Machining Delrin vs. Acrylic: An Essential Compariso

TL;DR

When choosing between Delrin and acrylic for machining, the primary trade-off is mechanical performance versus optical clarity. Delrin (Acetal) is a high-strength, low-friction engineering plastic that machines exceptionally well, making it ideal for durable, precise mechanical parts like gears and bearings. In contrast, acrylic (PMMA) offers superior optical clarity and a polished finish for aesthetic applications but is more brittle and requires careful machining to prevent melting and cracking.

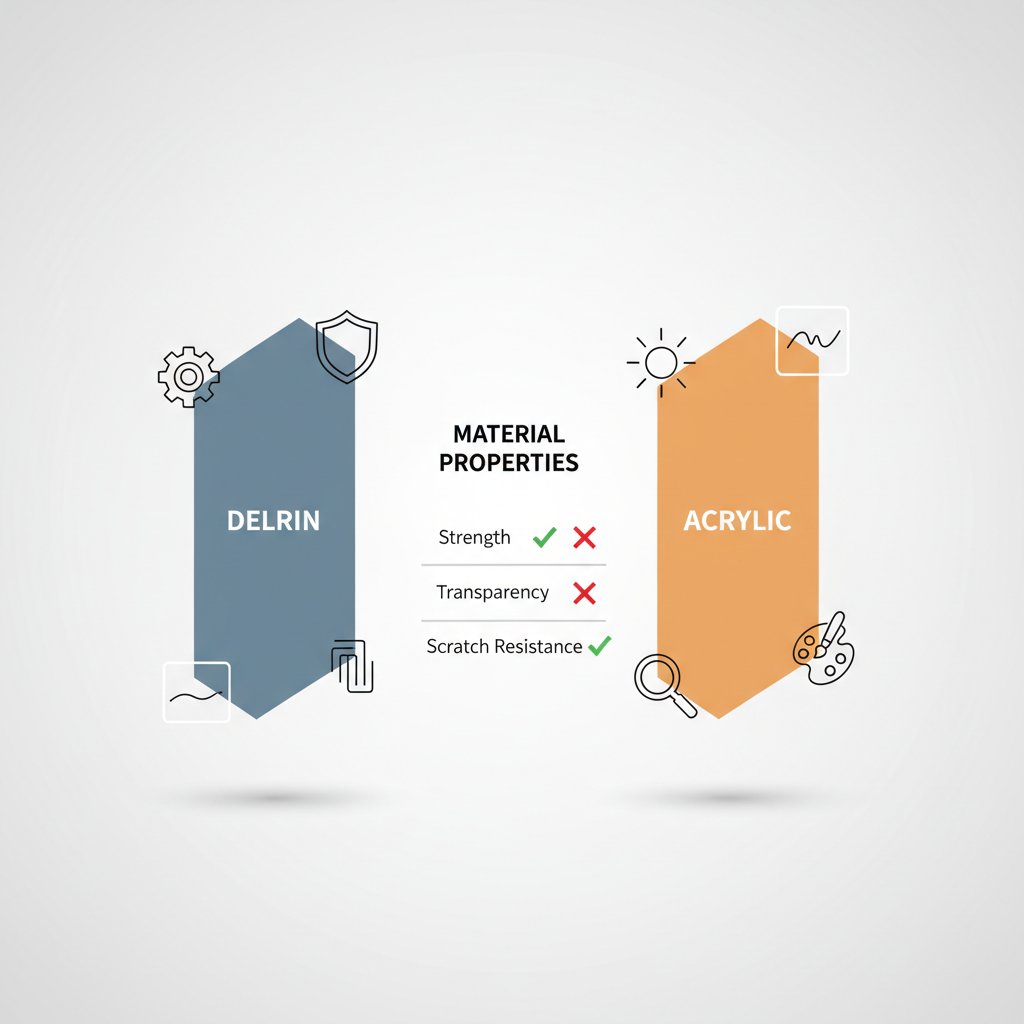

Material Properties at a Glance: Head-to-Head Comparison

Understanding the fundamental differences between Delrin (also known as Acetal or POM) and Acrylic (PMMA) is crucial for selecting the right material for your project. Both are popular thermoplastics, but their distinct molecular structures give them vastly different performance characteristics. Delrin is a semi-crystalline thermoplastic prized for its stiffness and dimensional stability, behaving almost like a metal. Acrylic is an amorphous thermoplastic known for its glass-like transparency and weather resistance.

Delrin's key advantages lie in its mechanical prowess. It boasts a low coefficient of friction, making it naturally slippery and an excellent choice for parts that slide or rotate. Its high tensile strength and fatigue resistance ensure it can withstand repeated stress cycles without failure. Furthermore, its low moisture absorption means it remains dimensionally stable even in humid environments. Acrylic's main strength is its visual appeal. With up to 92% light transmission, it is one of the clearest plastics available and serves as a lightweight, impact-resistant alternative to glass.

However, these strengths come with corresponding weaknesses. Delrin has poor resistance to UV radiation, making it unsuitable for long-term outdoor applications without additives. Acrylic, while clear, is significantly more brittle and has much lower impact resistance compared to Delrin. Delrin offers significantly higher impact resistance than acrylic. This brittleness makes it more susceptible to cracking under stress or impact.

