High-Performance Custom CNC Parts for Drones

TL;DR

Custom CNC parts for drones offer unparalleled precision, durability, and performance for any build. Through advanced CNC machining, you can obtain high-tolerance components from materials like aerospace-grade aluminum and carbon fiber. This process enables the creation of complex, lightweight designs, with services offering rapid quotes and parts delivered in just days to get your project airborne faster.

Why CNC Machining is Ideal for Custom Drone Parts

When it comes to manufacturing custom drone parts, Computer Numerical Control (CNC) machining stands out as the premier method for achieving professional-grade results. This technology translates digital designs into physical components with robotic precision, making it indispensable for an industry where every gram and millimeter counts. The process is perfectly suited for creating everything from robust frames to intricate motor mounts, ensuring each part performs flawlessly under demanding flight conditions. By carving parts from solid blocks of material, CNC machining produces components with superior structural integrity compared to other methods like 3D printing.

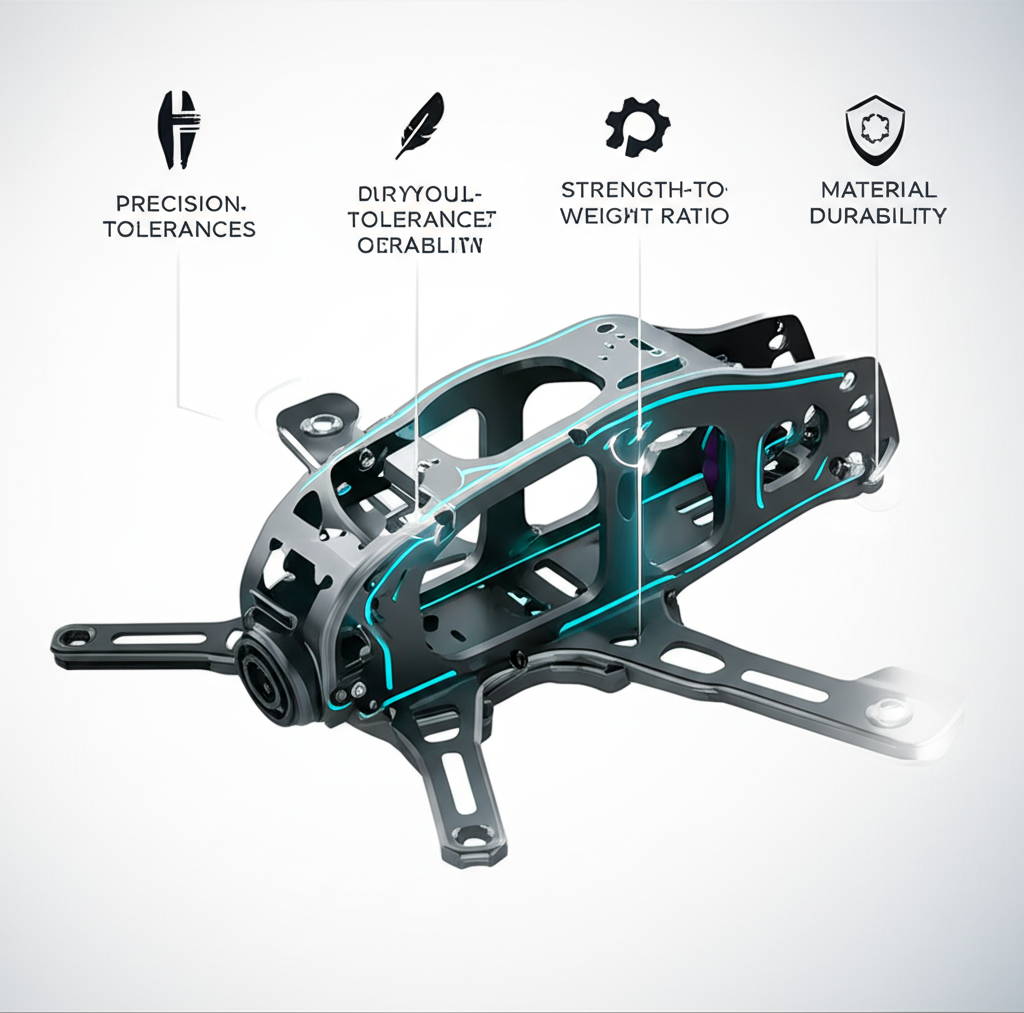

The core advantages of using CNC machining for drone components directly address the primary challenges of aerial vehicle design: performance, reliability, and weight management. Whether for rapid prototyping or full-scale production, this manufacturing approach provides the consistency and quality necessary for commercial, racing, or cinematic drones. The key benefits include:

- Unmatched Precision and Tight Tolerances: CNC machines can achieve incredibly tight tolerances, often within ±0.001 to ±0.005 inches. This level of accuracy is critical for ensuring parts fit together perfectly, which minimizes vibrations, enhances stability, and optimizes the drone's overall aerodynamic efficiency.

- Superior Strength-to-Weight Ratio: Drones must be as light as possible without sacrificing strength. CNC machining allows for the use of high-performance materials and the creation of complex geometries that maximize rigidity while minimizing mass, leading to longer flight times and greater payload capacity.

- Material Versatility: The process is compatible with a vast range of materials, from various aluminum alloys and titanium to advanced composites like carbon fiber and engineering plastics. This flexibility allows designers to select the perfect material for each specific component's functional requirements.

- Complex Geometries and Customization: Advanced multi-axis CNC systems can produce highly complex and intricate designs that would be difficult or impossible to create with other manufacturing techniques. This capability is essential for fabricating custom, aerodynamically optimized parts that elevate a drone's performance.

