamlined and transparent quoting process. Many modern services offer instant online quotes, but also evaluate whether they provide DFM feedback with the quote.

- Quality Assurance: Verify their quality control processes. Ask about certifications like ISO 9001, which demonstrates a commitment to quality management systems. This is crucial for parts that need to meet stringent safety and performance standards.

- Lead Times: In the fast-paced automotive industry, speed is critical. Inquire about their standard lead times and their ability to accommodate expedited orders for urgent projects.

- Automotive Industry Experience: Prioritize companies that can showcase a portfolio of past automotive projects. Experience in the sector means they understand its unique challenges, materials, and quality expectations.

To streamline your selection process, follow this action plan: First, finalize your CAD design file and gather all technical specifications. Second, request quotes from at least three different suppliers to compare costs, lead times, and services. Third, analyze the quotes beyond just the price—consider the value of included DFM feedback and their stated quality guarantees. Finally, ask about their specific experience with parts similar to yours to gauge their expertise.

The CNC Prototyping Workflow: From Digital Design to Physical Part

Understanding the CNC prototyping workflow demystifies the process and helps you prepare your project for a smooth and efficient manufacturing experience. The journey from a digital concept to a physical, high-precision part involves several distinct stages, each critical to achieving the final desired outcome. This structured process ensures accuracy, quality, and efficiency, minimizing errors and costly rework.

The entire operation is a blend of digital precision and advanced mechanical execution. It starts with your design and ends with a tangible component ready for testing. For automotive engineers, knowing these steps helps in optimizing designs for manufacturability and setting realistic timelines for development projects. A reliable service provider will maintain clear communication throughout this workflow, ensuring the final part perfectly matches the initial specifications.

The typical CNC prototyping workflow includes the following key steps:

- CAD Design Submission: The process begins when you upload your 3D CAD (Computer-Aided Design) file to the service provider's platform. Common file formats include STEP, IGES, or SLDPRT. This digital blueprint contains all the geometric information the CNC machine needs to create the part.

- Design for Manufacturability (DFM) Analysis: Before any cutting begins, engineers review the CAD model for manufacturability. This DFM check identifies potential issues like features that are too thin, deep pockets that are hard to machine, or internal corners that are too sharp. This feedback is invaluable for optimizing the design to reduce machining time and cost.

- CAM Programming: A programmer uses CAM (Computer-Aided Manufacturing) software to translate the CAD file into a set of instructions, known as G-code. This code dictates every movement of the CNC machine, including the toolpath, speed, and feed rate.

- Machining Operation: The block of raw material is secured in the CNC machine. The machine then executes the G-code, using cutting tools to subtract material and shape the part. Depending on the complexity, this may involve processes like milling (for complex shapes) or turning (for cylindrical parts).

- Post-Processing and Finishing: Once the main machining is complete, the part may undergo various post-processing steps to achieve the desired surface finish or properties. Common options include bead blasting for a uniform matte finish, anodizing for corrosion resistance on aluminum parts, or polishing for a smooth surface.

- Quality Inspection: The final part is thoroughly inspected to ensure it meets all dimensional tolerances specified in the design. This is often done using precision measuring tools like calipers, micrometers, or a Coordinate Measuring Machine (CMM).

To ensure a successful outcome, designers can optimize their CAD models by using standard fillet radii, avoiding overly complex surfaces where possible, and clearly defining critical tolerances. These small adjustments can significantly improve manufacturability and reduce the overall cost of the prototype.

Frequently Asked Questions

1. What is the main difference between CNC prototyping and 3D printing for automotive parts?

The primary difference lies in the manufacturing method and material properties. CNC machining is a subtractive process that carves parts from a solid block of production-grade metal or plastic, resulting in components with excellent mechanical strength and a smooth surface finish ideal for functional testing. 3D printing is an additive process that builds parts layer by layer, which is better for creating complex geometries quickly for visual models but may not have the same strength as a solid machined part.

2. How fast can I receive an automotive CNC prototype?

Lead times vary depending on the complexity of the part, the material selected, and the service provider's capacity. However, many online CNC services are optimized for speed, with some providers capable of delivering simpler parts in as few as 1-3 business days. More complex parts or those requiring special finishing may take 8-10 days or longer.

3. What file format is required to get a quote for CNC machining?

Most CNC machining services accept 3D CAD files in universal formats like STEP (.stp or .step) and IGES (.igs or .iges). Many also accept native files from popular CAD software such as SolidWorks (.sldprt), Parasolid (.x_t), or AutoCAD (.dwg). Providing a 3D model is essential for the service provider to analyze the geometry and generate an accurate quote.

-

Posted in

automotive manufacturing, cnc machining, CNC services, product development, rapid prototyping