CNC Prototyping Aluminum Parts: A Technical Overview

TL;DR

CNC prototyping with aluminum parts involves using computer-controlled machines to precisely cut custom components from aluminum blocks. This process is highly valued for its speed, accuracy, and ability to create parts with aluminum's key benefits, such as a high strength-to-weight ratio, excellent machinability, and natural corrosion resistance, making it ideal for rapid product development and testing.

Why Choose Aluminum for CNC Prototypes?

Aluminum is one of the most popular materials for CNC prototyping for several compelling reasons. Its unique combination of properties makes it a versatile and cost-effective choice for a vast range of applications, from aerospace components to consumer electronics. Engineers and designers frequently turn to aluminum to validate designs, test functionality, and create high-quality end-use parts.

The primary advantage of aluminum is its exceptional strength-to-weight ratio. This allows for the creation of parts that are both lightweight and robust, a critical requirement in industries like automotive and aerospace where reducing weight directly improves fuel efficiency and performance. Furthermore, aluminum is significantly easier to machine than harder metals like steel or titanium. Its softness allows for higher cutting speeds and faster material removal, which reduces machining time and lowers production costs.

Beyond its mechanical properties, aluminum offers excellent thermal and electrical conductivity, making it a preferred material for components like heat sinks and electrical enclosures. Its natural ability to form a protective oxide layer provides inherent corrosion resistance, which can be further enhanced through finishing processes like anodizing. This combination of machinability, durability, and versatility makes aluminum an ideal material for producing functional prototypes that closely mimic the performance of final production parts.

Selecting the Right Aluminum Alloy: A Comparison

Choosing the correct aluminum alloy is a critical step that directly impacts the performance, cost, and manufacturability of your prototype. While different alloys may look similar, their distinct metallurgical compositions give them unique properties tailored for specific applications. Understanding these differences is key to ensuring your part meets its functional requirements. For instance, an alloy ideal for a marine environment will differ greatly from one designed for high-stress aerospace applications.

The most commonly used alloys in CNC machining include 6061, 7075, and 5052. Aluminum 6061 is often considered the workhorse of aluminum alloys due to its excellent all-around properties, including good strength, weldability, and high corrosion resistance. It is also easily anodized, making it a popular choice for parts requiring a durable and decorative finish. In contrast, Aluminum 7075 is an aerospace-grade material known for its exceptional strength, comparable to many steels, but it is less corrosion-resistant and more challenging to weld. For applications requiring excellent formability and superior resistance to saltwater corrosion, Aluminum 5052 is the preferred choice.

To help clarify these distinctions, here is a comparison of common aluminum alloys:

| Alloy | Key Properties | Common Applications |

|---|---|---|

| Aluminum 6061 | Versatile, good strength-to-weight ratio, excellent machinability, weldable, high corrosion resistance. | Structural components, electronic enclosures, bicycle frames, general-purpose parts. |

| Aluminum 7075 | Extremely high strength, hard, good machinability. Lower corrosion resistance than 6061. | Aerospace components, high-stress parts, molds, military applications. |

| Aluminum 5052 | Excellent corrosion resistance (especially in marine environments), good formability, not heat-treatable. | Marine components, sheet metal parts, fuel tanks, electronic chassis. |

| Aluminum 2024 | High strength, good fatigue resistance. Poor corrosion resistance compared to other alloys. | Aircraft structures, wings, fuselages, and parts under tension. |

The CNC Aluminum Prototyping Process: From Design to Part

The journey from a digital concept to a physical aluminum prototype follows a structured and precise manufacturing workflow. This process ensures that the final part accurately reflects the design intent and meets all specified tolerances. Understanding these steps can help designers optimize their models for manufacturing and collaborate more effectively with machining partners.