Key Materials for Peak Aerial Performance

The choice of material is one of the most critical decisions in designing custom drone parts, directly impacting durability, weight, and flight characteristics. CNC machining’s compatibility with diverse materials allows for precise optimization based on the specific application of each component. For example, a frame requires rigidity and strength, while a camera gimbal needs to be lightweight and vibration-dampening. Selecting the right material ensures the drone not only flies well but also withstands the rigors of its operational environment, from high-speed racing to heavy-lift cinematic work.

Below is a comparison of the most common materials used for CNC-machined drone parts, highlighting their properties and typical applications.

| Material | Key Properties | Best For |

|---|---|---|

| Aluminum Alloys (e.g., 6061, 7075) | Excellent strength-to-weight ratio, corrosion resistance, good machinability. | Frames, motor mounts, landing gear, heat sinks. |

| Carbon Fiber Composites | Extremely high stiffness and strength-to-weight ratio, low thermal expansion. | High-performance frames, arms, propellers, plates. |

| Titanium | Exceptional strength, heat and corrosion resistance, higher cost. | Critical load-bearing parts, rotor hubs, high-stress fasteners. |

| Engineering Plastics (e.g., Delrin, ABS, Nylon) | Lightweight, impact resistance, good for insulating electronics. | Enclosures, casings, gimbal assemblies, non-structural parts. |

While Aluminum 6061 is a popular all-around choice, Aluminum 7075 offers significantly higher strength, making it ideal for drones that will be subjected to high stress. Carbon fiber remains the top choice for racing and professional applications where minimizing weight is paramount. As noted in a comparison of manufacturing methods, while 3D printing is excellent for initial prototypes, CNC machining provides the superior strength and precision required for final, functional parts, especially when using high-performance composites like carbon fiber.

Our Custom Drone Part Manufacturing Capabilities

Transforming a digital design into a high-performance physical component requires sophisticated technology and deep expertise. Modern manufacturing partners offer a comprehensive suite of services tailored to the unique demands of the drone industry. For instance, providers like XTJ exemplify the industry's capabilities, offering rapid prototyping and volume production with lead times as short as three days. Their advanced 4 and 5-axis CNC machining centers can handle over 30 materials with tolerances down to +/- 0.005mm, ensuring components meet the most demanding specifications for aerospace and other high-tech applications.

A capable CNC service provider can produce a wide array of drone components, each optimized for its specific function. The ability to create parts with complex geometries and superior surface finishes is essential for maximizing performance. Key manufacturing capabilities to look for include:

- Rapid Prototyping: The ability to quickly produce and test new designs allows for faster innovation and refinement before committing to a final version.

- Complex Geometries: Multi-axis (3, 4, and 5-axis) CNC machining enables the creation of intricate shapes, internal pockets, and aerodynamically optimized surfaces.

- High-Volume Production: For commercial drone manufacturing, the ability to scale from single prototypes to thousands of units with consistent quality is crucial. Leading services like Xometry are often certified to standards like ISO 9001 and AS9100D, guaranteeing reliability.

- Finishing Services: Post-processing options such as anodizing, powder coating, and laser engraving enhance durability, corrosion resistance, and aesthetics.

Commonly manufactured custom CNC parts for drones include chassis frames, motor and sensor mounts, propellers, landing gear, camera gimbals, and protective enclosures for electronics. Each part is engineered to provide the perfect balance of strength, weight, and functionality.

Getting Your Quote: A Simple 3-Step Process

One of the greatest advantages of modern CNC machining services is the streamlined and user-friendly process for ordering custom parts. Gone are the days of lengthy consultations and complex quoting procedures. Today, you can go from a digital design to a production order in minutes, allowing you to focus more on innovation and less on logistics. The process is typically designed to be fast, transparent, and efficient.

Follow these simple steps to bring your custom drone parts to life:

- Upload Your CAD Design: The process begins with your 3D model. Most services accept standard file formats like STEP, STP, or IGS. You can upload your design directly to an online quoting platform to receive instant feedback on manufacturability.

- Specify Materials and Finishes: Select from a wide range of materials, including different grades of aluminum, carbon fiber, or plastics. You can also specify any required post-processing finishes, such as anodizing for durability or painting for aesthetics.

- Receive Your Quote and Parts: Once your specifications are entered, an automated system will generate an instant quote with pricing and lead time options. After confirming your order, the parts are manufactured to your exact specifications and shipped directly to you, often within a matter of days.

Frequently Asked Questions

1. What is the best material for drone parts?

The best material depends entirely on the part's function and the drone's purpose. For frames in high-performance or racing drones, carbon fiber is often the top choice due to its incredible stiffness and low weight. Aluminum alloys like 7075 are excellent for structural components that require high strength, while lightweight plastics like ABS or Nylon are ideal for non-structural parts like electronics enclosures or landing gear.

2. What parts do you need to build a drone?

The essential components required to build a standard quadcopter drone include a frame, a flight controller (the drone's brain), four motors, four Electronic Speed Controllers (ESCs) to control the motors, a set of propellers, a battery, and a radio transmitter and receiver to control it. For FPV (First-Person View) flying, you would also need a camera, a video transmitter, and FPV goggles or a screen.

3. Are DIY drones legal?

Regulations for DIY drones vary significantly by country and region. In the United States, for example, the Federal Aviation Administration (FAA) has specific rules. Drones weighing under 250 grams (0.55 lbs) can often be flown recreationally without registration, but heavier drones must be registered. Flying in certain areas, like near airports, is restricted. Always check with your local aviation authority for the most current laws and regulations before flying.

-

Posted in

aluminum drone parts, carbon fiber drone parts, cnc machining, custom cnc parts, drone manufacturing