To make the choice clearer, here is a direct comparison of their key properties:

| Property | Delrin (Acetal/POM) | Acrylic (PMMA) |

|---|---|---|

| Tensile Strength | High (approx. 10,000 psi) | Moderate |

| Hardness | High (Rockwell M94) | Moderate (Scratch Resistant) |

| Coefficient of Friction | Very Low (Self-Lubricating) | Moderate |

| Impact Resistance | Excellent | Low (Brittle) |

| Optical Clarity | Opaque | Excellent (up to 92% transmission) |

| Moisture Absorption | Very Low | Low |

| UV Resistance | Poor | Excellent |

| Relative Cost | Moderate | Low to Moderate |

Machinability Deep Dive: Which Is Easier to Work With?

For machinists, the difference between working with Delrin and acrylic is night and day. The consensus is clear: Delrin is significantly easier to machine. Often described as cutting "like butter," its high stiffness and excellent dimensional stability allow it to be milled, turned, and drilled to extremely tight tolerances with a smooth, clean finish. Because it produces predictable, well-formed chips, it clears away from the cutting tool easily, reducing the risk of tool gumming and improving surface quality.

Acrylic, on the other hand, presents several challenges. Its primary drawback is a low melting point, which causes it to soften and melt if cutting speeds, feed rates, or tool sharpness are not carefully managed. This can lead to gummed-up tools, poor surface finishes, and dimensional inaccuracies. Furthermore, acrylic's brittle nature means it is prone to chipping and cracking, especially during aggressive cutting operations or when drilling. Achieving a high-gloss, transparent finish on a machined acrylic surface requires additional post-processing steps like flame polishing or buffing.

When it comes to laser cutting, these thermal properties remain a key differentiator. Acrylic requires less laser power than Delrin for a given thickness because of its lower melting point. However, this also means extra care must be taken to avoid melting and thermal expansion. For projects demanding the highest precision and tight tolerances of +/- 0.005mm, partnering with a specialized service like XTJ CNC Milling can ensure optimal results, especially when dealing with the nuances of different plastics. Their expertise in handling a wide range of materials ensures parts are made to exact specifications, avoiding common pitfalls associated with challenging plastics like acrylic.

To achieve the best results, follow these material-specific tips:

- Tips for Machining Delrin: Use sharp carbide tools for the best finish. Maintain high cutting speeds and moderate feed rates. Although coolant is not always necessary due to its low friction, it can help achieve the best possible surface finish on critical features. Its stability makes it an excellent choice for parts requiring high dimensional accuracy.

- Tips for Machining Acrylic: Use sharp tools specifically designed for plastics to prevent chipping. Employ lower spindle speeds and higher feed rates to minimize heat buildup. Air blast or a specialized coolant can help clear chips and cool the workpiece, but be cautious as some coolants can cause crazing (cloudy spots) on the surface. To avoid cracking, ensure the material is well-supported and avoid excessive clamping pressure.

Performance and Durability in Real-World Applications

The choice between Delrin and acrylic ultimately comes down to the intended application and environment. Their distinct properties make them suitable for very different real-world scenarios, placing them in separate categories of function versus form. Delrin is the workhorse material for high-performance mechanical components, while acrylic excels in applications where aesthetics and optical properties are paramount.

Delrin's combination of high strength, low friction, and excellent wear resistance makes it the ideal material for moving parts that experience repeated stress. Its self-lubricating nature is perfect for components that cannot be easily lubricated. Because it holds tight tolerances and resists moisture, it is frequently used for precision parts in a variety of industries. Common applications for Delrin include:

- Gears, bearings, and bushings

- Jigs, fixtures, and manufacturing tooling

- Medical device components and surgical instruments

- Pump and valve parts

- Electrical insulators and connectors

Conversely, acrylic is chosen when visual appearance is the top priority. Its exceptional clarity and ability to be polished to a high gloss make it a go-to choice for consumer-facing products and display components. Its UV stability also makes it a durable option for outdoor use where Delrin would degrade. Common applications for acrylic include:

- Transparent housings and enclosures

- Light pipes, lenses, and light fixtures

- Retail displays and signage

- Automotive trim and light covers

- Protective barriers and windows

To simplify the decision, consider this summary: Choose Delrin if your part needs to be strong, slippery, dimensionally stable, and withstand repeated mechanical wear. Choose Acrylic if your part needs to be transparent, lightweight, UV-resistant, and serve a primarily visual or optical function without being subjected to high mechanical stress.

Frequently Asked Questions

1. Can Delrin be machined easily?

Yes, Delrin is widely regarded as one of the easiest and most stable plastics to machine. Its high stiffness, good chip formation, and thermal stability allow it to be cut cleanly and precisely, making it straightforward to achieve very tight tolerances and an excellent surface finish with standard cutting tools.

2. Is acrylic good for machining?

Acrylic can be machined to produce parts with excellent visual appeal, but it requires more care than Delrin. Its low melting point and brittle nature mean that machinists must carefully control heat buildup by using sharp tools, appropriate speeds, and effective cooling to prevent melting, chipping, or cracking. When handled correctly, it can be machined to a smooth, translucent finish that can be polished for full transparency.

-

Posted in

Acrylic, cnc machining, Delrin, material selection, plastic machining