The entire prototyping process, from initial design to final inspection, is handled with precision by expert service providers. For instance, companies like XTJ offer comprehensive CNC machining services, leveraging advanced 4 and 5-axis machines to produce complex parts with tight tolerances for various industries. Their capabilities span from rapid prototyping to full-scale production, ensuring a seamless transition as projects mature.

The key stages in the process are as follows:

- CAD Model Preparation: The process begins with a 3D Computer-Aided Design (CAD) model. This digital blueprint contains all the geometric information for the part. Designers must ensure the model is optimized for manufacturability, considering factors like tool access and feature feasibility.

- CAM Programming: The completed CAD model is imported into Computer-Aided Manufacturing (CAM) software. A programmer then generates the toolpaths—the precise movements the CNC machine's cutting tool will follow. This stage also involves selecting the appropriate tools, cutting speeds, and feed rates based on the chosen aluminum alloy.

- Machine Setup: A block of the selected aluminum alloy is securely fixed onto the CNC machine's workholding device, such as a vise or vacuum table. The cutting tools are loaded into the machine's tool changer, and the machine is calibrated to ensure the starting point is accurate.

- Machining: The CNC machine executes the programmed toolpaths, cutting away material to shape the part. This can involve various operations like milling, drilling, and turning. Machines with more axes, like 5-axis CNCs, can create highly complex geometries in a single setup, improving accuracy and efficiency.

- Post-Processing and Finishing: After machining, the part is removed from the machine. It may require post-processing steps like deburring to remove sharp edges. Depending on the application, a surface finish like anodizing or powder coating is applied to improve corrosion resistance, wear resistance, or aesthetics.

- Quality Inspection: The final part is thoroughly inspected using precision measurement tools like calipers, micrometers, or a Coordinate Measuring Machine (CMM) to verify that all dimensions and features are within the specified tolerances.

Key Design Considerations for Manufacturability

Designing for manufacturability (DFM) is a crucial practice that bridges the gap between a theoretical design and a high-quality, cost-effective physical part. By considering the capabilities and limitations of the CNC machining process during the design phase, engineers can avoid common pitfalls that lead to increased costs, longer lead times, and compromised part quality. Simple adjustments to a design can have a significant impact on the final outcome.

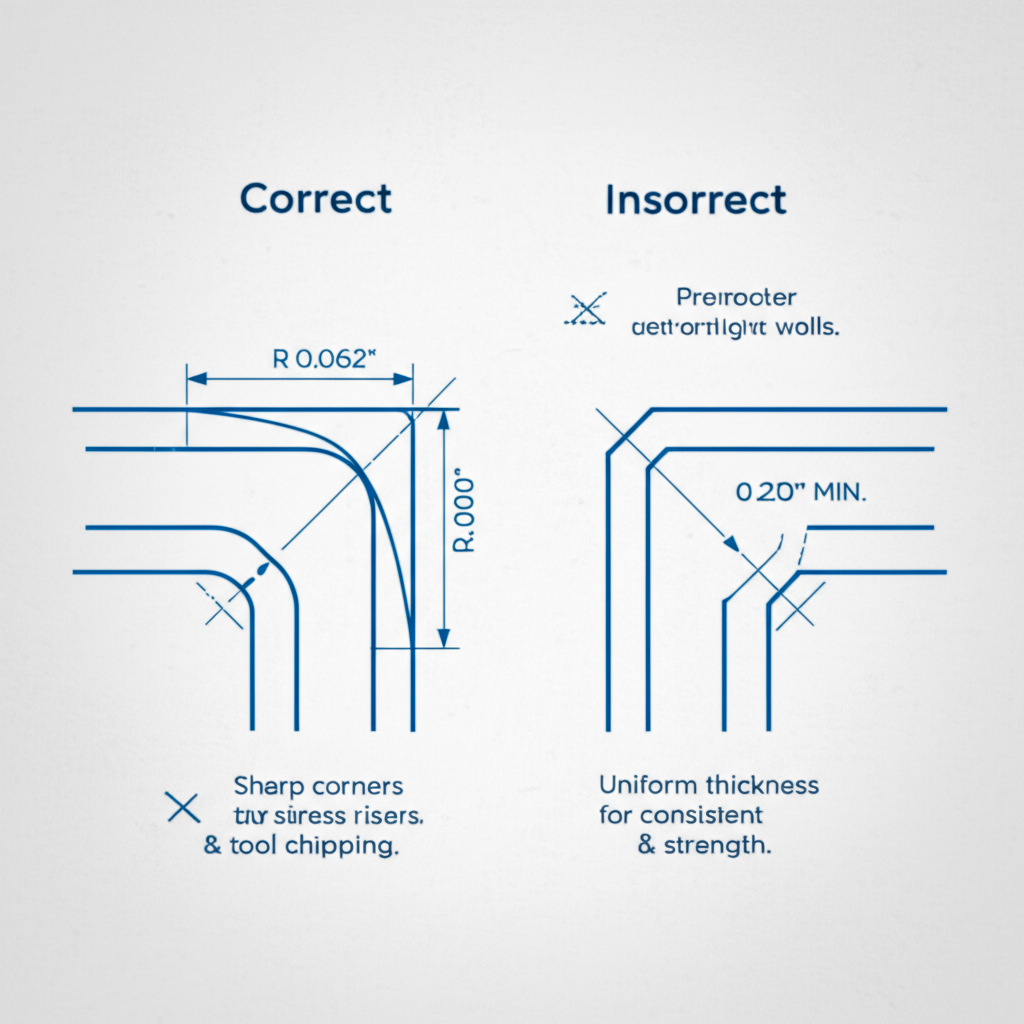

One of the most important considerations is managing internal corners. CNC cutting tools are round, meaning they cannot create perfectly sharp internal corners; there will always be a radius. Designers should specify a corner radius that is as large as possible, ideally slightly larger than the radius of the cutting tool. This allows the machine to operate more efficiently and reduces stress concentrations in the finished part. Attempting to create very small radii requires smaller tools, which are less rigid and more prone to breaking, increasing machining time and cost.

Wall thickness is another critical factor. Walls that are too thin can be difficult to machine accurately, as they may vibrate or warp under the force of the cutting tool. As a best practice, maintain a uniform wall thickness throughout the part whenever possible. Deep pockets and tall, thin walls should be avoided, as they require specialized tooling and longer machining times. Similarly, when designing holes, it's more cost-effective to use standard drill bit sizes and to keep hole depths to less than four times their diameter to ensure accuracy and prevent tool breakage. Adhering to these principles will result in a more robust and economically produced aluminum prototype.

Frequently Asked Questions

-

What are the most common surface finishes for CNC aluminum parts?

The most common finishes are anodizing (Type I, II, and III), which increases corrosion and wear resistance while allowing for different colors; powder coating for a durable, protective layer; and bead blasting for a uniform matte texture. As-machined finishes are also common for prototypes where aesthetics are not a primary concern. You can learn more about these finishes at Protolabs.

-

What is the difference between 3-axis and 5-axis CNC machining?

3-axis CNC machines move the cutting tool along the X, Y, and Z linear axes. They are ideal for simpler parts with features on a single plane. 5-axis CNC machines add two rotational axes, allowing the tool to approach the part from multiple angles in a single setup. This is essential for creating complex geometries and contoured surfaces, improving accuracy and reducing the need for multiple setups.

-

How do I choose between aluminum alloys like 6061 and 7075?

The choice depends on your application's requirements. Use 6061 for general-purpose applications that need good strength, weldability, and excellent corrosion resistance. Choose 7075 when maximum strength and hardness are critical, such as in high-stress aerospace or structural components, and you can accommodate its lower corrosion resistance. Detailed comparisons can be found on resources like PCBWay.

-

Posted in

aluminium prototyping, cnc machining, custom aluminum parts, manufacturing, rapid prototyping